Engine Unit -- Reassembly |

| 1. INSTALL CRANKSHAFT PULLEY SET KEY |

Install the 2 pulley set keys to the crankshaft.

| 2. INSTALL NO. 4 CHAIN VIBRATION DAMPER |

Install the vibration damper with the 2 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

| 3. INSTALL NO. 2 CHAIN SUB-ASSEMBLY |

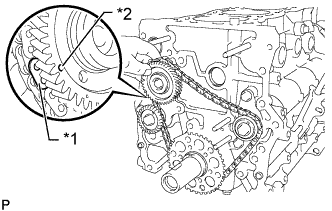

Install the No. 2 crankshaft timing sprocket as shown in the illustration.

- NOTICE:

- Check that the No. 1 cylinder is at TDC and that the weights of the No. 1 and No. 2 balance shafts are at the bottom.

- HINT:

- Install the timing sprocket with the front mark facing forward.

|

As shown in the illustration, install the chain to the sprocket and gear with the mark plates aligned with the timing marks on the sprocket and gear.

Text in Illustration *1 Mark Plate (Yellow) *2 Timing Mark

|

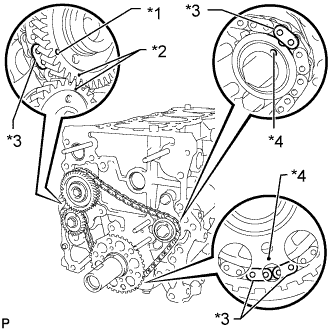

Fit the other mark plate of the chain behind the large timing mark of the balance shaft drive gear.

Text in Illustration *1 Mark Plate (Yellow) *2 Large Timing Mark

|

Insert the balance shaft drive gear shaft through the balance shaft drive gear so that it fits into the thrust plate hole.

Align the small timing mark of the balance shaft drive gear with the large timing mark of the balance shaft timing gear.

Text in Illustration *1 Large Timing Mark *2 Small Timing Mark *3 Mark Plate (Yellow)

|

Install the bolt to the balance shaft drive gear.

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

Check that each timing mark is aligned with the corresponding mark plate.

Text in Illustration *1 Large Timing Mark *2 Small Timing Mark *3 Mark Plate (Yellow) *4 Timing Mark - NOTICE:

- Check that the No. 1 cylinder is at TDC and that the weights of the No. 1 and No. 2 balance shafts are at the bottom.

|

| 4. INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY |

Install the chain tensioner assembly with the nut.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

- NOTICE:

- Install the chain tensioner with the pin installed, and then remove the pin after installation. When performing this step, do not push the vibration damper against the chain.

Move the stopper plate downward to release the lock and push the plunger deep into the tensioner.

Text in Illustration *1 Plunger *2 Stopper Plate

|

Move the stopper plate upward to set the lock and insert a hexagon wrench into the stopper plate hole.

| 5. INSTALL NO. 3 CHAIN VIBRATION DAMPER |

Install the chain vibration damper with the 2 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

| 6. INSTALL NO. 2 CHAIN VIBRATION DAMPER |

Install the chain vibration damper with the bolt.

- Torque:

- 27 N*m{270 kgf*cm, 20 ft.*lbf}

Remove the pin from the chain tensioner assembly to release the plunger.

| 7. INSTALL NO. 1 TAPER SCREW PLUG |

Install the screw plug to the cylinder block.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

| 8. INSTALL OIL FILTER BRACKET SUB-ASSEMBLY |

Using a hexagon wrench, install the oil filter bracket union.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

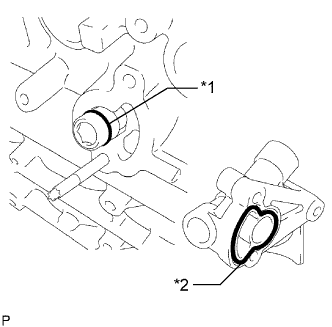

Install a new oil filter bracket gasket to the oil filter bracket.

Text in Illustration *1 New O-Ring *2 New Oil Filter Bracket Gasket

|

Install a new O-ring to the oil filter bracket union.

- NOTICE:

- Apply a light coat of engine oil to the O-ring and oil filter bracket.

Install 2 new gaskets and the 2 screw plugs to the oil filter bracket.

- Torque:

- 49 N*m{500 kgf*cm, 36 ft.*lbf}

Install the oil filter bracket with the 2 bolts and nut.

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

Using a 27 mm socket wrench, install the oil filter union.

- Torque:

- 43 N*m{439 kgf*cm, 32 ft.*lbf}

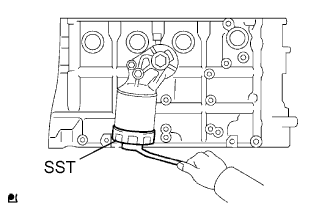

| 9. INSTALL OIL FILTER SUB-ASSEMBLY |

Check and clean the oil filter installation surface.

Apply clean engine oil to the gasket of a new oil filter.

Lightly screw the oil filter into place, and tighten it until the gasket contacts the seat.

Using SST, tighten the oil filter.

- SST

- 09228-07501

- Torque:

- 17 N*m{175 kgf*cm, 13 ft.*lbf}

|

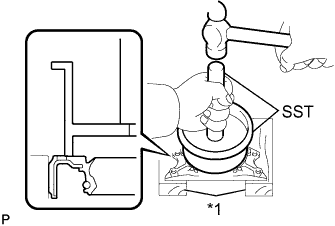

| 10. INSTALL REAR CRANKSHAFT OIL SEAL |

Place the oil seal retainer on wooden blocks.

Text in Illustration *1 Wooden Block

|

Apply a light coat of MP grease to the lip of a new oil seal.

- NOTICE:

- Do not allow foreign matter to contact the lip of the oil seal.

- Do not allow MP grease to contact the dust seal.

Using SST, tap in a new oil seal until its surface is flush with the oil seal retainer edge.

- SST

- 09223-15030

09950-70010(09951-07150)

- NOTICE:

- Wipe off any extra grease from the crankshaft.

- Do not tap in the oil seal at an angle.

| 11. INSTALL REAR ENGINE OIL SEAL RETAINER |

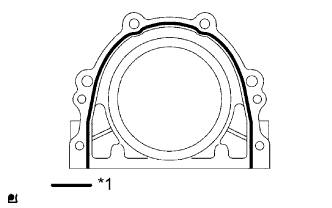

Apply seal packing in a continuous bead as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 2.0 to 3.0 mm (0.0787 to 0.118 in.)

Text in Illustration *1 Seal Packing - NOTICE:

- Remove any oil from the contact surface.

- Install the rear oil seal retainer within 3 minutes after applying seal packing.

- Do not start the engine for at least 4 hours after installation.

|

Install the oil seal retainer with the 6 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

| 12. INSTALL OIL CONTROL VALVE FILTER |

Check that no foreign matter is on the mesh part of the filter.

If foreign matter is present, clean the part thoroughly.

Using an 8 mm hexagon wrench, install a new gasket and the oil control valve filter with the screw plug.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

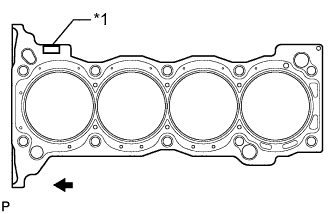

| 13. INSTALL CYLINDER HEAD GASKET |

Place a new cylinder head gasket on the cylinder block surface with the lot No. stamp facing upward.

Text in Illustration *1 Lot No.

Front - NOTICE:

- Make sure that the cylinder head gasket is installed so that it is facing in the correct direction.

|

| 14. INSTALL CYLINDER HEAD SUB-ASSEMBLY |

- HINT:

- The cylinder head bolts are tightened in 3 successive steps.

Place the cylinder head on the cylinder block.

- NOTICE:

- Make sure that no oil is on the mounting surface of the cylinder head.

- Place the cylinder head on the cylinder block gently so as not to damage the gasket with the bottom part of the head.

Install the plate washers to the cylinder head bolts.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

Step 1:

Using several steps, install and uniformly tighten the 10 cylinder head bolts with plate washers in the sequence shown in the illustration.- Torque:

- 39 N*m{398 kgf*cm, 29 ft.*lbf}

|

Mark the front of each cylinder head bolt head with paint.

Step 2:

Tighten the cylinder head bolts 90° in the sequence shown in step 1.

Step 3:

Tighten the cylinder head bolts another 90° in the sequence shown in step 1.

Check that the paint marks are now at a 180° angle to the front.

| 15. INSTALL CAMSHAFT TIMING SPROCKET |

Mount the camshaft in a vise and install the camshaft timing sprocket to the camshaft with the sprocket bolt.

- Torque:

- 78 N*m{795 kgf*cm, 58 ft.*lbf}

- NOTICE:

- Do not damage the camshaft in the vise.

| 16. INSTALL CAMSHAFT TIMING GEAR ASSEMBLY |

Align the pin hole and straight pin and install the camshaft timing gear to the camshaft.

Text in Illustration *1 Straight Pin *2 Pin Hole

|

Lightly press the gear against the camshaft and turn the gear. Push further at the position where the pin enters the groove.

- HINT:

- Make sure that there is no gap between the flange of the gear and the camshaft.

With the camshaft timing gear fixed in place, install the flange bolt.

- Torque:

- 78 N*m{795 kgf*cm, 58 ft.*lbf}

Check that the camshaft timing gear can move in the retard direction and becomes locked at the most retarded position.

| 17. INSTALL VALVE LASH ADJUSTER ASSEMBLY |

Inspect each valve lash adjuster before installing it (HILUX_TGN26 RM00000447K00LX_01_0017.html).

Install the 16 valve lash adjusters to the cylinder head.

- NOTICE:

- Install each lash adjuster to the same place it was removed from.

| 18. INSTALL VALVE STEM CAP |

Apply a light coat of engine oil to the valve stem ends.

Install the 16 valve stem caps to the cylinder head.

- NOTICE:

- Do not drop the valve stem caps into the cylinder head.

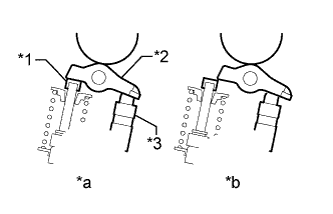

| 19. INSTALL NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

Apply clean engine oil to the valve lash adjuster tips and valve stem cap surfaces.

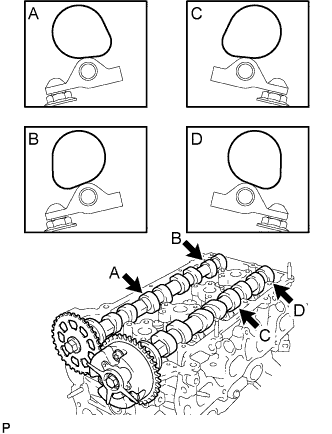

Install the 16 valve rocker arms as shown in the illustration.

Text in Illustration *1 Valve Stem Cap *2 Valve Rocker Arm *3 Valve Lash Adjuster *a CORRECT *b INCORRECT - NOTICE:

- Install the valve stem cap, lash adjuster and valve rocker arm to the same places they were removed from.

|

| 20. INSTALL CAMSHAFT |

Apply clean engine oil to the camshaft cams and cylinder head journals.

|

Position the camshaft and No. 2 camshaft as shown in the illustration.

| 21. INSTALL CAMSHAFT BEARING CAP |

Temporarily install the No. 1 camshaft bearing cap.

|

Confirm the location for each No. 2 camshaft bearing cap and install each one to the proper location.

Install a new O-ring to the No. 1 camshaft bearing cap.

Text in Illustration *1 O-Ring

|

Temporarily install the oil delivery pipe.

Install the 21 bolts and tighten them in the order shown in the illustration.

- Torque:

- for bolt A:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

- except bolt A:

- 16 N*m{158 kgf*cm, 11 ft.*lbf}

|

| 22. INSTALL CRANKSHAFT TIMING SPROCKET |

Install the timing sprocket as shown in the illustration.

|

| 23. INSTALL NO. 1 CHAIN VIBRATION DAMPER |

Install the vibration damper with the bolt and nut.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 24. INSTALL CHAIN SUB-ASSEMBLY |

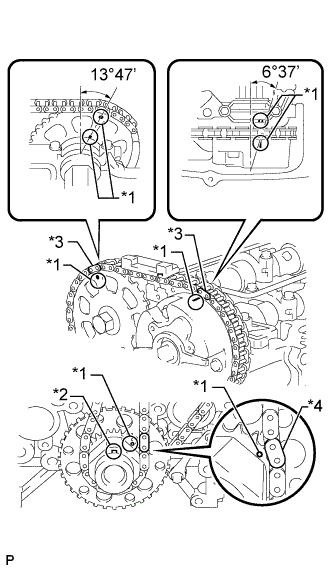

As shown in the illustration, install the chain to the sprocket and gear with the mark plates aligned with the timing marks on the sprocket and gear.

Text in Illustration *1 Timing Mark *2 Key *3 Mark Plate (Orange) *4 Mark Plate (Yellow) - HINT:

- The camshaft mark plate is orange.

- The crankshaft mark plate is yellow.

|

Use a rope to secure the chain of the crankshaft timing sprocket. Tie the rope near the sprocket.

- NOTICE:

- After the chain tensioner has been installed, the rope must be removed.

- HINT:

- The rope is used to prevent the chain from jumping a tooth.

|

| 25. INSTALL CHAIN TENSIONER SLIPPER |

Install the tensioner slipper with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 26. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY |

Move the stopper plate upward to release the lock and push the plunger deep into the tensioner.

Text in Illustration *1 Plunger *2 Stopper Plate *3 Hexagon Wrench

|

Move the stopper plate downward to set the lock and insert a hexagon wrench into the hole of the stopper plate.

Install a new gasket and the chain tensioner with the bolt and nut.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 27. INSTALL TIMING CHAIN GUIDE |

Install a new O-ring to the camshaft bearing cap.

Text in Illustration *1 New O-Ring

|

Install the timing chain guide with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 28. INSTALL ENGINE WATER PUMP ASSEMBLY |

Install a new gasket and the engine water pump with the 8 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

| 29. INSTALL OIL PUMP RELIEF VALVE |

Coat the relief valve with engine oil.

Insert the relief valve and spring into the pump body hole.

Install a new gasket to the plug.

Using a 27 mm socket wrench, install the plug.

- Torque:

- 49 N*m{500 kgf*cm, 36 ft.*lbf}

| 30. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY |

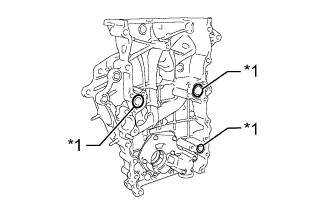

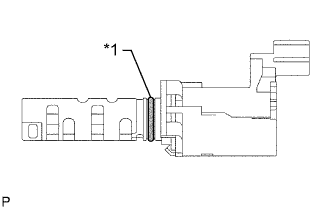

Install 3 new O-rings to the timing chain cover as shown in the illustration.

Text in Illustration *1 New O-Ring

|

Apply adhesive to the timing chain cover plug.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Using a 10 mm socket hexagon wrench, install the timing chain cover plug.

- Torque:

- 17 N*m{169 kgf*cm, 12 ft.*lbf}

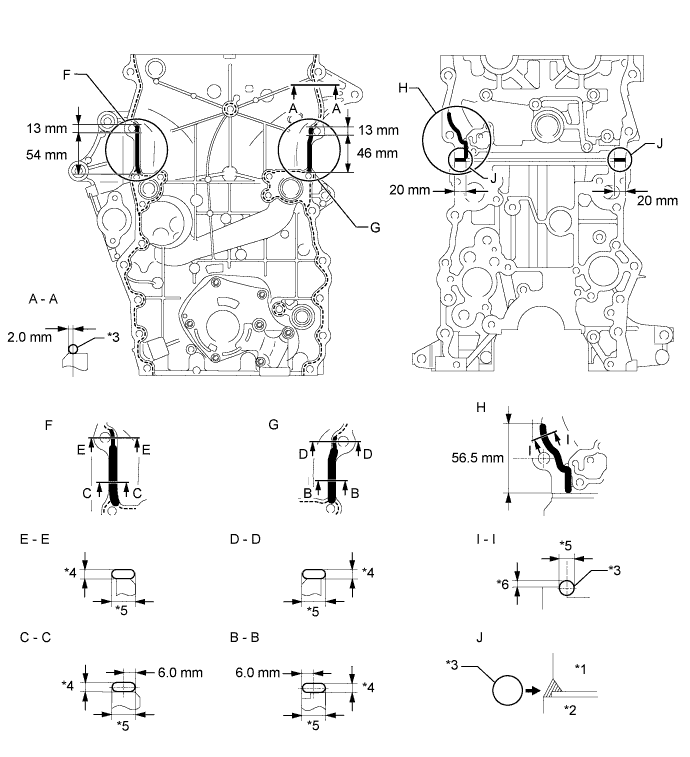

Apply seal packing to the timing chain cover in a continuous line as shown in the following illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Text in Illustration *1 Cylinder Head *2 Cylinder Block *3 Seal Packing *4 Seal Packing Thickness *5 Seal Packing Width *6 Protrusion - Application Specification:

Area Seal Packing Diameter Distance from Edge of Cover to Center of Seal Packing Seal Packing Application Length Protrusion from Cylinder Head A - A

(Dashed line)2.5 to 4.0 mm (0.0984 to 0.157 in.) 2.0 mm (0.0787 in.) - - B - B

(Continuous line)10 to 14 mm (0.394 to 0.551 in.) wide and 2.5 to 4.0 mm (0.0984 to 0.157 in.) thick 6.0 mm (0.236 in.) 46 mm (1.81 in.) from top of bolt hole - C - C

(Continuous line)10 to 14 mm (0.394 to 0.551 in.) wide and 2.5 to 4.0 mm (0.0984 to 0.157 in.) thick 6.0 mm (0.236 in.) 54 mm (2.13 in.) from top of bolt hole - D - D

(Continuous line)9.0 to 13 mm (0.354 to 0.512 in.) wide and 2.5 to 4.0 mm (0.0984 to 0.157 in.) thick - 13 mm (0.512 in.) from top of bolt hole - E - E

(Continuous line)9.0 to 13 mm (0.354 to 0.512 in.) wide and 2.5 to 4.0 mm (0.0984 to 0.157 in.) thick - 13 mm (0.512 in.) from top of bolt hole - I - I

(Continuous line)8.0 mm (0.315 in.) - 56.5 mm (2.22 in.) from bottom of cylinder head 2.0 to 3.0 mm (0.0787 to 0.118 in.) J 10 mm (0.394 in.) - 20 mm (0.787 in.) -

- NOTICE:

- Remove any oil from the contact surface.

- When the contact surfaces are wet, wipe them with an oil-free cloth before applying seal packing.

- Install the timing chain cover within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

- Do not start the engine for at least 4 hours after the installation.

Align the drive rotor spline of the oil pump and crankshaft timing gear as shown in the illustration.

Text in Illustration *1 Drive Rotor Spline *2 Crankshaft Timing Gear

|

Temporarily install the timing chain cover with the 19 bolts and 2 nuts.

Text in Illustration *1 Area 1 *2 Area 2 *3 Area 3 *4 Area 4 *5 Nut - - - Bolt Length:

Item Length Thread Diameter Bolt A 75 mm (2.95 in.) 10 mm (0.394 in.) Bolt B 75 mm (2.95 in.) 8 mm (0.315 in.) Bolt C 90 mm (3.54 in.) 8 mm (0.315 in.) Bolt D 95 mm (3.74 in.) 8 mm (0.315 in.) Bolt E 35 mm (1.38 in.) 8 mm (0.315 in.) Bolt F 75 mm (2.95 in.) 10 mm (0.394 in.)

Excluding the bolts labeled A and F, tighten the bolts and nuts in this order: Area 1, Area 3, Area 2.

- Torque:

- for bolt C:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

- for bolt B, D and nut:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Tighten the bolts labeled A in this order: Area 2 and Area 3.

- Torque:

- 60 N*m{612 kgf*cm, 44 ft.*lbf}

Tighten the bolts labeled F.

- Torque:

- 46 N*m{469 kgf*cm, 34 ft.*lbf}

Tighten the bolts labeled E in Area 4.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 31. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

|

Temporarily install the belt tensioner with the 3 bolts.

- HINT:

- Make sure the flanges of the bolts are contacting the tensioner surface.

Install the tensioner with the 3 bolts.

- Torque:

- for bolt A:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

- for bolt B:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

- for bolt C:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Text in Illustration

Bolt A

Bolt B

Bolt C

| 32. INSTALL FRONT CRANKSHAFT OIL SEAL |

Apply MP grease to the lip of a new oil seal.

- NOTICE:

- Do not allow foreign matter to contact the lip of the oil seal.

- Do not allow MP grease to contact the dust seal.

|

Temporarily install the oil seal to the timing chain cover.

Using SST and a hammer, tap in the oil seal until its surface is flush with the chain cover edge.

- SST

- 09223-75010

09950-70010(09951-07100)

- NOTICE:

- Keep the lip free from foreign matter.

- Do not tap the oil seal at an angle.

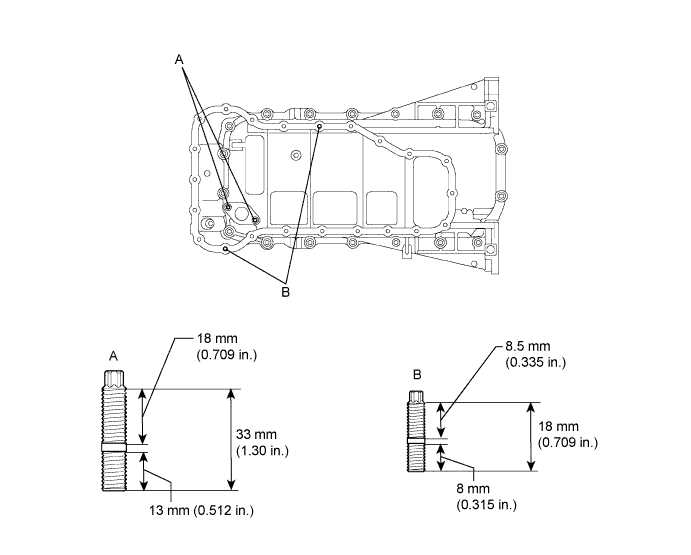

| 33. INSTALL OIL PAN STUD BOLT |

- NOTICE:

- If a stud bolt is deformed or its threads are damaged, replace it.

Using E5 and E7 "TORX" socket wrenches, install the stud bolts.

- Torque:

- for stud bolt A:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

- for stud bolt B:

- 3.0 N*m{31 kgf*cm, 27 in.*lbf}

| 34. INSTALL OIL PAN SUB-ASSEMBLY |

Install a new O-ring.

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Application Specification:

Area Seal Packing Diameter Distance from Edge of Cover or Center of Bolt Hole to Center of Seal Packing A - A and C - C 2.0 to 3.0 mm (0.0787 to 0.118 in.) 8.0 mm (0.315 in.) B - B 2.0 to 3.0 mm (0.0787 to 0.118 in.) 6.5 mm (0.256 in.)

Text in Illustration *1 Seal Packing - NOTICE:

- Remove any oil from the contact surface.

- Install the oil pan within 3 minutes after applying seal packing.

- Do not start the engine for at least 4 hours after the installation.

|

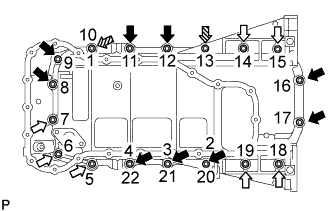

Temporarily install the oil pan with the 16 bolts and 2 nuts.

- Bolt Length:

Item Length Bolt A 20 mm (0.787 in.) Bolt B 40 mm (1.57 in.)

Text in Illustration

Bolt A

Bolt B

Nut

|

Uniformly tighten the 16 bolts and 2 nuts in the order shown in the illustration.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

| 35. INSTALL OIL STRAINER SUB-ASSEMBLY |

Install a new gasket and the oil strainer with the bolt and 2 nuts.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

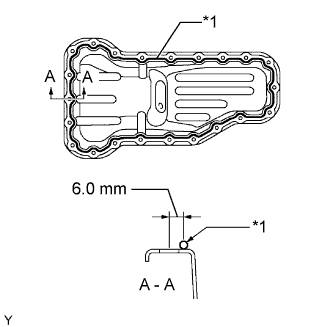

| 36. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY |

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Application Specification:

Seal Packing Diameter Distance from Edge of Cover or Center of Bolt Hole to Center of Seal Packing 2.5 to 3.5 mm (0.0984 to 0.138 in.) 6.0 mm (0.236 in.)

Text in Illustration *1 Seal Packing - NOTICE:

- Remove any oil from the contact surface.

- Install the oil pan within 3 minutes after applying seal packing.

- Do not start the engine for at least 4 hours after the installation.

|

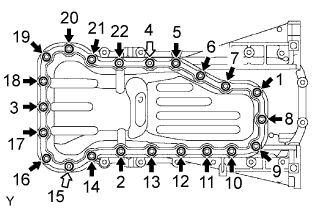

Temporarily install the No. 2 oil pan with the 20 bolts and 2 nuts.

Uniformly tighten the 20 bolts and 2 nuts in the order shown in the illustration.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

Text in Illustration

Bolt

Nut

|

Install a new gasket and the drain plug.

- Torque:

- 38 N*m{382 kgf*cm, 28 ft.*lbf}

| 37. INSTALL CRANKSHAFT PULLEY |

Align the key groove of the pulley with the pulley set key and slide on the crankshaft pulley.

|

Using SST, install a new crankshaft pulley bolt.

- SST

- 09213-54015(91651-60855)

09330-00021

- Torque:

- 260 N*m{2651 kgf*cm, 192 ft.*lbf}

Text in Illustration *a Hold

Turn - NOTICE:

- Do not reuse the pulley bolt.

| 38. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

Install 2 new cover gaskets to the head cover.

Apply seal packing to the places shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Seal packing diameter:

- 4.0 mm (0.157 in.)

Text in Illustration

Seal Packing - NOTICE:

- Remove any oil from the contact surface.

- Install the head cover within 3 minutes after applying seal packing.

- Do not start the engine for at least 4 hours after the installation.

|

Temporarily install the cylinder head cover with the 19 bolts and 2 nuts.

Uniformly tighten the 19 bolts and 2 nuts in the order shown in the illustration.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

In numerical order, confirm that the bolts labeled 1 to 8 are tightened to the specified torque. Tighten the bolts as necessary.

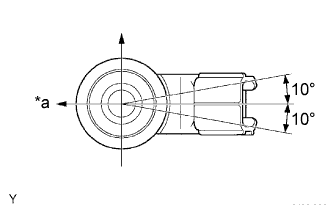

| 39. INSTALL THERMOSTAT |

Install a new gasket to the thermostat.

Text in Illustration *1 Gasket *a CORRECT *b INCORRECT *c Upward - HINT:

- When installing the thermostat to the gasket, be careful not to deform the gasket. Make sure that the thermostat is properly installed into the groove of the gasket as shown in the illustration.

|

Insert the thermostat into the cylinder block with the jiggle valve facing straight upward.

- HINT:

- The jiggle valve may be set within 10° of either side of the prescribed position.

| 40. INSTALL WATER INLET |

Install a new gasket and the water inlet with the 2 nuts and bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Connect the power steering oil pressure switch connector.

| 41. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

Apply a light coat of engine oil to a new O-ring and install the O-ring to the camshaft timing oil control valve.

Text in Illustration *1 New O-Ring

|

Install the camshaft timing oil control valve with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

- NOTICE:

- Do not allow foreign matter to contact the oil seal face of the camshaft timing oil control valve (surface which contacts the cylinder head).

- Be careful that the O-ring is not cracked when installing the camshaft timing oil control valve.

Connect the camshaft timing oil control valve connector.

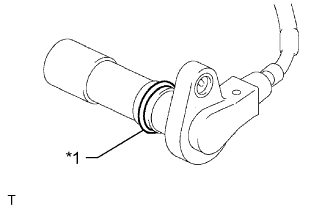

| 42. INSTALL CRANKSHAFT POSITION SENSOR |

Apply a light coat of engine oil to the O-ring of the crankshaft position sensor.

Text in Illustration *1 O-Ring

|

Install the crankshaft position sensor with the bolt.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

- NOTICE:

- Make sure that the O-ring is not cracked or jammed when installing the sensor.

Connect the crankshaft position sensor connector to the connector bracket.

Attach the harness clamp.

Connect the crankshaft position sensor connector.

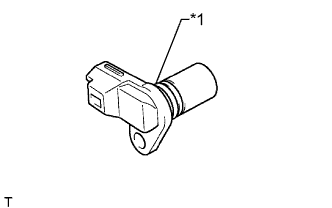

| 43. INSTALL CAMSHAFT POSITION SENSOR |

Apply a light coat of engine oil to the O-ring of the camshaft position sensor.

Text in Illustration *1 O-Ring

|

Install the camshaft position sensor with the bolt.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

- NOTICE:

- Make sure that the O-ring is not cracked or jammed when installing the sensor.

Connect the camshaft position sensor connector.

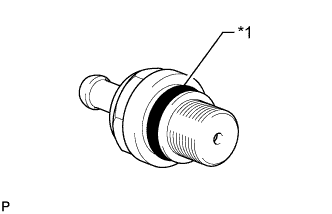

| 44. INSTALL PCV VALVE SUB-ASSEMBLY |

Apply a light coat of engine oil to the O-ring.

Text in Illustration *1 O-Ring

|

Install the PCV valve sub-assembly.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

- HINT:

- When reusing the PCV valve sub-assembly, inspect the O-ring.

Connect the PCV hose to the PCV valve sub-assembly.

Secure the hose with the clamp.

| 45. INSTALL OIL FILLER CAP SUB-ASSEMBLY |

Install the gasket to the oil filler cap.

Install the oil filler cap.

| 46. INSTALL ENGINE COOLANT TEMPERATURE SENSOR |

Install a new gasket to the engine coolant temperature sensor.

Install the engine coolant temperature sensor.

- Torque:

- 20 N*m{200 kgf*cm, 14 ft.*lbf}

Connect the engine coolant temperature sensor connector.

| 47. INSTALL KNOCK SENSOR |

Install the knock sensor with the bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Text in Illustration *a Front - NOTICE:

- Make sure that the knock sensor is at the correct angle when installing it.

|

Connect the knock sensor connector.

| 48. INSTALL ENGINE OIL PRESSURE SWITCH ASSEMBLY |

Apply adhesive to 2 or 3 threads of the engine oil pressure switch.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

- NOTICE:

- Do not let adhesive adhere to the oil hole.

Using a 24 mm deep socket wrench, install the engine oil pressure switch.

- Torque:

- 15 N*m{153 kgf*cm, 11 ft.*lbf}

- NOTICE:

- Do not start the engine within 1 hour of installation.

Connect the engine oil pressure switch connector.

| 49. INSTALL SPARK PLUG |

Using a 16 mm spark plug wrench, install the 4 spark plugs.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}