Cylinder Block (W/ Glow Plug Controller) -- Inspection |

| 1. INSPECT CYLINDER BLOCK OIL ORIFICE |

Check the oil orifice for damage or clogging.

If necessary, replace the cylinder block oil orifice.

| 2. INSPECT OIL CHECK VALVE SUB-ASSEMBLY |

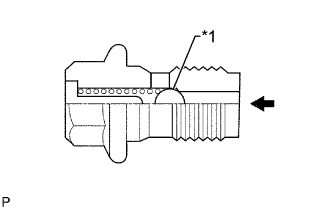

Push the ball of the oil check valve with a wooden stick to check if it is stuck.

If the ball of the oil check valve is stuck, replace the oil check valve sub-assembly.Text in Illustration *1 Ball

Push

|

| 3. INSPECT NO. 1 OIL NOZZLE SUB-ASSEMBLY |

Check the No. 1 oil nozzle for damage or clogging.

If necessary, replace the No. 1 oil nozzle sub-assembly.

| 4. CLEAN CYLINDER BLOCK SUB-ASSEMBLY |

Using a gasket scraper, remove all the gasket material from the top surface of the cylinder block.

Using a soft brush and solvent, thoroughly clean the cylinder block sub-assembly.

| 5. INSPECT CYLINDER BLOCK FOR WARPAGE |

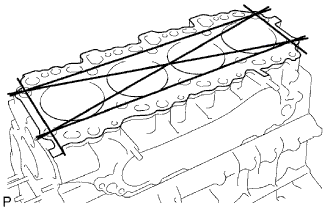

Inspect for warpage.

Using a precision straightedge and feeler gauge, measure the surface of the cylinder block that contacts the cylinder head for warpage.

- Maximum warpage:

- 0.1 mm (0.00394 in.)

|

Visually check the cylinders for vertical scratches.

If deep scratches are present, rebore all 4 cylinders. If necessary, replace the cylinder block.

| 6. INSPECT CYLINDER BORE |

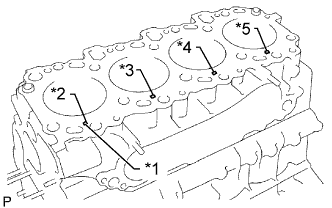

Inspect the cylinder bore diameter.

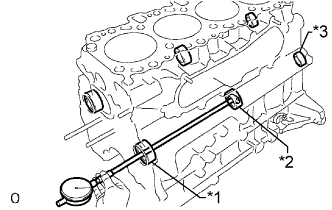

Text in Illustration *1 Mark 1, 2 or 3 *2 No. 1 *3 No. 2 *4 No. 3 *5 No. 4 - HINT:

- There are 3 standard cylinder bore diameter sizes, marked 1, 2 and 3 accordingly. The mark is stamped on the cylinder block.

Using a cylinder gauge, measure the cylinder bore diameter at positions A, B and C in the thrust and axial directions.

- Standard Diameter:

Item Specified Condition STD Mark 1 96.00 to 96.01 mm (3.7795 to 3.7799 in.) STD Mark 2 96.01 to 96.02 mm (3.7799 to 3.7803 in.) STD Mark 3 96.02 to 96.03 mm (3.7803 to 3.7807 in.) O/S 0.50 96.50 to 96.53 mm (3.7992 to 3.8004 in.) O/S 0.75 96.75 to 96.78 mm (3.8090 to 3.8102 in.) O/S 1.00 97.00 to 97.03 mm (3.8189 to 3.8201 in.)

- Maximum Diameter:

Item Specified Condition STD 96.23 mm (3.7886 in.) O/S 0.50 96.73 mm (3.8083 in.) O/S 0.75 96.98 mm (3.8181 in.) O/S 1.00 97.23 mm (3.8279 in.)

If the diameter is more than the maximum, rebore all 4 cylinders. If necessary, replace the cylinder block sub-assembly.Text in Illustration *1 Axial Direction *2 Thrust Direction *3 Center

Front

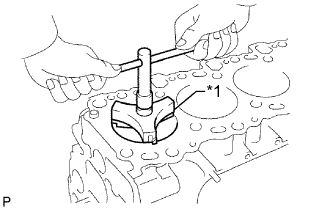

If the wear is less than 0.2 mm (0.0078 in.), using a ridge reamer, grind the top of the cylinder.Text in Illustration *1 Ridge Reamer

|

| 7. CLEAN PISTON |

Using a groove cleaning tool or broken ring, clean the piston ring grooves.

Using solvent and a brush, thoroughly clean the piston.

- NOTICE:

- Do not use a wire brush.

| 8. INSPECT PISTON WITH PIN SUB-ASSEMBLY |

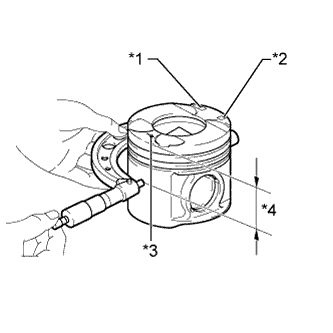

Using a micrometer, measure the piston diameter according to the following conditions: 1) measure at a right angle to the piston center line, and 2) measure at the indicated distance from the piston head.

- Distance:

- 63.5 mm (2.50 in.)

- Standard Piston Diameter:

Item Specified Condition STD Mark 1 95.92 to 95.93 mm (3.7764 to 3.7768 in.) STD Mark 2 95.93 to 95.94 mm (3.7768 to 3.7772 in.) STD Mark 3 95.94 to 95.95 mm (3.7772 to 3.7776 in.) O/S 0.50 96.42 to 96.45 mm (3.7960 to 3.7972 in.) O/S 0.75 96.67 to 96.70 mm (3.8059 to 3.8070 in.) O/S 1.00 96.92 to 96.95 mm (3.8157 to 3.8169 in.)

- Standard Pin Hole Inside Diameter:

Item Specified Condition Mark A 34.011 to 34.015 mm (1.3390 to 1.3392 in.) Mark B 34.015 to 34.019 mm (1.3392 to 1.3393 in.) Mark C 34.019 to 34.023 mm (1.3393 to 1.3395 in.)

Text in Illustration *1 Size Mark *2 Piston Pin Hole Inside Diameter Mark *3 Front Mark (Arrow) *4 Distance

|

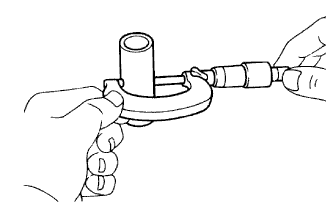

Using a micrometer, measure the piston pin diameter.

- Standard Piston Pin Diameter:

Item Specified Condition Mark A 34.000 to 34.004 mm (1.3386 to 1.3387 in.) Mark B 34.004 to 34.008 mm (1.3387 to 1.3389 in.) Mark C 34.008 to 34.012 mm (1.3389 to 1.3391 in.)

|

Subtract the piston pin diameter measurement from the piston pin hole inside diameter measurement.

- Standard oil clearance:

- 0.007 to 0.015 mm (0.000276 to 0.000591 in.)

Inspect the piston pin fit.

At 80°C (176°F), check that the piston pin can be pushed into the piston pin hole with your thumb.

If the pin can be installed at a lower temperature, replace the piston with pin sub-assembly.

|

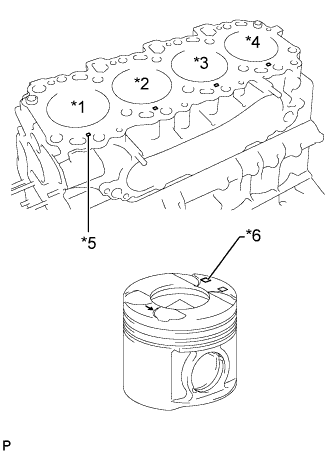

| 9. INSPECT PISTON OIL CLEARANCE |

Measure the cylinder bore diameter in the thrust direction.

Text in Illustration *1 No. 1 *2 No. 2 *3 No. 3 *4 No. 4 *5 Mark 1, 2 or 3 *6 Size Mark

|

Subtract the piston diameter measurement from the cylinder bore diameter measurement.

- Standard oil clearance:

- 0.07 to 0.09 mm (0.00276 to 0.00354 in.)

- Maximum oil clearance:

- 0.14 mm (0.00551 in.)

If necessary, replace the cylinder block sub-assembly.- HINT:

- When the cylinder block is replaced, use a piston with the same number mark as the cylinder diameter marked on a new cylinder block.

| 10. INSPECT RING GROOVE CLEARANCE |

Using a feeler gauge, measure the clearance between a new piston ring and the wall of the ring groove.

- Standard Groove Clearance:

Item Specified Condition No. 1 piston ring 0.091 to 0.135 mm (0.00358 to 0.00531 in.) No. 2 piston ring 0.090 to 0.135 mm (0.00354 to 0.00531 in.) Oil ring 0.030 to 0.075 mm (0.00118 to 0.00295 in.)

| 11. INSPECT PISTON RING END GAP |

Insert the piston ring into the cylinder bore.

Using a piston, push the piston ring a little beyond the bottom of the ring travel, 120 mm (4.72 in.) from the top of the cylinder block.

Using a feeler gauge, measure the end gap.

- Standard End Gap:

Item Specified Condition No. 1 piston ring 0.27 to 0.39 mm (0.0106 to 0.0154 in.) No. 2 piston ring 0.55 to 0.70 mm (0.0217 to 0.0276 in.) Oil ring 0.20 to 0.40 mm (0.00787 to 0.0157 in.)

- Maximum End Gap:

Item Specified Condition No. 1 piston ring 0.85 mm (0.0335 in.) No. 2 piston ring 1.07 mm (0.0421 in.) Oil ring 0.77 mm (0.0303 in.)

If the end gap is more than the maximum even with a new piston ring, rebore all 4 cylinders or replace the cylinder block sub-assembly.

| 12. INSPECT PISTON PIN OIL CLEARANCE |

Using a caliper gauge, measure the inside diameter of the connecting rod bush.

- Standard Bush Inside Diameter:

Item Specified Condition Mark A 34.012 to 34.016 mm (1.3390 to 1.3392 in.) Mark B 34.016 to 34.020 mm (1.3392 to 1.3394 in.) Mark C 34.020 to 34.024 mm (1.3394 to 1.3395 in.)

Text in Illustration *1 Connecting Rod Bush Inside Diameter Mark A, B or C *2 Front Mark

|

Subtract the piston pin diameter measurement from the bush inside diameter measurement.

- Standard oil clearance:

- 0.008 to 0.016 mm (0.000315 to 0.000630 in.)

- Maximum oil clearance:

- 0.03 mm (0.0118 in.)

If necessary, replace the piston with pin sub-assembly.

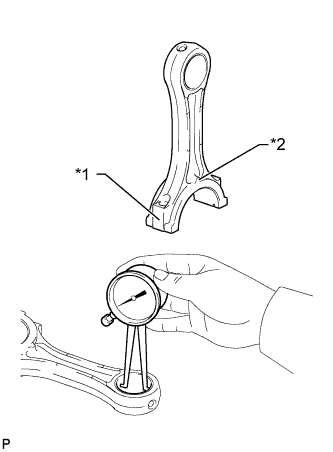

| 13. INSPECT CONNECTING ROD SUB-ASSEMBLY |

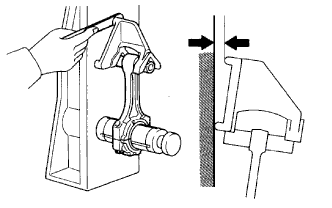

Using a rod aligner and feeler gauge, check the connecting rod alignment.

Check if the connecting rod is bent.

- Maximum bend:

- 0.03 mm (0.00118 in.) per 100 mm (3.94 in.)

Check if the connecting rod is twisted.

- Maximum twist:

- 0.15 mm (0.00591 in.) per 100 mm (3.94 in.)

| 14. INSPECT CONNECTING ROD BOLT |

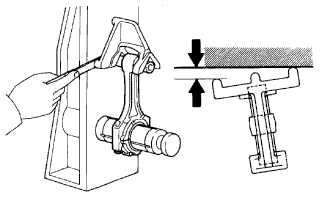

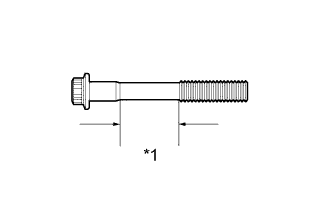

Using a vernier caliper, measure the diameter of the tension portion of the bolt.

- Standard diameter:

- 8.5 to 8.6 mm (0.335 to 0.339 in.)

- Minimum diameter:

- 8.3 mm (0.327 in.)

If the diameter is less than the minimum, replace the connecting rod bolt.Text in Illustration *1 Tension Portion

|

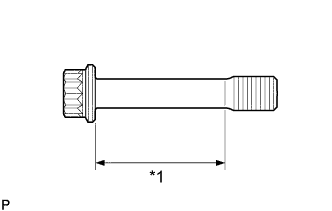

| 15. INSPECT NO. 1 BALANCESHAFT SUB-ASSEMBLY |

|

Using a cylinder gauge, measure the inside diameter of the balanceshaft bearing.

- Standard Bearing Inside Diameter:

Item Specified Condition No. 1 42.000 to 42.020 mm (1.6535 to 1.6543 in.) No. 2 41.000 to 41.020 mm (1.6142 to 1.6150 in.) No. 3 32.000 to 32.020 mm (1.2598 to 1.2606 in.)

Text in Illustration *1 No. 1 *2 No. 2 *3 No. 3

Using a micrometer, measure the outside diameter of the balanceshaft main journals.

- Standard Main Journal Diameter:

Item Specified Condition No. 1 41.941 to 41.960 mm (1.6512 to 1.6520 in.) No. 2 40.931 to 40.950 mm (1.6115 to 1.6122 in.) No. 3 31.941 to 31.960 mm (1.2575 to 1.2583 in.)

|

Subtract the outside diameter of the balanceshaft main journal from the inside diameter of the balanceshaft bearing.

- Standard Oil Clearance:

Item Specified Condition No. 1 0.040 to 0.079 mm (0.00157 to 0.00311 in.) No. 2 0.050 to 0.089 mm (0.00197 to 0.00350 in.) No. 3 0.040 to 0.079 mm (0.00157 to 0.00311 in.)

- Maximum Oil Clearance:

Item Specified Condition No. 1 0.18 mm (0.00709 in.) No. 2 0.19 mm (0.00748 in.) No. 3 0.18 mm (0.00709 in.)

| 16. INSPECT NO. 2 BALANCESHAFT SUB-ASSEMBLY |

Using a cylinder gauge, measure the inside diameter of the balanceshaft bearing.

- Standard Bearing Inside Diameter:

Item Specified Condition No. 1 42.000 to 42.020 mm (1.6535 to 1.6543 in.) No. 2 41.000 to 41.020 mm (1.6142 to 1.6150 in.) No. 3 32.000 to 32.020 mm (1.2598 to 1.2606 in.)

Text in Illustration *1 No. 1 *2 No. 2 *3 No. 3

|

Using a micrometer, measure the outside diameter of the balanceshaft main journals.

- Standard Main Journal Diameter:

Item Specified Condition No. 1 41.941 to 41.960 mm (1.6512 to 1.6520 in.) No. 2 40.931 to 40.950 mm (1.6115 to 1.6122 in.) No. 3 31.941 to 31.960 mm (1.2575 to 1.2583 in.)

|

Subtract the outside diameter of the balanceshaft main journal from the inside diameter of the balanceshaft bearing.

- Standard Oil Clearance:

Item Specified Condition No. 1 0.040 to 0.079 mm (0.00157 to 0.00311 in.) No. 2 0.050 to 0.089 mm (0.00197 to 0.00350 in.) No. 3 0.040 to 0.079 mm (0.00157 to 0.00311 in.)

- Maximum Oil Clearance:

Item Specified Condition No. 1 0.18 mm (0.00709 in.) No. 2 0.19 mm (0.00748 in.) No. 3 0.18 mm (0.00709 in.)

| 17. INSPECT CRANKSHAFT |

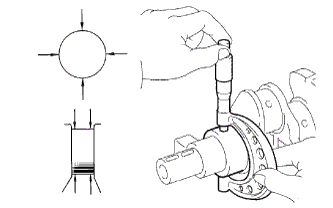

Inspect for circle runout.

Place the crankshaft on V-blocks.

Using a dial indicator, measure the circle runout at the center journal.

- Maximum circle runout:

- 0.03 mm (0.00118 in.)

Inspect the main journals and crank pins.

Using a micrometer, measure the diameter of each main journal and crank pin.

- Standard Main Journal Diameter:

Item Specified Condition Mark 1 69.994 to 70.000 mm (2.7557 to 2.7559 in.) Mark 2 69.988 to 69.994 mm (2.7554 to 2.7557 in.) Mark 3 69.982 to 69.988 mm (2.7552 to 2.7554 in.) U/S 0.25 69.745 to 69.755 mm (2.7459 to 2.7463 in.) U/S 0.50 69.495 to 69.505 mm (2.7360 to 2.7364 in.)

- Standard Crank Pin Diameter:

Item Specified Condition Mark 1 58.994 to 59.000 mm (2.3226 to 2.3228 in.) Mark 2 58.988 to 58.994 mm (2.3224 to 2.3226 in.) Mark 3 58.982 to 58.988 mm (2.3221 to 2.3224 in.)

Check each main journal and crank pin for taper and out-of-round as shown in the illustration.

- Maximum taper and out-of-round:

- 0.02 mm (0.000787 in.)

|

If necessary, grind and hone the main journals and/or crank pins.

Grind and hone the main journals and/or crank pins to the finished undersized diameter (refer to the procedures above).

Install new main journal and/or crank pin undersized bearings.

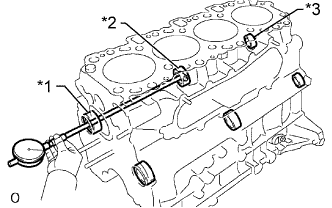

| 18. INSPECT CRANKSHAFT BEARING CAP SET BOLT |

Using a vernier caliper, measure the diameter of the crankshaft bearing cap set bolt in the measuring area.

- Standard diameter:

- 13.5 to 14.0 mm (0.531 to 0.551 in.)

- Minimum diameter:

- 12.6 mm (0.496 in.)

If the diameter is less than the minimum, replace the crankshaft bearing cap set bolt.Text in Illustration *1 Measuring Area

|