Dtc P0500 Vehicle Speed Sensor A

DESCRIPTION

MONITOR DESCRIPTION

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

CONFIRMATION DRIVING PATTERN

WIRING DIAGRAM

INSPECTION PROCEDURE

READ VALUE USING INTELLIGENT TESTER (VEHICLE SPEED)

CHECK COMBINATION METER SYSTEM

CHECK HARNESS AND CONNECTOR (ECM - COMBINATION METER)

CHECK HARNESS AND CONNECTOR (ECM - JUNCTION CONNECTOR)

DTC P0500 Vehicle Speed Sensor "A" |

DESCRIPTION

The vehicle speed sensor outputs 4 pulses for every revolution of the rotor shaft, which is rotated by the transmission output shaft via the driven gear. After this signal is converted into a more precise rectangular waveform by the waveform shaping circuit inside the combination meter, it is then transmitted to the ECM. The ECM determines the vehicle speed based on the frequency of this pulse signal.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0500

| While the vehicle is being driven, no vehicle speed signal is input to the ECM (2 trip detection logic).

| - Open or short in speed signal circuit

- Vehicle speed sensor

- Combination meter assembly

- ECM

|

MONITOR DESCRIPTION

- The ECM assumes that the vehicle is being driven when the indicated engine speed is 1500 to 4000 rpm and the engine load calculated by the ECM is more than a certain level. If there is no signal from the vehicle speed sensor, despite these conditions being met, the ECM interprets this as a malfunction in the speed signal circuit. The ECM then illuminates the MIL and stores the DTC.

- The ECM assumes that the vehicle is being driven when the idle fuel-cut operation* is being executed. If there is no signal from the vehicle speed sensor despite this condition being met, the ECM interprets this as a malfunction in the speed signal circuit. The ECM then illuminates the MIL and stores the DTC.

*: Idle fuel-cut is executed when the throttle valve is fully closed and engine speed is over 2500 rpm.

MONITOR STRATEGY

Required Sensors/Components (Main)

| Vehicle speed sensor, Combination meter assembly

|

Required Sensors/Components (Related)

| Engine coolant temperature sensor, Mass air flow meter, Crankshaft position sensor and Throttle position sensor

|

Frequency of Operation

| Continuous

|

TYPICAL ENABLING CONDITIONS

Either condition is met

| A or B

|

A. Both conditions are met

| 1 and 2

|

1. Engine speed

| 1500 to 4000 rpm

|

2. Engine load

| 31.6% or more

|

B. Fuel-cut

| ON

|

TYPICAL MALFUNCTION THRESHOLDS

Vehicle speed sensor signal

| No pulse input

|

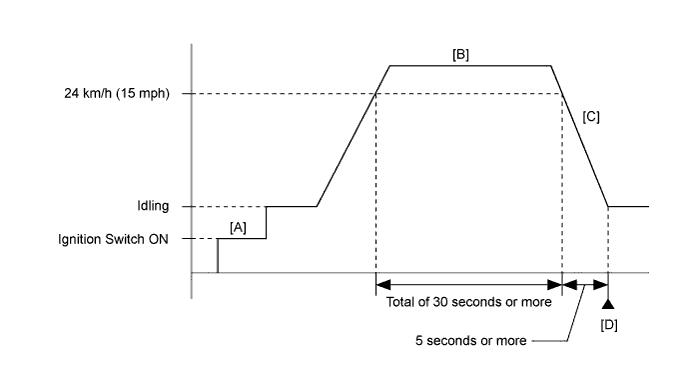

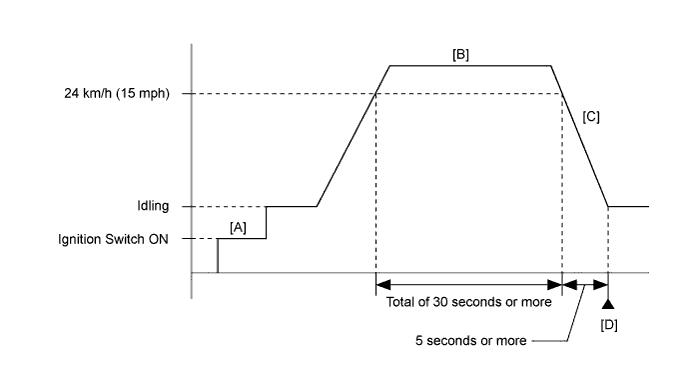

CONFIRMATION DRIVING PATTERN

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to ON and turn the intelligent tester on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC operation).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON and turn the intelligent tester on [A].

- Start the engine.

- On the intelligent tester, enter the following menus to check the fuel-cut status: Powertrain / Engine and ECT / Data List / Idle Fuel Cut.

- Drive the vehicle at 24 km/h (15 mph) or more for a total of 30 seconds or more [B].

- Decelerate the vehicle by releasing the accelerator pedal for 5 seconds or more to perform the fuel-cut [C].

- Stop the vehicle.

- Enter the following menus: Powertrain / Engine and ECT / DTC [D].

- Read the pending DTCs.

- HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P0500.

- Check the DTC judgment result.

Intelligent Tester Display

| Description

|

NORMAL

| - DTC judgment completed

- System normal

|

ABNORMAL

| - DTC judgment completed

- System abnormal

|

INCOMPLETE

| - DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

|

N/A

| - Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

|

- HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

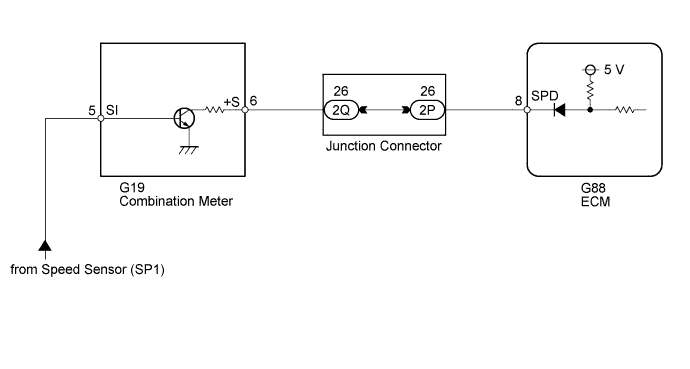

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.READ VALUE USING INTELLIGENT TESTER (VEHICLE SPEED) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Vehicle Speed.

Drive the vehicle.

Read the value displayed on the intelligent tester.

- OK:

- Vehicle speeds displayed on intelligent tester and speedometer display are equal.

| 2.CHECK COMBINATION METER SYSTEM |

Inspect the circuits that send vehicle speed signals to this system in the meter system (HILUX_TGN26 RM000002UD705SX.html).

During inspection for the meter section, if there is an instruction that indicates to go back to inspections for each system, proceed to the next step.

| 3.CHECK HARNESS AND CONNECTOR (ECM - COMBINATION METER) |

Disconnect the ECM connector.

Disconnect the combination meter connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

G19-6 (+S) - G88-8 (SPD)

| Always

| Below 1 Ω

|

| 4.CHECK HARNESS AND CONNECTOR (ECM - JUNCTION CONNECTOR) |

Disconnect the ECM connector.

Disconnect the junction connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

2P-26 - G88-8 (SPD)

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (ECM - JUNCTION CONNECTOR) |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR (JUNCTION CONNECTOR IS DEFECTIVE) |

|