Manual Transaxle Unit (For Sedan) -- Inspection |

| 1. INSPECT SYNCHRONIZER RING NO.3 |

|

Check for wear and damage.

Coat the 5th gear cone with gear oil.

Turn the synchronizer ring in one direction while pushing it against the 5th gear cone.

Check that the ring locks.

If the synchronizer ring does not lock, replace the synchronizer ring.

Using a feeler gauge, measure the clearance between the synchronizer ring back and the gear spline end.

- Minimum clearance:

- 0.75 mm (0.0295 in.)

|

| 2. INSPECT TRANSMISSION HUB SLEEVE NO.3 |

|

Check the sliding condition between transmission hub sleeve No. 3 and transmission clutch hub No. 3.

Check that the edges of the transmission hub sleeve No. 3 spline gear are not worn down.

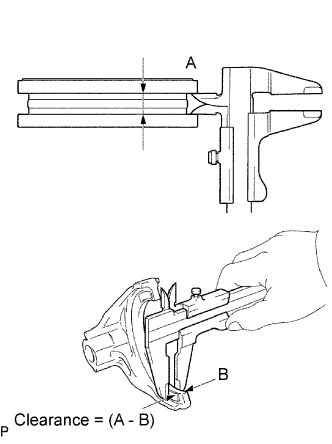

Using vernier calipers, measure the width of the transmission hub sleeve No. 3 groove (A) and the thickness of the claw part on the gear shift fork No. 3 (B), and calculate the clearance.

- Standard clearance (A - B):

- 0.3 to 0.5 mm (0.012 to 0.0020 in.)

|

| 3. INSPECT 5TH GEAR |

|

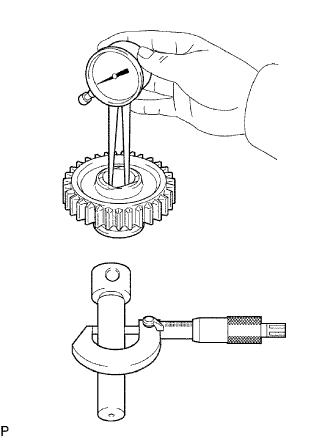

Using a caliper gauge, measure the inside diameter of the 5th gear.

- Standard inside diameter:

- 29.915 to 29.931 mm (1.1778 to 1.1783 in.)

- Maximum inside diameter:

- 29.931 mm (1.1783 in.)

| 4. INSPECT REVERSE IDLER GEAR SUB-ASSEMBLY |

|

Using a caliper gauge, inspect the reverse idle gear.

- Standard inside diameter:

- 18.040 to 18.058 mm (0.7102 to 0.7109 in.)

- Maximum inside diameter:

- 18.058 mm (0.7109 in.)

Using a micrometer, inspect the reverse idler gear shaft as shown in the illustration.

- Standard outer diameter:

- 17.966 to 17.984 mm (0.7073 to 0.7080 in.)

- Minimum outer diameter:

- 17.966 mm (0.7073 in.)