Cooling System (For Hatchback) -- On-Vehicle Inspection |

- CAUTION:

- Be sure that the ignition switch is off if you work near the electric cooling fans or radiator grille. With the ignition switch ON, the electric cooling fans may automatically start if the engine coolant temperature is high or the air conditioning is on.

| 1. INSPECT FOR COOLANT LEAK |

- CAUTION:

- To avoid the danger of being burned, do not remove the water filler cap sub-assembly while the engine and radiator assembly are still hot. Thermal expansion will cause hot engine coolant and steam to blow out from the radiator assembly.

Fill the radiator assembly with engine coolant, then attach a radiator cap tester.

Text in Illustration *1 Radiator Cap Tester

|

Pump the tester to 137 kPa (1.4 kgf/cm2, 19.9 psi), then check that the pressure does not drop.

If the pressure drops, check the hoses, radiator assembly and water pump assembly for leakage. If there are no signs or traces of external engine coolant leakage, check the heater core, cylinder block and head.

| 2. INSPECT RESERVOIR TANK COOLANT LEVEL |

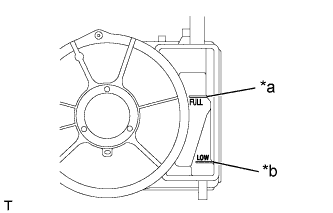

The engine coolant level should be between the LOW and FULL lines when the engine is cold.

Text in Illustration *a FULL Line *b LOW Line - HINT:

- If it is below the LOW line, check for leakage and add Toyota Super Long Life Coolant (SLLC) or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, and non-borate coolant with long-life hybrid organic acid technology up to the FULL line.

|

| 3. INSPECT COOLANT QUALITY |

Remove the water filler cap sub-assembly.

- CAUTION:

- To avoid the danger of being burned, do not remove the water filler cap sub-assembly while the engine and radiator assembly are still hot. Thermal expansion will cause hot engine coolant and steam to blow out from the radiator assembly.

Check for excessive deposits of rust or scale around the water filler cap sub-assembly and radiator filler hole. The coolant should be free of oil.

If excessively dirty, replace the engine coolant.

Reinstall the water filler cap sub-assembly.