Fuel System (For Hatchback) -- Precaution |

| 1.PRECAUTIONS |

Before working on the fuel system, disconnect the cable from the negative battery terminal.

- NOTICE:

- after turning the ignition switch off, waiting time may be required before disconnecting the cable from the battery terminal. Therefore, make sure to read the disconnecting the cable from the battery terminal notice proceeding with work (YARIS_NCP93 RM00000482L007X.html).

Do not work on the fuel system near any open flames. Never smoke when working on this system.

Keep rubber and leather parts away from gasoline.

| 2.DISCHARGE FUEL SYSTEM PRESSURE |

- CAUTION:

- Perform this procedure when the engine coolant temperature is below 60°C (140°F).

- Perform the following procedure to prevent fuel from spilling out before removing any fuel system parts.

- Even after discharging the fuel pressure, when disconnecting a fuel line, cover it with a piece of cloth to prevent fuel from spraying or coming out.

for 60/40 Split Seat Type LH Side:

Remove the rear seat assembly LH (YARIS_NCP93 RM0000026GD010X.html).

for 60/40 Split Seat Type RH Side:

Remove the rear seat assembly RH (YARIS_NCP93 RM0000026GL010X.html).

for Fold Down Seat Type:

Remove the rear seat assembly (YARIS_NCP93 RM000000T0T009X.html).

Remove the rear floor service hole cover.

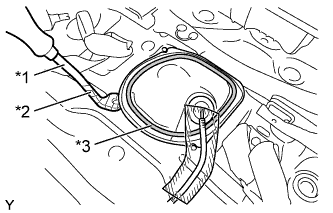

Text in Illustration *1 Clip Remover *2 Protective Tape *3 Butyl Tape Disconnect the connector from the fuel suction tube assembly with fuel pump and gauge assembly.

Start the engine.

After the engine stops naturally, turn the ignition switch off.

- NOTICE:

- Do not increase the engine speed or drive the vehicle while waiting for the engine to stop naturally.

- HINT:

- DTC P0171/25 may be set.

Crank the engine again and make sure that the engine does not start.

Remove the fuel tank cap and discharge the pressure from the fuel tank.

Disconnect the cable from the negative battery terminal.

Connect the connector of the fuel suction tube assembly with fuel pump and gauge assembly.

|

|

| 3.FUEL SYSTEM |

When disconnecting the high-pressure fuel line, a large amount of gasoline will splash out. Take the following precautions.

Discharge the fuel system pressure.

Remove the fuel tube clip.

Disconnect the fuel tube.

Drain the fuel remaining inside the fuel pump tube into a container.

Protect the contact surface by covering it with a plastic bag.

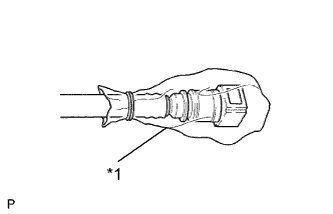

Text in Illustration *1 Plastic Bag - NOTICE:

- Do not damage the pipe or fuel tube connector, and prevent entry of foreign objects.

Put a container under the connection part.

Observe the following precautions when disconnecting the fuel tube connector (Quick Type A).

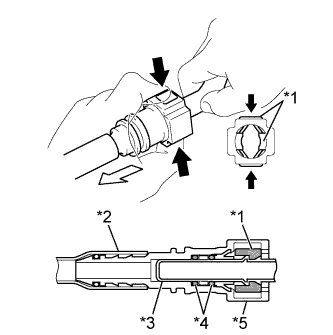

Text in Illustration *1 No. 1 Fuel Pipe Clamp Remove the No. 1 fuel pipe clamp.

Check for dirt or other foreign matter on the parts to be disconnected and clean them if necessary.

Pinch the retainer of the fuel tube connector, and then pull out the fuel tube connector to disconnect the fuel tube from the fuel pipe.

Text in Illustration *1 Retainer *2 Nylon Tube *3 Pipe *4 O-Ring *5 Fuel Tube Connector

Pinch

Pull Out - NOTICE:

- Do not use any tools.

If the connector and pipe are stuck, pinch the retainer with your hand, and then push and pull the connector to disconnect them.

Text in Illustration

Pull

Push - NOTICE:

- Do not use any tools.

Check the sealing surfaces of the disconnected parts, and clean them if necessary.

Protect the contact surface by covering it with a plastic bag.

Text in Illustration *1 Plastic Bag - NOTICE:

- Do not damage the pipe or fuel tube connector, and prevent entry of foreign objects.

Observe the following precautions when connecting the fuel tube connectors (Quick Type A).

Push Check that there are no scratches or foreign objects on the connecting part.

Line up the pipe and connector and push them together until a "click" sound is heard.

- HINT:

- If the pipe is difficult to push into the connector, apply a small amount of clean engine oil to the tip of the pipe and reinsert it.

After connecting the pipes, check that the pipe and connector are securely connected by pulling on them.

Text in Illustration

Pull Install the No. 1 fuel pipe clamp.

Inspect for fuel leaks.

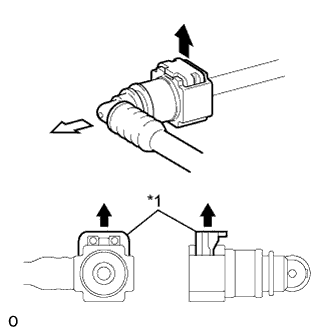

Observe the following procedure when disconnecting the fuel tube connectors (Quick Type B).

Text in Illustration *1 Retainer

Pull

Pull Out Check for dirt or other foreign matter on the parts to be disconnected and clean them if necessary.

Pull the tabs of the fuel tube connector retainer. Pull the retainer up to disconnect the fuel tube connector from the pipe.

- NOTICE:

- Do not use any tools.

If the connector and pipe are stuck, hold the fuel pipe by hand and push and pull on the connector. Pull the two pipes apart to separate the connector.

Text in Illustration

Pull

Push - NOTICE:

- Do not use any tools.

Check the sealing surfaces of the disconnected parts, and clean them if necessary.

- NOTICE:

- Do not use any tools.

Protect the contact surface by covering it with a plastic bag.

Protect the contact surface by covering it with a plastic bag.

Text in Illustration *1 Plastic Bag - NOTICE:

- Do not damage the pipe or fuel tube connector, and prevent entry of foreign objects.

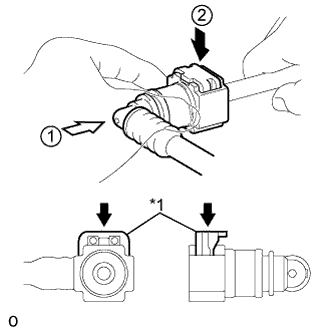

Observe the following procedure when connecting the fuel tube connector (Quick Type B).

Check that there are no scratches or foreign objects on the connecting part.

Line up the pipe and connector and push them together until a "click" sound is heard. If the pipe is difficult to push into the connector, apply a small amount of clean engine oil to the tip of the pipe and reinsert it.

Text in Illustration *1 Retainer

Push

Push After connecting the pipes, check that the pipe and connector are securely connected by pulling on them.

Inspect for fuel leaks.

|

|

|

|

| 4.INJECTOR |

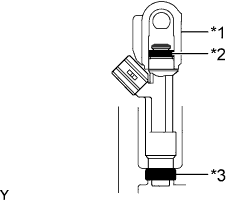

Observe the following precautions when removing and installing the fuel injector.

Do not reuse the O-ring and insulator.

When placing a new O-ring onto the injector, do not damage the O-ring.

Coat the new O-ring with gasoline or spindle oil before installing it. Do not use engine, gear or brake oil.

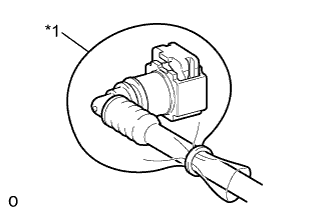

Install the injector into the delivery pipe and cylinder head, as shown in the illustration. Apply gasoline or spindle oil to the contact surfaces of the delivery pipe and the injector before installing the injector.

Text in Illustration *1 Delivery pipe *2 O-ring *3 Insulator

|

|

| 5.INSPECT FOR FUEL LEAK |

Check that there is no fuel leakage after performing maintenance anywhere on the fuel system (YARIS_NCP93 RM000001IQZ080X_01_0001.html).