Engine Unit (For Sedan) Installation

INSTALL EXHAUST MANIFOLD

INSTALL MANIFOLD SUPPORT BRACKET

INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

INSTALL WIRE HARNESS CLAMP BRACKET

INSTALL ENGINE WIRE

INSTALL BOOSTER VACUUM TUBE

INSTALL NO. 1 WATER BY-PASS PIPE

INSTALL INTAKE MANIFOLD

INSTALL ENGINE OIL LEVEL DIPSTICK

INSTALL GENERATOR ASSEMBLY

INSTALL NO. 1 IGNITION COIL

INSTALL WATER FILLER SUB-ASSEMBLY

INSTALL FUEL TUBE SUB-ASSEMBLY

INSTALL VENTILATION HOSE

Engine Unit (For Sedan) -- Installation |

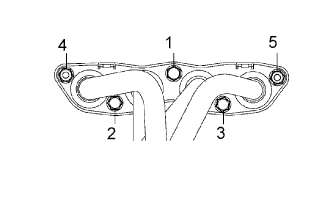

| 1. INSTALL EXHAUST MANIFOLD |

Install the exhaust manifold with the 3 bolts and 2 nuts, in the order shown in the illustration, through a new gasket.

- Torque:

- 27 N*m{275 kgf*cm, 20 ft.*lbf}

| 2. INSTALL MANIFOLD SUPPORT BRACKET |

Install the manifold bracket with the 3 bolts.

- Torque:

- 44 N*m{449 kgf*cm, 33 ft.*lbf}

| 3. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the exhaust manifold insulator with the 4 bolts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 4. INSTALL WIRE HARNESS CLAMP BRACKET |

Install the 2 wire harness clamp brackets with the 2 bolts.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf} bolt A

- 13 N*m{131 kgf*cm, 10 ft.*lbf} bolt B

Connect all sensor connectors and wire harness clamps to the engine assembly and install the engine wire harness.

| 6. INSTALL BOOSTER VACUUM TUBE |

Install the booster vacuum tube with the 2 bolts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

| 7. INSTALL NO. 1 WATER BY-PASS PIPE |

Install the No. 1 water bypass pipe through a new gasket with the 2 bolts and 2 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

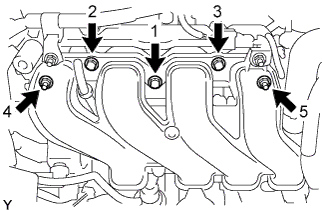

| 8. INSTALL INTAKE MANIFOLD |

Install a new gasket onto the intake manifold.

Provisionally tighten the intake manifold nuts and bolts in the order shown in the illustration, and then tighten them to the specified torque.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

Connect the water by-pass hose to the No. 1 water by-pass pipe.

Connect the water bypass hose to the cylinder head.

Connect the union to connector tube hose to the booster vacuum tube.

| 9. INSTALL ENGINE OIL LEVEL DIPSTICK |

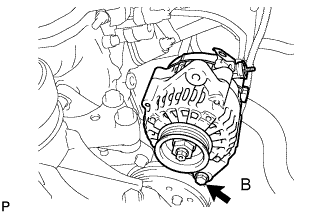

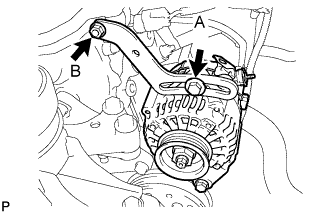

| 10. INSTALL GENERATOR ASSEMBLY |

Provisionally install the generator with fixing bolt B.

Provisionally install the fan belt adjusting slider with fan belt adjusting slider fixing bolts A and B, then move the generator toward the cylinder block and tighten bolt B.

- Torque:

- 11 N*m{112 kgf*cm, 8.1 ft.*lbf}

Install the connector and the wire harness clamp.

Install terminal B with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 7.2 ft.*lbf}

Install the terminal cap.

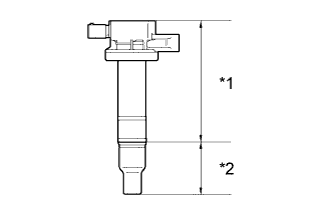

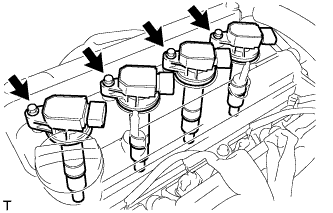

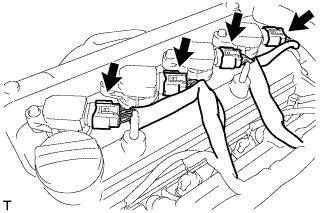

| 11. INSTALL NO. 1 IGNITION COIL |

Install the 4 ignition coils with the 4 bolts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

- NOTICE:

- If the body or cap of the ignition coil is dropped or subjected to a strong impact, replace the ignition coil with a new one.

Text in Illustration*1

| Body

|

*2

| Cap

|

Connect the 4 ignition coil connectors.

| 12. INSTALL WATER FILLER SUB-ASSEMBLY |

Connect the No. 1 radiator hose to the cylinder head.

Install the water filler sub-assembly with 2 nuts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

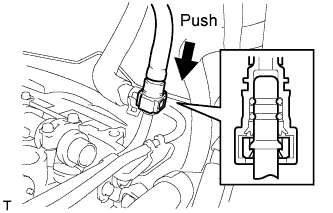

| 13. INSTALL FUEL TUBE SUB-ASSEMBLY |

Insert the fuel tube connector into the fuel delivery pipe until a click sound can be heard.

- NOTICE:

- Check that there are no scratches or foreign matter around the disconnected parts of the fuel tube connector and pipe before performing this work.

- After connecting the fuel tube, check that the fuel tube connector and pipe are securely connected by pulling them.

Install the fuel pipe clamp.

| 14. INSTALL VENTILATION HOSE |

Install the ventilation hose.