Front Crankshaft Oil Seal (For Sedan) Installation

INSTALL OIL PUMP SEAL

INSTALL CRANKSHAFT DAMPER SUB-ASSEMBLY

INSTALL ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

INSTALL FAN AND GENERATOR V BELT

ADJUST FAN AND GENERATOR V BELT

INSPECT FAN AND GENERATOR V BELT

INSPECT FOR OIL LEAK

INSTALL ENGINE UNDER COVER RH

INSTALL FRONT WHEEL RH

Front Crankshaft Oil Seal (For Sedan) -- Installation |

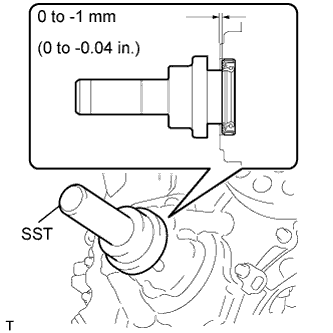

Apply MP grease to the lip of a new oil seal.

- NOTICE:

- Keep the lip free of foreign matter.

Using SST and hammer, tap in the oil seal until its surface is flush with the timing chain cover.

- SST

- 09223-22010

- NOTICE:

- Do not tap the oil seal at an angle.

- Wipe off extra grease from the crankshaft.

| 2. INSTALL CRANKSHAFT DAMPER SUB-ASSEMBLY |

Align the pin hole of the crankshaft damper with the pin and install the crankshaft damper sub-assembly.

Provisionally install the bolt.

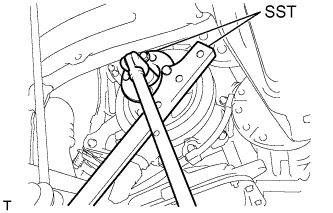

Using 2 SSTs, tighten the bolt while holding the crankshaft damper sub-assembly.

- SST

- 09213-14010(91651-60865)

09330-00021

- Torque:

- 128 N*m{1305 kgf*cm, 95 ft.*lbf}

- NOTICE:

- Check the SST installation positions when installing them, to avoid the SST fixing bolts from coming into contact with the oil pump assembly.

| 3. INSTALL ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH |

Install the engine mounting insulator sub-assembly RH with the 5 bolts and nut.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

| 4. INSTALL FAN AND GENERATOR V BELT |

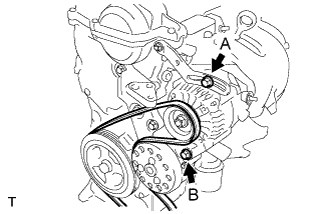

Provisionally install the fan and generator V belt onto each pulley.

- NOTICE:

- Make sure that there is no foreign matter or liquid, such as oil, on the belt and pulleys.

- Make sure that the V belt is securely fitted into the rib grooves of the pulley.

| 5. ADJUST FAN AND GENERATOR V BELT |

Insert an adjusting bar between the engine mounting bracket and generator assembly. Pull the adjusting bar toward the vehicle front to adjust the generator V belt tension (YARIS_NCP93 RM000001DCH00ZX_01_0001.html).

Text in Illustration*a

| OK

|

*b

| NG

|

- NOTICE:

- Do not insert the adjusting bar between the camshaft timing oil control valve assembly and generator assembly. It could damage the camshaft timing oil control valve assembly.

First tighten bolt A, then tighten bolt B.

- Torque:

- 19 N*m{189 kgf*cm, 14 ft.*lbf} for bolt A

- 54 N*m{551 kgf*cm, 40 ft.*lbf} for bolt B

| 6. INSPECT FAN AND GENERATOR V BELT |

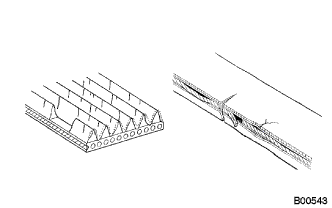

Check the belt for wear, cracks or other signs of damage.

If any of the following defects is found, replace the V-ribbed belt.

- HINT:

- The belt is cracked.

- The belt is worn out to the extent that the wires are exposed.

- The belt has chunks missing from the ribbed groves.

Check that the belt fits properly in the ribbed grooves.

Text in Illustration*a

| CORRECT

|

*b

| INCORRECT

|

- HINT:

- Check with your hand, to confirm that the belt has not slipped out of the grooves on the bottom to the pulley. If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt correctly.

|

Inspect the V belt deflection and tension.

Text in Illustration*A

| w/o Air Conditioner

|

*B

| w/ Air Conditioner

|

- Deflection:

Item

| Specified Condition

|

New belt

| 8.0 to 9.0 mm (0.31 to 0.35 in)

|

Used belt

| 12.5 to 13.5 mm (0.49 to 0.53 in)

|

- Tension:

Item

| Specified Condition

|

New belt

| 700 to 800 N (71 to 82 kg, 157 to 180 lb)

|

Used belt

| 300 to 400 N (31 to 41 kg, 67 to 90 lb)

|

If the V belt deflection is not as specified, adjust it.

- HINT:

- When inspecting the V belt deflection, apply 98 N (10 kgf) tensile force to it.

- Perform the V belt inspection and adjustment while the engine is cold.

- V-ribbed belt tension and deflection should be checked immediately after installation of a new belt, and after cranking the engine when inspecting a used belt.

- Check the V belt deflection at the point between the specified pulleys where the deflection is greatest.

- When installing a new belt, set its tension to the intermediate value of the specification.

- When inspecting a belt which has been used for over 5 minutes, apply the Used Belt specifications.

- When reinstalling a belt which has been used for over 5 minutes, adjust its deflection and tension to the intermediate values of each Used Belt specification.

- V-ribbed belt tension and deflection should be checked after 2 revolutions of engine cranking.

- When using a belt tension gauge, confirm its accuracy by using a master gauge first.

| 8. INSTALL ENGINE UNDER COVER RH |

| 9. INSTALL FRONT WHEEL RH |

- Torque:

- 103 N*m{1050 kgf*cm, 76 ft.*lbf}