Brake Master Cylinder -- Installation |

| 1. INSPECT AND ADJUST BRAKE BOOSTER PUSH ROD |

- NOTICE:

- Make an adjustment with no vacuum in the brake booster assembly. (Depress the brake pedal several times with the engine stopped.)

- HINT:

- Adjustment of the brake booster push rod is required when the brake master cylinder sub-assembly is replaced with a new one.

- Adjustment is not necessary when the removed brake master cylinder sub-assembly is reused and the brake booster assembly is replaced with a new one.

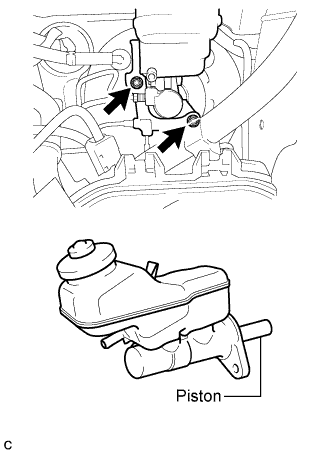

Apply chalk to the tip of the accessory tool.

- HINT:

- An accessory tool is enclosed with a new brake master cylinder sub-assembly.

Place the accessory tool on the brake booster assembly.

|

Measure the clearance between the brake booster push rod and accessory tool.

- Standard clearance:

- 0 mm (0 in.)

- HINT:

- Adjust the clearance in the following cases:

- If there is a clearance between the accessory tool and the shell of the brake booster (floating accessory tool), the push rod is protruding too far.

- If the chalk does not stick on the tip of the brake booster push rod, the push rod protrusion is insufficient.

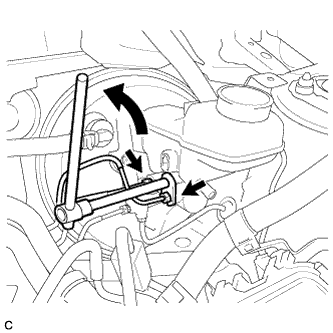

If the clearance is not as specified, adjust the push rod length by holding the rod using SST and turning the tip of the rod using a socket driver (7 mm).

- SST

- 09737-00020

- HINT:

- Check the push rod clearance again after adjustment.

|

| 2. INSTALL BRAKE MASTER CYLINDER SUB-ASSEMBLY |

Install a new O-ring to the brake master cylinder sub-assembly.

Install the brake master cylinder sub-assembly and brake tube way to the brake booster assembly with the 2 nuts.

- Torque:

- 13 N*m{132 kgf*cm, 10 ft.*lbf}

- NOTICE:

- The master cylinder requires careful handling. Do not allow the master cylinder to receive any impact, such as from being dropped. Do not reuse a master cylinder that has been dropped.

- Do not strike or pinch the master cylinder piston, and do not cause any damage to the master cylinder piston by any other means.

- When installing the master cylinder to the brake booster, or when removing the master cylinder from the brake booster, make sure that the master cylinder is kept horizontal or its tip faces downward (the piston faces upward) to prevent the master cylinder piston from falling off.

- Do not allow any foreign objects to contaminate the master cylinder piston. If a foreign object gets on the piston, remove it by using a piece of cloth and then apply an even layer of lithium soap base glycol grease around the circumference (sliding part) of the piston.

- Do not use any other type of grease or fluid.

|

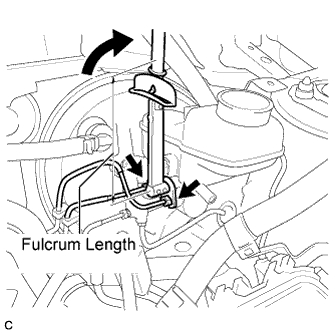

Using a union nut wrench (10 mm or 12 mm), connect the 4 brake lines to the brake master cylinder sub-assembly.

- Torque:

- w/o VSC without a union nut wrench:

- 15 N*m{155 kgf*cm, 11 ft.*lbf}

- w/o VSC with a union nut wrench:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

- w/ VSC without a union nut wrench:

- 20 N*m{200 kgf*cm, 14 ft.*lbf}

- w/ VSC with a union nut wrench:

- 18 N*m{178 kgf*cm, 13 ft.*lbf}

- NOTICE:

- Use a torque wrench with a fulcrum length of 250 mm (9.84 in.).

- This torque value is effective when the union nut wrench is parallel to the torque wrench.

|

Engage the clamp and connect the connector.

|

| 3. CONNECT CLUTCH TUBE (for Manual Transaxle) |

Connect the clutch tube to the brake master cylinder reservoir assembly with the clip.

|

| 4. FILL RESERVOIR WITH BRAKE FLUID |

Fill the reservoir with brake fluid.

- Brake Fluid:

- SAE J1703 or FMVSS No. 116 DOT 3

- NOTICE:

- Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while bleeding the brakes.

| 5. BLEED CLUTCH LINE (for C59) |

Remove the bleeder plug cap.

Connect a vinyl tube to the bleeder plug.

Depress the clutch pedal several times, and then loosen the bleeder plug while the pedal is depressed.

When fluid no longer comes out, tighten the bleeder plug, and then release the clutch pedal.

Repeat the previous 2 steps until all the air in the fluid is completely bled.

Tighten the bleeder plug.

- Torque:

- 8.4 N*m{86 kgf*cm, 74 in.*lbf}

Install the bleeder plug cap.

Check that all the air has been bled from the clutch line.

| 6. BLEED CLUTCH LINE (for E351) |

Remove the bleeder plug cap.

Connect a vinyl tube to the bleeder plug.

Depress the clutch pedal several times, and then loosen the bleeder plug while the pedal is depressed.

When fluid no longer comes out, tighten the bleeder plug, and then release the clutch pedal.

Repeat the previous 2 steps until all the air in the fluid is completely bled.

Tighten the bleeder plug.

- Torque:

- 8.4 N*m{86 kgf*cm, 74 in.*lbf}

Install the bleeder plug cap.

Check that all the air has been bled from the clutch line.

| 7. BLEED BRAKE MASTER CYLINDER |

- NOTICE:

- If the master cylinder is reinstalled or if the reservoir becomes empty, bleed the master cylinder.

- To prevent brake fluid from damaging painted surface, cover any surrounding parts with a piece of cloth.

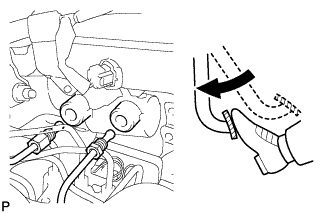

Using a union nut wrench (10 mm or 12 mm), disconnect the 2 brake lines from the master cylinder.

|

Slowly depress the brake pedal and hold it*1.

|

Cover the 2 outer holes with fingers, and release the brake pedal*2.

|

Repeat *1 and *2 3 or 4 times.

Using a union nut wrench (10 mm or 12 mm), connect the 2 brake lines to the master cylinder.

- Torque:

- w/o VSC without a union nut wrench:

- 15 N*m{155 kgf*cm, 11 ft.*lbf}

- w/o VSC with a union nut wrench:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

- w/ VSC without a union nut wrench:

- 20 N*m{200 kgf*cm, 14 ft.*lbf}

- w/ VSC with a union nut wrench:

- 18 N*m{178 kgf*cm, 13 ft.*lbf}

- NOTICE:

- Use a torque wrench with a fulcrum length of 250 mm (9.84 in.).

- This torque value is effective when the union nut wrench is parallel to the torque wrench.

|

| 8. BLEED BRAKE LINE |

- NOTICE:

- Bleed the brake line of the wheel farthest from the master cylinder first.

- Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while bleeding the brakes.

Connect a vinyl tube to the bleeder plug.

Depress the brake pedal several times, and then loosen the bleeder plug with the pedal depressed*1.

When fluid stops coming out, tighten the bleeder plug, and then release the brake pedal*2.

Repeat *1 and *2 until all the air in the fluid is completely bled out.

Tighten the bleeder plug completely.

- Torque:

- Front bleeder plug:

- 8.3 N*m{85 kgf*cm, 73 in.*lbf}

- Rear bleeder plug (for Drum Brake):

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

- Rear bleeder plug (for Disc Brake):

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Repeat the above procedure for each wheel to bleed the brake line.

| 9. BLEED BRAKE ACTUATOR (w/ VSC) |

- NOTICE:

- After bleeding the brake system, if the specified height or feel of the brake pedal cannot be obtained, bleed the brake actuator assembly with the Techstream by following the procedure below.

Depress the brake pedal more than 20 times with the ignition switch off.

Connect the Techstream to the DLC3, and then turn the ignition switch to ON.

- NOTICE:

- Do not start the engine.

Turn the Techstream on and select "Air Bleeding" on the screen.

- NOTICE:

- Refer to the Techstream operator's manual for further details.

- Bleed air by following the steps displayed on the Techstream.

Bleed air according to "Step 1: Increase Line" on the Techstream display.

- NOTICE:

- Make sure that the master cylinder reservoir tank does not run out of brake fluid.

- Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while bleeding the brakes.

Connect a vinyl tube to either one of the bleeder plugs.

Depress the brake pedal several times, and then loosen the bleeder plug connected to the vinyl tube with the pedal depressed*3.

When fluid stops coming out, tighten the bleeder plug, and then release the brake pedal*4.

Repeat *3 and *4 until all the air in the fluid is completely bled out.

Tighten the bleeder plug completely.

- Torque:

- Front bleeder plug:

- 8.3 N*m{85 kgf*cm, 73 in.*lbf}

- Rear bleeder plug (for Drum Brake):

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

- Rear bleeder plug (for Disc Brake):

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Repeat the above procedure for the rest of the wheels to bleed the brake lines.

Bleed the suction line according to "Step 2: Inhalation Line" on the Techstream display.

- NOTICE:

- Bleed the suction line by following the steps displayed on the Techstream.

- Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while bleeding the brakes.

Connect a vinyl tube to the bleeder plug at the right front wheel or the right rear wheel and loosen the bleeder plug.

Operate the brake actuator assembly to bleed air using the Techstream*5.

- NOTICE:

- During this step, be sure to release the brake pedal.

- The actuator operation stops automatically in 4 seconds.

Check that the actuator operation has stopped by referring to the Techstream display, and tighten the bleeder plug*6.

Repeat *5 and *6 until all the air in the fluid is completely bled out.

Tighten the bleeder plug completely.

- Torque:

- Front bleeder plug:

- 8.3 N*m{85 kgf*cm, 73 in.*lbf}

- Rear bleeder plug (for Drum Brake):

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

- Rear bleeder plug (for Disc Brake):

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

For the rest of the wheels, bleed air in the same way as stated in the above procedure.

Bleed the pressure reduction line according to "Step 3: Decrease Line" on the Techstream display.

- NOTICE:

- Bleed the pressure reduction line by following the steps displayed on the Techstream.

- Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while bleeding the brakes.

Connect a vinyl tube to either one of the bleeder plugs.

Loosen the bleeder plug*7.

While keeping the brake pedal fully depressed, operate the brake actuator assembly using the Techstream.

- NOTICE:

- The actuator operation stops automatically in 4 seconds. When performing this procedure continuously, an interval of at least 20 seconds is required.

- After the operation is completed, the brake pedal goes down slightly. This is a normal phenomenon when the solenoid opens.

- During this procedure, the pedal seems heavy, but completely depress it so that the brake fluid comes out from the bleeder plug.

- Be sure to keep the brake pedal depressed. Never depress and release the pedal repeatedly.

Tighten the bleeder plug, and then release the brake pedal*8.

Repeat steps *7 to *8 until all the air in the fluid is completely bled out.

Tighten the bleeder plug completely.

- Torque:

- Front bleeder plug:

- 8.3 N*m{85 kgf*cm, 73 in.*lbf}

- Rear bleeder plug (for Drum Brake):

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

- Rear bleeder plug (for Disc Brake):

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Repeat the above procedure for the rest of the brakes to bleed the brake lines.

Bleed the brake lines again according to "Step 4: Increase Line" on the Techstream display.

- NOTICE:

- Bleed air by following the steps displayed on the Techstream.

- Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while bleeding the brakes.

Connect a vinyl tube to either one of the bleeder plugs.

Depress the brake pedal several times, and then loosen the bleeder plug connected to the vinyl tube with the pedal depressed*9.

When fluid stops coming out, tighten the bleeder plug, and then release the brake pedal*10.

Repeat *9 and *10 until all the air in the fluid is completely bled out.

Tighten the bleeder plug completely.

- Torque:

- Front bleeder plug:

- 8.3 N*m{85 kgf*cm, 73 in.*lbf}

- Rear bleeder plug (for Drum Brake):

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

- Rear bleeder plug (for Disc Brake):

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Repeat the above procedure for each brake to bleed the brake lines.

Finish "Air Bleeding" on the Techstream, and then turn the Techstream off.

Disconnect the Techstream from the DLC3.

Turn the ignition switch off.

| 10. INSPECT FOR BRAKE FLUID LEAK |

| 11. INSPECT FLUID LEVEL |

Check the fluid level.

If brake fluid level is lower than the MIN line, check for leaks and inspect the disc brake pads. If necessary, refill the reservoir with brake fluid to the MAX line after repair or replacement.- Brake Fluid:

- SAE J1703 or FMVSS No. 116 DOT 3

|

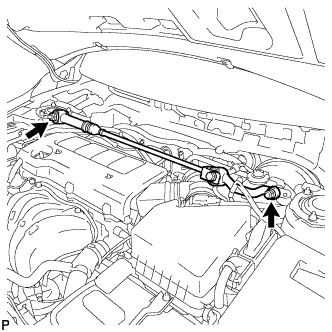

| 12. INSTALL SUSPENSION TOWER DAMPER ASSEMBLY (w/ Front Strut Bar) |

Fully tighten the 2 nuts.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

|

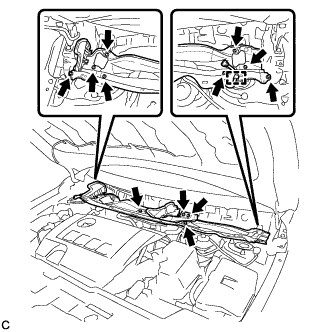

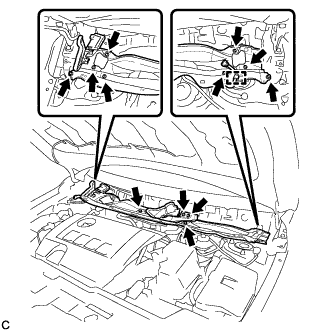

| 13. INSTALL OUTER COWL TOP PANEL (for TMC Made) |

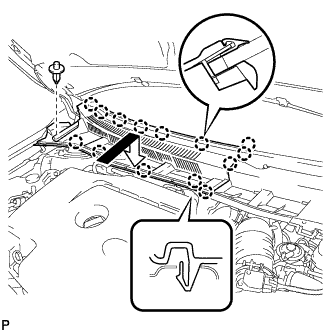

Install the outer cowl top panel with the 12 bolts.

- Torque:

- 8.8 N*m{90 kgf*cm, 78 in.*lbf}

|

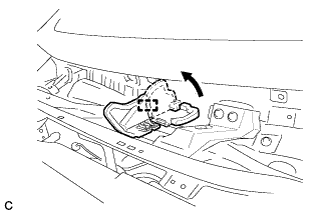

Engage the clamp.

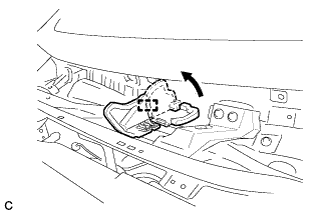

Bend the water guard plate RH as shown in the illustration and engage the clamp.

|

| 14. INSTALL OUTER COWL TOP PANEL (except TMC Made) |

Install the outer cowl top panel with the 12 bolts.

- Torque:

- 8.8 N*m{90 kgf*cm, 78 in.*lbf}

|

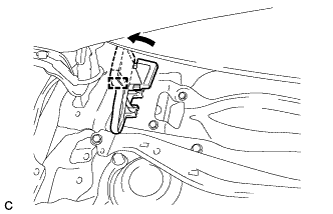

Engage the clamp.

Bend the water guard plate RH as shown in the illustration, and engage the clamp.

|

Bend the No. 1 heater air duct splash shield seal as shown in the illustration, and engage the clamp.

|

| 15. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY |

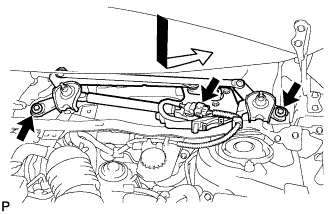

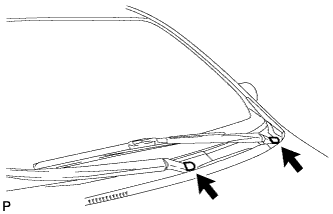

Install the windshield wiper motor and link assembly with the 2 bolts.

- Torque:

- 5.5 N*m{56 kgf*cm, 49 in.*lbf}

|

Connect the connector.

| 16. INSTALL COWL TOP VENTILATOR LOUVER LH |

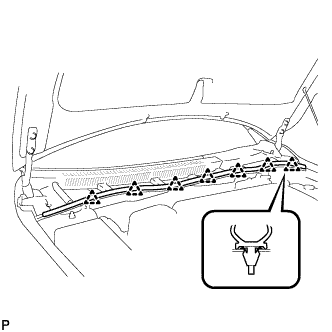

Engage the clip and 8 claws to install the cowl top ventilator louver LH.

|

| 17. INSTALL CENTER NO. 1 COWL TOP VENTILATOR LOUVER |

Engage the clip and 14 claws to install the center No. 1 cowl top ventilator louver.

|

| 18. INSTALL HOOD TO COWL TOP SEAL |

Engage the 7 clips to install the hood to cowl top seal.

|

| 19. INSTALL FRONT WIPER ARM AND BLADE ASSEMBLY RH |

Operate the wiper and stop the windshield wiper motor at the automatic stop position.

Clean the wiper arm serrations.

|

When reinstalling:

Clean the wiper pivot serrations with a wire brush.

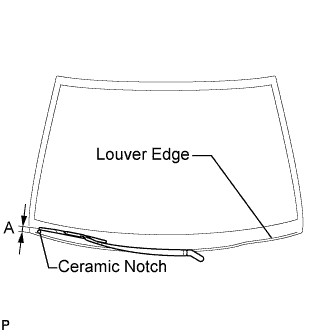

Install the front wiper arm and blade assembly RH with the nut to the position shown in the illustration.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

- HINT:

- Hold the arm hinge by hand while fastening the nut.

Area Measurement A 27.5 to 42.5 mm (1.08 to 1.67 in.)

|

| 20. INSTALL FRONT WIPER ARM AND BLADE ASSEMBLY LH |

Operate the front wipers and stop the windshield wiper motor at the automatic stop position.

Clean the wiper arm serrations.

|

When reinstalling:

Clean the wiper pivot serrations with a wire brush.

Install the front wiper arm and blade assembly LH with the nut to the position shown in the illustration.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

- HINT:

- Hold the arm hinge by hand while fastening the nut.

Area Measurement A 31.5 to 46.5 mm (1.24 to 1.83 in.)

|

Operate the front wipers while spraying washer fluid on the windshield glass. Make sure that the front wipers function properly and the wipers do not come into contact with the vehicle body.

| 21. INSTALL FRONT WIPER ARM HEAD CAP |

Install the 2 front wiper arm head caps.

|

| 22. INSTALL AIR CLEANER CASE (for 2ZR-FE) |

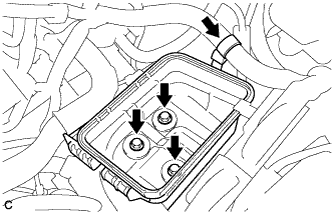

Install the air cleaner case with the 3 bolts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

|

Install the wire harness clamp to the air cleaner case.

Install the air cleaner filter element.

| 23. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (for 2ZR-FE) |

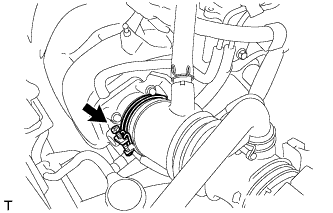

Install the air cleaner cap sub-assembly with hose with the 2 clamps.

Tighten the hose clamp to the specified torque.

- Torque:

- 2.0 N*m{20 kgf*cm, 18 in.*lbf}

|

Connect the ventilation hose.

|

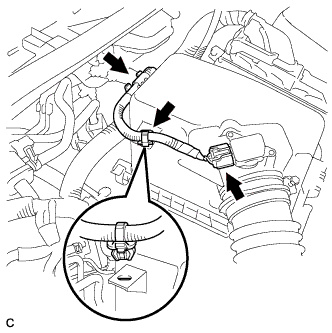

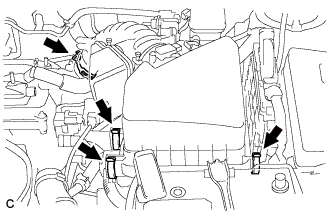

Connect the 2 wire harness clamps and mass air flow meter connector.

|

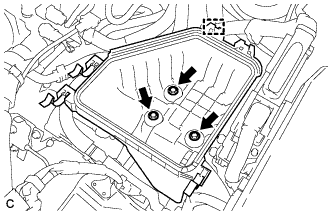

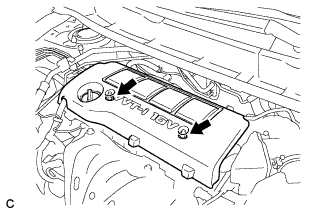

| 24. INSTALL NO. 2 CYLINDER HEAD COVER (for 2ZR-FE) |

Engage the 4 clips to install the No. 2 cylinder head cover.

- NOTICE:

- Be sure to engage the clips securely.

- Do not apply excessive force or do not hit the cover to engage the clips. This may cause the cover to break.

|

| 25. INSTALL AIR CLEANER CASE (for 2AZ-FE) |

Install the air cleaner case with the 3 bolts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

|

Install the engine wire clamp to the air cleaner case.

Install the air cleaner filter element.

| 26. INSTALL AIR CLEANER CAP SUB-ASSEMBLY WITH HOSE (for 2AZ-FE) |

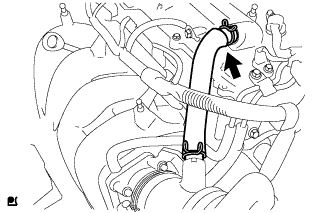

Install the air cleaner cap sub-assembly with hose and lock the 3 clamps.

|

Tighten the air cleaner hose clamp.

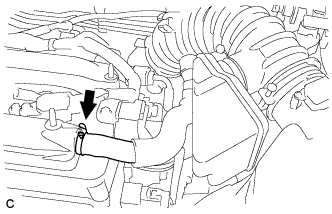

Connect the ventilation hose.

|

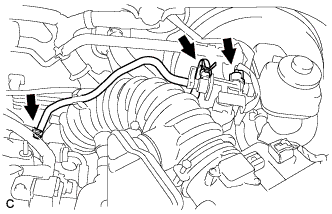

Connect the 2 vacuum hoses and No. 1 vacuum switching valve connector.

|

Connect the 2 wire harness clamps and the mass air flow meter connector.

|

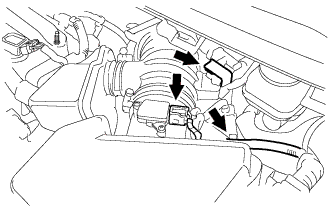

| 27. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY (for 2AZ-FE) |

Install the No. 1 engine cover sub-assembly with the 2 nuts.

|