Transmission Wire -- Installation |

| 1. INSTALL TRANSMISSION WIRE |

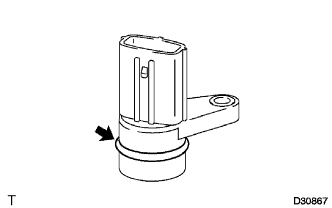

Coat a new O-ring of the transmission wire connector with ATF WS and install it to the transmission wire.

|

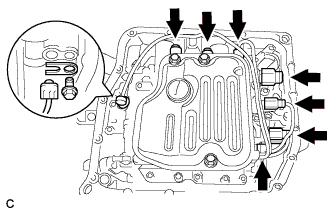

Install the transmission wire with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

|

Connect the transmission wire connector.

| 2. CONNECT TRANSMISSION WIRE |

Coat the O-ring of the ATF temperature sensor with ATF WS.

|

Install the ATF temperature sensor with the lock plate and bolt.

- Torque:

- 6.6 N*m{67 kgf*cm, 58 in.*lbf}

Connect the 7 shift solenoid valve connectors.

| 3. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-ASSEMBLY |

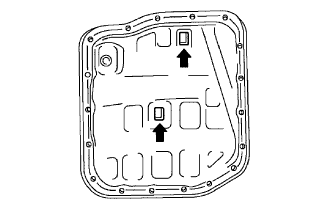

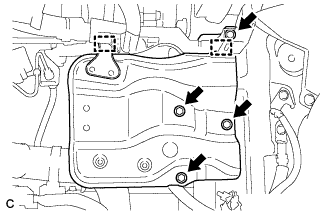

Install the 2 magnets in the oil pan.

|

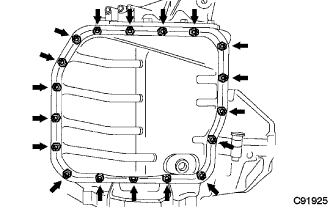

Apply adhesive or equivalent to the 18 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Using a new gasket, install the oil pan to the transaxle case with the 18 bolts.

- Torque:

- 7.8 N*m{80 kgf*cm, 69 in.*lbf}

- NOTICE:

- Since the bolts should be seal bolts, apply adhesive to the bolts and tighten them within 10 minutes of application.

|

| 4. INSTALL TRANSMISSION OIL FILLER TUBE SUB-ASSEMBLY |

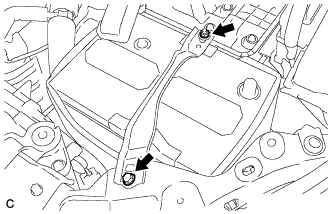

Apply ATF to a new O-ring, and install it to the transmission oil filler tube sub-assembly.

Install the transmission oil filler tube sub-assembly to the automatic transaxle with the bolt.

- Torque:

- 5.5 N*m{56 kgf*cm, 49 in.*lbf}

|

Connect the transmission wire connector, park/neutral position switch connector and 2 wire harness clamps.

Install the transmission oil level gauge sub-assembly to the transmission oil filler tube sub-assembly.

| 5. INSTALL BATTERY CARRIER |

Install the battery carrier with the 4 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

|

Connect the 2 wire harness clamps.

| 6. INSTALL BATTERY |

Install the battery tray, battery and battery insulator.

Install the battery clamp with the bolt and nut.

- Torque:

- Bolt:

- 6.5 N*m{66 kgf*cm, 58 in.*lbf}

- Nut:

- 3.5 N*m{36 kgf*cm, 31 in.*lbf}

|

Connect the battery cables.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 7. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (COROLLA_ZRE142 RM00000315Z05EX.html).

| 8. INSTALL ENGINE UNDER COVER LH |

| 9. ADD AUTOMATIC TRANSAXLE FLUID |

| 10. INSPECT TRANSAXLE FLUID LEVEL |

- HINT:

- Drive the vehicle so that the engine and transaxle are at normal operating temperature.

- Fluid temperature:

- 70 to 80°C (158 to 176°F)

Park the vehicle on a level surface and set the parking brake.

|

With the engine idling and the brake pedal depressed, move the shift lever to all positions from P to S. Then return it to P.

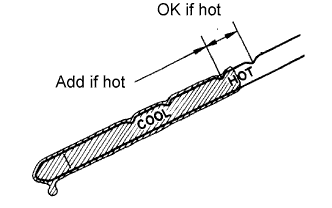

Pull out the dipstick and wipe it clean.

Push the dipstick back fully into the pipe.

Pull the dipstick out again and check that the fluid level is within the HOT range. If the fluid level is below the HOT range, add new fluid and recheck the fluid level. If the fluid level exceeds the HOT range, drain the fluid once, add a proper amount of new fluid and recheck the fluid level.