Exhaust Manifold Installation

INSTALL NO. 1 MANIFOLD CONVERTER INSULATOR

INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR

INSTALL EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY

INSTALL NO. 2 MANIFOLD STAY

INSTALL MANIFOLD STAY

INSTALL AIR FUEL RATIO SENSOR

INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

INSTALL FRONT EXHAUST PIPE ASSEMBLY

INSTALL CENTER EXHAUST PIPE ASSEMBLY

INSTALL GENERATOR ASSEMBLY

INSTALL V-RIBBED BELT

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

INSPECT FOR EXHAUST GAS LEAK

Exhaust Manifold -- Installation |

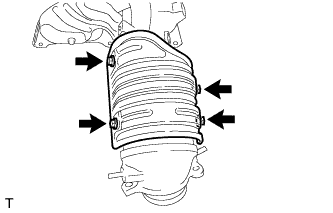

| 1. INSTALL NO. 1 MANIFOLD CONVERTER INSULATOR |

Install the No. 1 manifold converter insulator with the 4 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

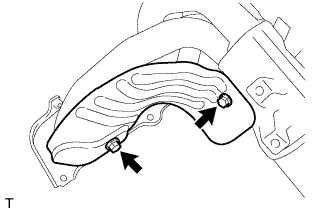

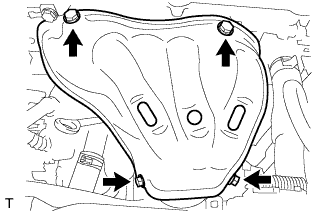

| 2. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR |

Install the No. 2 exhaust manifold heat insulator with the 2 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

| 3. INSTALL EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY |

Install a new gasket.

Install the exhaust manifold converter sub-assembly with the 5 nuts in the order shown in the illustration.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

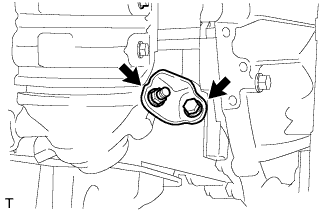

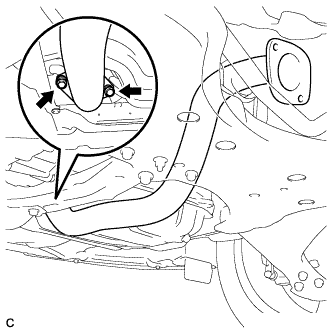

| 4. INSTALL NO. 2 MANIFOLD STAY |

Install the No. 2 manifold stay with the bolt and nut.

- Torque:

- 44 N*m{449 kgf*cm, 33 ft.*lbf}

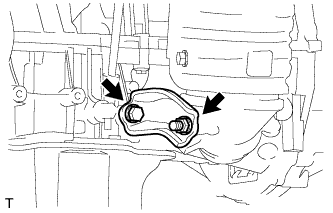

Install the manifold stay with the bolt and nut.

- Torque:

- 44 N*m{449 kgf*cm, 33 ft.*lbf}

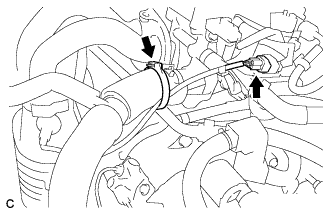

| 6. INSTALL AIR FUEL RATIO SENSOR |

Using SST, install the air fuel ratio sensor.

- SST

- 09224-00010

- Torque:

- without SST:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

- with SST:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

- NOTICE:

- This torque value can be obtained by using a torque wrench with a fulcrum length of 300 mm (11.81 in.) and SST with a measure of 30 mm (1.18 in.) (COROLLA_ZRE142 RM000000UYX0ETX.html).

- This torque value is effective when SST is parallel to the torque wrench.

Connect the air fuel ratio sensor connector and wire harness clamp.

| 7. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the No. 1 exhaust manifold heat insulator with the 4 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

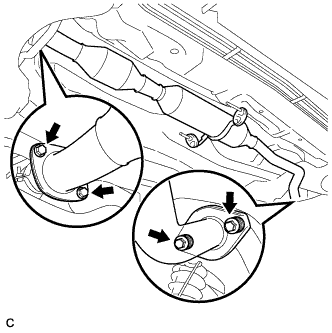

| 8. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression springs.

Minimum

| 41.5 mm (1.63 in.)

|

- HINT:

- If the free length is less than the minimum, replace the compression spring.

Remove the remains of exhaust manifold converter with wire brash.

Fully insert a new gasket to the exhaust manifold.

- NOTICE:

- Be sure to install the gasket in the correct direction.

- Do not reuse the gasket.

- Do not damage the gasket.

Install the front exhaust pipe assembly with the 2 bolts and 2 compression springs.

- Torque:

- 43 N*m{440 kgf*cm, 32 ft.*lbf}

Connect the heated oxygen sensor connector.

| 9. INSTALL CENTER EXHAUST PIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression springs.

Minimum

| 38.5 mm (1.52 in.)

|

- HINT:

- If the free length is less than the minimum, replace the compression spring.

Fully insert a new gasket to the center exhaust pipe assembly.

- NOTICE:

- Be sure to install the gasket in the correct direction.

- Do not reuse the gasket.

- Do not damage the gasket.

Install a new gasket to the front exhaust pipe assembly.

Connect the center exhaust pipe assembly to the 2 exhaust pipe supports.

Install the center exhaust pipe assembly with the 4 bolts and 2 compression springs.

- Torque:

- 43 N*m{440 kgf*cm, 32 ft.*lbf}

| 10. INSTALL GENERATOR ASSEMBLY |

(COROLLA_ZRE142 RM0000026ZB01OX.html)

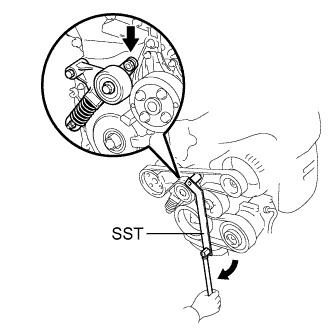

| 11. INSTALL V-RIBBED BELT |

- HINT:

- The illustration shows the V-ribbed belt layout.

Using SST, slowly turn the V-ribbed belt tensioner clockwise and install the V-ribbed belt.

- SST

- 09216-42010(09216-04010)

- NOTICE:

- Make sure that SST and other tools are set to the tensioner securely.

- When compressing the V-ribbed belt tensioner, slowly turn the tensioner.

| 12. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 13. INSPECT FOR EXHAUST GAS LEAK |