Cylinder Head Gasket -- Installation |

| 1. INSTALL CYLINDER HEAD GASKET |

Place a new gasket on the cylinder block surface with the Lot No. stamp facing upward.

- NOTICE:

- Remove any oil from the contact surface.

- Make sure that the gasket is installed in the correct direction.

|

| 2. INSTALL CYLINDER HEAD SUB-ASSEMBLY |

- HINT:

- The cylinder head bolts are tightened in 2 progressive steps.

Apply a light coat of engine oil to the bolt threads and the area beneath the bolt heads that come in contact with the washers.

Install the bolts and plate washers to the cylinder head.

- NOTICE:

- Do not drop the washers into the cylinder head.

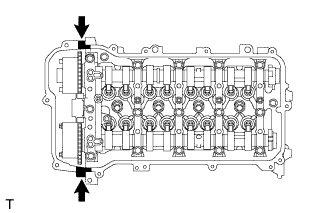

Using several passes, uniformly install and tighten the 10 cylinder head set bolts and plate washers with a 10 mm bi-hexagon wrench in the order shown in the illustration.

- Torque:

- 49 N*m{500 kgf*cm, 36 ft.*lbf}

|

Mark the front side of the cylinder head bolts with paint.

|

Further tighten the cylinder head bolts an additional 90°, then once more 45° as shown in the illustration.

Check that the paint mark is now at a 135° angle to the front.

| 3. INSTALL VALVE LASH ADJUSTER ASSEMBLY |

- NOTICE:

- Keep the lash adjuster free of dirt and foreign matter.

- Only use clean engine oil.

Place the lash adjuster into a container filled with engine oil.

Insert the tip of SST into the lash adjuster plunger and use the tip to press down on the check ball inside the plunger.

- SST

- 09276-75010

|

Squeeze SST and the lash adjuster together to move the plunger up and down 5 to 6 times.

Check the movement of the plunger and bleed it.

- OK:

- Plunger moves up and down.

- NOTICE:

- When bleeding air from the high-pressure chamber, make sure that the tip of SST is actually pressing the check ball as shown in the illustration. If the check ball is not pressed, the high-pressure chamber will not be bled.

After bleeding, remove SST. Then, try to press the plunger quickly and firmly by hand.

- OK:

- Plunger is very difficult to move.

Install the lash adjusters.

- NOTICE:

- Install the lash adjuster to the same place it was removed from.

| 4. INSTALL NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

Apply engine oil to the lash adjuster tip and valve stem cap end.

Make sure that the valve rocker arms are installed as shown in the illustration.

|

| 5. INSTALL NO. 1 CAMSHAFT BEARING |

Clean both surfaces of the 2 No. 1 camshaft bearings.

- NOTICE:

- Do not apply engine oil to the bearings or the contact surfaces.

Install the 2 No. 1 camshaft bearings.

Using a vernier caliper, measure the distance between the bearing cap edge and the camshaft bearing edge.

- Dimension (A - B):

- 0.7 mm (0.0276 in.) or less

- NOTICE:

- Position the bearings to the center of the bearing cap by measuring dimensions A and B.

|

| 6. INSTALL NO. 2 CAMSHAFT BEARING |

Clean both surfaces of the bearings.

Install the 2 No. 2 camshaft bearings.

Using a vernier caliper, measure the distance between the bearing cap edge and the camshaft bearing edge.

- Dimension (A):

- 1.05 to 1.75 mm (0.0413 to 0.0689 in.)

- NOTICE:

- Position the bearings to the center of the bearing cap by measuring dimension A.

|

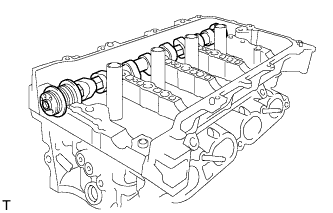

| 7. INSTALL NO. 2 CAMSHAFT |

Clean the camshaft journals.

Apply a light coat of engine oil to the camshaft journals, camshaft housings and bearing caps.

Install the No. 2 camshaft to the camshaft housing.

|

| 8. INSTALL CAMSHAFT |

Clean the camshaft journals.

Apply a light coat of engine oil to the camshaft journals, camshaft housings and bearing caps.

Install the camshaft to the camshaft housing.

|

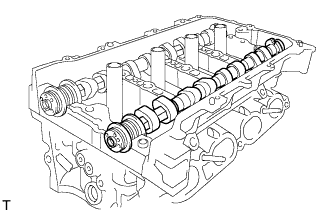

| 9. INSTALL CAMSHAFT BEARING CAP |

Apply engine oil to the camshaft journals, camshaft housings and bearing caps.

Make sure of the marks and numbers on the camshaft bearing caps and place them in each proper position and direction.

- HINT:

- Make sure that the knock pin of the camshaft is positioned as shown in the illustration.

|

Tighten the 10 bolts in the order shown in the illustration.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

|

| 10. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY |

Make sure that the valve rocker arm is installed as shown in the illustration.

|

Apply seal packing in a continuous bead as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Bead diameter:

- 3.5 to 4.0 mm (0.138 to 0.158 in.)

- NOTICE:

- Remove any oil from the contact surface.

- Install the camshaft housing sub-assembly within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing.

|

Set the camshaft and No. 2 camshaft as shown in the illustration.

|

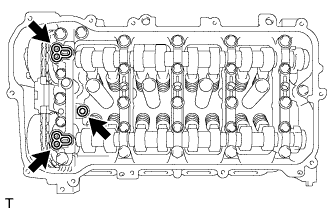

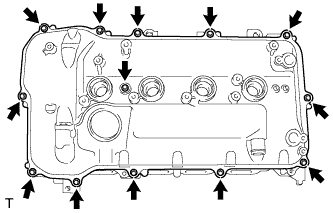

Install the camshaft housing and tighten the 17 bolts in the order shown in the illustration.

- Torque:

- 27 N*m{275 kgf*cm, 20 ft.*lbf}

- NOTICE:

- After installing the camshaft housing, make sure that the cam lobes are positioned as shown in the illustration.

- If any of the bolts are loosened during installation, remove the camshaft housing, clean the installation surfaces, and reapply seal packing.

- If the camshaft housing is removed because any of the bolts are loosened during installation, make sure that the previously applied seal packing does not enter any oil passages.

- After installing the camshaft housing, wipe off any seal packing that seeped out from between the housing and the cylinder head.

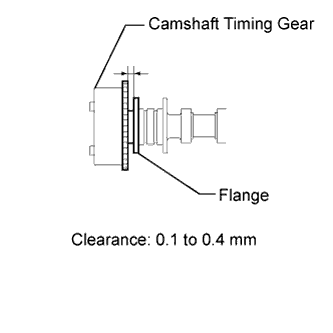

| 11. INSTALL CAMSHAFT TIMING GEAR ASSEMBLY |

Check that the knock pin is installed on the camshaft.

Put the camshaft timing gear and camshaft together with the straight pin and key groove misaligned, as shown in the illustration.

- NOTICE:

- Do not forcefully push in the camshaft timing gear assembly. This may cause the camshaft knock pin tip to damage the installation surface of the camshaft timing gear assembly.

|

Turn the camshaft timing gear as shown in the illustration while pushing it gently against the camshaft. Push further at the position where the pin fits into the groove.

- NOTICE:

- Do not turn the camshaft timing gear in the retard direction (clockwise).

|

Measure the clearance between the gear and the camshaft flange.

- Clearance:

- 0.1 to 0.4 mm (0.004 to 0.016 in.)

|

Tighten the flange bolt with the camshaft timing gear secured in place.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

|

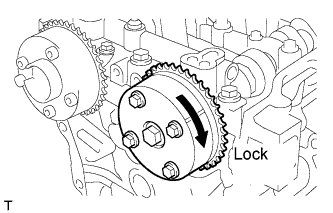

Check that the camshaft timing gear can move in the retard direction (clockwise) and is locked in the most retarded position.

|

| 12. INSTALL CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY |

Check that the knock pin is installed on the camshaft.

Put the camshaft timing exhaust gear and camshaft together by aligning the key groove and straight pin.

|

Lightly press the gear against the camshaft, and turn the gear. Push further at the position where the pin enters the groove.

- NOTICE:

- Be sure not to turn the camshaft timing exhaust gear in the retard direction (clockwise).

Check that there is no clearance between the gear and the camshaft flange.

Tighten the flange bolt with the camshaft timing exhaust gear secured.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

|

Check the camshaft timing exhaust gear lock.

Make sure that the camshaft timing exhaust gear is locked.

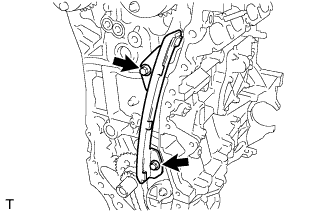

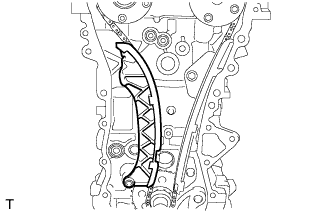

| 13. INSTALL NO. 1 CHAIN VIBRATION DAMPER |

Install the No. 1 chain vibration damper with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 16 ft.*lbf}

|

| 14. INSTALL NO. 2 CHAIN VIBRATION DAMPER |

Install the No. 2 chain vibration damper with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

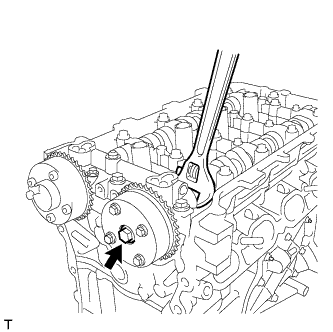

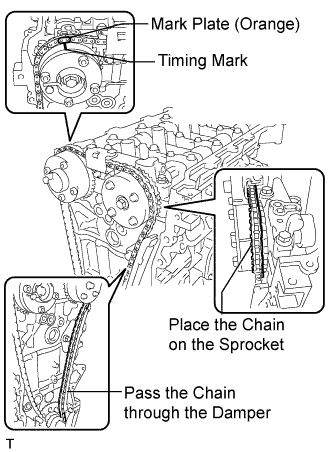

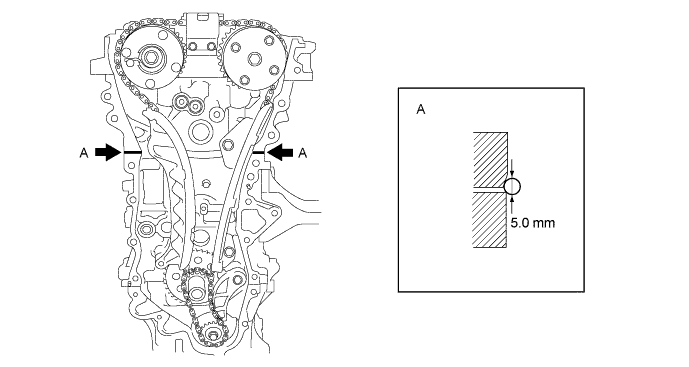

| 15. INSTALL CHAIN SUB-ASSEMBLY |

Check the No. 1 cylinder TDC/compression.

Temporarily tighten the crankshaft pulley bolt.

Turn the crankshaft counterclockwise to position the timing gear key to the top.

Remove the crankshaft pulley bolt.

Check the timing marks on each camshaft timing gear.

Align the mark plate (orange) with the timing mark of the No. 2 camshaft as shown in the illustration and install the chain.

- HINT:

- Be sure to position the mark plate at the front of the engine.

- The mark plate on the camshaft side is colored orange.

- Do not pass the chain around the sprocket of the camshaft timing gear assembly. Only place it on the sprocket.

- Pass the chain through the No. 1 vibration damper.

|

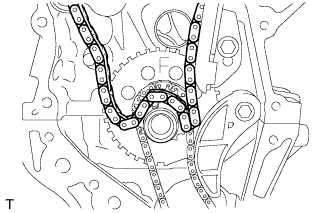

Place the chain on the crankshaft without passing it around the shaft.

|

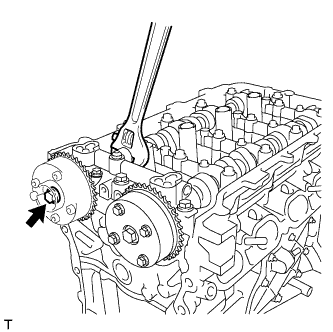

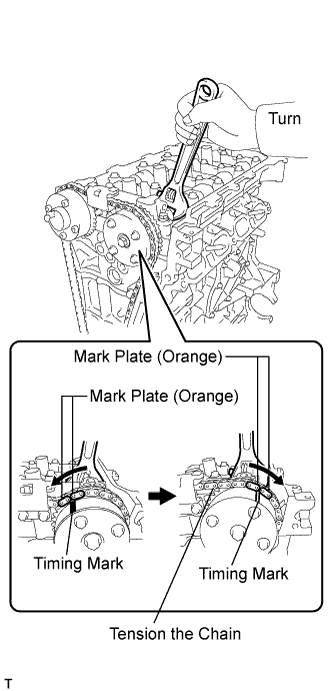

Hold the hexagonal portion of the camshaft with a wrench and turn the camshaft timing gear assembly counterclockwise to align the mark plate (orange) and timing mark.

- HINT:

- Be sure to position the mark plate at the front of the engine.

- The mark plate on the camshaft side is colored orange.

|

Hold the hexagonal portion of the camshaft with a wrench and turn the camshaft timing gear assembly clockwise.

- HINT:

- To tension the chain, slowly turn the camshaft timing gear assembly clockwise to prevent the chain from being misaligned.

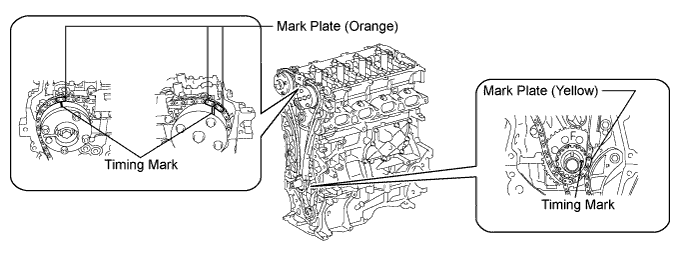

Align the mark plate (yellow) and timing mark and install the chain to the crankshaft timing gear.

- HINT:

- The mark plate on the crankshaft side is colored yellow.

|

Recheck each timing mark at TDC/compression.

| 16. INSTALL CHAIN TENSIONER SLIPPER |

Install the chain tensioner slipper.

|

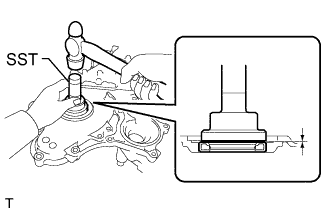

| 17. INSTALL TIMING CHAIN COVER OIL SEAL |

Using SST, tap in a new oil seal until its surface is flush with the timing gear case edge.

- SST

- 09223-22010

|

Apply a light coat of MP grease to the lip of the oil seal.

- NOTICE:

- Keep the lip free of foreign matter.

- Do not tap on the oil seal at an angle.

- Make sure that the oil seal edge does not stick out of the timing chain cover.

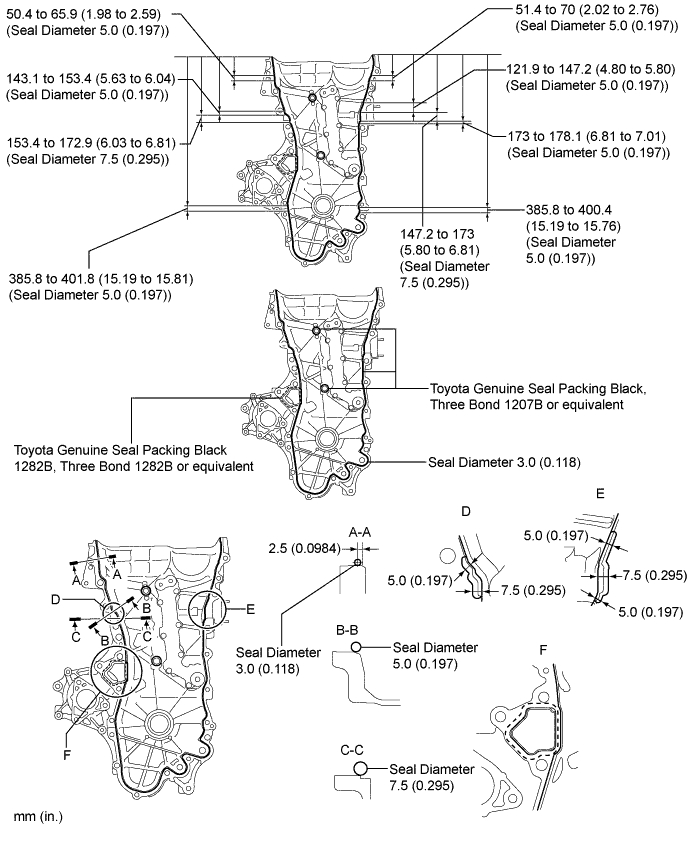

| 18. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY |

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the timing chain cover sub-assembly, cylinder head, and cylinder block.

Install 3 new O-rings.

|

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Seal diameter:

- 5.0 mm (0.196 in.)

- NOTICE:

- Remove any oil from the contact surfaces.

- Install the chain cover within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the timing chain cover sub-assembly.

Apply seal packing to the timing chain cover sub-assembly in a continuous line as shown in the following illustration.

- NOTICE:

- When the contact surfaces are wet, wipe them with oil-free cloth before applying seal packing.

- Install the timing chain cover sub-assembly within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing.

- Apply Seal Packing as Follows:

Area Seal Packing Diameter Application Position from Inside Seal Line Seal Packing Continuous Line Area 3.0 mm (0.118 in.) 2.5 mm (0.098 in.) Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Dashed Line Area 4.0 mm (0.156 in.) 3.0 mm (0.118 in.) Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent

Apply adhesive to the threads of the bolt E.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Temporarily install the timing chain cover sub-assembly with the 19 bolts.

- NOTICE:

- Remove any oil from the contact surfaces.

- Install the chain cover within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the timing chain cover sub-assembly.

- Bolt Length:

Item Length Bolt A, E 35 mm (1.38 in.) Bolt B 55 mm (2.16 in.) Bolt C 80 mm (3.15 in.) Bolt D 40 mm (1.57 in.)

|

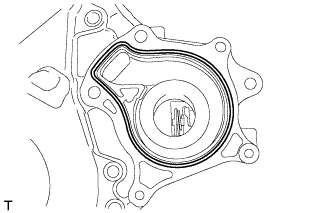

Install a new gasket.

- NOTICE:

- Remove any oil from the contact surfaces.

|

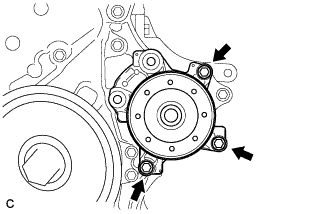

Install the water pump with the 3 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

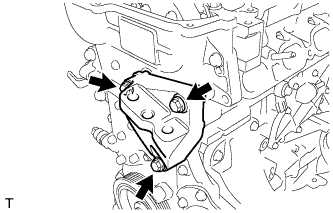

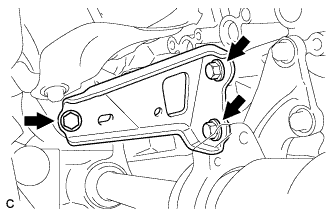

Temporarily install the engine mounting bracket with the 3 bolts.

- NOTICE:

- Install the mounting bracket within 10 minutes after installing the timing chain cover sub-assembly.

- Do not start the engine for at least 2 hours after installation.

- Bolt Length:

Item Length Bolt 80 mm (3.15 in.)

|

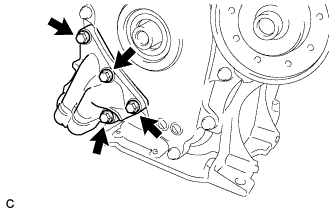

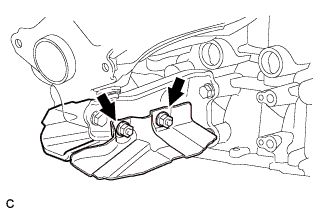

Install 2 new O-rings.

|

Temporarily install the oil filter bracket with the 4 bolts.

- NOTICE:

- Install the oil filter bracket within 10 minutes after installing the chain cover.

- Do not start the engine for at least 2 hours after installation.

- Bolt Length:

Item Length Bolt 35 mm (1.38 in.)

|

Fully tighten the timing chain cover sub-assembly with the 26 bolts as shown in the illustration.

- Torque:

- Bolt A, E:

- 26 N*m{260 kgf*cm, 19 ft.*lbf}

- Bolt B, C:

- 51 N*m{520 kgf*cm, 37 ft.*lbf}

- Bolt D:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

- NOTICE:

- When the contact surfaces are wet, wipe them with oil-free cloth before applying seal packing.

- Install the chain cover within 3 minutes and tighten the bolts within 15 minutes after applying the seal packing.

- Do not start the engine for at least 2 hours after installing.

| 19. INSTALL CRANKSHAFT PULLEY |

Align the pulley set key with the key groove of the pulley.

Using SST, hold the pulley in place and tighten the bolt.

- SST

- 09213-58014(91551-80840)

09330-00021

- Torque:

- 190 N*m{1940 kgf*cm, 140 ft.*lbf}

- NOTICE:

- Check the SST installation positions when installing them to prevent the SST fixing bolts from coming into contact with the timing chain cover sub-assembly.

|

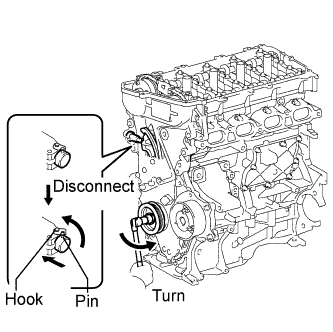

| 20. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY |

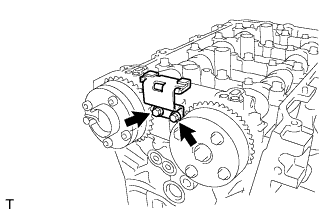

Release the ratchet pawl, then fully push in the plunger and engage the hook to the pin so that the plunger is in the position shown in the illustration.

- NOTICE:

- Make sure that the cam engages the first tooth of the plunger to allow the hook to pass over the pin.

|

Install a new gasket, bracket and No. 1 chain tensioner with the 2 nuts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

- NOTICE:

- If the hook releases the plunger while the chain tensioner is being installed, engage the hook again.

|

Turn the crankshaft counterclockwise, then disconnect the hook from plunger knock pin.

|

Turn the crankshaft clockwise, then check that the plunger is extended.

|

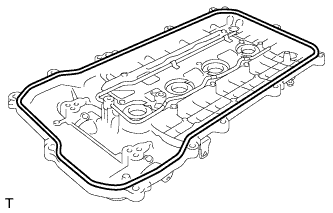

| 21. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

Install a new gasket to the cylinder head cover.

- NOTICE:

- Remove any oil from the contact surfaces.

|

Install 3 new gaskets to the No. 1 camshaft bearing cap.

|

Apply seal packing as shown the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surfaces.

- Install the cylinder head cover within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after the installation.

|

Install the cylinder head cover with a new seal washer and the 13 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

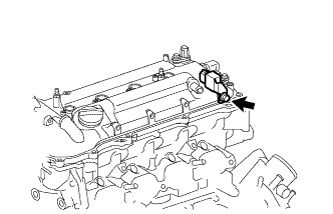

| 22. INSTALL RADIO SETTING CONDENSER |

Install the radio setting condenser with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

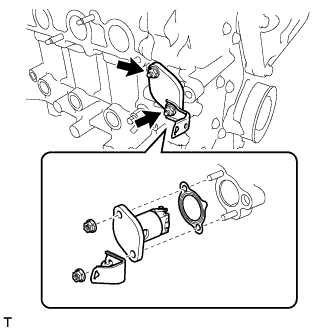

| 23. INSTALL THERMOSTAT |

Install a new gasket on the thermostat.

Install the thermostat to the water inlet with the jiggle valve upward.

- HINT:

- The jiggle valve may be set to within 10° on either side of the indicated position.

|

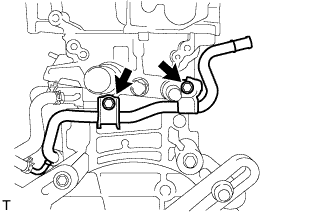

| 24. INSTALL WATER INLET |

Install the water inlet with the 2 nuts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

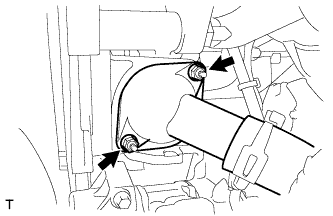

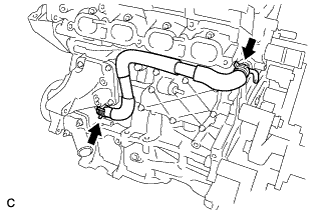

| 25. INSTALL INLET WATER HOSE |

Install the inlet water hose with the 2 clamps.

|

| 26. INSTALL WATER BY-PASS HOSE |

Install the water by-pass hose with the clamp.

| 27. INSTALL NO. 1 WATER BY-PASS PIPE |

Install the No. 1 water by-pass pipe with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 16 ft.*lbf}

|

| 28. CONNECT NO. 3 WATER BY-PASS HOSE |

| 29. INSTALL VENTILATION HOSE |

Install the ventilation hose.

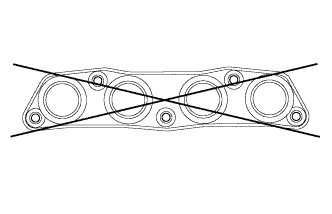

| 30. INSPECT EXHAUST MANIFOLD |

Using a precision straightedge and feeler gauge, measure the warpage on the contact surface of the cylinder head.

- Maximum warpage:

- 0.7 mm (0.028 in.)

- HINT:

- If the warpage is greater than the maximum, replace the manifold.

|

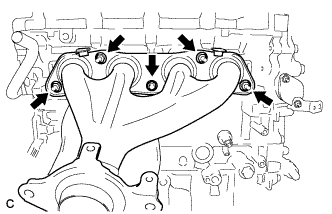

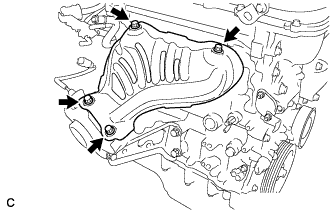

| 31. INSTALL EXHAUST MANIFOLD |

Install a new gasket onto the exhaust manifold.

|

Install the exhaust manifold with the 5 nuts.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

| 32. INSTALL MANIFOLD STAY |

Install the manifold stay with the 3 bolts.

- Torque:

- 43 N*m{439 kgf*cm, 32 ft.*lbf}

|

Install the 2 drive shaft heat insulator sub-assemblies with the 2 nuts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

|

| 33. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the No. 1 exhaust manifold heat insulator with the 4 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

|

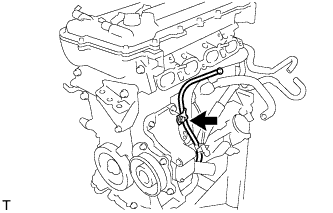

| 34. INSTALL OIL LEVEL DIPSTICK SUB-ASSEMBLY |

Apply engine oil to a new O-ring.

|

Install the oil level dipstick with the bolt through the new O-ring.

- Torque:

- 21 N*m{214 kgf*cm, 16 ft.*lbf}

| 35. INSTALL IGNITION COIL ASSEMBLY |

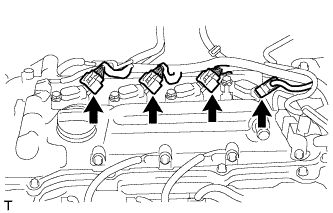

Install the 4 ignition coils with the 4 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

- NOTICE:

- When installing each ignition coil, do not damage the plug cap on the engine head cover opening or the upper edge of the spark plug tube.

|

Connect the 4 ignition coil connectors.

|

| 36. INSTALL FUEL INJECTOR ASSEMBLY |

Install 4 new injector vibration insulators to the 4 fuel injector assemblies.

|

Install 4 new injector vibration insulators to the 4 fuel injector assemblies.

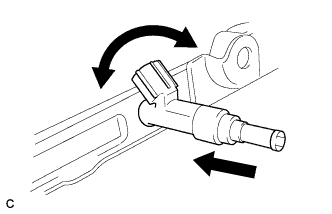

Apply a light coat of gasoline or spindle oil to the contact surfaces of the the O-rings of the fuel injector assemblies.

While turning the fuel injector assembly left and right, install it onto the fuel delivery pipe sub-assembly.

- NOTICE:

- Do not twist the O-ring.

- After installing the fuel injectors, check that they turn smoothly.

|

| 37. INSTALL NO. 1 DELIVERY PIPE SPACER |

Install the 2 No. 1 delivery pipe spacers onto the cylinder head.

Text in Illustration *a Delivery Pipe Side *b Cylinder Head Side - NOTICE:

- Install the No. 1 delivery pipe spacers in the correct direction.

|

| 38. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY |

Install the fuel delivery pipe sub-assembly with the 4 fuel injector assemblies, then temporarily install the 2 bolts.

- NOTICE:

- Do not drop the fuel injectors when installing the fuel delivery pipe sub-assembly.

- Check that the fuel injector assemblies rotate smoothly after installing the fuel delivery pipe sub-assembly.

|

Tighten the 2 bolts to the specified torque.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

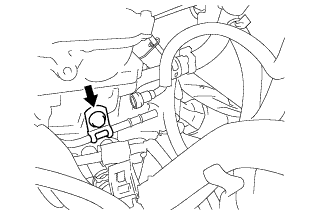

Install the bolt to secure the fuel delivery pipe sub-assembly.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

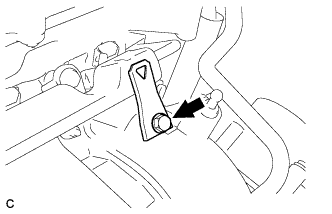

Install the wire harness bracket with the bolt.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

|

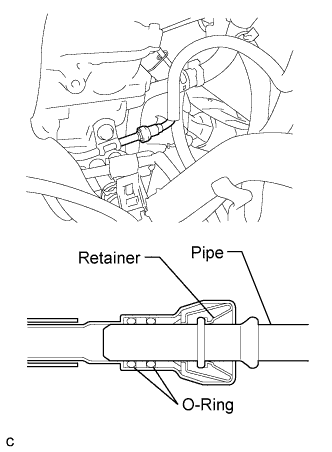

| 39. INSTALL FUEL TUBE SUB-ASSEMBLY |

Insert the fuel tube sub-assembly connector into the fuel delivery pipe until a "click" sound can be heard.

- NOTICE:

- Check that there are no scratches or foreign matter around the contact surfaces of the fuel tube connector and pipe before performing this work.

- After connecting the fuel tube, check that the fuel tube connector and pipe are securely connected by pulling on them.

|

Install a new No. 2 fuel pipe clamp (Type B).

|

Install a new No. 2 fuel pump clamp (Type A).

|

| 40. INSTALL INTAKE MANIFOLD |

Using a "TORX" socket wrench (E6), install the 2 stud bolts to the intake manifold.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Install the wire harness clamp bracket with the bolt.

- Torque:

- 15 N*m{153 kgf*cm, 11 ft.*lbf}

Install a new gasket to the intake manifold.

Install the intake manifold and intake manifold stay with the 4 bolts and 2 nuts.

- Torque:

- Bolt:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

- Nut:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

Connect the fuel vapor feed hose, ventilation hose and vacuum hose to the intake manifold.

Install the wire harness clamp bracket with an engine cover joint.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Install the engine cover joint.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Connect the 5 wire harness clamps.

| 41. REMOVE ENGINE STAND |

Attach the engine to a sling device with the chain block.

Remove the engine from the engine stand.

| 42. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE |

- HINT: