Dtc P2121 Throttle / Pedal Position Sensor / Switch D Circuit Range / Performance

DESCRIPTION

MONITOR DESCRIPTION

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

CONFIRMATION DRIVING PATTERN

FAIL-SAFE

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2121)

READ VALUE USING TECHSTREAM (ACCELERATOR POSITION SENSOR)

REPLACE ACCELERATOR PEDAL ASSEMBLY

CHECK WHETHER DTC OUTPUT RECURS (ACCELERATOR PEDAL POSITION SENSOR DTCS)

DTC P2121 Throttle / Pedal Position Sensor / Switch "D" Circuit Range / Performance |

DESCRIPTION

- HINT:

- This DTC relates to the accelerator pedal position sensor.

Refer to DTC P2120 (Link).DTC No.

| DTC Detection Condition

| Trouble Area

|

P2121

| Either of following conditions 1 or 2 met for 0.5 seconds (1 trip detection logic):

- 1. Difference between VPA and VPA2 is less than 0.4 V, or more than 1.2 V. (learned value of accelerator off position)

- 2. Difference between VPA and VPA2 is greater than or equal to the specified value.

| - Accelerator pedal sensor assembly

- ECM

|

MONITOR DESCRIPTION

The accelerator pedal position sensor is mounted on the accelerator pedal bracket. The accelerator pedal position sensor has 2 sensor elements and 2 signal outputs: VPA and VPA2. VPA is used to detect the actual accelerator pedal angle (used for engine control) and VPA2 is used to detect malfunctions in VPA. When the difference between the output voltages of VPA and VPA2 deviates from the standard, the ECM determines that the accelerator pedal position sensor is malfunctioning. The ECM illuminates the MIL and stores the DTC.

MONITOR STRATEGY

Related DTCs

| P2121: Accelerator pedal position sensor rationality

|

Required Sensors/Components (Main)

| Accelerator pedal sensor assembly

|

Required Sensors/Components (Related)

| -

|

Frequency of Operation

| Continuous

|

Duration

| 0.5 seconds

|

MIL Operation

| Immediate

|

Sequence of Operation

| None

|

TYPICAL ENABLING CONDITIONS

All (Case 1 and Case 2)Monitor runs whenever following DTCs not stored

| None

|

Either of following conditions met:

| 1 or 2

|

1. Ignition switch

| ON

|

2. Throttle actuator power

| ON

|

Accelerator pedal position sensor circuit fail (P2120, P2122, P2123, P2125, P2127, P2128, P2138)

| Not detected

|

Case 2VPA2 voltage

| Less than 4.84 V

|

Either of following conditions met:

| a or b

|

a) VPA voltage - Learned VPA accelerator off position voltage

| 0.04 V or higher

|

b) VPA2 voltage - Learned VPA2 accelerator off position voltage

| 0.04 V or higher

|

TYPICAL MALFUNCTION THRESHOLDS

Case 1Difference between VPA voltage and VPA2 voltage (learned value of accelerator off position)

| Less than 0.4 V, or higher than 1.2 V

|

Case 2|(VPA voltage - Learned VPA accelerator off position voltage) - (VPA2 voltage - Learned VPA2 accelerator off position voltage)|

| 0.165 V or higher (varies with accelerator position)

|

CONFIRMATION DRIVING PATTERN

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON and turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON and turn the Techstream on [A].

- Wait for 5 seconds after turning the ignition switch to ON.

- Operate the accelerator pedal in accordance with the following procedure [B].

- Enter the following menus: Powertrain / Engine and ECT / Data List / Gas Throttle / Accel Sens. No. 1 Volt %, and Accel Sens. No. 2 Volt %.

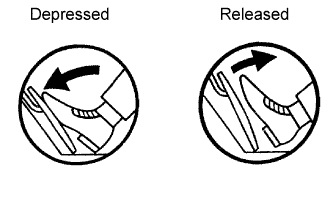

- Slowly depress the accelerator pedal until Accel Sens. No. 1 Volt % is approximately 30% and Accel Sens. No. 2 Volt % is approximately 46%, then slowly release the accelerator pedal.

- Enter the following menus: Powertrain / Engine and ECT / Trouble Codes [C].

- Read the pending DTCs.

- HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P2121.

- Check the DTC judgment result.

Techstream Display

| Description

|

NORMAL

| - DTC judgment completed

- System normal

|

ABNORMAL

| - DTC judgment completed

- System abnormal

|

INCOMPLETE

| - DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

|

N/A

| - Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

|

- HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform steps [B] and [C] again.

- If no pending DTC is output, perform a universal trip and check for permanent DTCs (COROLLA_ZRE142 RM000000PDK0ZBX.html).

- HINT:

- If a permanent DTC is output, the system is malfunctioning.

- If no permanent DTC is output, the system is normal.

FAIL-SAFE

The accelerator pedal position sensor has two (main and sub) sensor circuits. If a malfunction occurs in either of the sensor circuits, the ECM detects the abnormal signal voltage difference between the two sensor circuits and switches to limp mode. In limp mode, the functioning circuit is used to calculate the accelerator pedal opening angle to allow the vehicle to continue driving. If both circuits malfunction, the ECM regards the opening angle of the accelerator pedal as being fully closed. In this case, the throttle valve remains closed as if the engine is idling.If a pass condition is detected and then the ignition switch is turned off, the fail-safe operation stops and the system returns to a normal condition.

WIRING DIAGRAM

Refer to DTC P2120 (COROLLA_ZRE142 RM000000PFY0PRX_08.html).

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the Techstream. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

| 1.CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2121) |

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

Read DTCs.

- Result:

Result

| Proceed to

|

P2121

| A

|

P2121 and other DTCs

| B

|

- HINT:

- If any DTCs other than P2121 are output, troubleshoot those DTCs first.

| 2.READ VALUE USING TECHSTREAM (ACCELERATOR POSITION SENSOR) |

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Gas Throttle / Accel Sensor Out No. 1 and Accel Sensor Out No. 2.

Read the values displayed on the Techstream.

- Standard Voltage:

Accelerator Pedal Operation

| Accel Sensor Out No. 1

| Accel Sensor Out No. 2

|

Fully Released

| 0.5 to 1.1 V

| 1.2 to 2.0 V

|

Fully Depressed

| 2.6 to 4.5 V

| 3.4 to 4.75 V

|

| 3.REPLACE ACCELERATOR PEDAL ASSEMBLY |

Replace the accelerator pedal assembly (COROLLA_ZRE142 RM000003D3500AX.html).

| 4.CHECK WHETHER DTC OUTPUT RECURS (ACCELERATOR PEDAL POSITION SENSOR DTCS) |

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Clear the DTCs (COROLLA_ZRE142 RM000000PDK0ZBX.html).

Start the engine.

Drive the vehicle in accordance with the driving pattern described in the Confirmation Driving Pattern.

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

Read DTCs.

- Result:

Result

| Proceed to

|

P2121

| A

|

No output

| B

|