Tire And Wheel System Inspection

INSPECT TIRE

ROTATE TIRE

INSPECT WHEEL BALANCE

INSPECT FRONT AXLE HUB BEARING LOOSENESS

INSPECT REAR AXLE HUB BEARING LOOSENESS

INSPECT FRONT AXLE HUB RUNOUT

INSPECT REAR AXLE HUB RUNOUT

Tire And Wheel System -- Inspection |

Check the tires for wear and proper inflation pressure.

- Cold tire inflation pressure:

Tire size

| Front kPa (kgf*cm2, psi)

| Rear kPa (kgf*cm2, psi)

|

215/60R16 95V

| 4 passengers or less

| 250 (2.5, 36)*1, 230 (2.3, 33)*2, 210 (2.1, 31)*3

| 250 (2.5, 36)*1, 230 (2.3, 33)*2, 210 (2.1, 31)*3

|

5 passengers

| 270 (2.8, 39)*1, 250 (2.5, 36)*2, 220 (2.2, 32)*3

| 270 (2.8, 39)*1, 250 (2.5, 36)*2, 220 (2.2, 32)*3

|

*1: For driving at over 210 km/h (131 mph).

*2: For driving at 160 km/h (100 mph) to 210 km/h (131 mph).

*3: For driving at under 160 km/h (100 mph).

Using a dial indicator, check the runout of the tires.

- Tire runout:

- 1.4 mm (0.055 in.) or less

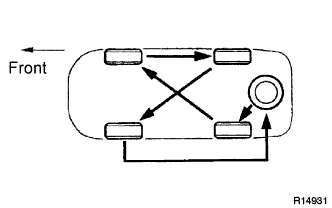

Rotate the tires as shown in illustration.

Check and adjust the off-the-car balance.

Steel wheel

If necessary, check and adjust the on-the-car balance.

- Imbalance after adjustment:

- 8.0 g (0.018 lb.) or less.

Except for steel wheel

If necessary, check and adjust the on-the-car balance.

- Imbalance after adjustment:

- 8.0 g (0.018 lb.) or less

- NOTICE:

- Use a cleaning detergent to remove dirt, oil and water from the surface where the balance weight attaches.

- Do not touch the sticking surface of the tape.

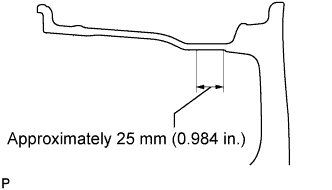

- Attach the sticking type balance weight to the flat position shown in the illustration.

- Push the balance weight securely with a finger to adhere it to the position.

- Do not reuse the balance weight.

- HINT:

- Inner side balance weight should be installed by clipping it to the rim.

| 4. INSPECT FRONT AXLE HUB BEARING LOOSENESS |

Using a dial indicator, check for looseness near the center of the axle hub.

- Maximum:

- 0.05 mm (0.0020 in.)

- NOTICE:

- Ensure that the dial indicator is set perpendicular to the measurement surface.

- HINT:

- If looseness exceeds the maximum, replace the bearing.

| 5. INSPECT REAR AXLE HUB BEARING LOOSENESS |

Using a dial indicator, check for looseness near the center of the axle hub.

- Maximum:

- 0.05 mm (0.0020 in.)

- NOTICE:

- Ensure that the dial indicator is set perpendicular to the measurement surface.

If looseness exceeds the maximum, replace the axle hub assembly.

| 6. INSPECT FRONT AXLE HUB RUNOUT |

Using a dial indicator, check for runout on the surface of the axle hub outside the hub bolt.

- Maximum:

- 0.05 mm (0.0020 in.)

- NOTICE:

- Ensure that the dial indicator is set perpendicular to the measurement surface.

- HINT:

- If runout exceeds the maximum, replace the axle hub.

| 7. INSPECT REAR AXLE HUB RUNOUT |

Using a dial indicator, check for runout on the surface of the axle hub outside the hub bolt.

- Maximum:

- 0.07 mm (0.0027 in.)

- NOTICE:

- Ensure that the dial indicator is set perpendicular to the measurement surface.

If runout exceeds the maximum, replace the axle hub assembly.