CHECK HARNESS AND CONNECTOR (POWER SOURCE VOLTAGE)

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM)

INSPECT MASS AIR FLOW METER SUB-ASSEMBLY

CHECK HARNESS AND CONNECTOR (SENSOR GROUND)

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM)

DTC P0100 Mass or Volume Air Flow Circuit |

DTC P0102 Mass or Volume Air Flow Circuit Low Input |

DTC P0103 Mass or Volume Air Flow Circuit High Input |

DESCRIPTION

The mass air flow meter sub-assembly is a sensor that measures the amount of air flowing through the throttle valve.The ECM uses this information to determine the fuel injection time and to provide the appropriate air fuel ratio.

Inside the mass air flow meter sub-assembly, there is a heated platinum wire which is exposed to the flow of intake air.

By applying a specific electrical current to the wire, the ECM heats it to a given temperature. The flow of incoming air cools both the wire and an internal thermistor, affecting their resistance. To maintain a constant current value, the ECM varies the voltage applied to these components in the mass air flow meter sub-assembly. The voltage level is proportional to the air flow through the sensor, and the ECM uses it to calculate the intake air volume.

The circuit is constructed so that the platinum hot wire and the temperature sensor create a bridge circuit, and the power transistor is controlled so that the potentials of A and B remain equal to maintain the predetermined temperature.

- HINT:

- When any of these DTCs are set, the ECM enters fail-safe mode. During fail-safe mode, the ignition timing is calculated by the ECM, according to the engine speed and throttle valve position. Fail-safe mode continues until a pass condition is detected.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0100 | Open or short in mass air flow meter sub-assembly circuit for 3 seconds (1 trip detection logic) |

|

| P0102 | Mass air flow meter sub-assembly voltage is less than 0.2 V for 3 seconds (1 trip detection logic) |

|

| P0103 | Mass air flow meter sub-assembly voltage is more than 4.9 V for 3 seconds (1 trip detection logic) |

|

- HINT:

- When any of these DTCs are set, check the air flow rate by entering the following menus on the intelligent tester: Powertrain / Engine and ECT / Data List / All Data / MAF.

| Mass Air Flow Rate (gm/sec) | Malfunction |

| Approximately 0.0 |

|

| 271.0 or more |

|

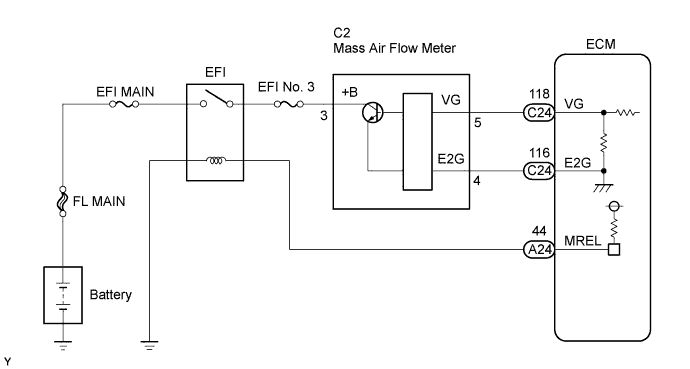

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- HINT:

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.READ DTC OUTPUT |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

- Result:

Result Proceed to DTC P0100 and P0102 or P0102 are output A DTC P0100 and P0103 or P0103 are output B

|

| ||||

| A | |

| 2.CHECK HARNESS AND CONNECTOR (POWER SOURCE VOLTAGE) |

Disconnect the mass air flow meter sub-assembly connector.

|

Turn the ignition switch to ON.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Switch Condition Specified Condition C2-3 (+B) - Body ground Ignition switch ON 11 to 14 V

Text in Illustration *1 Front view of wire harness connector

(to Mass Air Flow Meter Sub-assembly)

Reconnect the mass air flow meter sub-assembly connector.

|

| ||||

| OK | |

| 3.CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM) |

Disconnect the mass air flow meter sub-assembly connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection Condition Specified Condition C2-5 (VG) - C24-118 (VG) Always Below 1 Ω C2-4 (E2G) - C24-116 (E2G) Always Below 1 Ω

- Standard Resistance (Check for Short):

Tester Connection Condition Specified Condition C2-5 (VG) or C24-118 (VG) - Body ground Always 10 kΩ or higher

Reconnect the mass air flow meter sub-assembly connector.

Reconnect the ECM connector.

|

| ||||

| OK | |

| 4.INSPECT MASS AIR FLOW METER SUB-ASSEMBLY |

Perform On-vehicle Inspection (CAMRY_ACV40 RM000002A4Y01CX.html).

Inspect the function of the mass air flow meter sub-assembly.

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the tester to on.

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data / MAF.

Start the engine.

Check that the reading of the MAF changes when the engine is raced.

- OK:

- The reading changes.

|

| ||||

| OK | ||

| ||

| 5.CHECK HARNESS AND CONNECTOR (SENSOR GROUND) |

Disconnect the mass air flow meter sub-assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection Condition Specified Condition C2-4 (E2G) - Body ground Always Below 1 Ω

Reconnect the mass air flow meter sub-assembly connector.

|

| ||||

| OK | ||

| ||

| 6.CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM) |

Disconnect the mass air flow meter sub-assembly connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection Condition Specified Condition C2-4 (E2G) - C24-116 (E2G) Always Below 1 Ω

Reconnect the mass air flow meter sub-assembly connector.

Reconnect the ECM connector.

|

| ||||

| OK | ||

| ||