INSTALL IGNITION SWITCH ASSEMBLY (w/o Entry and Start System)

INSTALL UNLOCK WARNING SWITCH ASSEMBLY (w/o Entry and Start System)

INSTALL IGNITION SWITCH LOCK CYLINDER ASSEMBLY (w/o Entry and Start System)

INSPECT STEERING LOCK OPERATION (w/o Entry and Start System)

INSTALL STEERING COLUMN UPPER W/ SWITCH BRACKET ASSEMBLY (w/o Entry and Start System)

INSTALL TRANSPONDER KEY AMPLIFIER (w/o Entry and Start System)

INSTALL STEERING LOCK ACTUATOR ASSEMBLY (w/ Entry and Start System)

Steering Column Assembly (For Rhd) -- Reassembly |

| 1. INSTALL POWER STEERING MOTOR ASSEMBLY |

- NOTICE:

- Do not drop the power steering motor assembly, strike it with tools or subject it to impacts.

- If the power steering motor assembly is subjected to an impact, replace it with a new one.

- Do not pull the wire harness of the power steering motor assembly.

- Do not allow any moisture to come into contact with the power steering motor assembly.

- Do not loosen any bolts not mentioned in the procedure.

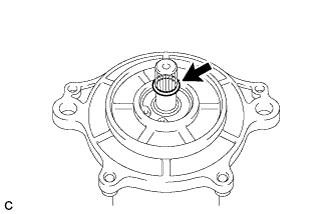

Install a new O-ring to the power steering motor assembly.

|

Apply grease to the serrated part of the power steering motor assembly.

- NOTICE:

- First wipe off the existing grease from the serrated part, and then apply the dedicated grease supplied with a new power steering motor assembly or electric power steering column sub-assembly.

|

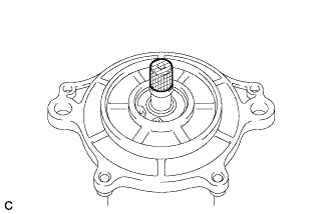

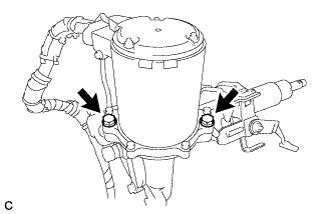

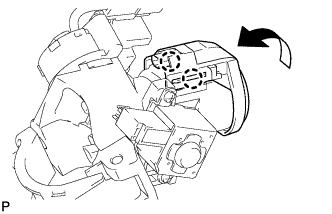

Temporarily install the power steering motor assembly to the electric power steering column sub-assembly with the 2 bolts.

- NOTICE:

- When temporarily installing the 2 bolts to the power steering motor assembly, do not tighten them all the way down.

|

Install the 2 service nuts to the steering main shaft.

- Recommended service nut:

- Thread diameter:

- 12.0 mm (0.472 in.)

- Thread pitch:

- 1.25 mm (0.0492 in.)

|

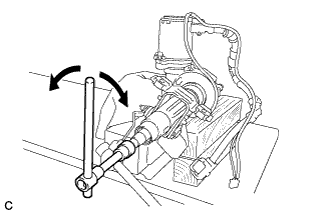

Rotate the 2 installed service nuts simultaneously to lock them: rotate the one installed first counter clockwise and rotate the one installed second clockwise.

- NOTICE:

- Do not apply excess torque to the service nuts by using a tool such as an impact wrench.

- HINT:

- These nuts are installed to turn the steering main shaft. They should be removed after inspecting the steering main shaft rotating torque.

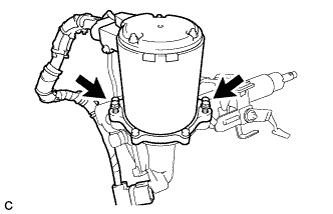

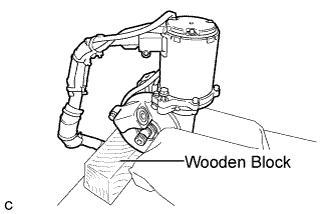

Secure the steering column assembly in a vice using aluminum plates or a piece of cloth as shown in the illustration.

- NOTICE:

- Do not overtighten the vice, as the steering column assembly may become deformed.

- Secure the power steering motor assembly so that it is directly upright.

- Support the steering column assembly with a wooden block or similar item to ensure that it does not fall.

|

Turn the steering main shaft once 180 degrees to the left and then 180 degrees to the right at a speed of 60 rpm, and repeat 2 to 3 times to adjust the axis of the power steering motor assembly.

|

Remove the steering column assembly from the vice.

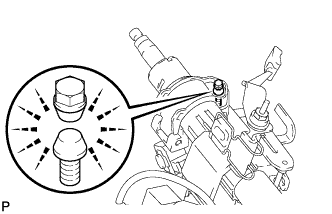

Tighten the 2 bolts.

- Torque:

- 19 N*m{189 kgf*cm, 14 ft.*lbf}

- NOTICE:

- Make sure not to move the power steering motor assembly after adjusting the axis.

|

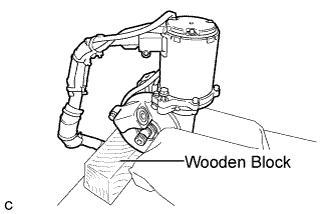

Secure the steering column assembly in a vice using aluminum plates or a piece of cloth as shown in the illustration.

- NOTICE:

- Do not overtighten the vice, as the steering column assembly may become deformed.

- Support the steering column assembly with a wooden block or similar item to ensure that it does not fall.

|

Measure the turning torque of the steering main shaft.

- Torque:

- Turning torque:

- 1.20 to 1.85 N*m{13 to 18 kgf*cm, 11 to 16 in.*lbf}

- NOTICE:

- Ensure that there is no abnormal resistance during rotation.

|

Remove the 2 service nuts from the steering main shaft.

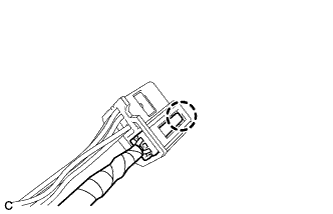

Engage the claw to install the torque sensor harness connector.

|

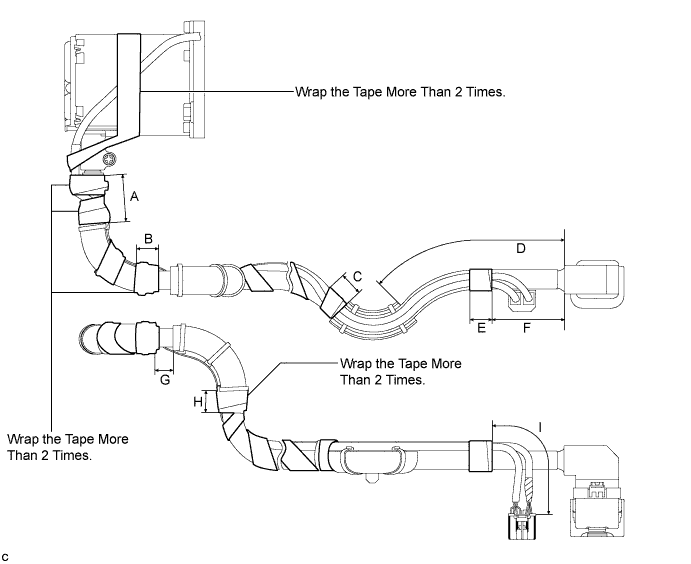

Apply tape to the wire harness as shown in the illustration.

A 40 mm (1.57 in.) B 30 mm (1.18 in.) C 30 mm (1.18 in.) D 145 to 155 mm (5.71 to 6.10 in.) E 30 mm (1.18 in.) F 55 to 65 mm (2.17 to 2.56 in.) G 10 to 20 mm (0.394 to 0.787 in.) H 30 mm (1.18 in.) I 95 to 105 mm (3.74 to 4.13 in.) - NOTICE:

- As heat from the power steering motor assembly may generate smoke, use heat resistant tape (resistant to 100°C (212°F) or more).

| 2. INSTALL IGNITION SWITCH ASSEMBLY (w/o Entry and Start System) |

|

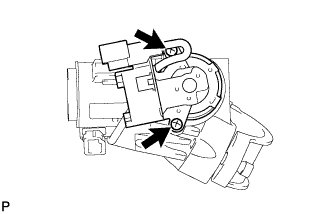

Install the ignition switch to the steering column bracket upper with the 2 screws.

| 3. INSTALL KEY INTERLOCK SOLENOID (w/o Entry and Start System) |

|

for Automatic Transaxle:

Install the key interlock solenoid to the steering column bracket assembly upper with the 2 screws.

| 4. INSTALL UNLOCK WARNING SWITCH ASSEMBLY (w/o Entry and Start System) |

|

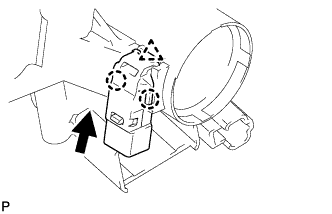

Attach the clip and 2 claws to install the unlock warning switch to the steering column bracket upper.

- HINT:

- Slide the unlock warning switch in the direction shown by the arrow in the illustration to install it.

| 5. INSTALL IGNITION SWITCH LOCK CYLINDER ASSEMBLY (w/o Entry and Start System) |

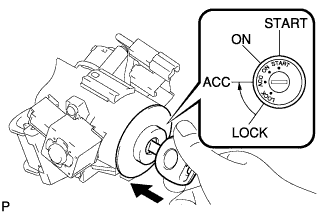

Insert the key and turn it to the ACC position.

Install the ignition switch lock cylinder to the steering column bracket upper.

|

Make sure that the ignition switch lock cylinder is securely fixed to the steering column upper with switch bracket.

| 6. INSPECT STEERING LOCK OPERATION (w/o Entry and Start System) |

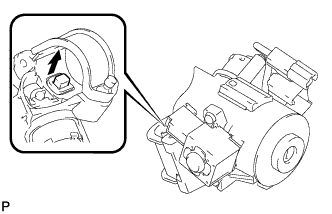

Remove the key and check that the steering lock function is activated.

|

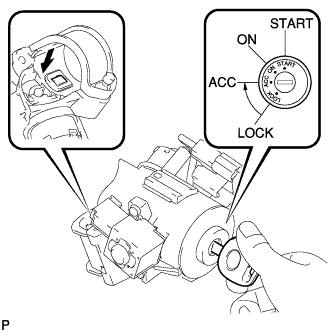

Insert the key, turn the ignition switch on (ACC) and check that the steering lock function is deactivated.

|

| 7. INSTALL STEERING COLUMN UPPER W/ SWITCH BRACKET ASSEMBLY (w/o Entry and Start System) |

Fix the steering column in a vise between aluminum plates.

- NOTICE:

- Do not overtighten the vise.

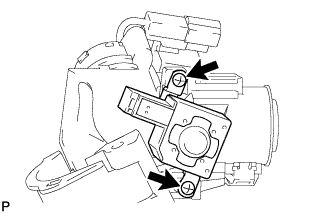

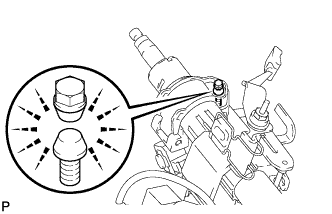

Install the steering column upper with switch bracket with a new steering lock set bolt, and then tighten the bolt until is head comes off.

|

| 8. INSTALL TRANSPONDER KEY AMPLIFIER (w/o Entry and Start System) |

|

Attach the 2 claws and install the transponder key amplifier to the steering column upper with the switch bracket.

| 9. INSTALL STEERING LOCK ACTUATOR ASSEMBLY (w/ Entry and Start System) |

Fix the steering column in a vise between aluminum plates.

- NOTICE:

- Do not overtighten the vise.

Install the steering lock actuator with a steering lock set bolt, and then tighten the bolts until their head comes off.

|