INSPECT INPUT SHAFT

INSPECT 4TH GEAR

INSPECT 3RD GEAR

INSPECT 2ND SYNCHRONIZER OUTER RING

INSPECT NO. 3 SYNCHRONIZER RING

INSPECT NO. 2 TRANSAXLE HUB SLEEVE

Input Shaft -- Inspection |

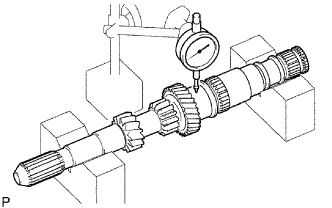

Using V-blocks and dial indicator, measure the shaft for runout.

- Maximum runout:

- 0.03 mm (0.0012 in.)

If the runout is greater than the maximum, replace the input shaft.

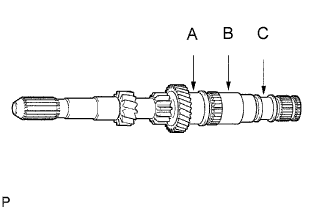

Using a micrometer, measure the diameter of the input shaft journal surface.

- Standard diameter:

Journal Position

| Specified Condition

|

A

| 35.984 to 36.000 mm (1.4167 to 1.4173 in.)

|

B

| 35.984 to 36.000 mm (1.4167 to 1.4173 in.)

|

C

| 27.957 to 27.972 mm (1.1007 to 1.1013 in.)

|

- Minimum diameter:

Journal Position

| Specified Condition

|

A

| 35.984 mm (1.4167 in.)

|

B

| 35.984 mm (1.4167 in.)

|

C

| 27.957 mm (1.1007 in.)

|

If the diameter is less than the minimum, replace the input shaft.

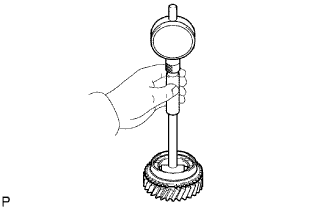

Using a cylinder gauge, measure the inside diameter of the 4th gear.

- Standard inside diameter:

- 42.009 to 42.025 mm (1.6933 to 1.6939 in.)

- Maximum inside diameter:

- 42.025 mm (1.6939 in.)

If the inside diameter is greater than the maximum, replace the 4th gear.

Using a cylinder gauge, measure the inside diameter.

- Standard inside diameter:

- 43.009 to 43.025 mm (1.6933 to 1.6939 in.)

- Maximum inside diameter:

- 43.025 mm (1.6939 in.)

If the inside diameter is greater than the maximum, replace the 3rd gear.

| 4. INSPECT 2ND SYNCHRONIZER OUTER RING |

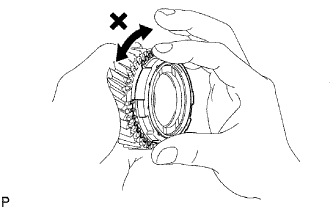

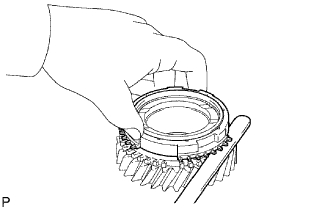

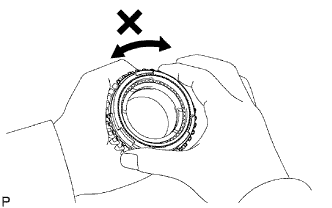

Coat the 4th gear cone with gear oil. Turn the 2nd synchronizer outer ring (synchronizer ring No. 4) in one direction while pushing it against the 4th gear cone. Check that the ring locks.

If the 2nd synchronizer outer ring does not lock, replace the ring or the 4th gear.

Using a feeler gauge, measure the clearance between the 2nd synchronizer outer ring (No. 4 synchronizer ring) back and 4th gear spline end.

- Standard clearance:

- 0.7 to 1.45 mm (0.0276 to 0.0571 in.)

If the clearance is out of the specification, replace the 2nd synchronizer outer ring.

| 5. INSPECT NO. 3 SYNCHRONIZER RING |

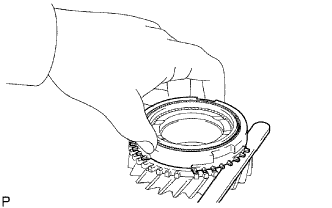

Coat the 3rd gear cone with gear oil. Turn the No. 3 synchronizer ring in one direction while pushing it against the 3rd gear cone. Check that the ring locks.

If the No. 3 synchronizer ring does not lock, replace the ring or the 3rd gear.

Using a feeler gauge, measure the clearance between the No. 3 synchronizer ring back and 3rd gear spline end.

- Standard clearance:

- 0.65 to 1.75 mm (0.0256 to 0.0689 in.)

If the clearance is out of the specification, replace the No. 3 synchronizer ring.

| 6. INSPECT NO. 2 TRANSAXLE HUB SLEEVE |

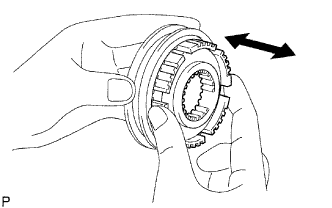

Inspect the sliding condition between the No. 2 transaxle hub sleeve and No. 2 transaxle clutch hub.

Inspect the tip of the spline gear on the No. 2 transaxle hub sleeve for wear.

If any defects are found, replace the transaxle hub sleeve or the transaxle clutch hub.

Using vernier calipers, measure the width of the No. 2 transaxle hub sleeve groove (A) and the thickness of the claw part on the No. 2 gear shift fork (B), and calculate the clearance.

- Standard clearance:

- A - B = 0.11 to 0.69 mm

If the clearance is out of the specification, replace the No. 2 transaxle hub sleeve and No. 2 gear shift fork with new ones.