Underdrive Clutch Disassembly

INSPECT PACK CLEARANCE OF UNDERDRIVE CLUTCH

REMOVE NO. 1 UNDERDRIVE CLUTCH DISC

INSPECT NO. 1 UNDERDRIVE CLUTCH DISC

INSPECT UNDERDRIVE CLUTCH DRUM SUB-ASSEMBLY

REMOVE UNDERDRIVE CLUTCH DRUM O-RING

REMOVE UNDERDRIVE CLUTCH PISTON SET

INSPECT UNDERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY

Underdrive Clutch -- Disassembly |

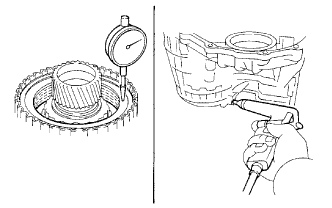

| 1. INSPECT PACK CLEARANCE OF UNDERDRIVE CLUTCH |

Install the underdrive clutch to the transaxle.

- NOTICE:

- Be careful not to damage the oil seal rings.

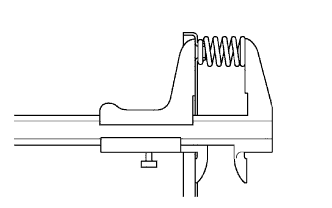

Install a dial indicator as shown in the illustration.

Measure the underdrive clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0kgf/cm2, 57 psi)

- Standard pack clearance:

- 1.51 to 1.90 mm (0.0594 to 0.0748 in.)

If the pack clearance is not as specified, inspect the discs, plates and flange.

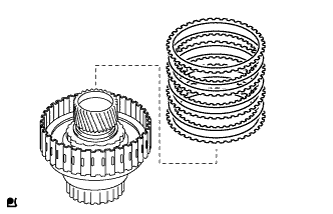

| 2. REMOVE NO. 1 UNDERDRIVE CLUTCH DISC |

Using a screwdriver, pry out the underdrive clutch flange snap ring.

Remove the flange, 3 discs and 3 plates from the underdrive clutch drum.

| 3. INSPECT NO. 1 UNDERDRIVE CLUTCH DISC |

Check to see if the sliding surface of the disc, plate and flange are worn or burnt. If necessary, replace them.

- HINT:

- If the lining of the discs is peeling off or discolored, or even if a part of the printed mark is defaced, replace all discs.

- Before assembling new discs, soak them in ATF for at least 15 minutes.

| 4. INSPECT UNDERDRIVE CLUTCH DRUM SUB-ASSEMBLY |

Using a caliper gauge measure the inside diameter of the underdrive clutch drum bush.

- Standard drum bush:

- 37.06 to 37.08 mm (1.4591 to 1.4598 in.)

- Maximum drum bush:

- 37.13 mm (1.4618 in.)

If the inside diameter is greater then the maximum, replace the underdrive clutch drum sub-assembly.

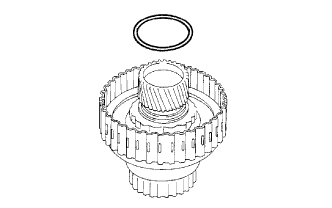

| 5. REMOVE UNDERDRIVE CLUTCH DRUM O-RING |

| 6. REMOVE UNDERDRIVE CLUTCH PISTON SET |

Place SST on the clutch balancer and compress the spring with a press.

- SST

- 09350-32014(09351-32070)

Using a snap ring expander, remove the snap ring.

- NOTICE:

- Stop the press when the spring sheet is lowered to a position 1 to 2 mm (0.04 to 0.08 in.) from the snap ring groove.

- This prevents the spring sheet from being deformed.

- Do not expand the snap ring excessively.

Remove the clutch balancer from the underdrive clutch drum.

Remove the piston return spring from the underdrive clutch drum.

Install the underdrive clutch to the transaxle.

- NOTICE:

- Be careful not to damage the oil seal rings.

Holding the underdrive clutch piston with your hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the transaxle case to remove the underdrive clutch piston.

| 7. INSPECT UNDERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY |

Using a vernier caliper, measure the free length of the spring together with the spring seat.

- Standard free length:

- 17.14 mm (0.6752 in.)