Lexus IS250 IS220d GSE20 ALE20 4GR-FSE ENGINE CONTROL SYSTEM

INSPECT IGNITION COIL ASSEMBLY (POWER SOURCE)

CHECK HARNESS AND CONNECTOR (IGNITION COIL ASSEMBLY - ECM (IGT SIGNAL TERMINAL))

CHECK ECM (IGT1, IGT2, IGT3, IGT4, IGT5, IGT6, IGF1, IGF2 SIGNAL)

DTC P0351 Ignition Coil "A" Primary / Secondary Circuit

DTC P0352 Ignition Coil "B" Primary / Secondary Circuit

DTC P0353 Ignition Coil "C" Primary / Secondary Circuit

DTC P0354 Ignition Coil "D" Primary / Secondary Circuit

DTC P0355 Ignition Coil "E" Primary / Secondary Circuit

DTC P0356 Ignition Coil "F" Primary / Secondary Circuit

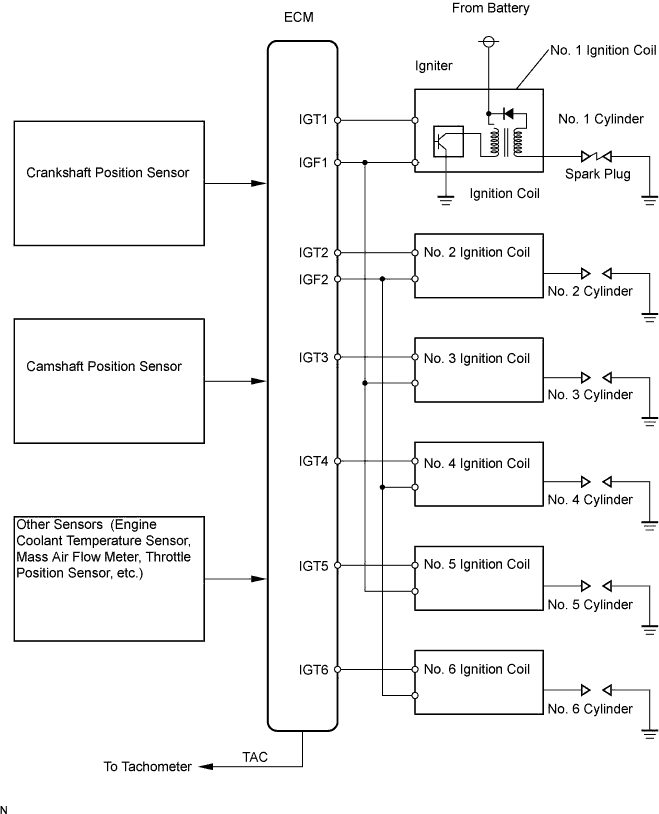

DESCRIPTION

- HINT:

A Direct Ignition System (DIS) is used on this vehicle.

The DIS is a 1-cylinder ignition system in which each cylinder is ignited by one ignition coil and spark plug is connected to the end of each secondary wiring. A powerful voltage, generated in the secondary wiring, is applied directly to each spark plug. The sparks of the spark plugs pass from the center electrode to the ground electrodes.

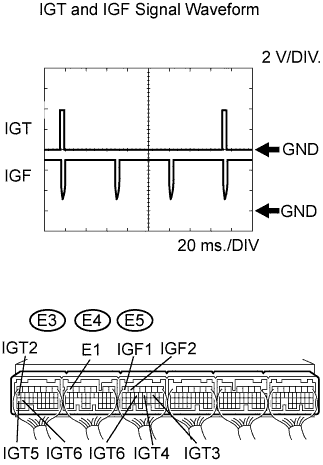

The ECM determines the ignition timing and transmits the ignition signals (IGT) to each cylinder. Using the IGT signal, the ECM turns the power transistor inside the igniter on and off. The power transistor, in turn, switches on and off the current to the primary coil. When the current to the primary coil is cut off, a powerful voltage is generated in the secondary coil. This voltage is applied to the spark plugs, causing them to spark inside the cylinders. As the ECM cuts the current to the primary coil, the igniter sends back an ignition confirmation signal (IGF) to the ECM, for each cylinder ignition.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0351 P0352 P0353 P0354 P0355 P0356 | No IGF signal to ECM while engine running (1 trip detection logic) | Ignition system Open or short in IGF1, IGF2 or IGT circuit (1 to 6) between ignition coil and ECM No. 1 to No. 6 ignition coils ECM |

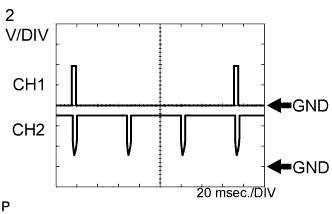

| Item | Content |

| Terminals | CH1: IGT1, IGT2, IGT3, IGT4, IGT5, IGT6 - E1 CH2: IGF1, IGF2 - E1 |

| Equipment Settings | 2 V/DIV. 20 ms./DIV. |

| Conditions | Cranking or idling |

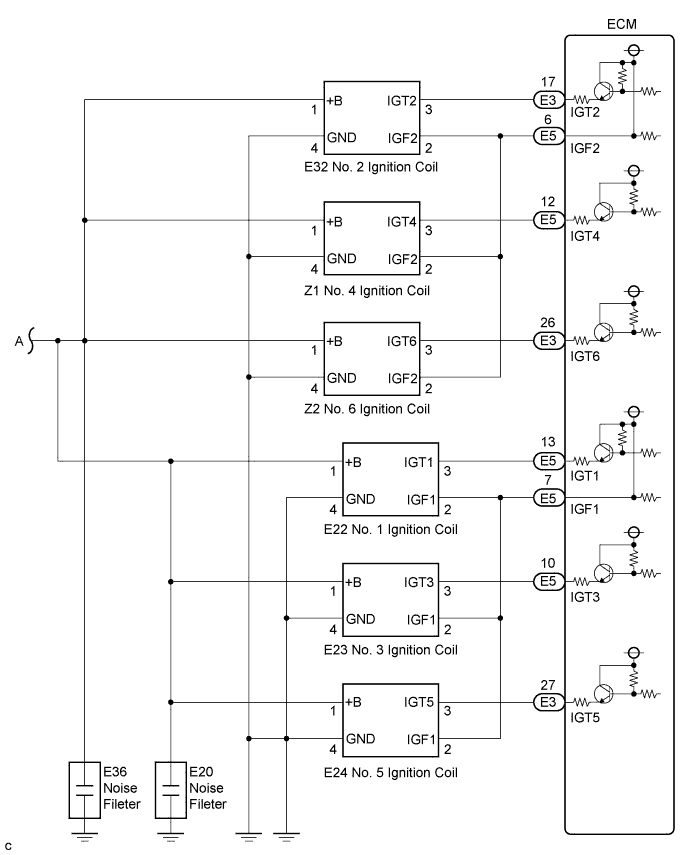

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred .

| 1.PERFORM SIMULATION TEST |

Clear the DTC(s) .

Change the arrangement of the ignition coils (with igniters).

- NOTICE:

- Do not change the location of the connectors.

Reform a simulation test.

- Result:

Display (DTC Output) Proceed to Same DTCs (that have been erased) A Other DTCs B

|

| ||||

| A | |

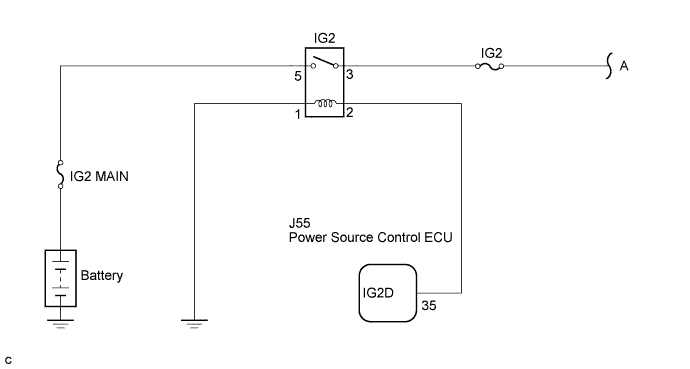

| 2.INSPECT IGNITION COIL ASSEMBLY (POWER SOURCE) |

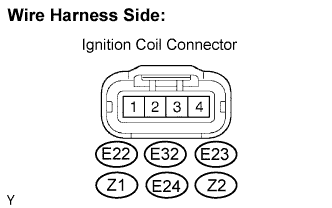

Disconnect the E22, E32, E23, Z1, E24 or Z2 ignition coil connector.

Turn the engine switch on (IG).

Measure the voltage of the wire harness side connector and body ground.

- Standard voltage:

Tester Connection Specified Condition E22-1 - Body ground 9 to 14 V E32-1 - Body ground 9 to 14 V E23-1 - Body ground 9 to 14 V Z1-1 - Body ground 9 to 14 V E24-1 - Body ground 9 to 14 V Z2-1 - Body ground 9 to 14 V

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection Specified Condition E22-4 - Body ground Below 1 Ω E32-4 - Body ground Below 1 Ω E23-4 - Body ground Below 1 Ω Z1-4 - Body ground Below 1 Ω E24-4 - Body ground Below 1 Ω Z2-4 - Body ground Below 1 Ω

|

| ||||

| OK | |

| 3.CHECK HARNESS AND CONNECTOR (IGNITION COIL ASSEMBLY - ECM (IGT SIGNAL TERMINAL)) |

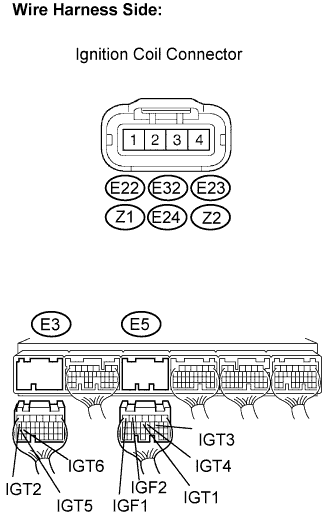

Disconnect the E22, E32, E23, Z1, E24 or Z2 ignition coil connector.

Disconnect the ECM E5 and E3 connectors.

Measure the resistance of the wire harness side connectors.

- Standard resistance (Check for open):

Tester Connection Specified Condition IGT1 (E22-3) - IGT1 (E5-13) Below 1 Ω IGT2 (E32-3) - IGT2 (E3-17) Below 1 Ω IGT3 (E23-3) - IGT3 (E5-10) Below 1 Ω IGT4 (Z1-3) - IGT4 (E5-12) Below 1 Ω IGT5 (E24-3) - IGT5 (E3-27) Below 1 Ω IGT6 (Z2-3) - IGT6 (E3-26) Below 1 Ω

- Standard resistance (Check for short):

Tester Connection Specified Condition IGT1 (E22-3) or IGT1 (E5-13) - Body ground 10 kΩ or higher IGT2 (E32-3) or IGT2 (E3-17) - Body ground 10 kΩ or higher IGT3 (E23-3) or IGT3 (E5-10) - Body ground 10 kΩ or higher IGT4 (Z1-3) or IGT4 (E5-12) - Body ground 10 kΩ or higher IGT5 (E24-3) or IGT5 (E3-27) - Body ground 10 kΩ or higher IGT6 (Z2-3) or IGT6 (E3-26) - Body ground 10 kΩ or higher

- Standard resistance (Check for open):

Tester Connection Specified Condition IGF1 (E22-2) - IGF1 (E5-7) Below 1 Ω IGF2 (E32-2) - IGF2 (E5-6) Below 1 Ω IGF3 (E23-2) - IGF1 (E5-7) Below 1 Ω IGF4 (Z1-2) - IGF2 (E5-6) Below 1 Ω IGF5 (E24-2) - IGF1 (E5-7) Below 1 Ω IGF6 (Z2-2) - IGF2 (E5-6) Below 1 Ω

- Standard resistance (Check for short):

Tester Connection Specified Condition IGF1 (E22-2) or IGF1 (E5-7) - Body ground 10 kΩ or higher IGF2 (E32-2) or IGF2 (E5-6) - Body ground 10 kΩ or higher IGF3 (E23-2) or IGF1 (E5-7)- Body ground 10 kΩ or higher IGF4 (Z1-2) or IGF2 (E5-6) - Body ground 10 kΩ or higher IGF5 (E24-2) or IGF1 (E5-7) - Body ground 10 kΩ or higher IGF6 (Z2-2) or IGF2 (E5-6) - Body ground 10 kΩ or higher

|

| ||||

| OK | |

| 4.CHECK ECM (IGT1, IGT2, IGT3, IGT4, IGT5, IGT6, IGF1, IGF2 SIGNAL) |

Inspect the ECM using an oscilloscope.

While cranking or idling, check the waveform of the ECM connectors.

- Standard:

Tester Connection Specified Condition IGF1 (E5-7) - E1 (E4-7)

IGF2 (E5-6) - E1 (E4-7)

IGT1 (E5-13) - E1 (E4-7)

IGT2 (E3-17) - E1 (E4-7)

IGT3 (E5-10) - E1 (E4-7)

IGT4 (E5-12) - E1 (E4-7)

IGT5 (E3-27) - E1 (E4-7)

IGT6 (E3-26) - E1 (E4-7)Correct waveform is shown

|

| ||||

| OK | |

| 5.CHECK IF DTC OUTPUT RECURS |

Clear the DTC .

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG) and turn the intelligent tester ON.

Enter the following menus: Power train / Engine / DTC.

Read DTC.

- Result:

Display (DTC Output) Proceed to P0351, P0352, P0353, P0354, P0355 and/or P0356 are output A No output B

|

| ||||

| A | ||

| ||