Lexus IS250 IS220d GSE20 ALE20 4GR-FSE ENGINE CONTROL SYSTEM

INSPECT CRANKSHAFT POSITION SENSOR

CHECK HARNESS AND CONNECTOR (CRANKSHAFT POSITION SENSOR - ECM)

CHECK CRANK POSITION SENSOR (SENSOR INSTALLATION)

CHECK CRANKSHAFT POSITION SENSOR PLATE (TEETH OF SENSOR PLATE)

DTC P0335 Crankshaft Position Sensor "A" Circuit

DTC P0339 Crankshaft Position Sensor "A" Circuit Intermittent

DESCRIPTION

The crankshaft position (CKP) sensor system consists of a crankshaft position sensor plate and a magnetic coil.

The sensor plate has 34 teeth and is installed on the crankshaft. The pickup coil is made of windings, an iron core and magnet. The sensor plate rotates and as each tooth passes through the pickup coil, a pulse signal is created. The pickup coil generates 34 signals for each engine revolution. Based on these signals, the ECM calculates the crankshaft position and engine RPM. Using these calculations, the fuel injection time and ignition time are controlled.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0335 | No CKP sensor signal to ECM while cranking (1 trip detection logic) No CKP sensor signal to ECM at engine speed of 600 rpm or more (1 trip detection logic) | Open or short in CKP sensor circuit CKP sensor CKP sensor plate ECM |

| P0339 | Under conditions (a), (b) and (c), no CKP sensor signal to ECM for 0.05 seconds or more (1 trip detection logic): (a) Engine speed 1,000 rpm or more (b) Starter signal OFF (c) 3 seconds or more have lapsed since starter signal switched from ON to OFF | Open or short in CKP sensor circuit CKP sensor CKP sensor plate ECM |

- HINT:

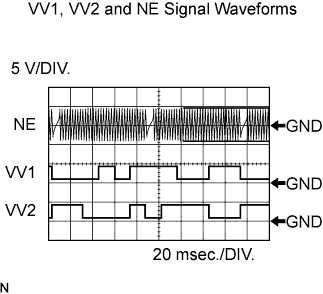

| Item | Content |

| Terminals | VV1+ - VV1- VV2+ - VV2- NE+ - NE- |

| Equipment Settings | 5 V/DIV, 20 ms./DIV. |

| Conditions | Cranking or idling |

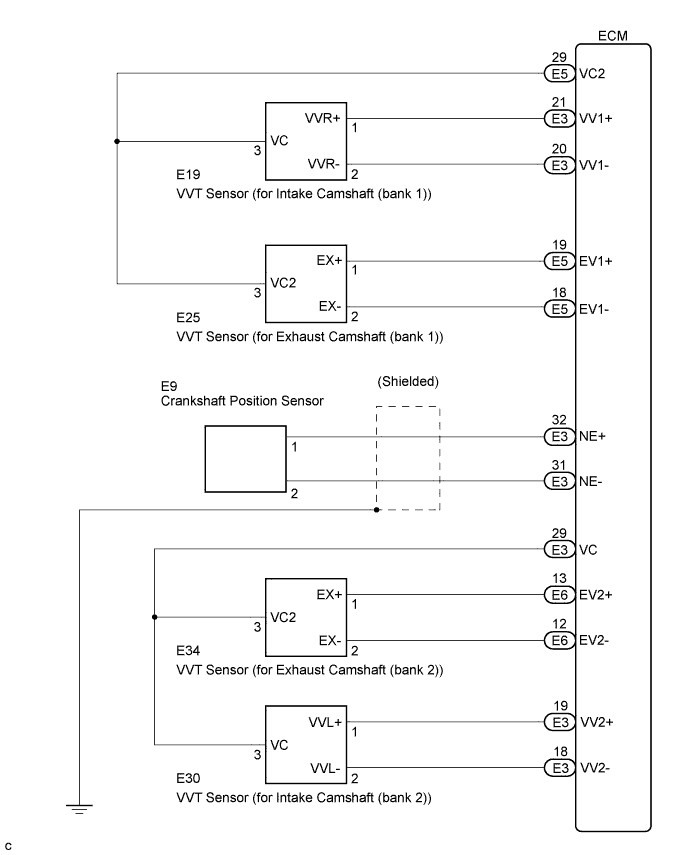

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

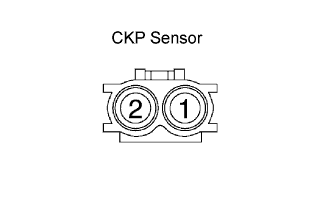

| 1.INSPECT CRANKSHAFT POSITION SENSOR |

Disconnect the E9 crankshaft position (CKP) sensor connector.

Measure the resistance of the CKP sensor.

- Standard resistance:

Tester Connection Condition Specified Condition 1 - 2 Cold 1,630 to 2,740 Ω 1 - 2 Hot 2,065 to 3,225 Ω

- HINT:

- Terms cold and hot refer to the temperature of the coils. Cold means approximately -10 to 50°C (14 to 122°F). Hot means approximately 50 to 100°C (122 to 212°F).

Reconnect the CKP sensor connector.

|

| ||||

| OK | |

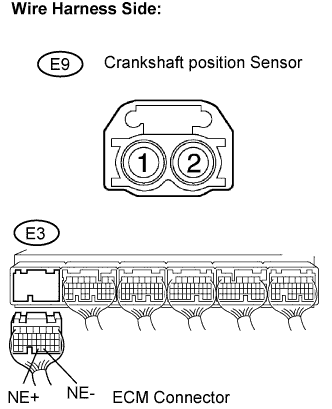

| 2.CHECK HARNESS AND CONNECTOR (CRANKSHAFT POSITION SENSOR - ECM) |

Disconnect the E9 CKP sensor connector.

Disconnect the E3 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance (Check for open):

Tester Connection Specified Condition E9-1 - NE+ (E3-32) Below 1 Ω E9-2 - NE- (E3-31) Below 1 Ω

- Standard resistance (Check for short):

Tester Connection Specified Condition E9-1 or NE+ (E3-32) - Body ground 10 kΩ or higher E9-2 or NE- (E3-31) - Body ground 10 kΩ or higher

Reconnect the ECM connector.

Reconnect the CKP sensor connector.

|

| ||||

| OK | |

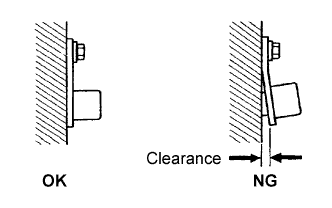

| 3.CHECK CRANK POSITION SENSOR (SENSOR INSTALLATION) |

Check the CKP sensor installation.

- OK:

- Sensor is installed correctly.

|

| ||||

| OK | |

| 4.CHECK CRANKSHAFT POSITION SENSOR PLATE (TEETH OF SENSOR PLATE) |

Check the teeth of the sensor plate.

- OK:

- Sensor plate does not have any crack or deformation.

|

| ||||

| OK | ||

| ||