Lexus IS250 IS220d GSE20 ALE20 2AD-FHV ENGINE CONTROL SYSTEM

READ VALUE OF INTELLIGENT TESTER (DIFFERENTIAL PRESSURE)

CHECK VACUUM HOSES (CONNECTION OF VACUUM HOSES)

CHECK VACUUM HOSES AND TRANSMITTING PIPES (BLOCKAGE OF VACUUM HOSES AND TRANSMITTING PIPES)

CHECK HARNESS AND CONNECTOR (DIFFERENTIAL PRESSURE SENSOR - ECM)

DTC P1425 Differential Pressure Sensor Circuit

DTC P1427 Differential Pressure Sensor Circuit Low

DTC P1428 Differential Pressure Sensor Circuit High

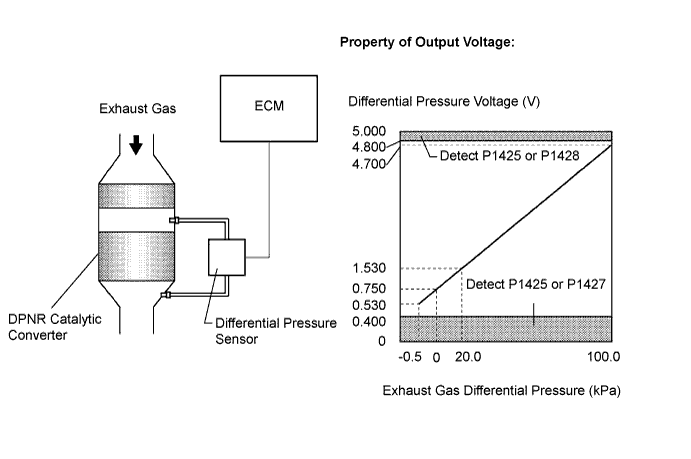

DESCRIPTION

- HINT:

- *1: Diesel Clean Advanced Technology.

The two sensing chambers of the differential pressure sensor are mounted to monitor the pressure before and after the DPNR (*2) catalytic converter. The sensor itself is not located on the engine assembly in order to reduce the influence of vibration. The sensor is a semiconductor-type that is not influenced by exhaust gases.

The ECM compares the exhaust gas pressure before and after DPNR catalytic converter by monitoring the pressure using the upstream and downstream sensing chambers of the differential pressure sensor. If the difference between the pressure before and after the catalytic converter exceeds a predetermined level, the ECM judges that the catalytic converter has clogged with particulate matter (PM). When the ECM judges that a partially clogged condition exists, the ECM begins to perform DPNR catalyst regeneration.

When the output voltage of the sensor deviates from the normal operating range, the ECM interprets this as a malfunction of the sensor circuit, and sets DTC P1425, P1427, or P1428 and illuminates the MIL.

*2: Diesel Particulate-NOx Reduction system

- HINT:

- If the vacuum hoses of the differential pressure sensor are incorrectly connected (crossed), the ECM interprets this as abnormal pressure difference, sets DTC P1426 (Differential Pressure Sensor [Installation]) and illuminates the MIL.

| DTC No. | DTC Detection Condition | Trouble Area |

| P1425 | Differential pressure sensor output voltage is less than 0.4 V, or more than 4.8 V for 3 seconds or more (1 trip detection logic) | Open or short in differential pressure sensor circuit Incorrect differential pressure sensor hose routing Differential pressure sensor ECM |

| P1427 | Differential pressure sensor output voltage is less than 0.4 V for 3 seconds or more (1 trip detection logic) | |

| P1428 | Differential pressure sensor output voltage is more than 4.8 V for 3 seconds or more (1 trip detection logic) |

- HINT:

| Condition | Differential Pressure Output | Sensor Condition |

| Engine Switch ON (IG) | Approximately 0 kPa | Normal |

| Always | 3 kPa | Open or short circuit |

| 3,000 rpm (No engine load) | Negative output | Incorrect arrangement of hose piping |

MONITOR DESCRIPTION

In order to detect abnormality in the differential pressure sensor at any time, the ECM always monitors output voltage from the sensor. When the sensor output voltage deviates from the normal operating range (between 0.4 V and 4.8 V) for more than 3 seconds, the ECM interprets this as a malfunction in the sensor circuit and illuminates the MIL.

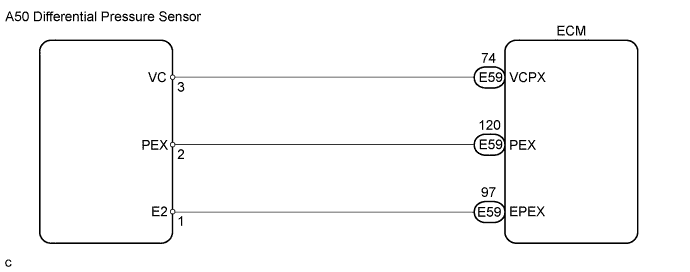

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.READ VALUE OF INTELLIGENT TESTER (DIFFERENTIAL PRESSURE) |

Connect the intelligent tester to the DLC3.

Turn the engine switch ON (IG) and turn the intelligent tester ON.

Enter the following menus: "Powertrain / Engine / Data List / DPNR Differential Pressure".

Check that differential pressure is within the specification below.

- Result:

Condition Differential Pressure Proceed to Always -5 kPa or less A Engine Switch ON (IG) -4 kPa to 98 kPa B Always 99 kPa C

|

| ||||

| A | |

| 2.CHECK VACUUM HOSES (CONNECTION OF VACUUM HOSES) |

Check if the vacuum hose routing between the differential pressure sensor and the vacuum transmitting pipe is correct.

Check that there is no exhaust gas leakage between the differential pressure sensor and the vacuum transmitting pipe.

|

| ||||

| OK | |

| 3.CHECK VACUUM HOSES AND TRANSMITTING PIPES (BLOCKAGE OF VACUUM HOSES AND TRANSMITTING PIPES) |

- CAUTION:

- Be careful not to get burned by exhaust gases during the following inspection.

Disconnect the vacuum hose (both upstream and downstream) on the differential pressure sensor.

Start the engine.

Check if there are exhaust gas pulsations from both vacuum hoses during idling.

|

| ||||

| OK | |

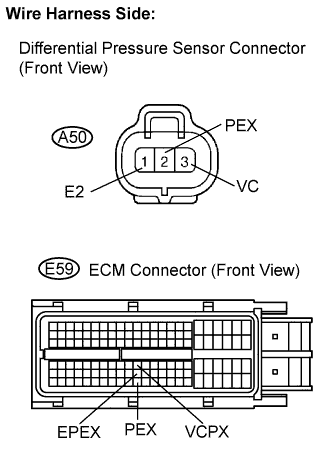

| 4.CHECK HARNESS AND CONNECTOR (DIFFERENTIAL PRESSURE SENSOR - ECM) |

Disconnect the A50 differential pressure sensor connector.

Disconnect the E59 ECM connector.

Check the resistance between the wire harness side connectors.

- Standard resistance (Check for open):

Tester Connection Specified Condition PEX (E59-120) - PEX (A50-2) Below 1 Ω VCPX (E59-74) - VC (A50-3) Below 1 Ω EPEX (E59-97) - E2 (A50-1) Below 1 Ω

- Standard resistance (Check for short):

Tester Connection Specified Condition PEX (E59-120) or PEX (A50-2) - Body ground 10 kΩ or higher VCPX (E59-74) or VC (A50-3) - Body ground 10 kΩ or higher

Reconnect the differential pressure sensor connector.

Reconnect the ECM connector.

|

| ||||

| OK | ||

| ||