Meter / Gauge System Fuel Gauge Malfunction

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY (FUEL SENDER GAUGE)

CHECK WIRE HARNESS (METER - GAUGE)

METER / GAUGE SYSTEM - Fuel Gauge Malfunction |

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY (FUEL SENDER GAUGE) |

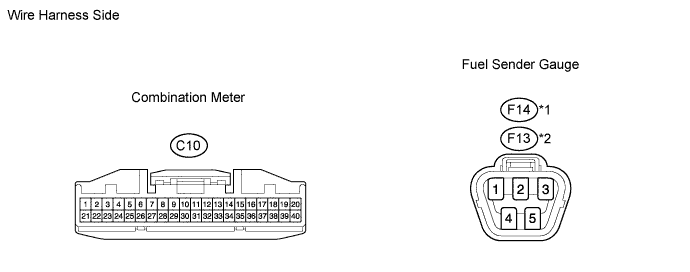

Disconnect the F14*1 or F13*2 pump and gauge connector.

- HINT:

- *1: 1GR-FE

- *2: 1KD-FTV

Turn the ignition switch ON, and then check the position of the receiver gauge needle.

- OK:

- Fuel receiver gauge indicates E.

Connect terminals 2 and 3 on the wire harness side connector.

Turn the ignition switch ON, and then check the position of the receiver gauge needle.

- OK:

- Fuel receiver gauge indicates F.

| | REPLACE FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY |

|

|

| 2.CHECK WIRE HARNESS (METER - GAUGE) |

Disconnect the C10 meter connector.

Disconnect the F14*1 or F13*2 pump and gauge connector.

- HINT:

- *1: 1GR-FE

- *2: 1KD-FTV

Measure the resistance of the wire harness side connectors.

- Standard resistance:

1GR-FETester Connection

| Specified Condition

|

C10-2 - F14-3

| Below 1 Ω

|

C10-3 - F14-2

|

- 1KD-FTV:

Tester Connection

| Specified Condition

|

C10-2 - F13-3

| Below 1 Ω

|

C10-3 - F13-2

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE COMBINATION METER ASSEMBLY |

|