Generator -- Inspection |

| 1. INSPECT GENERATOR ROTOR ASSEMBLY |

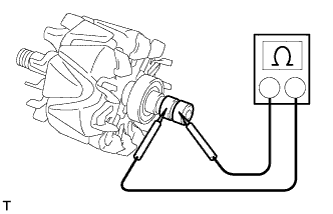

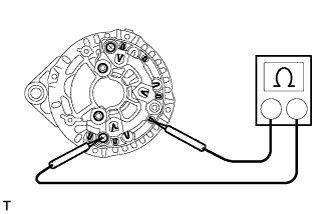

Check the rotor for an open circuit.

Measure the resistance between the slip rings.

- Standard resistance:

- 1.8 to 2.8 Ωat 20°C (68°F)

|

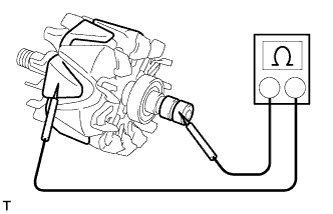

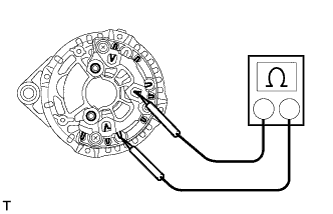

Check if the rotor is grounded.

Measure the resistance between the slip ring and rotor.

- Standard resistance:

- 10 kΩ or higher

|

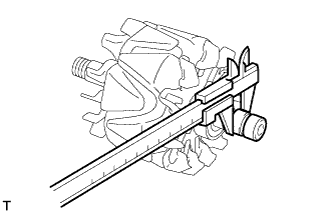

Check that the slip rings are not rough or scored.

If rough or scored, replace the rotor assembly.

Using a vernier caliper, measure the slip ring diameter.

- Standard diameter:

- 15.3 to 15.5 mm (0.602 to 0.610 in.)

- Minimum diameter:

- 14.9 mm (0.587 in.)

|

| 2. INSPECT GENERATOR STATOR SUB-ASSEMBLY WITH RECTIFIER |

- HINT:

- For terminal positions of the stator generator, refer to the illustration.

Inspect the positive (+) rectifier.

- HINT:

- Inspect the positive terminal after pulling it up.

Using an ohmmeter, connect one tester probe to the positive (+) terminal and the other to each rectifier terminal.

Reverse the polarity of the tester probes and repeat the step above.

Check that one shows a resistance of below 1 Ω and the other shows a resistance of 10 kΩ or higher.

If the result is not as specified, replace the generator stator sub-assembly with rectifier.

|

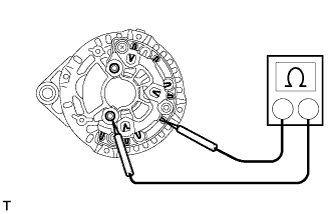

Inspect the negative (-) rectifier.

Using an ohmmeter, connect one tester probe to the negative (-) terminal and the other to each rectifier terminal.

Reverse the polarity of the tester probes and repeat the step above.

Check that one shows a resistance of below 1 Ω and the other shows a resistance of 10 kΩ or higher.

If the result is not as specified, replace the generator stator sub-assembly with rectifier.

|

Inspect the stator coil for an open circuit.

Measure the resistance between the rectifier terminals.

- Standard resistance:

- Below 1 Ω

|

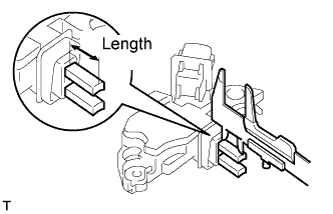

| 3. INSPECT BRUSH |

|

Using a vernier caliper, measure the exposed brush length.

- Standard exposed length on new brush:

- 13.2 mm (0.520 in.)

- Minimum exposed length:

- 6.0 mm (0.236 in.)

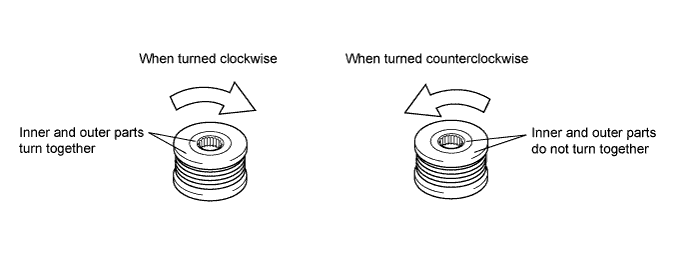

| 4. INSPECT GENERATOR PULLEY WITH CLUTCH |

When rotating the outer part of the pulley, check that it is as follows: 1) rotating it clockwise causes the inner and outer part of the pulley to turn together; and 2) rotating it counterclockwise causes only the outer part of the pulley to turn.

If the result is not as specified, replace the generator pulley with clutch.