Engine Assembly -- Installation |

| 1. INSTALL FRONT ENGINE MOUNTING BRACKET LH |

Install the mounting bracket with the 4 bolts.

- Torque:

- 51 N*m{520 kgf*cm, 38 ft.*lbf}

|

| 2. INSTALL FRONT ENGINE MOUNTING BRACKET RH |

Install the mounting bracket with the 4 bolts.

- Torque:

- 51 N*m{520 kgf*cm, 38 ft.*lbf}

|

| 3. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE |

|

Apply a coat of engine oil to a new O-ring.

Install a new O-ring to the oil control valve.

Install the oil control valve with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

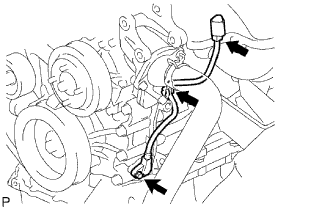

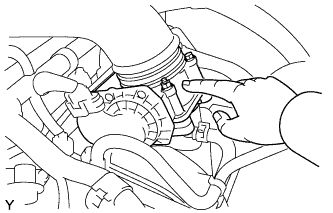

| 4. INSTALL CRANKSHAFT POSITION SENSOR |

Apply a light coat of engine oil to the O-ring of the sensor.

|

Install the sensor with the bolt.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

Install the connector to the connector bracket.

Attach the harness clamp.

Connect the sensor connector.

| 5. INSTALL CAMSHAFT POSITION SENSOR |

Apply a coat of engine oil to a new O-ring.

|

Install the O-ring to the sensor.

Install the sensor with the bolt.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

| 6. INSTALL ENGINE COOLANT TEMPERATURE SENSOR |

Using a 19 mm deep socket wrench, install a new gasket and the sensor.

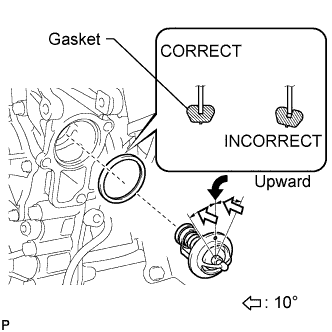

| 7. INSTALL KNOCK SENSOR |

Install the sensor so that it is horizontal as shown in the illustration. Then install the bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

- HINT:

- It is acceptable for the sensor to be tilted +-10°.

|

Connect the sensor connector.

| 8. INSTALL NO. 1 WATER BY-PASS PIPE |

Install a new gasket and the water by-pass pipe with the 2 nuts.

- Torque:

- 17.5 N*m{178 kgf*cm, 13 ft.*lbf}

|

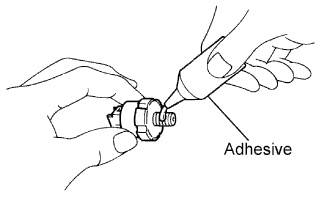

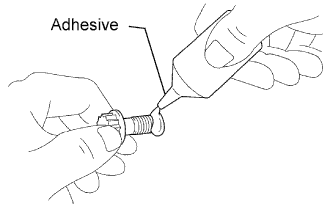

| 9. INSTALL ENGINE OIL PRESSURE SWITCH |

Apply adhesive to 2 or 3 threads of the oil pressure switch.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

|

Install the oil pressure switch.

- Torque:

- 15 N*m{153 kgf*cm, 11 ft.*lbf}

- NOTICE:

- Do not start the engine for at least 1 hour after installation of the switch.

Connect the oil pressure switch connector.

Start the engine and check for engine oil leaks.

| 10. INSTALL NO. 1 IDLER PULLEY |

Install the spacer, idler pulley and pulley plate with the bolt.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

|

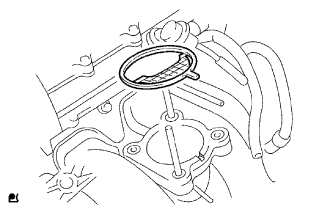

| 11. INSTALL THERMOSTAT |

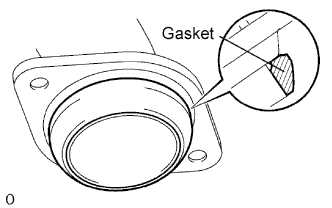

Install a new gasket to the thermostat.

- HINT:

- When installing the thermostat to the gasket, be careful not to deform the gasket. Make sure that the thermostat is properly installed into the groove of the gasket, as shown in the illustration.

|

Insert the thermostat into the cylinder block with the jiggle valve facing straight upward.

- HINT:

- The jiggle valve may be set within 10° of either side of the prescribed position.

| 12. INSTALL WATER INLET |

Install the inlet with the 2 nuts and bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

|

Connect the connector.

|

| 13. INSTALL V-RIBBED BELT TENSIONER |

Temporarily install the belt tensioner with the 3 bolts.

- HINT:

- Make sure the flanges of the bolts are contacting the tensioner surface.

|

Install the tensioner by tightening the 3 bolts in the order shown in the illustration.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}for bolt 1

- 21 N*m{214 kgf*cm, 15 ft.*lbf}for bolt 2

- 43 N*m{438 kgf*cm, 32 ft.*lbf}for bolt 3

| 14. INSTALL COMPRESSOR MOUNTING BRACKET (w/ Air Conditioning System) |

- NOTICE:

- In order to prevent misalignment, which causes belt rattle, the 5 bolts must be tightened exactly as described in the procedures below.

Temporarily install the mounting bracket with the 3 bolts labeled A.

- HINT:

- Make sure the flanges of the bolts are contacting the bracket surface.

|

Make sure there is no clearance between the cylinder block and bracket as shown in the illustration. Then install the bolt labeled B.

- Torque:

- 45 N*m{459 kgf*cm, 33 ft.*lbf}for bolt B

Tighten the bolts labeled A and install the bolt labeled C.

- Torque:

- 45 N*m{459 kgf*cm, 33 ft.*lbf}for bolt A

- 24.5 N*m{250 kgf*cm, 18 ft.*lbf}for bolt C

|

| 15. INSTALL EXHAUST MANIFOLD |

Install a new gasket and the exhaust manifold with the 6 nuts.

- Torque:

- 36 N*m{367 kgf*cm, 27 ft.*lbf}

|

| 16. INSTALL EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with the 5 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

|

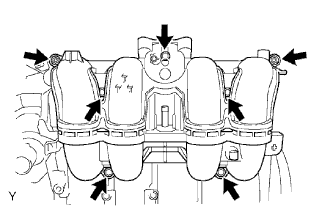

| 17. INSTALL INTAKE MANIFOLD |

Install a new gasket and the intake manifold with the 5 bolts and 2 nuts.

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

|

Connect the crankshaft position sensor to the clamp.

| 18. INSTALL INJECTOR |

Install each of the 4 injectors as follows.

Install a new insulator to the injector.

Apply a light coat of grease or gasoline to a new O-ring and install it to the injector.

Apply a light coat of grease or gasoline on the place where the delivery pipe touches the O-ring.

To install the fuel injector into the fuel delivery pipe, push the fuel injector while twisting it right and left.

- NOTICE:

- Be careful not to twist the O-ring.

- After installing the fuel injector, check that it turns smoothly. If it does not, reinstall it with a new O-ring.

Position the injector connector so that it faces downward.

| 19. INSTALL FUEL DELIVERY PIPE |

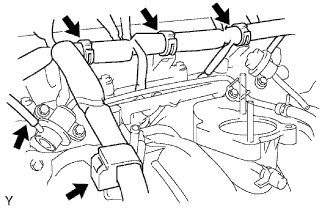

Install the 4 spacers to the cylinder head.

|

Install the delivery pipe together with the 4 injectors and 2 spacers with the 2 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

|

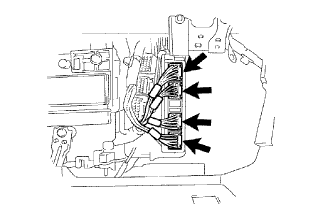

Connect the 4 injector connectors.

Connect the 4 clamps and wire harness to the delivery pipe.

|

Connect the vacuum hose.

| 20. INSTALL THROTTLE BODY |

Install a new gasket on the intake manifold.

- HINT:

- Align the protrusion of the gasket with the groove of the intake manifold.

|

Install the throttle body with the 2 bolts and 2 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

Connect the 2 water by-pass hoses to the throttle body.

Connector the throttle position sensor and control motor connector.

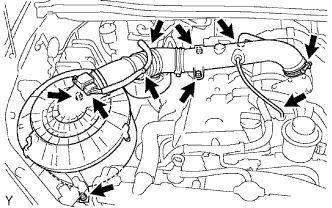

| 21. INSTALL ENGINE WIRE |

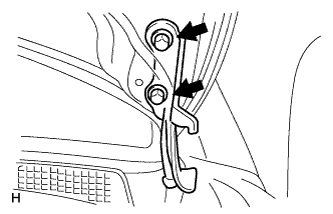

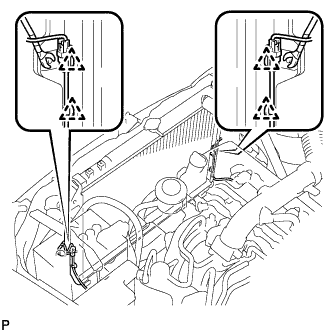

Connect the wire harness (engine ground wire) to the engine rear side with the 2 bolts so that it is within the specified range shown in the illustration.

- Torque:

- 31 N*m{316 kgf*cm, 23 ft.*lbf}

|

Connect the oil pressure sensor connector.

Connect the noise filter connector.

Connect the camshaft position sensor connector.

Connect the 4 injector connectors.

Connect the crankshaft position sensor connector.

Connect the oil control valve connector.

for Unleaded Gasoline Specification Vehicle:

Connect the purge VSV connector.

Connect the throttle body connector.

Connect the engine coolant temperature sensor connector.

Connect the knock sensor connector.

Connect the wire harness to the clamps.

| 22. INSTALL GENERATOR |

Install the generator with the 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

|

Install the generator wire with the bolt and nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Attach the terminal cap.

Connect the connector.

| 23. INSTALL VENTILATION PIPE |

Install the ventilation pipe with the bolt.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

| 24. INSTALL SPARK PLUG |

| 25. INSTALL IGNITION COIL |

Install the 4 ignition coils with the 4 bolts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

Connect the 4 ignition coil connectors.

| 26. REMOVE ENGINE FROM ENGINE STAND |

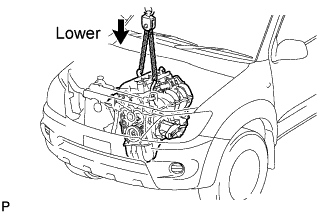

| 27. INSTALL ENGINE ASSEMBLY |

Attach the engine sling device and chain block to the engine hangers.

|

Slowly lower the engine assembly into the engine compartment.

Install the engine mounting brackets with the 4 bolts and 4 nuts.

- Torque:

- 38 N*m{388 kgf*cm, 28 ft.*lbf}

|

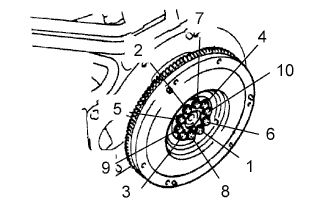

| 28. INSTALL REAR END PLATE |

Install the end plate with the 2 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

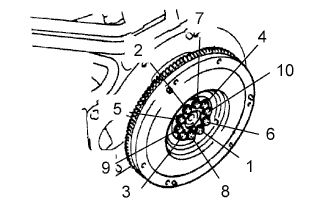

| 29. INSTALL FLYWHEEL |

- HINT:

The mounting bolts are tightened in 2 progressive steps.

- If a mounting bolts is broken or deformed, replace it.

Apply adhesive to 2 or 3 threads of the mounting bolt end.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the flywheel.

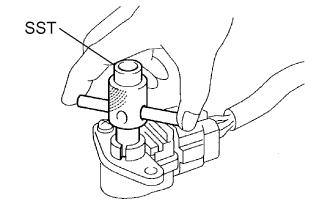

Fix the crankshaft in place with SST.

- SST

- 09213-54015(91651-60855)

09330-00021

|

Install and uniformly tighten the 10 mounting bolts in several passes in the order shown in the illustration.

- Torque:

- 26.5 N*m{270 kgf*cm, 20 ft.*lbf}

|

Mark the mounting bolts with paint.

|

Retighten the mounting bolts by 90° in the numerical order shown in the illustration.

Check that the painted marks are now at a 90° angle to the previous position.

|

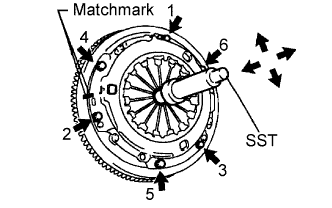

| 30. INSTALL CLUTCH DISC |

Insert SST into the clutch disc. Then insert the SST (together with the clutch disc) into the flywheel.

- SST

- 09301-00110

- NOTICE:

- Take care not to insert the clutch disc facing the wrong direction.

|

| 31. INSTALL CLUTCH COVER |

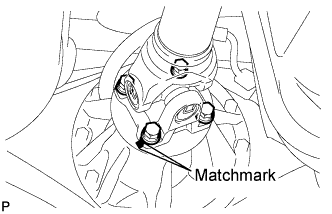

Align the matchmarks on the clutch cover and flywheel.

|

Tighten the 6 bolts as described below.

Determine the first bolt to be tightened by choosing the bolt closest to the knock pin.

Uniformly tighten the 6 bolts in diametrically opposite pairs relative to the position of the first bolt. Use the illustration as a reference.

- Torque:

- 19 N*m{195 kgf*cm, 14 in.*lbf}

Lightly move SST up and down, and right and left.

- SST

- 09301-00110

Check that the disc is in the center, and then tighten the bolts.

| 32. INSTALL MANUAL TRANSMISSION UNIT |

Install the manual transmission unit (Toyota Fortuner RM0000011B0004X.html).

| 33. INSTALL CLUTCH RELEASE CYLINDER |

Install the clutch release cylinder with the 2 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

| 34. INSTALL STARTER |

Install the starter with the 2 bolts.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

|

Install the starter wire to terminal 30 with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Attach the terminal cap.

Connect the starter connector.

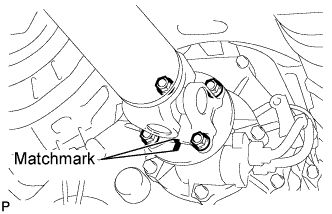

| 35. INSTALL REAR PROPELLER SHAFT ASSEMBLY |

|

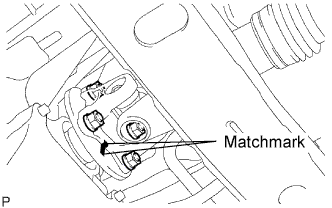

Align the matchmarks on the propeller shaft flange and transfer flange.

Connect the propeller shaft with the 4 washers and 4 nuts.

- Torque:

- 88 N*m{897 kgf*cm, 65 ft.*lbf}

Align the matchmarks on the propeller shaft flange and differential flange.

Install the propeller shaft with the 4 bolts, 4 washers and 4 nuts.

- Torque:

- 88 N*m{897 kgf*cm, 65 ft.*lbf}

|

| 36. INSTALL FRONT PROPELLER SHAFT ASSEMBLY |

|

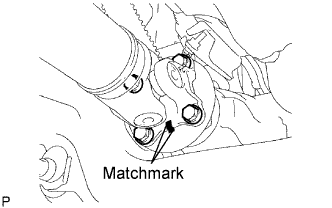

Align the matchmarks on the yoke and transfer flange.

Connect the propeller shaft with the 4 washers and 4 nuts.

- Torque:

- 88 N*m{897 kgf*cm, 65 ft.*lbf}

Align the matchmarks on the yoke and differential flange.

|

Install the front propeller shaft with the 4 bolts, 4 washers and 4 nuts.

- Torque:

- 88 N*m{897 kgf*cm, 65 ft.*lbf}

| 37. INSTALL FRONT EXHAUST PIPE |

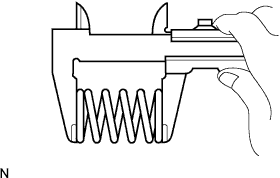

Using a vernier caliper, measure the free length of the compression spring.

- Minimum length:

- 40 mm (1.57 in.)

|

Install the front pipe to the pipe support.

Install a new gasket to the exhaust manifold.

- HINT:

- Using a plastic-faced hammer, uniformly strike the gasket so that the gasket and exhaust manifold are properly fit.

- NOTICE:

- Be careful with the installation direction of the gasket.

- Do not reuse the gasket.

- To ensure a proper seal, do not use the front pipe to force the gasket onto the exhaust manifold.

|

Install the front pipe with the 2 compression springs and 2 bolts. Alternately tighten the bolts in several passes.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

| 38. INSTALL HOOD ASSEMBLY |

|

Install the hood with the 4 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Adjust the hood position (Toyota Fortuner RM00000138K003X.html).

| 39. INSTALL COOLER COMPRESSOR (w/ Air Conditioning System) |

Loosely install the bolt labeled A to install the compressor.

|

Install the compressor completely by tightening the 4 bolts in the order shown in the illustration.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

- NOTICE:

- In order to prevent misalignment, which causes belt rattle, tightening of the bolts must be performed in the order shown.

Connect the suction hose with the 2 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

|

Connect the compressor connector.

| 40. INSTALL OIL DIPSTICK GUIDE |

Install a new O-ring and the dipstick guide with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 41. INSTALL OIL DIPSTICK |

| 42. INSTALL VANE PUMP |

Install the vane pump with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

Connect the PS oil pressure switch connector.

| 43. CONNECT ENGINE WIRE |

Connect the 2 engine room junction block connectors and connect the wire clamp.

|

Connect the cable to the engine room junction block with the nut.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Install the engine room relay block cover (upper).

Install the engine room relay block cover (side).

Connect the ground wire with the bolt and clamp.

- Torque:

- 31 N*m{316 kgf*cm, 23 ft.*lbf}

Connect the ground wire to the frame with the bolt so that it is within the range shown in the illustration.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

|

Push the engine wire through the dash panel into the cabin. The wire should be within the range shown in the illustration.

Connect the sensor clamp with the bolt.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Connect the ECM connectors.

Connect the 4 ECM connectors.

Install the glove compartment door.

|

Connect the wire clamp to the engine mounting bracket front LH with the bolt.

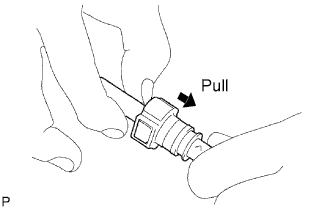

| 44. CONNECT FUEL HOSE |

Connect the No. 2 fuel hose to the pressure regulator.

|

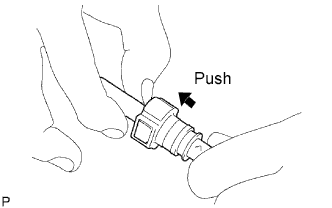

Connect the No. 1 fuel hose to the pulsation damper.

Check that there is no damage or contamination in the connected part of the pipe.

Align the axis of the connector with the axis of the pipe. Push the pipe into the connector until the connector makes a "click" sound. If the connection is tight, apply a small amount of fresh engine oil on the tip of the pipe.

After having finished the connection, try to pull apart the pipe and the connector and confirm that they are securely connected.

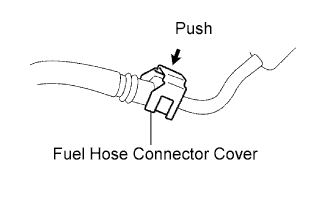

Attach the lock claws to the connector by pushing down on the cover, as shown in the illustration.

| 45. CONNECT HOSE |

Connect the vacuum hose to the intake manifold.

|

for Unleaded Gasoline Specification Vehicle:

Connect the hose to the purge VSV.

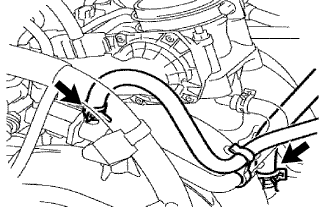

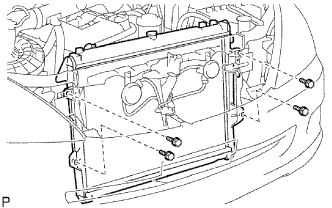

| 46. INSTALL RADIATOR ASSEMBLY |

Install the radiator with the 4 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

|

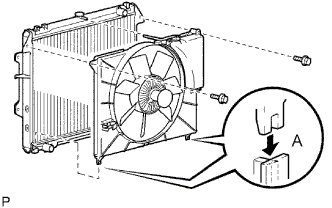

Attach the 4 clamps to the radiator side as shown in the illustration.

|

Connect the 2 front airbag sensor connectors.

| 47. INSTALL FAN PULLEY |

| 48. INSTALL FAN SHROUD |

|

Install the fan pulley to the water pump.

Place the shroud together with the fluid coupling fan between the radiator and engine.

- NOTICE:

- Be careful not to damage the radiator core.

Install the coupling fan to the water pump with the 4 nuts. Tighten the nuts as much as possible by hand.

Attach the shroud's claws to the radiator as shown in A in the illustration.

Install the shroud with the 2 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Connect the reservoir hose to the radiator tank upper.

Install the drive belt (Toyota Fortuner RM000000YMN008X.html).

Tighten the 4 nuts of the fluid coupling fan.

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

| 49. INSTALL DRIVE BELT |

Install the drive belt to all the pulleys except the drive belt tensioner pulley.

|

Use the hexagon-shaped part indicated by the arrow in the illustration to move the tensioner pulley downward and then install the drive belt to the tensioner pulley.

- NOTICE:

- The backside of the drive belt should face the tensioner pulley.

- Check that the drive belt is properly set to each pulley.

After a new belt has been installed, check that the tensioner indicator mark is within range A shown in the illustration.

|

| 50. CONNECT RADIATOR OUTLET HOSE |

| 51. CONNECT RADIATOR INLET HOSE |

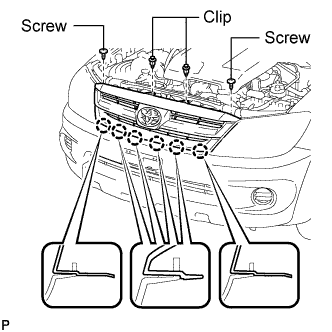

| 52. INSTALL RADIATOR GRILLE |

Attach the 6 claws to install the radiator grille.

|

Install the 2 clips and 2 screws.

| 53. INSTALL INTAKE AIR CONNECTOR AND AIR CLEANER ASSEMBLY |

Install the air cleaner and intake air connector assembly with the 4 bolts, and tighten the hose clamp.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}for air cleaner

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}for intake air connector

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}for hose clamp

|

Connect the MAF meter connector and harness clamps.

Connect the No. 2 ventilation hose.

Connect the vacuum hose.

| 54. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 55. ADD ENGINE OIL |

Clean and install the oil drain plug with a new gasket.

- Torque:

- 37.5 N*m{382 kgf*cm, 28 ft.*lbf}

Add fresh engine oil.

- Standard capacity:

Item Specified Condition Drain and refill with oil filter change 5.6 liters (5.9 US qts, 4.9 Imp. qts) Drain and refill without oil filter change 5.3 liters (5.6 US qts, 4.6 Imp. qts) Dry fill 6.3 liters (6.7 US qts, 5.5 Imp. qts)

Install the oil filler cap.

| 56. ADD ENGINE COOLANT |

Tighten all the plugs and fill the radiator with TOYOTA Super Long Life Coolant (SLLC).

- Torque:

- 24.5 N*m{250 kgf*cm, 18 ft.*lbf}for cylinder block drain cock plug

- Standard capacity:

- 7.8 liters (8.2 US qts, 6.8 Imp. qts)

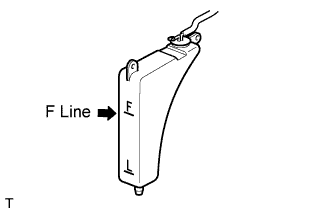

Fill the radiator with TOYOTA SLLC to the F line.

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

- Please contact your TOYOTA dealer for further details.

- NOTICE:

- Never use water as a substitute for engine coolant.

Press the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level drops below the F line, add TOYOTA SLLC to the F line.

Install the radiator cap.

Bleed air from the cooling system.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

Maintain the engine speed at 2,500 to 3,000 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- CAUTION:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine and wait until the coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check the coolant level in the radiator reservoir.

If the coolant level is below the L line, add SLLC to the reservoir F line.

|

| 57. INSPECT FOR FUEL LEAK |

Check that there are no fuel leaks after performing maintenance anywhere on the fuel system.

If there are fuel leaks, repair or replace parts as necessary.

| 58. INSPECT FOR OIL LEAK |

Start the engine, and check that there are no oil leaks after performing maintenance.

| 59. INSPECT FOR FOR COOLANT LEAK |

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Fill the radiator with coolant and attach a radiator cap tester.

|

Warm up the engine.

Using the radiator cap tester, increase the pressure inside the radiator to 118 kPa (1.2 kgf/cm2, 17.1 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the cylinder block and head.

| 60. INSTALL NO. 1 ENGINE UNDER COVER |

Install the No. 1 under cover with the 4 bolts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

Install the side cover RH with the 3 clips and 3 bolts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

Install the side cover LH with the 3 clips and 3 bolts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 61. INSPECT IGNITION TIMING |

Warm up the engine and stop the engine.

- NOTICE:

- A warmed up engine should have an engine coolant temperature of over 80°C (176°F), have an engine oil temperature of 60°C (140°F), and the engine rpm should be stabilized.

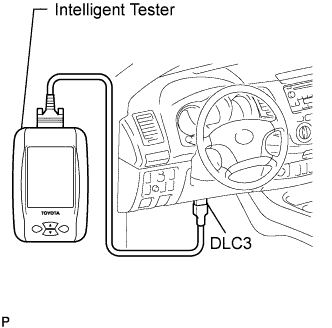

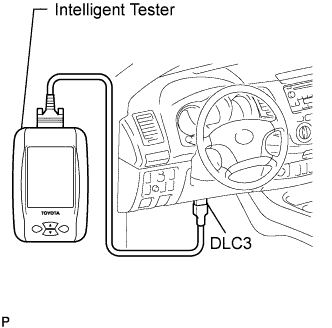

When using the intelligent tester:

Check the ignition timing.Connect the intelligent tester to the DLC3.

Start the engine and idle the engine.

Turn the intelligent tester main switch ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / IGN Advance.

- Standard ignition timing:

- 0 to 20° BTDC @ idle

- HINT:

- Please refer to the intelligent tester operator's manual for further details.

|

When not using the intelligent tester:

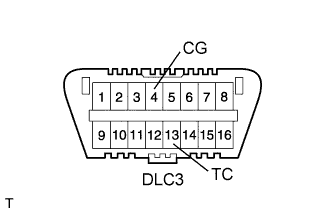

Check the ignition timing.Using SST, connect a tachometer tester probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

- NOTICE:

- Confirm the terminal number before connecting SST. Connection with a wrong terminal can damage the engine.

- Turn off all electrical systems before connecting SST.

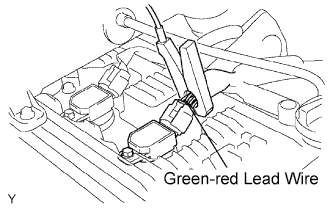

Clamp a timing light tester probe to the No. 1 cylinder ignition coil connector's 4 lead wires or green-red lead wire.

Start the engine.

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

- NOTICE:

- When checking the ignition timing, the transmission should be in the neutral position.

- HINT:

- After connecting terminals TC and CG, the engine rpm changes to approximately 1,000 to 1,500 rpm for 5 seconds, and then returns to idle speed. This occurs because the ECM checks that the ISC (idle speed control system) is operating properly.

- Perform the inspection of the ignition timing after the engine rpm has returned to idle speed.

Using a timing light, measure the ignition timing.

- Standard ignition timing:

- 3 to 7° BTDC @ idle

Remove SST from terminals 13 (TC) and 4 (CG) of the DLC3.

Check the ignition timing.

- Standard ignition timing:

- 0 to 20° BTDC @ idle

Confirm that the ignition timing moves to the advanced angle side when the engine speed is increased.

Remove the timing light.

|

| 62. CHECK IDLE SPEED |

Warm up and stop the engine.

- NOTICE:

- A warmed up engine should have an engine coolant temperature of over 80°C (176°F), have an engine oil temperature of 60°C (140°F), and the engine rpm should be stabilized.

When using the intelligent tester:

Check the idle speed.Connect the intelligent tester to the DLC3.

- HINT:

- Please refer to the intelligent tester operator's manual for further details.

Start the engine and idle the engine.

Turn the intelligent tester main switch ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Engine SPD.

- Standard idle speed:

- 600 to 700 rpm

- NOTICE:

- When checking the idle speed, the transmission should be in the neutral position.

- Switch off all accessories and the air conditioning before connecting the intelligent tester.

When not using the intelligent tester:

Check the idle speed.Using SST, connect a tachometer tester probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

- NOTICE:

- Confirm the terminal number before connecting SST. Connection with a wrong terminal can damage the engine.

- Turn off all electrical systems before connecting SST.

Start the engine and idle the engine.

Check the idle speed.

- Standard idle speed:

- 600 to 700 rpm

|

| 63. CHECK CO (for Leaded Gasoline Specification Vehicle) |

- HINT:

- This check is used only to determine whether or not the idle CO complies with regulations.

Initial condition:

Engine at normal operating temperature

Air cleaner installed

All pipes and hoses of air induction system connected

All accessories switched OFF

All vacuum lines properly connected

SFI system wiring connectors fully seated

Ignition timing set correctly

Transmission in neutral position

Tachometer and CO meter calibration at idle

- NOTICE:

- If a CO meter is not available, do not attempt to adjust the idle mixture. Always use a CO meter when adjusting the idle mixture. Use of the idle mixture screw for adjustments is typically not necessary if the vehicle is in good condition.

Warm up the engine at a constant speed (approximately 50 km/h (31 mph)). Close the throttle valve for 5 minutes after the engine coolant temperature becomes stable (80 to 90°C (176 to 194°F)) and idle the engine for 5 minutes.

Insert a tester probe at least 40 cm (1.3 ft.) into the tailpipe.

|

Wait at least 1 minute before measuring to allow the concentration to stabilize. Complete the measuring within 3 minutes.

- Standard idle CO concentration:

- 0.5 to 2.5%

If the CO concentration does not conform to regulations, adjust it by turning the idle mixture adjusting screw in the variable resistor with SST.

- SST

- 09243-00020

|

The idle mixture adjusting screw can be adjusted within a 180° angle range.

If the CO concentration is within the specification, this adjustment is complete.

If the CO concentration cannot be corrected by idle mixture adjustment, see the table below for other possible causes.CO Problems Causes High Rough idle

(black smoke from exhaust)- Clogged air filter

- Plugged ventilation valve

- Faulty SFI system

- Faulty fuel pressure regulator

- Clogged fuel pressure regulator

- Defective engine coolant temperature (ECT) sensor

- Faulty ECM

- Faulty injectors

- Faulty throttle position sensor

- Faulty MAF meter

- Clogged air filter

|

| 64. CHECK CO/HC (for Unleaded Gasoline Specification Vehicle) |

Start and warm up the engine.

Run the engine at 2,500 rpm for approximately 180 seconds and idle the engine.

Insert a CO/HC meter testing probe at least 40 cm (1.3 ft.) into the tailpipe.

|

Check the CO/HC concentration at idle.

- Idle CO concentration:

- 0 to 0.5%

- Idle HC concentration:

- Applicable local regulation

If the CO/HC concentration is not as specified, perform troubleshooting in the order given below.

Check the heated oxygen sensor operation (Toyota Fortuner RM000000ZQ9007X.html).

See the table below for possible causes, and then inspect and repair the applicable causes as necessary.

CO HC Problems Causes Normal High Rough idle - Faulty ignitions:

- Incorrect timing

- Plugs are contaminated, shorted or gaps are defective

- Incorrect valve clearance

- Leaks in intake and exhaust valves

- Leaks in cylinders

Low High Rough idle

(Fluctuating HC reading)- Vacuum leaks:

- Ventilation hoses

- Intake manifold

- Throttle body

- Brake booster line

- Lean mixture causing misfire

High High Rough idle

(Black smoke from exhaust)- Restricted air filter

- Plugged ventilation valve

- Faulty SFI system:

- Faulty pressure regulator

- Defective ECT sensor

- Defective Mass Air Flow (MAF) meter

- Faulty ECM

- Faulty injectors

- Faulty throttle position sensor

- Faulty ignitions:

| 65. CHECK FUNCTION OF THROTTLE BODY |

Check the throttle control motor operating sound.

Turn the ignition switch ON.

When pressing the accelerator pedal, check the operating sound of the running motor. Make sure that no friction noises emit from the motor.

If friction noise is heard, replace the throttle body.

|

Check the throttle position sensor.

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON.

Under Current Data, check that the throttle valve opening percentage (Throttle Pos) is within the standard.

- Standard throttle valve opening percentage:

- 60% or more

- NOTICE:

- When checking the standard throttle valve opening percentage, the shift lever should be in the N position.

|