Engine -- On-Vehicle Inspection |

| 1. CHECK ENGINE IDLE SPEED AND MAXIMUM SPEED |

- HINT:

- For more information about the intelligent tester, refer to its operator's manual.

Connect the intelligent tester to the DLC3.

|

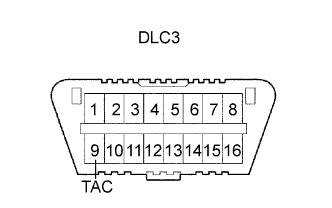

If an intelligent tester is not available, connect a tester probe of a tachometer to terminal 9 (TAC) of the DLC3 with SST.

- SST

- 09843-18030

|

Check the idle speed.

- HINT:

- The engine is warmed up.

- The A/C switch is OFF.

Start the engine and measure the idle speed.

- Standard idle speed:

- 700 to 800 rpm

Check the maximum speed.

Start the engine.

Fully depress the accelerator pedal.

Measure the maximum speed.

- Standard maximum speed:

- 4,450 to 4,750 rpm

If the tester probe of the tachometer is connected to the DLC3, disconnect the tester probe with SST from terminal 9 of the DLC3.

Disconnect the intelligent tester from the DLC3.

| 2. INSPECT CYLINDER COMPRESSION PRESSURE |

- HINT:

- Measure the compression pressure if the engine power is insufficient, oil is consumed excessively and/or fuel economy is poor.

Remove the 4 glow plugs.

Disconnect the 4 injector connectors.

Turn the ignition switch to START to expel soot and other foreign matter from the inside of the cylinder.

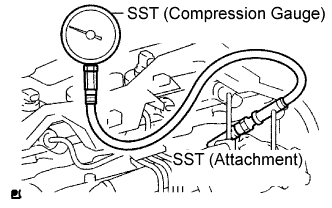

Measure the compression pressure.

Set SST (attachment) into the glow plug hole.

- SST

- 09992-00025(09992-00121)

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Connect SST (compression gauge) to SST (attachment).

- SST

- 09992-00025(09992-00211)

Measure the compression pressure while cranking the engine.

- HINT:

- Always use a fully charged battery to obtain an engine revolution of 250 rpm or more.

|

Perform the step above for each cylinder.

- NOTICE:

- This measurement must be done in as short a time as possible.

- Standard compression pressure:

- 2,700 kPa (27.5 kgf/cm2, 391 psi) or more

- Minimum pressure:

- 2,200 kPa (22.5 kgf/cm2, 320 psi)

- Standard difference between each cylinder:

- 500 kPa (5.0 kgf/cm2, 71 psi) or less

- HINT:

- If poor compression improves after adding the engine oil, the piston rings and/or cylinder bore may be worn or damaged.

- If the pressure stays low, a valve may be stuck or seated improperly, or pressure may be leaking through the gasket.

Remove SST (attachment and compression gauge).

Connect the 4 injector connectors.

Install the 4 glow plugs.