Valve Clearance -- Adjustment |

| 1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL |

- CAUTION:

- Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

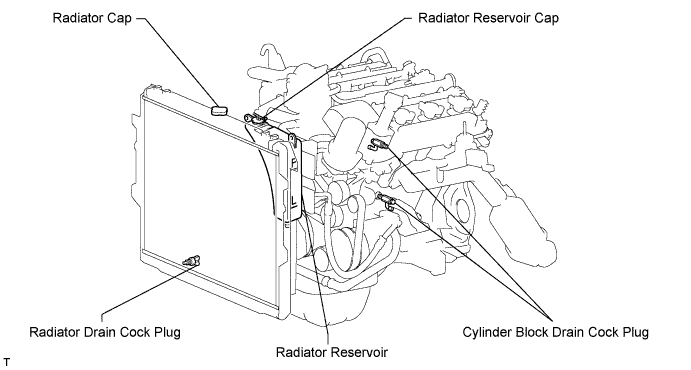

| 2. DRAIN ENGINE COOLANT |

Remove the radiator cap.

Loosen the 2 cylinder block drain cock plugs and radiator drain cock plug, and then drain the coolant.

- HINT:

- Collect the coolant in a container and dispose of it according to the regulations in your area.

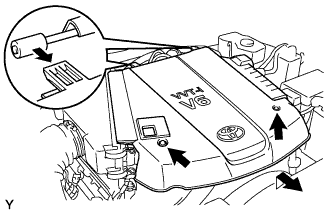

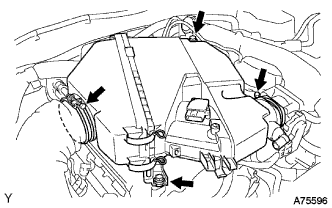

| 3. REMOVE V-BANK COVER |

Remove the 2 nuts and V-bank cover.

|

| 4. REMOVE NO. 2 VENTILATION HOSE |

|

| 5. REMOVE AIR CLEANER |

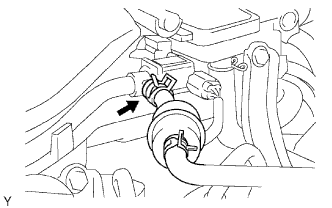

Disconnect the vacuum hose.

|

Disconnect the MAF meter connector.

Remove the 2 wire harness clamps.

Loosen the 2 hose clamps.

|

Remove the 2 bolts and air cleaner.

| 6. REMOVE INTAKE AIR SURGE TANK |

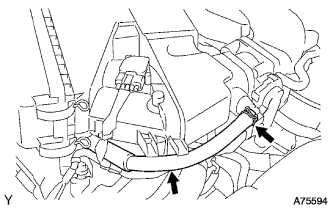

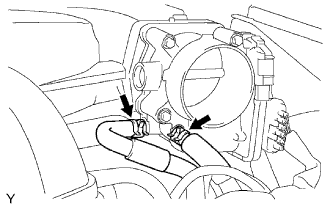

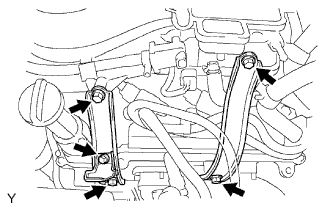

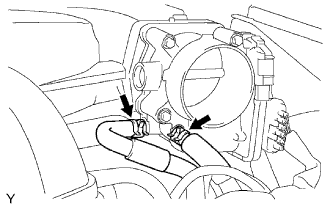

Disconnect the 2 water by-pass hoses.

|

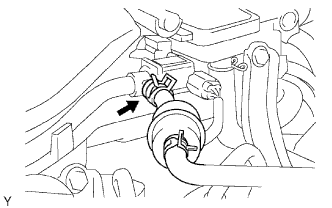

Disconnect the purge line hose.

|

Disconnect the ventilation hose.

|

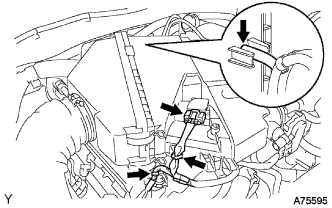

Disconnect the 2 VSV connectors.

|

Disconnect the throttle body with motor connector.

Separate the 3 wire harness clamps and hose clamp.

Remove the 2 bolts and throttle body bracket.

|

Remove the bolt and oil baffle plate.

|

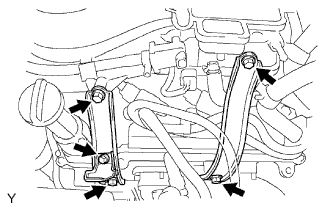

Remove the 4 bolts and 2 surge tank stays.

Remove the 2 nuts.

|

Using an 8 mm hexagon socket wrench, remove the 4 bolts, intake air surge tank and gasket.

| 7. REMOVE IGNITION COIL |

| 8. REMOVE CYLINDER HEAD COVER RH |

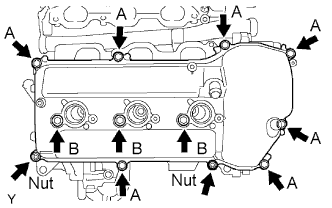

Remove the 10 bolts, 3 seal washers, 2 nuts, cylinder head cover and gasket.

|

| 9. REMOVE CYLINDER HEAD COVER LH |

Remove the 10 bolts, 3 seal washers, 2 nuts, cylinder head cover and gasket.

|

| 10. SET NO. 1 CYLINDER TO TDC/COMPRESSION |

Turn the crankshaft pulley, and align its groove with the timing mark 0 of the timing chain cover.

|

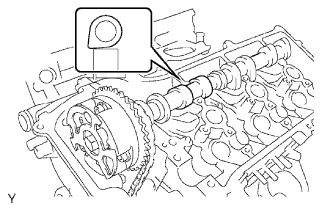

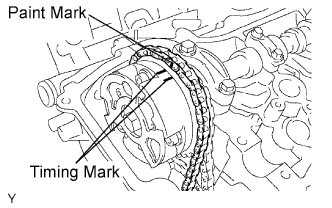

Check that the timing marks of the camshaft timing gears are aligned with the timing marks of the bearing cap as shown in the illustration.

If not, turn the crankshaft 1 complete revolution (360°) and align the timing marks as described above.

|

| 11. INSPECT VALVE CLEARANCE |

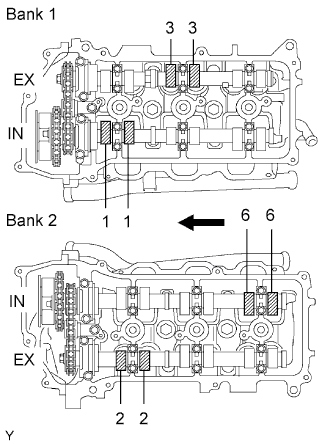

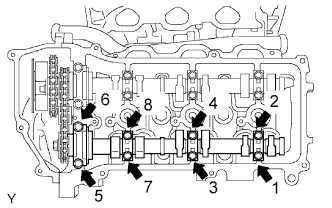

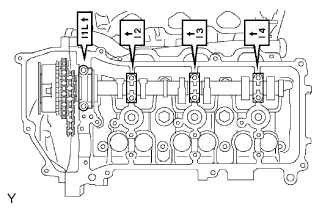

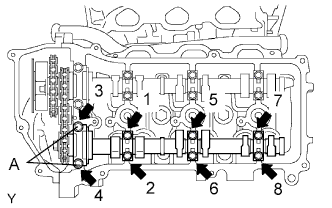

Check the valves indicated in the illustration.

Using a feeler gauge, measure the clearance between the valve lifter and camshaft.

- Standard valve clearance (Cold):

Item Specified Condition Intake 0.15 to 0.25 mm (0.006 to 0.010 in.) Exhaust 0.29 to 0.39 mm (0.011 to 0.015 in.)

- HINT:

- Write down valve clearance measurements that are not within the specified range. They will be used later to determine the required replacement valve lifter.

|

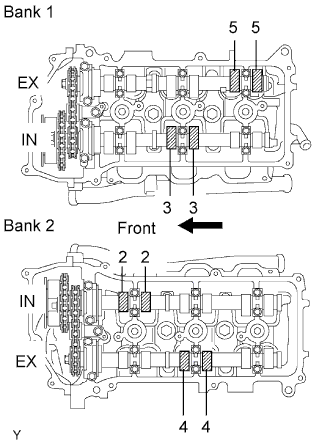

Turn the crankshaft 2/3 of a revolution (240°), and check the valves indicated in the illustration.

Using a feeler gauge, measure the clearance between the valve lifter and camshaft.

- Standard valve clearance (Cold):

Item Specified Condition Intake 0.15 to 0.25 mm (0.006 to 0.010 in.) Exhaust 0.29 to 0.39 mm (0.011 to 0.015 in.)

Write down valve clearance measurements that are not within the specified range. They will be used later to determine the required replacement valve lifter.

|

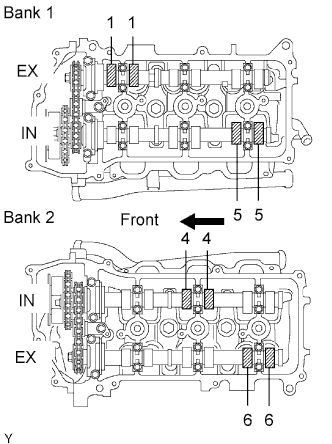

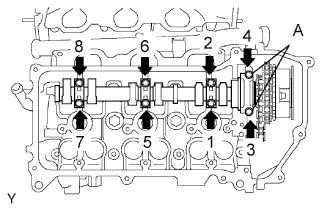

Turn the crankshaft 2/3 of a revolution (240°), and check the valves indicated in the illustration.

Using a feeler gauge, measure the clearance between the valve lifter and camshaft.

- Standard valve clearance (Cold):

Item Specified Condition Intake 0.15 to 0.25 mm (0.006 to 0.010 in.) Exhaust 0.29 to 0.39 mm (0.011 to 0.015 in.)

Write down valve clearance measurements that are not within the specified range. They will be used later to determine the required replacement valve lifter.

|

| 12. ADJUST VALVE CLEARANCE |

Set the No. 1 cylinder to TDC/compression.

Turn the crankshaft pulley, and align the notch with the timing mark 0 of the timing chain cover.

Check that the timing marks of the camshaft timing gears are aligned with the timing marks of the bearing cap as shown in the illustration.

If not, turn the crankshaft 1 complete revolution (360°) and align the timing marks as described above.Place paint marks on the No. 1 chain links that correspond with the timing marks of the camshaft timing gears.

|

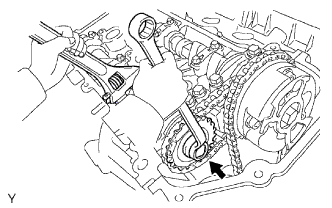

Remove the No. 1 chain tensioner.

- NOTICE:

- Never rotate the crankshaft with the chain tensioner removed.

- When rotating the camshaft with the timing chain removed, turn the crankshaft counterclockwise 40° from the TDC first.

Remove the 4 bolts, timing chain cover plate and gasket.

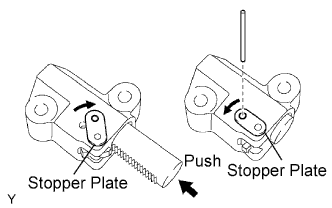

While rotating the stopper plate of the tensioner upward, push in the plunger of the chain tensioner as shown in the illustration.

While rotating the stopper plate of the tensioner downward, insert a pin of φ3.5 mm (0.138 in.) into the holes in the stopper plate and tensioner to fix the stopper plate.

Remove the 2 bolts and chain tensioner.

Remove the No. 2 camshaft.

- NOTICE:

- As the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being removed. If the camshaft is not kept level, the portion of the cylinder head which receives the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

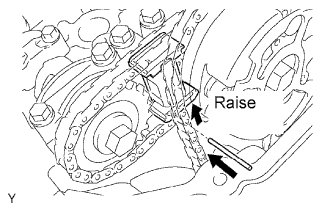

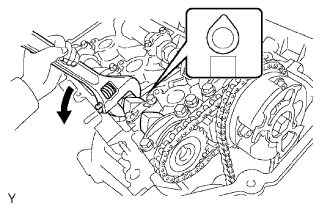

While raising up the No. 2 chain tensioner, insert a pin of φ1.0 mm (0.039 in.) into the hole to fix it.

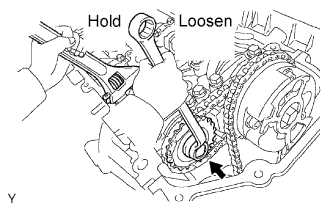

Hold the hexagonal portion of the No. 2 camshaft with a wrench, and remove the camshaft timing gear set bolt.

- NOTICE:

- Be careful not to damage the cylinder head and valve lifter with the wrench.

Separate the camshaft timing gear from the No. 2 camshaft.

Rotate the camshaft counterclockwise using the wrench so that the cam lobes of the No. 1 cylinder face upward as shown in the illustration.

Uniformly loosen and remove the 8 bearing cap bolts in several passes in the sequence shown in the illustration.

Remove the 4 bearing caps and No. 2 camshaft.

Remove the No. 2 chain tensioner.

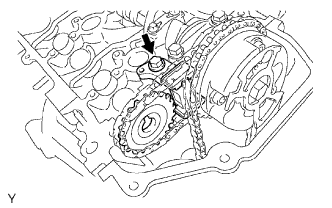

Remove the No. 2 chain tensioner bolt, and then remove the No. 2 chain tensioner and camshaft timing gear.

|

Remove the No. 1 camshaft.

- NOTICE:

- As the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being removed. If the camshaft is not kept level, the portion of the cylinder head which receives the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

Hold the hexagonal portion of the No. 1 camshaft with a wrench, and loosen the camshaft timing gear set bolt.

- NOTICE:

- Be careful not to damage the cylinder head and valve lifter with the wrench.

- Do not disassemble the camshaft timing gear assembly.

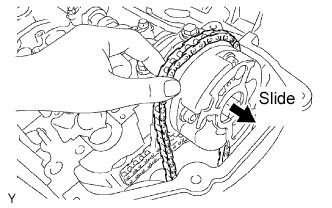

Slide the camshaft timing gear and separate the No. 1 chain from the camshaft timing gear.

Rotate the No. 1 camshaft counterclockwise using the wrench so that the cam lobes of No. 1 cylinder face downward as shown in the illustration.

Uniformly loosen and remove the 8 bearing cap bolts in several passes in the sequence shown in the illustration.

Remove the 4 bearing caps.

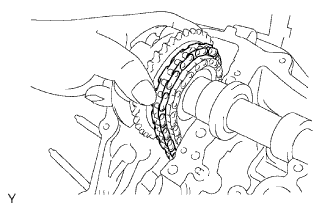

Remove the camshaft timing gear set bolt with the No. 1 camshaft lifted up, and then remove the No. 1 camshaft and camshaft timing gear with No. 2 chain.

Tie the No. 1 chain with a string as shown in the illustration.

- NOTICE:

- Be careful not to drop anything inside the timing chain cover.

Remove the No. 4 camshaft.

- NOTICE:

- As the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being removed. If the camshaft is not kept level, the portion of the cylinder head which receives the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

While pushing down the No. 3 chain tensioner, insert a pin of φ1.0 mm (0.039 in.) into the hole to fix it.

Hold the hexagonal portion of the No. 4 camshaft with a wrench, and remove the camshaft timing gear set bolt.

- NOTICE:

- Be careful not to damage the cylinder head and valve lifter with the wrench.

Separate the camshaft timing gear from the No. 4 camshaft.

Uniformly loosen and remove the 8 bearing cap bolts in several passes in the sequence shown in the illustration.

Remove the 4 bearing caps and No. 4 camshaft.

Remove the No. 3 chain tensioner assembly.

Remove the No. 3 chain tensioner bolt, and then remove the No. 3 chain tensioner and camshaft timing gear.

|

Remove the No. 3 camshaft sub-assembly.

- NOTICE:

- As the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being removed. If the camshaft is not kept level, the portion of the cylinder head which receives the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

Using several steps, loosen and remove the 8 bearing cap bolts uniformly in the sequence as shown in the illustration.

Remove the 4 bearing caps.

Hold the No. 1 chain, and remove the No. 3 camshaft, camshaft timing gear and No. 2 chain.

Tie the No. 1 chain with a string as shown in the illustration.

- NOTICE:

- Be careful not to drop anything inside the timing chain cover.

Remove the valve lifters.

Determine the replacement valve lifter size by following the procedures below.

Using a micrometer, measure the thickness of the removed lifter.

Calculate the thickness of a new lifter so that the valve clearance comes within the specified value.

T Thickness of removed lifter A Measured valve clearance N Thickness of new lifter - New lifter thickness:

Item Thickness Intake N = T + (A to 0.20 mm (0.008 in.)) Exhaust N = T + (A to 0.30 mm (0.012 in.))

Select a new intake side lifter with a thickness as close as possible to the calculated value.

- HINT:

- Lifters are available in 35 sizes in increments of 0.020 mm (0.0008 in.), from 5.060 mm (0.1992 in.) to 5.740 mm (0.2260 in.).

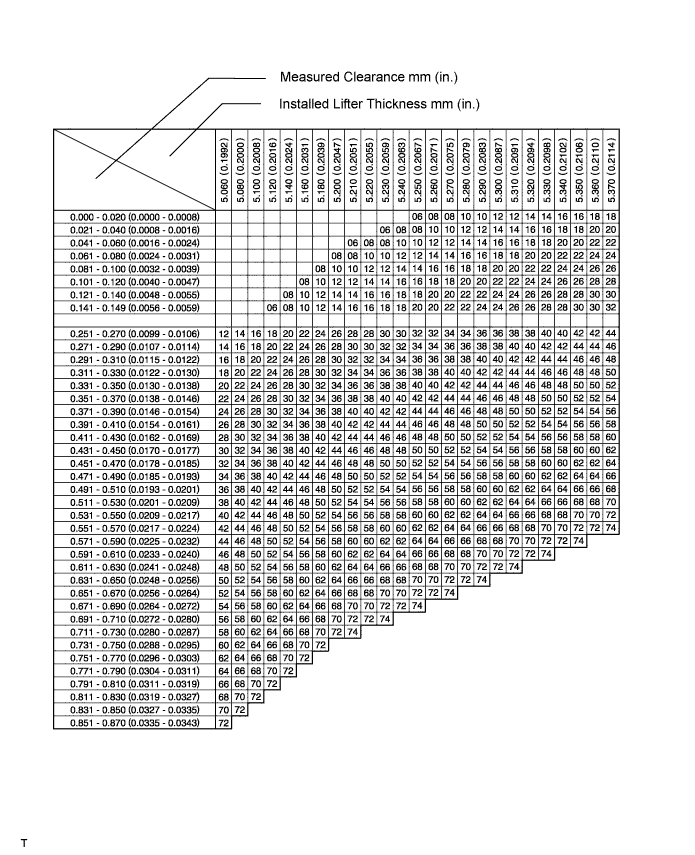

Valve lifter selection chart (intake).

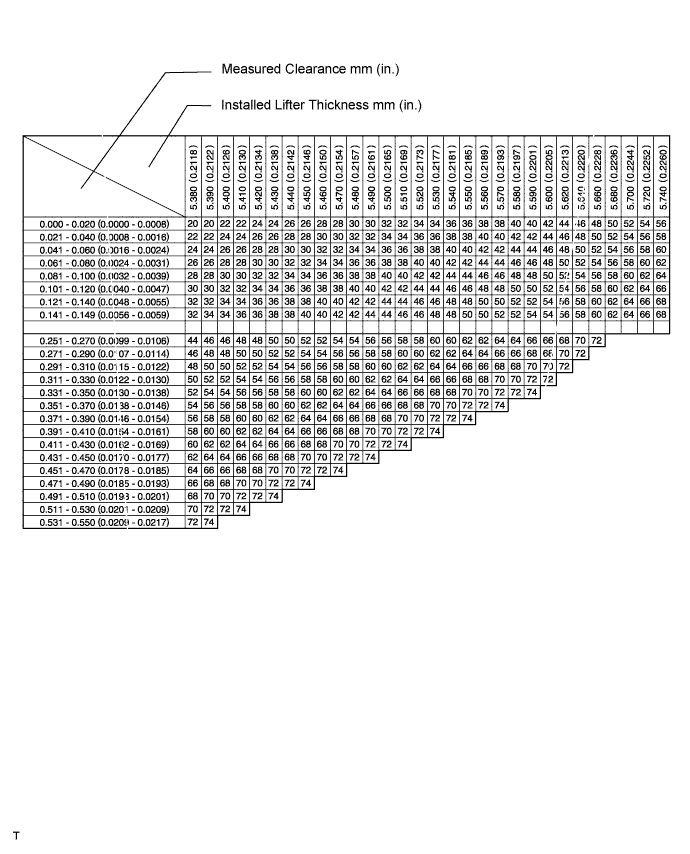

Valve lifter selection chart (intake) (continued).

- New lifter thickness:

No. Thickness No. Thickness No. Thickness 06 5.060 mm (0.1992 in.) 30 5.300 mm (0.2087 in.) 54 5.540 mm (0.2181 in.) 08 5.080 mm (0.2000 in.) 32 5.320 mm (0.2094 in.) 56 5.560 mm (0.2189 in.) 10 5.100 mm (0.2008 in.) 34 5.340 mm (0.2102 in.) 58 5.580 mm (0.2197 in.) 12 5.120 mm (0.2016 in.) 36 5.360 mm (0.2110 in.) 60 5.600 mm (0.2205 in.) 14 5.140 mm (0.2024 in.) 38 5.380 mm (0.2118 in.) 62 5.620 mm (0.2213 in.) 16 5.160 mm (0.2031 in.) 40 5.400 mm (0.2126 in.) 64 5.640 mm (0.2220 in.) 18 5.180 mm (0.2039 in.) 42 5.420 mm (0.2134 in.) 66 5.660 mm (0.2189 in.) 20 5.200 mm (0.2047 in.) 44 5.440 mm (0.2142 in.) 68 5.680 mm (0.2236 in.) 22 5.220 mm (0.2055 in.) 46 5.460 mm (0.2150 in.) 70 5.700 mm (0.2244 in.) 24 5.240 mm (0.2063 in.) 48 5.480 mm (0.2157 in.) 72 5.720 mm (0.2252 in.) 26 5.260 mm (0.2071 in.) 50 5.500 mm (0.2165 in.) 74 5.740 mm (0.2260 in.) 28 5.280 mm (0.2079 in.) 52 5.520 mm (0.2173 in.) - -

- Standard intake valve clearance (Cold):

- 0.15 to 0.25 mm (0.006 to 0.010 in.)

The 5.250 mm (0.2067 in.) lifter is installed, and the measured clearance is 0.400 mm (0.0158 in.)

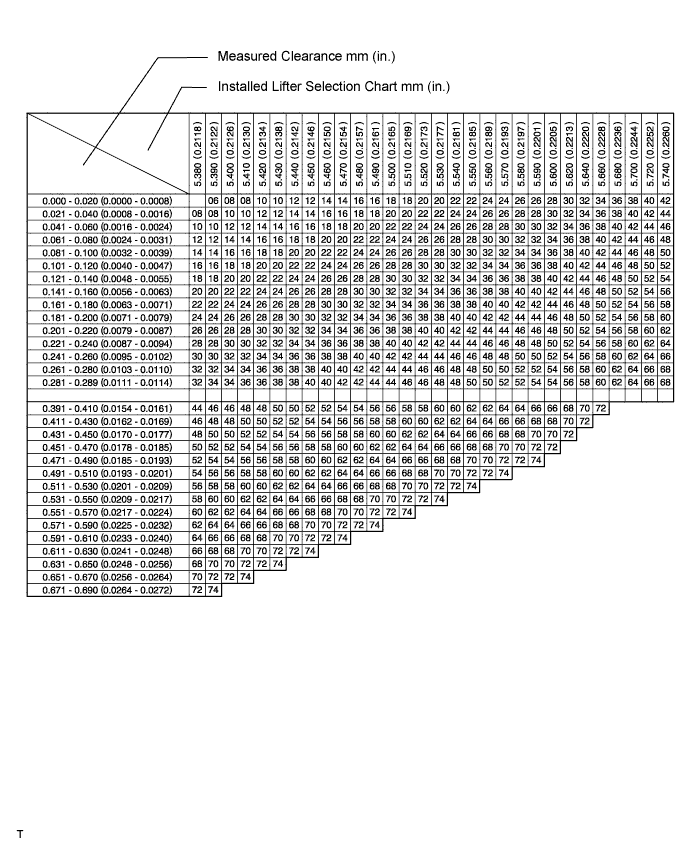

Replace the 5.250 mm (0.2067 in.) lifter with a new No. 46 lifter.Valve lifter selection chart (exhaust).

Valve lifter selection chart (exhaust) (continued).

- New lifter thickness mm (in.):

No. Thickness No. Thickness No. Thickness 06 5.060 mm (0.1992 in.) 30 5.300 mm (0.2087 in.) 54 5.540 mm (0.2181 in.) 08 5.080 mm (0.2000 in.) 32 5.320 mm (0.2094 in.) 56 5.560 mm (0.2189 in.) 10 5.100 mm (0.2008 in.) 34 5.340 mm (0.2102 in.) 58 5.580 mm (0.2197 in.) 12 5.120 mm (0.2016 in.) 36 5.360 mm (0.2110 in.) 60 5.600 mm (0.2205 in.) 14 5.140 mm (0.2024 in.) 38 5.380 mm (0.2118 in.) 62 5.620 mm (0.2213 in.) 16 5.160 mm (0.2031 in.) 40 5.400 mm (0.2126 in.) 64 5.640 mm (0.2220 in.) 18 5.180 mm (0.2039 in.) 42 5.420 mm (0.2134 in.) 66 5.660 mm (0.2189 in.) 20 5.200 mm (0.2047 in.) 44 5.440 mm (0.2142 in.) 68 5.680 mm (0.2236 in.) 22 5.220 mm (0.2055 in.) 46 5.460 mm (0.2150 in.) 70 5.700 mm (0.2244 in.) 24 5.240 mm (0.2063 in.) 48 5.480 mm (0.2157 in.) 72 5.720 mm (0.2252) 26 5.260 mm (0.2071 in.) 50 5.500 mm (0.2165 in.) 74 5.740 mm (0.2260) 28 5.280 mm (0.2079 in.) 52 5.520 mm (0.2173 in.) - -

- Standard exhaust valve clearance (Cold):

- 0.29 to 0.39 mm (0.011 to 0.015 in.)

The 5.340 mm (0.2102 in.) lifter is installed, and the measured clearance is 0.480 mm (0.0189 in.)

Replace the 5.340 mm (0.2102 in.) lifter with a new No. 48 lifter.- HINT:

- Lifters are available in 35 sizes in increments of 0.020 mm (0.0008 in.), from 5.060 mm (0.1992 in.) to 5.740 mm (0.2260 in.).

Install the No. 3 camshaft.

- NOTICE:

- As the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being installed. If the camshaft is not kept level, the portion of the cylinder head which receives the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

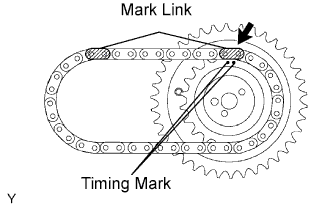

Align the mark link (yellow) with the timing mark (2 dot mark) of the camshaft timing gear as shown in the illustration.

Apply new engine oil to the thrust portion and journal of the camshafts.

Temporarily put the No. 1 chain on the No. 2 chain of the camshaft timing gear.

Set the No. 3 camshaft onto the LH cylinder head with the cam lobes of the No. 2 cylinder facing downward as shown in the illustration.

Install the 4 bearing caps in their proper locations.

Apply a light coat of engine oil on the threads of the bearing cap bolts.

Install the 8 bearing cap bolts. Using several steps, tighten the bolts uniformly in the sequence as shown in the illustration.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf} for 10 mm (0.39 in.) head

- 24 N*m{245 kgf*cm, 18 in.*lbf} for 12 mm (0.47 in.) head (A)

Set the paint mark of the No. 1 chain between the timing marks of the camshaft timing gear.

Install the No. 3 chain tensioner.

While pushing in the tensioner, insert a pin of φ1.0 mm (0.039 in.) into the hole to fix it in place.

Temporarily install the camshaft timing gear and No. 3 chain tensioner, and align the mark links (yellow) with the timing marks (1 dot mark and 2 dot mark) of the camshaft timing gears.

Tighten the No. 3 chain tensioner bolt.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

|

Install the No. 4 camshaft.

- NOTICE:

- As the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being installed. If the camshaft is not kept level, the portion of the cylinder head which receives the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

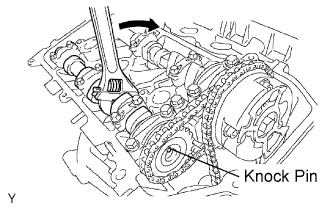

Align the knock pin hole in the camshaft timing gear with the knock pin of the No. 4 camshaft, and insert the No. 4 camshaft into the camshaft timing gear.

Temporarily install the camshaft timing gear set bolt.

Install the 4 bearing caps in their proper locations.

Apply a light coat of engine oil on the threads and under the heads of the bearing cap bolts.

Install the 8 bearing cap bolts. Using several steps, tighten the bolts uniformly in the sequence as shown in the illustration.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf} for 10 mm (0.39 in.) head

- 24 N*m{245 kgf*cm, 18 ft.*lbf} for 12 mm (0.47 in.) head (A)

Hold the hexagonal portion of the No. 4 camshaft with a wrench, and tighten the camshaft timing gear set bolt.

- Torque:

- 100 N*m{1,020 kgf*cm, 74 ft.*lbf}

Remove the pin from the No. 3 chain tensioner.

Install the camshaft.

- NOTICE:

- As the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being installed. If the camshaft is not kept level, the portion of the cylinder head which receives the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

Align the mark link (yellow) with the timing mark (1 dot mark) of the camshaft timing gear as shown in the illustration.

Apply new engine oil to the thrust portion and journal of the camshafts.

Temporarily put the No. 1 chain on the No. 2 chain of the camshaft timing gear.

Align the knock pin hole in the camshaft timing gear with the knock pin of the No. 1 camshaft, and insert the No. 1 camshaft into the camshaft timing gear.

Temporarily install the camshaft timing gear set bolt.

Set the No. 1 camshaft onto the RH cylinder head with the cam lobes of the No. 1 cylinder facing downward as shown in the illustration.

Install the 4 bearing caps in their proper locations.

Apply a light coat of engine oil on the threads and under the heads of the bearing cap bolts.

Install the 8 bearing cap bolts. Using several steps, tighten the bolts uniformly in the sequence as shown in the illustration.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf} for 10 mm (0.39 in.) head

- 24 N*m{245 kgf*cm, 18 ft.*lbf} for 12 mm (0.47 in.) head (A)

Hold the hexagonal portion of the No. 1 camshaft using a wrench. Rotate the No. 1 camshaft so that the timing mark of the camshaft timing gear is aligned with the timing marks of the camshaft bearing cap.

Align the paint mark of the No. 1 chain with the timing mark of the camshaft timing gear.

Hold the hexagonal portion of the No. 1 camshaft with a wrench, and tighten the camshaft timing gear set bolt.

- Torque:

- 100 N*m{1,020 kgf*cm, 74 ft.*lbf}

Install the No. 2 chain tensioner.

While pushing in the tensioner, insert a pin of φ1.0 mm (0.039 in.) into the hole to fix it in place.

Temporarily install the camshaft timing gear and No. 2 chain tensioner and align the mark links (yellow) with the timing marks (1 dot mark) of the camshaft timing gears.

Tighten the No. 2 chain tensioner bolt.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

|

Install the No. 2 camshaft.

- NOTICE:

- As the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being installed. If the camshaft is not kept level, the portion of the cylinder head which receives the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

Set the No. 2 camshaft onto the RH cylinder head with the cam lobes of No. 1 cylinder facing upward as shown in the illustration.

Install the 4 bearing caps in their proper locations.

Apply a light coat of engine oil on the threads and under the heads of the bearing cap bolts.

Install the 8 bearing cap bolts. Using several steps, tighten the bolts uniformly in the sequence as shown in the illustration.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf} for 10 mm (0.39 in.) head

- 24 N*m{245 kgf*cm, 18 ft.*lbf} for 12 mm (0.47 in.) head (A)

Rotate the No. 2 camshaft clockwise using a wrench so that the knock pin of the No. 2 camshaft is aligned with the knock pin hole of the camshaft timing gear.

Hold the hexagonal portion of the No. 2 camshaft with a wrench, and install the camshaft timing gear set bolt.

- Torque:

- 100 N*m{1,020 kgf*cm, 74 ft.*lbf}

Remove the pin from the No. 2 chain tensioner.

Install the No. 1 chain tensioner.

While turning the stopper plate of the tensioner clockwise, push in the plunger of the tensioner as shown in the illustration.

While turning the stopper plate of the tensioner counterclockwise, insert a pin of φ3.5 mm (0.138 in.) into the holes in the stopper plate and tensioner to fix the stopper plate.

Install the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Remove the pin from the chain tensioner.

Install a new gasket and the timing chain cover plate with the 4 bolts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

Slowly turn the crankshaft pulley 2 complete revolutions, and align the notch with timing mark 0 of the timing chain cover.

Check that the timing marks of the camshaft timing gears are aligned with the timing marks of the bearing cap as shown in the illustration.

|

| 13. INSTALL CYLINDER HEAD COVER LH |

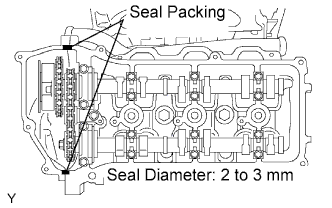

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder head, timing chain cover and cylinder head cover.

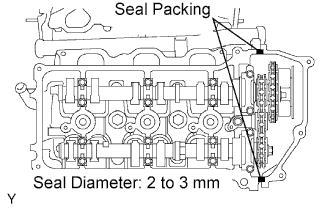

Apply seal packing (diameter: 2 to 3 mm (0.08 to 0.12 in.)) to the cylinder head and timing chain cover as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 2 to 3 mm (0.08 to 0.12 in.)

- NOTICE:

- Install the cylinder head cover within 3 minutes after applying seal packing. After installing it, the cylinder head cover bolts and nuts must be tightened within 15 minutes. Otherwise the seal packing must be removed and reapplied.

|

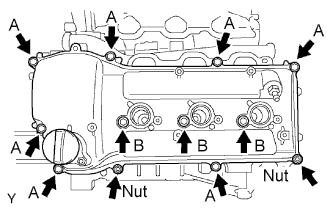

Install the seal washers to the bolts.

Install the cylinder head cover with the 10 bolts and 2 nuts. Uniformly tighten the bolts and nuts in several passes.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}for bolt A

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}for bolt B

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}for nut

|

| 14. INSTALL CYLINDER HEAD COVER RH |

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder head, timing chain cover and cylinder head cover.

Apply seal packing to the cylinder head and timing chain cover as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 2 to 3 mm (0.08 to 0.12 in.)

- NOTICE:

- Install the cylinder head cover within 3 minutes after applying seal packing. After installing it, the cylinder head cover bolts and nuts must be tightened within 15 minutes. Otherwise the seal packing must be removed and reapplied.

|

Install the seal washers to the bolts.

Install the cylinder head cover with the 10 bolts and 2 nuts. Uniformly tighten the bolts and nuts in several passes.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}for bolt A

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}for bolt B

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}for nut

|

| 15. INSTALL IGNITION COIL |

| 16. INSTALL INTAKE AIR SURGE TANK |

Install a new gasket to the intake air surge tank.

|

Using an 8 mm hexagon socket wrench, install the intake air surge tank with the 4 bolts. Install the 2 nuts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

Install the 2 surge tank stays with the 4 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

Install the oil baffle plate with the bolt.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

Install the throttle body bracket with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

Install the 3 wire harness clamps and hose clamp.

Connect the throttle body with motor connector.

Connect the 2 VSV connectors.

Connect the ventilation hose.

|

Connect the purge line hose.

|

Connect the 2 water by-pass hoses.

|

| 17. INSTALL AIR CLEANER |

Install a new gasket to the intake air surge tank.

Install the throttle position sensor and control motor connector.

- Torque:

- 11 N*m{112 kgf*cm, 9 ft.*lbf}

| 18. CONNECT NO. 2 VENTILATION HOSE |

| 19. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 20. ADD ENGINE COOLANT |

Tighten all the plugs and fill the radiator with TOYOTA Super Long Life Coolant (SLLC).

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf} for cylinder block drain cock plug

- Standard capacity:

Item Specified Condition A/T 9.8 liters (10.4 US qts, 8.6 Imp. qts) M/T 8.5 liters (9.0 US qts, 7.5 Imp. qts)

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

- Please contact your TOYOTA dealer for further details.

- NOTICE:

- Never use water as a substitute for engine coolant.

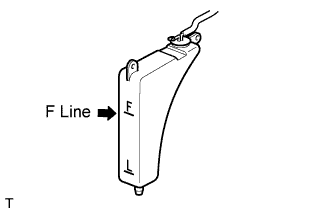

Fill the radiator reservoir with TOYOTA Super Long Life Coolant (SLLC) to the F line.

Install the radiator cap.

Bleed air from the cooling system.

Warm up the engine until the thermostat opens.

While the thermostat is open, circulate the coolant for several minutes.Maintain the engine speed at 2,500 to 3,000 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- CAUTION:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine and wait until the coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check the coolant level in the radiator reservoir.

If the coolant level is below the L line, add SLLC to the reservoir F line.

|

| 21. CHECK FOR ENGINE COOLANT LEAKS |

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

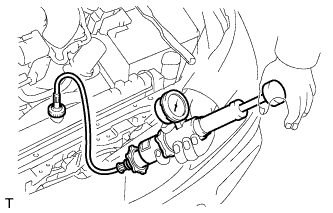

Fill the radiator with coolant and attach a radiator cap tester.

|

Warm up the engine.

Using the radiator cap tester, increase the pressure inside the radiator to 118 kPa (1.2 kgf/cm2, 17.1 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the cylinder block and head.

| 22. INSTALL V-BANK COVER |

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

| 23. INSPECT IGNITION TIMING |

When using intelligent tester:

Check the ignition timing.Connect the intelligent tester to the DLC3.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

- Standard ignition timing:

- 7 to 24°BTDC @ idle

(Transmission in neutral position)

Disconnect the intelligent tester from the DLC3.

|

When not using intelligent tester:

Check the ignition timing.Remove the air cleaner cap.

Connect the tester probe of a timing light to the green-red lead wire of the ignition coil connector of the No. 1 cylinder.

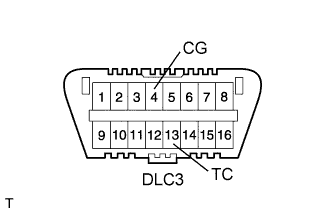

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

Using the timing light, check the ignition timing.

- Standard ignition timing:

- 10 +-2° BTDC @ idle

(Transmission in neutral position)

Remove SST from the DLC3.

Check the ignition timing.

- Standard ignition timing:

- 7 to 24° BTDC @ idle

(Transmission in neutral position)

Disconnect the timing light from the engine.

Install the air cleaner cap.

|