Dtc P0105/35 Manifold Absolute Pressure/Barometric Pressure Circuit

DESCRIPTION

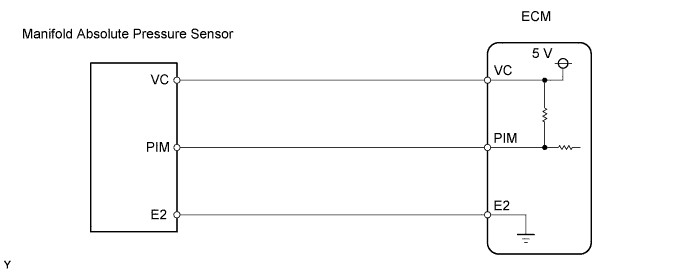

WIRING DIAGRAM

INSPECTION PROCEDURE

When using intelligent tester:

READ VALUE USING INTELLIGENT TESTER (MAP)

CHECK ECM (VC VOLTAGE)

CHECK ECM (PIM VOLTAGE)

CHECK WIRE HARNESS (MANIFOLD ABSOLUTE PRESSURE SENSOR - ECM)

INSPECT TURBOCHARGER SUB-ASSEMBLY

INSPECT EGR VALVE ASSEMBLY

When not using intelligent tester:

CHECK ECM (VC VOLTAGE)

CHECK ECM (PIM VOLTAGE)

CHECK WIRE HARNESS (MANIFOLD ABSOLUTE PRESSURE SENSOR - ECM)

INSPECT TURBOCHARGER SUB-ASSEMBLY

INSPECT EGR VALVE ASSEMBLY

DTC P0105/35 Manifold Absolute Pressure/Barometric Pressure Circuit |

DTC P0107/35 Manifold Absolute Pressure / Barometric Pressure Circuit Low Input |

DTC P0108/35 Manifold Absolute Pressure / Barometric Pressure Circuit High Input |

DESCRIPTION

The manifold absolute pressure sensor detects the intake manifold pressure by using the built-in sensor unit. The ECM determines the basic injection duration and injection advance timing based on the voltage output by the manifold absolute pressure sensor. The manifold absolute pressure sensor monitors the absolute pressure inside the intake manifold (default is 0 kPa (0 mmHg, 0 in.Hg)). As a result, the ECM controls the air-fuel ratio at the proper level under any driving conditions, and is not influenced by fluctuations in the atmospheric pressure due to factors such as high altitude, etc.

The manifold absolute pressure sensor detects the intake manifold pressure by using the built-in sensor unit. The ECM determines the basic injection duration and injection advance timing based on the voltage output by the manifold absolute pressure sensor. The manifold absolute pressure sensor monitors the absolute pressure inside the intake manifold (default is 0 kPa (0 mmHg, 0 in.Hg)). As a result, the ECM controls the air-fuel ratio at the proper level under any driving conditions, and is not influenced by fluctuations in the atmospheric pressure due to factors such as high altitude, etc.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0105/35

P0107/35

P0108/35

| Open or short in manifold absolute pressure sensor circuit for

0.5 seconds or more

(1 trip detection logic)

| - Open or short in manifold absolute pressure sensor circuit

- Manifold absolute pressure sensor

- Turbocharger sub-assembly

- ECM

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- If DTCs related to different systems that have terminal E2 as the ground terminal are output simultaneously, terminal E2 may have an open circuit.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, and other data from the time the malfunction occurred.

- NOTICE:

- If the ECM is replaced, the new ECM needs initialization (Toyota Fortuner RM0000012X2005X.html).

When using intelligent tester:

| 1.READ VALUE USING INTELLIGENT TESTER (MAP) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Data List / MAP.

Read the values.

- Standard:

- Same value as the actual atmospheric pressure.

| | CHECK FOR INTERMITTENT PROBLEMS |

|

|

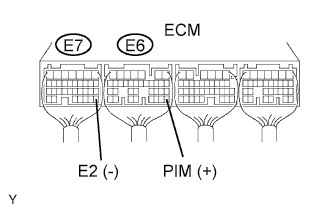

Turn the ignition switch ON.

Measure the voltage of the ECM connector.

- Standard voltage:

Tester Connection

| Specified Condition

|

E7-18 (VC) - E7-28 (E2)

| 4.5 to 5.5 V

|

| 3.CHECK ECM (PIM VOLTAGE) |

Turn the ignition switch ON.

Measure the voltage of the ECM connectors.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

E6-28 (PIM) - E7-28 (E2)

| Applied negative pressure of 40 kPa (300 mmHg, 11.8 in.Hg)

| 1.3 to 1.9 V

|

E6-28 (PIM) - 7-28 (E2)

| Same as atmospheric pressure

| 2.4 to 3.1 V

|

E6-28 (PIM) - E7-28 (E2)

| Applied positive pressure of 170 kPa (1,275 mmHg, 50.2 in.Hg)

| 3.7 to 4.3 V

|

| 4.CHECK WIRE HARNESS (MANIFOLD ABSOLUTE PRESSURE SENSOR - ECM) |

Disconnect the T9 sensor connector.

Disconnect the E6 and E7 ECM connectors.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

T9-2 (PIM) - E6-28 (PIM)

| Below 1 Ω

|

T9-3 (VC) - E7-18 (VC)

| Below 1 Ω

|

T9-1 (E2) - E7-28 (E2)

| Below 1 Ω

|

T9-2 (PIM) or E6-28 (PIM) - Body ground

| 10 kΩ higher

|

T9-3 (VC) or E7-18 (VC) - Body ground

| 10 kΩ higher

|

T9-1 (E2) or E7-28 (E2) - Body ground

| 10 kΩ higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 5.INSPECT TURBOCHARGER SUB-ASSEMBLY |

- OK:

- None of the inspection results show any abnormalities.

| | REPLACE TURBOCHARGER SUB-ASSEMBLY |

|

|

| 6.INSPECT EGR VALVE ASSEMBLY |

- OK:

- None of the inspection results show any abnormalities.

| | REPLACE EGR VALVE ASSEMBLY |

|

|

| OK |

|

|

|

| REPLACE MANIFOLD ABSOLUTE PRESSURE SENSOR |

|

When not using intelligent tester:

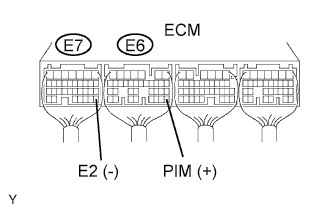

Turn the ignition switch ON.

Measure the voltage of the ECM connector.

- Standard voltage:

Tester Connection

| Specified Condition

|

E7-18 (VC) - E7-28 (E2)

| 4.5 to 5.5 V

|

| 2.CHECK ECM (PIM VOLTAGE) |

Turn the ignition switch ON.

Measure the voltage of the ECM connectors.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

E6-28 (PIM) - E78-28 (E2)

| Applied negative pressure of 40 kPa (300 mmHg, 11.8 in.Hg)

| 1.3 to 1.9 V

|

E6-28 (PIM) - E7-28 (E2)

| Same as atmospheric pressure

| 2.4 to 3.1 V

|

E6-28 (PIM) - E7-28 (E2)

| Applied positive pressure of 170 kPa (1,275 mmHg, 50.2 in.Hg)

| 3.7 to 4.3 V

|

| 3.CHECK WIRE HARNESS (MANIFOLD ABSOLUTE PRESSURE SENSOR - ECM) |

Disconnect the T9 sensor connector.

Disconnect the E6 and E7 ECM connectors.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

T9-2 (PIM) - E6-28 (PIM)

| Below 1 Ω

|

T9-3 (VC) - E7-18 (VC)

| Below 1 Ω

|

T9-1 (E2) - E7-28 (E2)

| Below 1 Ω

|

T9-2 (PIM) or E6-28 (PIM) - Body ground

| 10 kΩ higher

|

T9-3 (VC) or E7-18 (VC) - Body ground

| 10 kΩ higher

|

T9-1 (E2) or E7-28 (E2) - Body ground

| 10 kΩ higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 4.INSPECT TURBOCHARGER SUB-ASSEMBLY |

- OK:

- None of the inspection results show any abnormalities.

| | REPLACE TURBOCHARGER SUB-ASSEMBLY |

|

|

| 5.INSPECT EGR VALVE ASSEMBLY |

- OK:

- None of the inspection results show any abnormalities.

| | REPLACE EGR VALVE ASSEMBLY |

|

|

| OK |

|

|

|

| REPLACE DIESEL TURBO PRESSURE SENSOR |

|