Dtc P0443 Evaporative Emission Control System Purge Control Valve Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (PURGE VSV)

CHECK ECM (PRG VOLTAGE)

INSPECT PURGE VSV

CHECK WIRE HARNESS (ECM - PURGE VSV)

CHECK WIRE HARNESS (INTEGRATION RELAY [Marking: MAIN] - PURGE VSV)

DTC P0443 Evaporative Emission Control System Purge Control Valve Circuit |

DESCRIPTION

In order to reduce Hydrocarbon (HC) emissions, evaporated fuel from the fuel tank is routed through the charcoal canister to the intake manifold for combustion in the cylinders.The ECM changes the duty signal to the purge VSV so that the intake of HC emissions is appropriate for the driving conditions (engine load, engine speed, vehicle speed, etc.) after the engine is warmed up.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0443

| Proper response to ECM command does not occur

(1 trip detection logic)

| - Open or short in purge VSV circuit

- Purge VSV

- ECM

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (PURGE VSV) |

Disconnect the vacuum hose from the purge VSV.

Connect the intelligent tester to the DLC3.

Enter the engine and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VSV for EVAP Control. Press the right or left button.

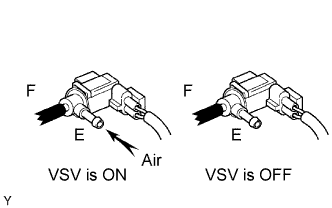

Place a finger on port E. Check if the disconnected port applies suction to your finger when operating the purge VSV using the intelligent tester.

- Standard condition:

Tester Operation

| Specified Condition

|

VSV is ON

| Applies suction to your finger

|

VSV is OFF

| Applies no suction to your finger

|

| | CHECK FOR INTERMITTENT PROBLEMS |

|

|

| 2.CHECK ECM (PRG VOLTAGE) |

Turn the ignition switch ON.

Measure the voltage of the E15 and E17 ECM connectors.

- Standard voltage:

Tester Connection

| Specified Condition

|

E15-34 (PRG) - E17-1 (E1)

| 9 to 14 V

|

- OK:

- Air flows when battery voltage is applied to purge VSV .

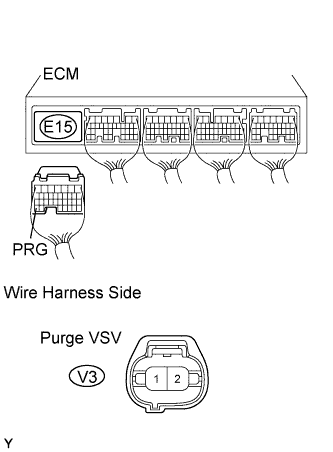

| 4.CHECK WIRE HARNESS (ECM - PURGE VSV) |

Disconnect the E15 connector.

Disconnect the V3 purge VSV connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

V3-2 - E15-34 (PRG)

| Below 1 Ω

|

V3-2 or E15-34 (PRG) - Body ground

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

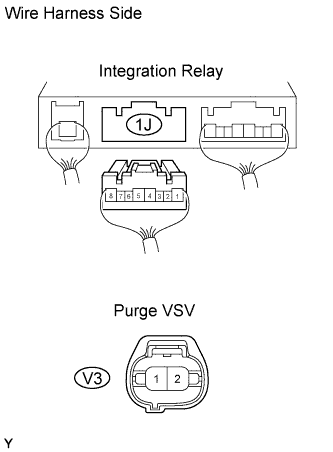

| 5.CHECK WIRE HARNESS (INTEGRATION RELAY [Marking: MAIN] - PURGE VSV) |

Disconnect the 1J integration relay connector from the engine room junction block (Toyota Fortuner RM0000014TJ00HX.html).

Disconnect the V3 purge VSV connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

V3-1 - 1J-5

| Below 1 Ω

|

V3-1 or 1J-5 - Body ground

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| OK |

|

|

|

| INSPECT ECM POWER SOURCE CIRCUIT |

|