PERFORM ACTIVE TEST USING INTELLIGENT TESTER (FUEL PUMP)

CHECK HARNESS AND CONNECTOR (FUEL PUMP ECU - ECM, BODY GROUND)

CONFIRM WHETHER DTC OUTPUT RECURS

INSPECT CIRCUIT OPENING RELAY (C/OPN)

INSPECT CIRCUIT OPENING RELAY (POWER SOURCE VOLTAGE)

CHECK HARNESS AND CONNECTOR (CIRCUIT OPENING RELAY (C/OPN) - ECM, FUEL PUMP ECU)

CHECK HARNESS AND CONNECTOR (FUEL PUMP - FUEL PUMP ECU)

CHECK HARNESS AND CONNECTOR (FUEL PUMP ECU - ECM, BODY GROUND)

CONFIRM WHETHER DTC OUTPUT RECURS

CHECK HARNESS AND CONNECTOR (C/OPN RELAY - EFI NO. 2 RELAY, IGN FUSE)

INSPECT EFI NO. 2 RELAY (EFI NO. 2)

CHECK HARNESS AND CONNECTOR (EFI NO. 2 RELAY - INTEGRATION RELAY, BATTERY, BODY GROUND)

DTC P0230 Fuel Pump Primary Circuit

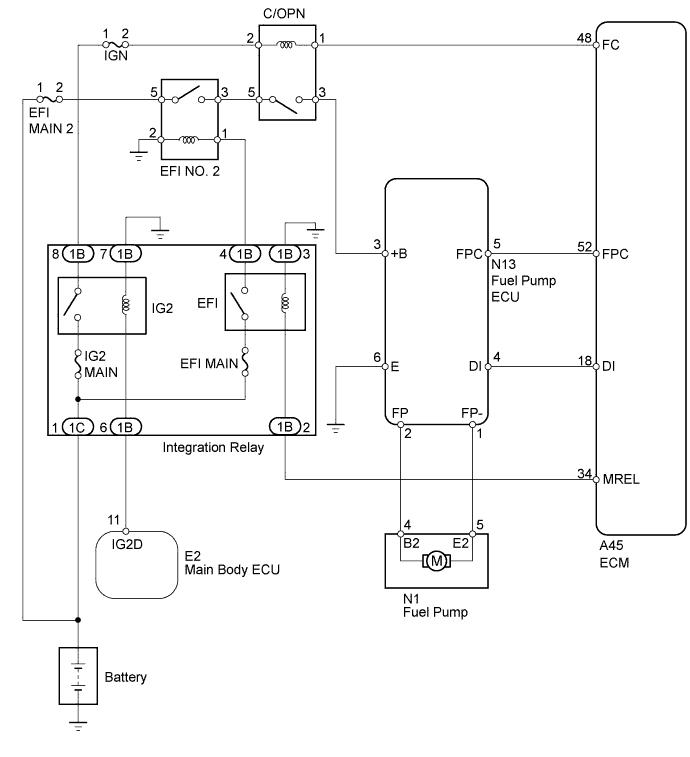

Description

When a malfunction in the fuel pump circuit is detected, DTC P0230 is stored. The fuel pump circuit consists of the ECM, fuel pump and fuel pump ECU (which operates the fuel pump). Based on the engine output, the ECM determines the fuel pump speed. The speed is then converted to a duty signal and sent to the fuel pump ECU. Based on the signal sent from the ECM, the fuel pump ECU adjusts the fuel pump operation speed between 3 settings. The fuel pump ECU also has a self-diagnosis function. Based on the fuel pump circuit condition, the fuel pump ECU outputs a diagnostic signal (DI) to the ECM, and the ECM determines if there is a malfunction in the fuel pump circuit.

| DTC Code | DTC Detection Condition | Trouble Area |

| P0230 | When either condition below is met (1 trip detection logic):

|

|

Monitor description

To monitor the fuel pump circuit, the ECM checks the fuel pump control signal (FPC) and diagnostic signal (DI). The FPC voltage varies between approximately 0 V to approximately 12 V (duty signal). Based on the condition of the fuel pump ECU malfunction, the DI voltage varies between approximately 0 V and approximately 12 V. The ECM then compares the variance of the FPC voltage and DI voltage, and determines if the fuel pump circuit is malfunctioning. When the ECM determines that the fuel pump circuit is malfunctioning, a DTC is stored immediately.

Wiring diagram

Inspection procedure

This troubleshooting procedure is based on the premise that the engine is started. If the engine is not started, proceed to the Problem Symptoms Table .

| 1.CHECK FOR DTC (B1500) |

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the tester on.

-

Enter the following menus: Body Electrical / Combination Meter / DTC.

-

Read the DTC.

Result Result Proceed to DTC B1500 is not output A DTC B1500 is output B

|

|

||||

| A | |

| 2.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (FUEL PUMP) |

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG) and turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

-

Check whether operating sounds can be heard while operating the fuel pump using the tester.

OK:

Operating sounds can be heard from fuel pump.

|

|

||||

| OK | |

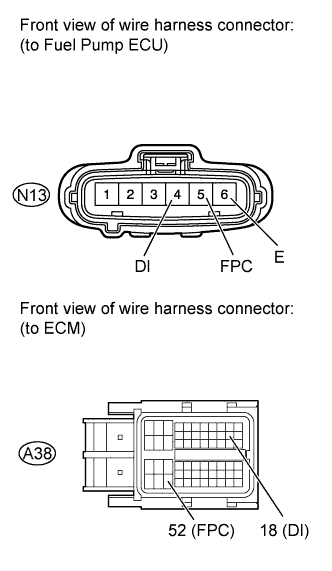

| 3.CHECK HARNESS AND CONNECTOR (FUEL PUMP ECU - ECM, BODY GROUND) |

-

Disconnect the N3 fuel pump ECU connector.

-

Disconnect the A38 ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection Condition Specified Condition N13-5 (FPC) - A38-52 (FPC) Always Below 1 ? N13-4 (DI) - A38-18 (DI) Always Below 1 ? N13-6 (E) - Body ground Always Below 1 ? N13-1 (FP-) - Body ground Always 10 k? or higher N13-5 (FPC) or A38-52 (FPC) - Body ground Always 10 k? or higher N13-4 (DI) or A38-18 (DI) - Body ground Always 10 k? or higher

|

|

||||

| OK | |

| 4.REPLACE FUEL PUMP ECU |

-

Replace the fuel pump ECU .

| NEXT | |

| 5.CONFIRM WHETHER DTC OUTPUT RECURS |

-

Check that there are 17 liters or more of fuel remaining.

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the tester on.

-

Clear DTCs .

-

Crank the engine for 15 seconds.

-

Idle the engine for 1 minute.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read the DTCs.

Result Result Proceed to DTC is not output A DTC P0230 is output B

|

|

||||

| A | |

|

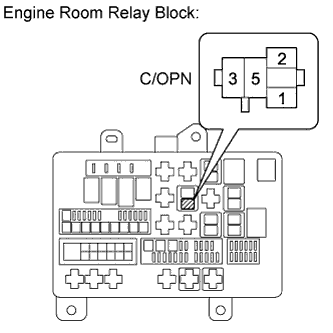

| 6.INSPECT CIRCUIT OPENING RELAY (C/OPN) |

-

Inspect the circuit opening relay (C/OPN) .

|

|

||||

| OK | |

| 7.INSPECT CIRCUIT OPENING RELAY (POWER SOURCE VOLTAGE) |

-

Remove the circuit opening relay (C/OPN) from the engine room relay block.

-

Turn the engine switch on (IG).

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage:

Tester Connection Switch Condition Specified Condition C/OPN relay (2) - Body ground Engine switch on (IG) 11 to 14 V C/OPN relay (5) - Body ground Engine switch on (IG) 11 to 14 V

|

|

||||

| OK | |

| 8.CHECK HARNESS AND CONNECTOR (CIRCUIT OPENING RELAY (C/OPN) - ECM, FUEL PUMP ECU) |

-

Remove the circuit opening relay (C/OPN) from the engine room relay block.

-

Disconnect the A38 ECM connector.

-

Disconnect the N13 fuel pump ECU connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection Condition Specified Condition C/OPN relay (1) - A38-48 (FC) Always Below 1 ? C/OPN relay (3) - N13-3 (+B) Always Below 1 ? C/OPN relay (1) or A38-48 (FC) - Body ground Always 10 k? or higher C/OPN relay (3) or N13-3 (+B) - Body ground Always 10 k? or higher

|

|

||||

| OK | |

| 9.CHECK HARNESS AND CONNECTOR (FUEL PUMP - FUEL PUMP ECU) |

-

Disconnect the N1 fuel pump connector.

-

Disconnect the N13 fuel pump ECU connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection Condition Specified Condition N1-4 (B2) - N13-2 (FP) Always Below 1 ? N1-5 (E2) - N13-1 (FP-) Always Below 1 ? N1-4 (B2) or N13-2 (FP) - Body ground Always 10 k? or higher N1-5 (E2) or N13-1 (FP-) - Body ground Always 10 k? or higher

|

|

||||

| OK | |

| 10.INSPECT FUEL PUMP |

-

Inspect the fuel pump .

|

|

||||

| OK | |

| 11.CHECK HARNESS AND CONNECTOR (FUEL PUMP ECU - ECM, BODY GROUND) |

-

Disconnect the N13 fuel pump ECU connector.

-

Disconnect the A38 ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection Condition Specified Condition N13-5 (FPC) - A38-52 (FPC) Always Below 1 ? N13-4 (DI) - A38-18 (DI) Always Below 1 ? N13-6 (E) - Body ground Always Below 1 ? N13-5 (FPC) or A38-52 (FPC) - Body ground Always 10 k? or higher N13-4 (DI) or A38-18 (DI) - Body ground Always 10 k? or higher

|

|

||||

| OK | |

| 12.REPLACE FUEL PUMP ECU |

-

Replace the fuel pump ECU .

| NEXT | |

| 13.CONFIRM WHETHER DTC OUTPUT RECURS |

-

Check that there is 17 liters or more of fuel remaining.

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the tester on.

-

Clear DTCs .

-

Crank the engine for 15 seconds.

-

Idle the engine for 1 minute.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read the DTCs.

Result Result Proceed to DTC is not output A DTC P0230 is output B

|

|

||||

| A | |

|

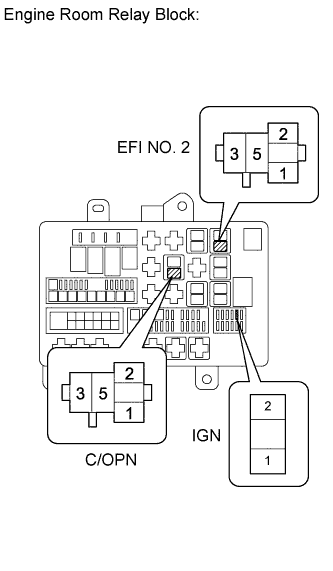

| 14.CHECK HARNESS AND CONNECTOR (C/OPN RELAY - EFI NO. 2 RELAY, IGN FUSE) |

-

Remove the circuit opening relay (C/OPN) from the engine room relay block.

-

Remove the EFI NO. 2 relay (EFI NO. 2) from the engine room relay block.

-

Remove the IGN fuse from the engine room relay block.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection Condition Specified Condition C/OPN relay (2) - IGN fuse (2) Always Below 1 ? C/OPN relay (5) - EFI NO. 2 relay (3) Always Below 1 ? C/OPN relay (2) or IGN fuse (2) - Body ground Always 10 k? or higher C/OPN relay (5) or EFI NO. 2 relay (3) - Body ground Always 10 k? or higher

|

|

||||

| OK | |

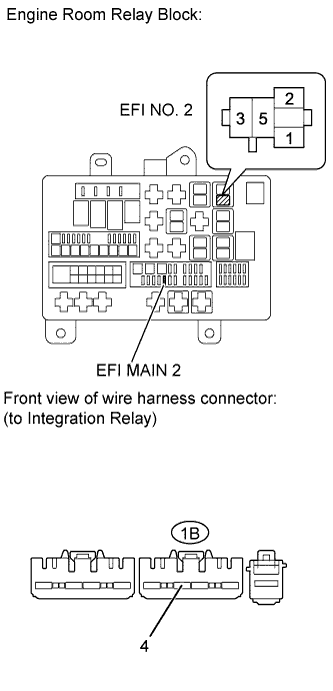

| 15.INSPECT EFI NO. 2 RELAY (EFI NO. 2) |

-

Inspect the EFI NO. 2 relay (EFI NO. 2) .

|

|

||||

| OK | |

| 16.CHECK HARNESS AND CONNECTOR (EFI NO. 2 RELAY - INTEGRATION RELAY, BATTERY, BODY GROUND) |

-

Remove the EFI MAIN 2 fuse from the engine room relay block.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection Condition Specified Condition EFI MAIN 2 fuse Always Below 1 ?

-

Reinstall the EFI MAIN 2 fuse.

-

Remove the EFI NO. 2 relay (EFI NO. 2) from the engine room relay block.

-

Remove the integration relay from the engine room relay block.

-

Disconnect the 1B integration relay connector.

-

Disconnect the cable from the battery positive (+) terminal.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection Condition Specified Condition EFI NO. 2 relay (1) - 1B-4 Always Below 1 ? EFI NO. 2 relay (5) - Positive (+) battery cable Always Below 1 ? EFI NO. 2 relay (2) - Body ground Always Below 1 ? EFI NO. 2 relay (1) or 1B-4 - Body ground Always 10 k? or higher EFI NO. 2 relay (5) or Positive (+) battery cable - Body ground Always 10 k? or higher

|

|

||||

| OK | |

|