Land Cruiser Prado GRJ150 TRJ150 TRJ155 KDJ150 TRJ155 LJ150 - МЕХАНИЧЕСКАЯ ЧАСТЬ ДВИГАТЕЛЯ 5L-E

INSTALL FRONT ENGINE MOUNTING INSULATOR

INSTALL ENGINE HANGER

REMOVE ENGINE FROM ENGINE STAND

INSTALL ENGINE ASSEMBLY

INSTALL FLYWHEEL HOUSING DUST SEAL

INSTALL REAR END PLATE

INSTALL FLYWHEEL SUB-ASSEMBLY

INSTALL CLUTCH DISC ASSEMBLY

INSTALL CLUTCH COVER ASSEMBLY

INSTALL REAR NO. 1 ENGINE MOUNTING INSULATOR

INSTALL MANUAL TRANSMISSION ASSEMBLY

INSTALL PROPELLER SHAFT ASSEMBLY

INSTALL FRONT PROPELLER SHAFT ASSEMBLY

INSTALL FRONT EXHAUST PIPE ASSEMBLY

INSTALL OIL FILTER SUB-ASSEMBLY

INSTALL STARTER ASSEMBLY

CONNECT CLUTCH RELEASE CYLINDER ASSEMBLY

INSTALL VANE PUMP ASSEMBLY

CONNECT FUEL HOSE

CONNECT HEATER WATER HOSE ASSEMBLY

INSTALL WIRING HARNESS CLAMP BRACKET (for LHD)

CONNECT ENGINE WIRE

INSTALL GLOVE COMPARTMENT DOOR ASSEMBLY

INSTALL GENERATOR ASSEMBLY

CONNECT COOLER COMPRESSOR ASSEMBLY

INSTALL INTAKE PIPE ASSEMBLY

INSTALL RADIATOR ASSEMBLY

INSTALL FAN SHROUD

INSTALL NO. 2 RADIATOR HOSE

INSTALL NO. 1 RADIATOR HOSE

INSTALL RADIATOR SIDE DEFLECTOR RH

INSTALL RADIATOR SIDE DEFLECTOR LH

INSTALL UPPER FRONT BUMPER RETAINER

INSTALL FRONT BUMPER COVER

INSTALL AIR CLEANER CASE ASSEMBLY

INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

INSTALL RESONATOR WITH AIR CLEANER CAP SUB-ASSEMBLY

INSTALL NO. 1 FRONT FENDER APRON TO FRAME SEAL LH

INSTALL FRONT FENDER APRON SEAL LH

INSTALL NO. 1 FRONT FENDER APRON TO FRAME SEAL RH

INSTALL FRONT FENDER APRON SEAL RH

INSTALL REAR ENGINE UNDER COVER ASSEMBLY

INSTALL TRANSMISSION UNDER COVER

INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY

INSTALL FRONT BUMPER COVER LOWER

INSTALL UPPER RADIATOR SUPPORT SEAL

INSTALL COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY

INSTALL HOOD SUB-ASSEMBLY

ADJUST HOOD SUB-ASSEMBLY

INSTALL BATTERY TRAY

INSTALL BATTERY

INSTALL BATTERY HOLD DOWN CLAMP

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

ADD ENGINE OIL

ADD ENGINE COOLANT

TIGHTEN FUEL TANK CAP ASSEMBLY

BLEED AIR FROM FUEL SYSTEM

INSPECT FOR FUEL LEAK

INSPECT FOR ENGINE OIL LEAK

INSPECT FOR COOLANT LEAK

ADD MANUAL TRANSMISSION OIL

INSPECT FOR GAS LEAK

INSPECT ENGINE IDLE SPEED

INSPECT MAXIMUM ENGINE SPEED

ДВИГАТЕЛЬ В СБОРЕ - УСТАНОВКА

| 1. INSTALL FRONT ENGINE MOUNTING INSULATOR |

Install the 2 front engine mounting insulators with the 2 nuts.

- Момент затяжки:

- 46 N*m{ 469 kgf*cm, 34 ft.*lbf}

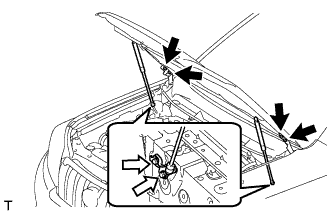

| 2. INSTALL ENGINE HANGER |

Install an engine hanger to each location shown in the illustration.

| *1 | No. 1 Engine Hanger |

| *2 | No. 2 Engine Hanger |

- УКАЗАНИЕ:

| No. 1 Engine Hanger | 12281-54080 |

| No. 2 Engine Hanger | 12282-54070 |

| Bolt (No. 1 Engine Hanger) | 90119-10736 |

| Bolt (No. 2 Engine Hanger) | 91622-61022 |

- Момент затяжки:

- for No. 1 Engine Hanger:

- 59 N*m{ 602 kgf*cm, 44 ft.*lbf}

- for No. 2 Engine Hanger:

- 37 N*m{ 377 kgf*cm, 27 ft.*lbf}

- ПРИМЕЧАНИЕ:

- Install the engine hangers with new bolts.

| 3. REMOVE ENGINE FROM ENGINE STAND |

Attach an engine sling device and hang the engine with a chain block.

Lift the engine and remove it from the engine stand.

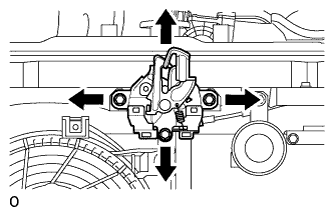

| 4. INSTALL ENGINE ASSEMBLY |

Slowly lower the engine into the engine compartment.

Install the engine with the 4 bolts and 4 nuts.

- Момент затяжки:

- 40 N*m{ 408 kgf*cm, 30 ft.*lbf}

- УКАЗАНИЕ:

- For RHD vehicles only:

- When tightening the nut closer to the rear of the vehicle for the engine mounting bracket on the right side, make sure that the claw (stopper) of the bolt does not protrude past the rear edge of the bracket.

| *1 | Claw (Stopper) |

| *2 | Bracket |

| *a | Correct |

| *b | Incorrect |

Remove the 2 bolts and 2 engine hangers.

| 5. INSTALL FLYWHEEL HOUSING DUST SEAL |

| 6. INSTALL REAR END PLATE |

Install the rear end plate with the 2 bolts.

- Момент затяжки:

- 27 N*m{ 275 kgf*cm, 20 ft.*lbf}

| 7. INSTALL FLYWHEEL SUB-ASSEMBLY |

Using SST, hold the crankshaft.

- SST

- 09213-54015(91651-60855)

09330-00021

Clean the bolts and bolt holes.

Apply adhesive to 2 or 3 threads of each of the bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the flywheel to the crankshaft.

Temporarily install the flywheel with the 8 bolts.

Tighten the 8 bolts uniformly in several steps in the order shown in the illustration.

- Момент затяжки:

- 123 N*m{ 1249 kgf*cm, 90 ft.*lbf}

- ПРИМЕЧАНИЕ:

- Do not start the engine for at least 1 hour after installing.

| 8. INSTALL CLUTCH DISC ASSEMBLY |

Insert SST into the clutch disc. Then insert SST (together with the clutch disc) into the flywheel to install the clutch disc.

- SST

- 09301-00110

| Flywheel Side |

- ПРИМЕЧАНИЕ:

- Be sure to install the clutch disc so that it is facing in the correct direction.

| 9. INSTALL CLUTCH COVER ASSEMBLY |

Align the matchmarks on the clutch cover and flywheel.

| *a | Matchmark |

Tighten the 6 bolts uniformly in the order shown in the illustration, starting with the bolt located near the knock pin on the top.

- SST

- 09301-00110

- Момент затяжки:

- 19 N*m{ 194 kgf*cm, 14 ft.*lbf}

- УКАЗАНИЕ:

- Move SST up and down, and right and left lightly after checking that the clutch disc assembly is in the center, and then tighten the bolts.

| 10. INSTALL REAR NO. 1 ENGINE MOUNTING INSULATOR |

Install the rear engine mounting insulator to the transmission with the 4 bolts.

- ПРИМЕЧАНИЕ:

- Perform this procedure when replacement of the engine mounting insulator is necessary.

- Момент затяжки:

- 65 N*m{ 663 kgf*cm, 48 ft.*lbf}

| 11. INSTALL MANUAL TRANSMISSION ASSEMBLY |

Install the manual transmission (See page ).

| 12. INSTALL PROPELLER SHAFT ASSEMBLY |

Совместите метки на фланце карданного вала и фланце дифференциала.

Установите карданный вал в сборе и закрепите его 4 болтами, 4 шайбами и 4 гайками.

- Момент затяжки:

- 88 N*m{ 899 kgf*cm, 65 ft.*lbf}

Нанесите метки на фланец карданного вала и фланец раздаточной коробки.

Закрепите карданный вал в сборе с помощью 4 шайб и 4 гаек.

- Момент затяжки:

- 88 N*m{ 899 kgf*cm, 65 ft.*lbf}

| 13. INSTALL FRONT PROPELLER SHAFT ASSEMBLY |

Совместите метки на вилке и фланце дифференциала.

Установите карданный вал в сборе и закрепите его 4 болтами, 4 шайбами и 4 гайками.

- Момент затяжки:

- 88 N*m{ 899 kgf*cm, 65 ft.*lbf}

Совместите метки на вилке и фланце раздаточной коробки.

Закрепите карданный вал в сборе с помощью 4 шайб и 4 гаек.

- Момент затяжки:

- 88 N*m{ 899 kgf*cm, 65 ft.*lbf}

| 14. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Install a new gasket and the front exhaust pipe to the exhaust manifold with 3 new nuts.

- Момент затяжки:

- 54 N*m{ 554 kgf*cm, 40 ft.*lbf}

Install the No. 1 exhaust pipe support bracket with the 2 bolts.

- Момент затяжки:

- 71 N*m{ 724 kgf*cm, 52 ft.*lbf}

Install the clamp with the bolt.

- Момент затяжки:

- 19 N*m{ 194 kgf*cm, 14 ft.*lbf}

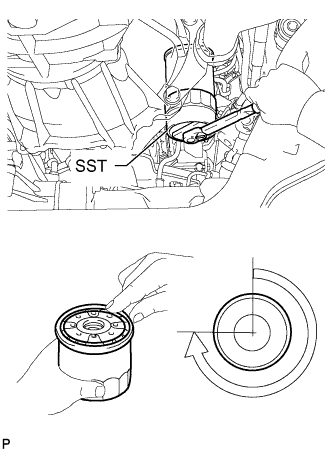

| 15. INSTALL OIL FILTER SUB-ASSEMBLY |

Check and clean the oil filter installation surface.

Apply clean engine oil to the gasket of a new oil filter.

Install the oil filter and tighten it by hand until the gasket contacts the installation surface.

Using SST, tighten the oil filter. Choose from the following to further tighten the oil filter.

- SST

- 09228-44011

Using a torque wrench, tighten the oil filter.

- Момент затяжки:

- 17 N*m{ 173 kgf*cm, 13 ft.*lbf}

Tighten the oil filter a 3/4 turn by hand or with a common wrench.

| 3/4 turn |

| 16. INSTALL STARTER ASSEMBLY |

Install the starter with the 2 bolts and nut.

- Момент затяжки:

- 68 N*m{ 693 kgf*cm, 50 ft.*lbf}

Connect the starter wire with the nut.

- Момент затяжки:

- 9.8 N*m{ 100 kgf*cm, 87 in.*lbf}

Install the terminal cap.

Connect the starter connector.

| 17. CONNECT CLUTCH RELEASE CYLINDER ASSEMBLY |

Connect the release cylinder with the 2 bolts.

- Момент затяжки:

- 12 N*m{ 120 kgf*cm, 9 ft.*lbf}

| 18. INSTALL VANE PUMP ASSEMBLY |

Temporarily install the vane pump with the 2 bolts and nut.

Install the pulley to the pump shaft.

Using SST, hold the pulley and install the nut.

- SST

- 09960-10010(09962-01000,09963-01000)

- Момент затяжки:

- 43 N*m{ 443 kgf*cm, 31 ft.*lbf}

| 19. CONNECT FUEL HOSE |

Connect the 2 fuel hoses.

| 20. CONNECT HEATER WATER HOSE ASSEMBLY |

Connect the 2 water hoses.

Install the heater water hose clamp with the bolt.

- Момент затяжки:

- 14 N*m{ 138 kgf*cm, 10 ft.*lbf}

| 21. INSTALL WIRING HARNESS CLAMP BRACKET (for LHD) |

Install the wiring harness clamp bracket with the bolt.

- Момент затяжки:

- 22 N*m{ 219 kgf*cm, 16 ft.*lbf}

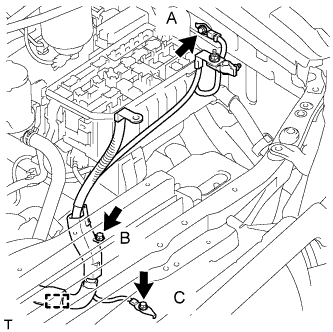

| 22. CONNECT ENGINE WIRE |

Connect the ECM connector.

Attach the grommet to the wire harness support.

| *1 | Grommet |

| *2 | Wire Harness Support |

Pass the wire harness into the vehicle and install the wire harness support.

Connect the 5 ECM connectors and attach the clamp.

| *A | for LHD |

| *B | for RHD |

for LHD:

Connect the 4 wire harness clamps.

Attach the 2 clamps and connect the connector.

Attach the 2 claws and install the nut.

- Момент затяжки:

- 11 N*m{ 112 kgf*cm, 8 ft.*lbf}

Install the No. 1 relay block cover.

Attach the clamp and install the 3 bolts.

- Момент затяжки:

- for bolt A:

- 8.5 N*m{ 87 kgf*cm, 75 in.*lbf}

- for bolt B:

- 8.0 N*m{ 82 kgf*cm, 71 in.*lbf}

- for bolt C:

- 19 N*m{ 194 kgf*cm, 14 ft.*lbf}

| 23. INSTALL GLOVE COMPARTMENT DOOR ASSEMBLY |

Install the glove compartment door (See page ).

| 24. INSTALL GENERATOR ASSEMBLY |

Temporarily install the generator with the 2 bolts.

Connect the vacuum pump oil outlet hose.

Install 2 new gaskets and the vacuum pump oil inlet hose with the union bolt.

- Момент затяжки:

- 14 N*m{ 140 kgf*cm, 10 ft.*lbf}

Connect the vacuum pump hose.

Attach the vacuum pump oil inlet hose to the cord clip.

Install the generator wire with the nut.

- Момент затяжки:

- 9.8 N*m{ 100 kgf*cm, 87 in.*lbf}

Install the terminal cap.

Connect the generator connector.

| 25. CONNECT COOLER COMPRESSOR ASSEMBLY |

Temporarily install the cooler compressor with the 2 bolts.

Temporarily install the idle pulley bracket with the 4 bolts.

Tighten the 6 bolts in the sequence shown in the illustration.

- Момент затяжки:

- for bolt A:

- 45 N*m{ 459 kgf*cm, 33 ft.*lbf}

- except bolt A:

- 25 N*m{ 250 kgf*cm, 18 ft.*lbf}

Connect the wire harness with the bolt.

- Момент затяжки:

- 13 N*m{ 131 kgf*cm, 9 ft.*lbf}

Connect the cooler compressor connector.

| 26. INSTALL INTAKE PIPE ASSEMBLY |

Install the intake pipe with the 2 bolts.

- Момент затяжки:

- 18 N*m{ 184 kgf*cm, 13 ft.*lbf}

Tighten the intake pipe clamp.

- Момент затяжки:

- 6.0 N*m{ 61 kgf*cm, 53 in.*lbf}

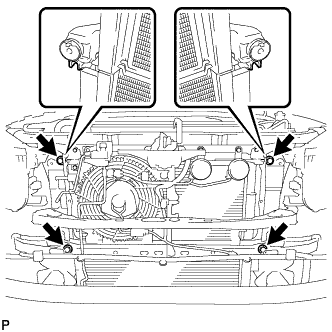

| 27. INSTALL RADIATOR ASSEMBLY |

Insert the tabs of the radiator support into the radiator service holes.

Install the radiator with the 4 bolts.

- Момент затяжки:

- 18 N*m{ 184 kgf*cm, 13 ft.*lbf}

| 28. INSTALL FAN SHROUD |

Install the fan pulley to the water pump.

Install the shroud together with the coupling fan between the radiator and engine.

- ПРИМЕЧАНИЕ:

- Be careful not to damage the radiator core.

Temporarily install the fluid coupling fan to the fan pulley with the 4 nuts. Tighten the nuts as much as possible by hand.

Attach the claws of the shroud as shown in the illustration.

Install the shroud with the 2 bolts.

- Момент затяжки:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

Install the fan and generator V belt and vane pump V belt (See page ).

Tighten the 4 nuts of the fluid coupling fan.

- Момент затяжки:

- 19 N*m{ 189 kgf*cm, 14 ft.*lbf}

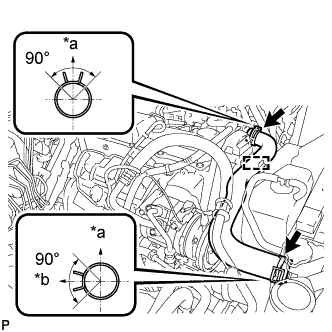

| 29. INSTALL NO. 2 RADIATOR HOSE |

Install the radiator hose.

| *a | Upper |

| *b | Front Side of Vehicle |

| *c | LH Side |

| *1 | Protrusion |

| *2 | Paint Mark |

- УКАЗАНИЕ:

- Position the hose clamps as shown in the illustration.

| 30. INSTALL NO. 1 RADIATOR HOSE |

Install the hose clamp with the 2 nuts.

- Момент затяжки:

- 8.5 N*m{ 87 kgf*cm, 75 in.*lbf}

Install the radiator hose.

| *a | Upper |

| *b | RH Side |

- УКАЗАНИЕ:

- Position the hose clamps as shown in the illustration.

| 31. INSTALL RADIATOR SIDE DEFLECTOR RH |

Attach the 3 claws.

Install the deflector with the clip.

| 32. INSTALL RADIATOR SIDE DEFLECTOR LH |

Attach the 3 claws.

Install the deflector with the clip.

| 33. INSTALL UPPER FRONT BUMPER RETAINER |

Install the upper retainer with the 3 bolts.

- Момент затяжки:

- 8.0 N*m{ 82 kgf*cm, 71 in.*lbf}

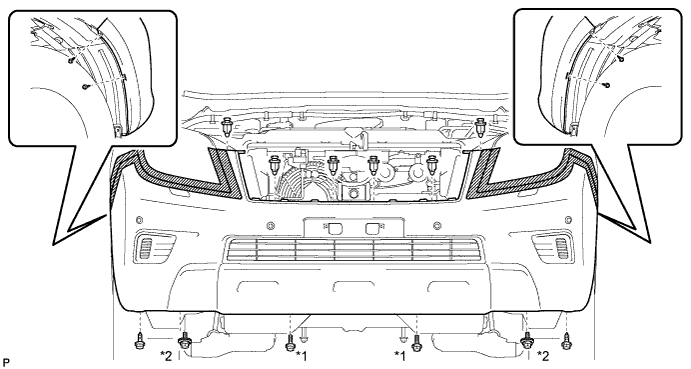

| 34. INSTALL FRONT BUMPER COVER |

Для моделей с сенсорной системой помощи при парковке TOYOTA и противотуманными фарами:

Подсоедините 3 разъема.

Для моделей с сенсорной системой помощи при парковке TOYOTA без противотуманных фар:

Подсоедините 2 разъема.

Для моделей без сенсорной системы помощи при парковке TOYOTA и с противотуманными фарами:

Подсоедините разъем.

Для моделей с системой очистителей фар:

Подсоедините шланг очистителя фар.

Закрепите 12 захватов, чтобы установить накладку переднего бампера.

Вверните 2 болта A, 2 болта B, 6 винтов и 6 фиксаторов.

- Момент затяжки:

- Болт A:

- 8,0 N*m{ 82 kgf*cm, 71 in.*lbf}

| *1 | Болт A | *2 | Болт B |

| 35. INSTALL AIR CLEANER CASE ASSEMBLY |

Install the air cleaner case with the 3 bolts.

- Момент затяжки:

- 12 N*m{ 122 kgf*cm, 9 ft.*lbf}

| 36. INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

| 37. INSTALL RESONATOR WITH AIR CLEANER CAP SUB-ASSEMBLY |

Вставьте петли крышки воздушного фильтра и шланг в корпус воздушного фильтра, а затем закрепите 4 откидных защелки.

Установите крышку воздушного фильтра и закрепите ее зажимом.

- Момент затяжки:

- 5,0 N*m{ 51 kgf*cm, 44 in.*lbf}

Закрепите зажим жгута проводов.

Подсоедините 2 зажима и разъем.

| 38. INSTALL NO. 1 FRONT FENDER APRON TO FRAME SEAL LH |

Install the No. 1 front fender apron to frame seal with the 5 clips.

| 39. INSTALL FRONT FENDER APRON SEAL LH |

Install the front fender apron seal with the 5 clips.

| 40. INSTALL NO. 1 FRONT FENDER APRON TO FRAME SEAL RH |

Install the No. 1 front fender apron to frame seal with the 5 clips.

| 41. INSTALL FRONT FENDER APRON SEAL RH |

Install the front fender apron seal with the 4 clips.

| 42. INSTALL REAR ENGINE UNDER COVER ASSEMBLY |

Install the rear engine under cover with the 4 bolts.

- Момент затяжки:

- 29 N*m{ 296 kgf*cm, 21 ft.*lbf}

| 43. INSTALL TRANSMISSION UNDER COVER |

Install the transmission under cover with the 2 bolts.

- Момент затяжки:

- 29 N*m{ 296 kgf*cm, 21 ft.*lbf}

| 44. INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY |

Hook the engine under cover to the vehicle body as shown in the illustration.

Install the 4 bolts.

- Момент затяжки:

- 29 N*m{ 296 kgf*cm, 21 ft.*lbf}

| 45. INSTALL FRONT BUMPER COVER LOWER |

Install the front bumper cover lower with the 5 bolts and clip.

- Момент затяжки:

- 8.0 N*m{ 82 kgf*cm, 71 in.*lbf}

| 46. INSTALL UPPER RADIATOR SUPPORT SEAL |

Установите верхнее уплотнение кронштейна радиатора и закрепите его 13 фиксаторами.

| 47. INSTALL COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY |

Install the cowl top ventilator louver (See page ).

| 48. INSTALL HOOD SUB-ASSEMBLY |

Install the hood with the 8 bolts.

- Момент затяжки:

- for bolt A:

- 13 N*m{ 133 kgf*cm, 10 ft.*lbf}

- for bolt B:

- 18 N*m{ 184 kgf*cm, 13 ft.*lbf}

| Bolt A |

| Bolt B |

Connect the washer nozzle hose.

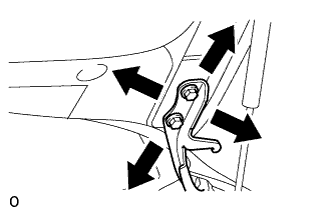

| 49. ADJUST HOOD SUB-ASSEMBLY |

Отрегулируйте положение капота.

Ослабьте 4 болта петель капота.

Для регулировки зазора между капотом и передним крылом подвиньте капот.

Затяните 4 болта петель капота.

- Момент затяжки:

- 13 N*m{ 133 kgf*cm, 10 ft.*lbf}

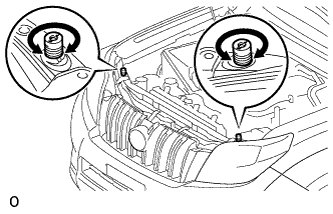

Отрегулируйте высоту передней части капота с помощью резиновых амортизаторов.

Отрегулируйте 2 резиновых амортизатора таким образом, чтобы капот и крыло оказались на одном уровне.

- УКАЗАНИЕ:

- Отрегулируйте высоту передней части капота, поворачивая 2 резиновых амортизатора.

Отрегулируйте замок капота.

Ослабьте 3 болта.

Отрегулируйте замок капота и затяните 3 болта.

- Момент затяжки:

- 7,5 N*m{ 76 kgf*cm, 66 in.*lbf}

Убедитесь, что защелка плавно входит в зацепление с замком капота.

| 50. INSTALL BATTERY TRAY |

| 51. INSTALL BATTERY |

| 52. INSTALL BATTERY HOLD DOWN CLAMP |

Install the battery hold down clamp with the 2 nuts.

- Момент затяжки:

- 6.0 N*m{ 61 kgf*cm, 53 in.*lbf}

Connect the engine wire with the nut labeled A.

- Момент затяжки:

- 7.5 N*m{ 76 kgf*cm, 66 in.*lbf}

| 53. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- ПРИМЕЧАНИЕ:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (See page ).

| 54. ADD ENGINE OIL |

Add fresh engine oil.

- Standard Engine Oil:

Oil Grade Oil Viscosity (SAE) API CF-4 or CF 10W-30

- Standard Capacity:

Item Specified Condition Drain and refill without oil filter change 6.0 liters (6.3 US qts, 5.3 Imp. qts) Drain and refill with oil filter change 6.9 liters (7.3 US qts, 6.1 Imp. qts) Dry fill 7.6 liters (8.0 US qts, 6.7 Imp. qts)

Install the oil filler cap.

| 55. ADD ENGINE COOLANT |

Затяните пробку сливного крана радиатора вручную.

Затяните пробку сливного крана блока цилиндров.

- Момент затяжки:

- 13 N*m{ 130 kgf*cm, 9 ft.*lbf}

Медленно заполните систему охлаждающей жидкостью двигателя.

- Номинальный объем:

- 8,6 литра (9,0 кварты США, 7,6 английской кварты)

- ПРИМЕЧАНИЕ:

- Не доливайте простую воду вместо охлаждающей жидкости двигателя.

- УКАЗАНИЕ:

Медленно залейте охлаждающую жидкость в расширительный бачок радиатора до отметки "FULL".

Установите пробку расширительного бачка.

Несколько раз сожмите рукой патрубки радиатора № 1 и № 2, а затем проверьте уровень охлаждающей жидкости. Если уровень охлаждающей жидкости недостаточен, добавьте жидкость.

Установите на место пробку радиатора.

Запустите двигатель и прогрейте его до открывания термостата.

- УКАЗАНИЕ:

- Время открывания термостата можно распознать, сжав шланг радиатора № 2 рукой и отметив момент, когда охлаждающая жидкость двигателя начнет поступать в шланг.

Поддерживайте частоту вращения коленчатого вала двигателя 2000–2500 об/мин.

- ПРИМЕЧАНИЕ:

Несколько раз сожмите патрубки радиатора № 1 и № 2 рукой, чтобы удалить воздух.

- ПРЕДОСТЕРЕЖЕНИЕ:

Остановите двигатель и подождите, пока охлаждающая жидкость остынет до температуры окружающего воздуха.

- ПРЕДОСТЕРЕЖЕНИЕ:

- Не снимайте пробку радиатора, пока двигатель и радиатор не остынут. Выброс горячей охлаждающей жидкости и пара под давлением может стать причиной серьезных ожогов.

Убедитесь, что уровень охлаждающей жидкости находится между отметками "LOW" и "FULL".

Если уровень охлаждающей жидкости ниже линии "Low", повторите все вышеперечисленные действия.

Если уровень охлаждающей жидкости выше уровня "FULL", слейте охлаждающую жидкость до уровня между отметками "FULL" и "LOW".

| 56. TIGHTEN FUEL TANK CAP ASSEMBLY |

| 57. BLEED AIR FROM FUEL SYSTEM |

Using the hand pump mounted on the fuel filter cap, bleed the air from the fuel system. Continue pumping until the pump resistance increases.

| 58. INSPECT FOR FUEL LEAK |

Check that there are no fuel leaks anywhere in the fuel system after performing maintenance.

- УКАЗАНИЕ:

- When checking for fuel leaks, make sure that there is pressure in the fuel line.

| 59. INSPECT FOR ENGINE OIL LEAK |

Start the engine. Make sure that there are no oil leaks from the areas that were worked on.

| 60. INSPECT FOR COOLANT LEAK |

- ПРЕДОСТЕРЕЖЕНИЕ:

- To avoid being burned, do not remove the radiator reservoir cap while the engine and radiator are still hot. Thermal expansion may cause hot engine coolant and steam to blow out from the radiator.

Fill the radiator with coolant and attach a radiator cap tester to the radiator.

Warm up the engine.

Using a radiator cap tester, increase the pressure inside the radiator to 123 kPa (1.3 kgf/cm2, 18 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator or water pump for leaks. If no external leaks are found, check the heater core, cylinder block, and cylinder head.

| 61. ADD MANUAL TRANSMISSION OIL |

| 62. INSPECT FOR GAS LEAK |

| 63. INSPECT ENGINE IDLE SPEED |

Warm up the engine.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

- Idle speed:

- 720 to 820 rpm

- ПРИМЕЧАНИЕ:

- УКАЗАНИЕ:

- Refer to the intelligent tester operator's manual for further details.

When not using an intelligent tester:

Using SST, connect the tachometer test probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

Check the idle speed.

- Standard idle speed:

- 720 to 820 rpm

| *a | Front View of DLC3 |

- ПРИМЕЧАНИЕ:

| 64. INSPECT MAXIMUM ENGINE SPEED |

Start the engine.

Fully depress the accelerator pedal.

Check the maximum speed.

- Maximum engine speed:

- 4850 to 4950 rpm