Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - LIGHTING EXT

HEADLIGHT ASSEMBLY (for Halogen Headlight) - ADJUSTMENT

- HINT:

| 1. VEHICLE PREPARATION FOR HEADLIGHT AIMING ADJUSTMENT |

Prepare the vehicle:

- HINT:

| 2. PREPARATION FOR HEADLIGHT AIMING (Using a screen) |

Prepare the vehicle.

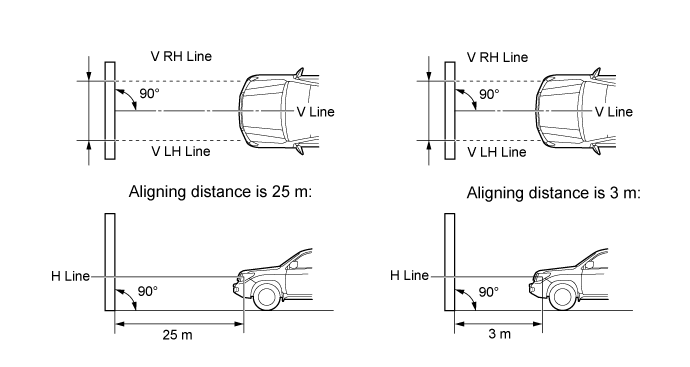

| *a | 90° |

| *b | 25 m or 3 m |

- NOTICE:

- A distance of 25 m (82 ft.) between the vehicle (headlight bulb center) and the wall is necessary for proper aim adjustment. If unavailable, secure a distance of exactly 3 m (9.84 ft.) for the check and adjustment. (The target zone will change with the distance, so follow the instructions in the illustration).

Prepare a piece of thick white paper approximately 2 m (6.56 ft.) (height) x 4 m (13.1 ft.) (width) to use as a screen.

Draw a vertical line down the center of the screen (V line).

Set the screen as shown in the illustration.

- HINT:

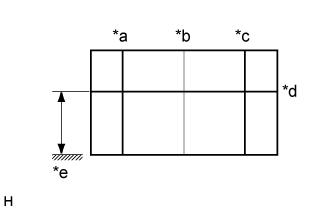

Draw base lines (H, V LH, and V RH lines) on the screen as shown in the illustration.

| *a | V LH Line |

| *b | V Line |

| *c | V RH Line |

| *d | H Line |

| *e | Ground |

- HINT:

H Line (Headlight height):

Draw a horizontal line across the screen so that it passes through the center marks. The H line should be at the same height as the headlight bulb center marks of the low beam headlights.

V LH Line, V RH Line (Center mark position of the left-hand (LH) and right-hand (RH) headlights):

Draw 2 vertical lines so that they intersect the H line at each center mark (aligned with the center of the low beam headlight bulbs).

| 3. INSPECT HEADLIGHT AIMING |

Cover the headlight or disconnect the connector of the headlight on the opposite side to prevent light from the headlight that is not being inspected from affecting the headlight aiming.

- NOTICE:

- Do not keep the headlight covered for more than 3 minutes. The headlight lens is made of synthetic resin, which may melt or be damaged due to excessive heat.

- HINT:

- When checking the aim of the high beam headlight, cover the low beam headlight or disconnect the connector.

Start the engine.

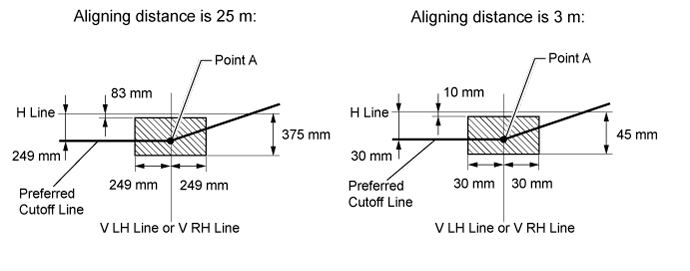

Turn on the headlight and check if the cutoff line matches the preferred cutoff line in the following illustration.

- HINT:

The low beam cutoff line should be within 83 mm (3.27 in.) and 375 mm (14.8 in.) below the H line as well as 249 mm (9.80 in.) left or right of the V LH or V RH line.

The low beam cutoff line should be within 10 mm (0.394 in.) and 45 mm (1.77 in.) below the H line as well as 30 mm (1.18 in.) left or right of the V LH or V RH line.

The horizontal line of the preferred low beam cutoff line is 249 mm (9.80 in.) below the H line and point A of the preferred low beam cutoff line is on the V LH or V RH line.

The horizontal line of the preferred low beam cutoff line is 30 mm (1.18 in.) below the H line and point A of the preferred low beam cutoff line is on the V LH or V RH line.

Turn on the high beams and check if the center of intensity for each high beam matches the center of intensity in the illustration.

- HINT:

The high beam center of intensity should be within 175 mm (6.88 in.) above and 249 mm (9.80 in.) below the H line as well as 497 mm (1.63 ft.) left or right of the V LH or V RH line.

The high beam center of intensity should be within 21 mm (0.82 in.) above and 30 mm (1.18 in.) below the H line as well as 60 mm (2.36 in.) left or right of the V LH or V RH line.

| 4. ADJUSTMENT HEADLIGHT AIMING |

Headlight low beam.

Using a screwdriver, adjust the aim.

| *A | w/ Projector | *B | w/o Projector |

| *1 | Vertical Aiming Screw | *2 | Horizontal Aiming Screw |

| *3 | Screwdriver | - | - |

Adjust the aim of each headlight so that it is within the specified range by turning each aiming screw with a screwdriver.

- NOTICE:

- The final turn of the aiming screw should be made in the clockwise direction. If the screw is tightened excessively, loosen it and then retighten it, so that the final turn of the screw is in the clockwise direction.

- HINT:

Headlight high beam.

Using a screwdriver, adjust the aim.

| *A | w/ Projector | *B | w/o Projector |

| *1 | Vertical Aiming Screw | *2 | Horizontal Aiming Screw |

| *3 | Screwdriver | - | - |

Adjust the aim of each headlight so that it is within the specified range by turning each aiming screw with a screwdriver.

- NOTICE:

- The final turn of the aiming screw should be made in the clockwise direction. If the screw is tightened excessively, loosen it and then retighten it, so that the final turn of the screw is in the clockwise direction.

- HINT: