Lighting System - Headlight Beam Level Control Actuator Circuit

DESCRIPTION

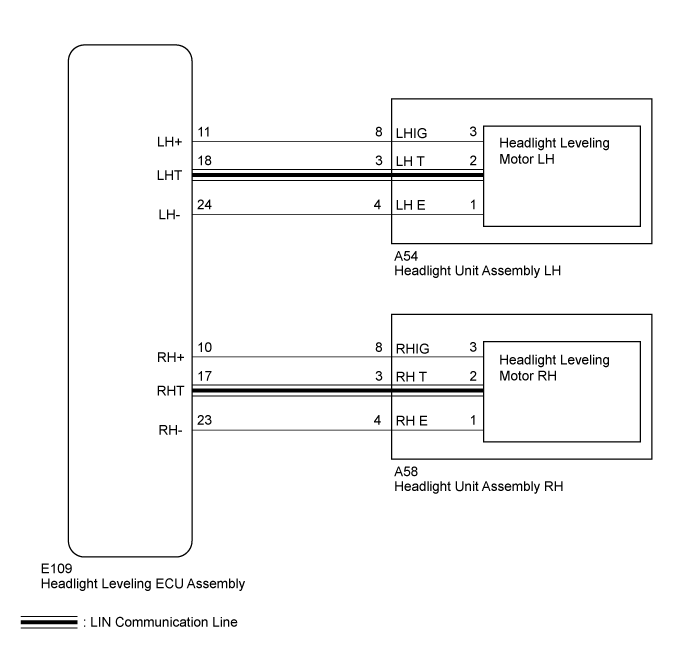

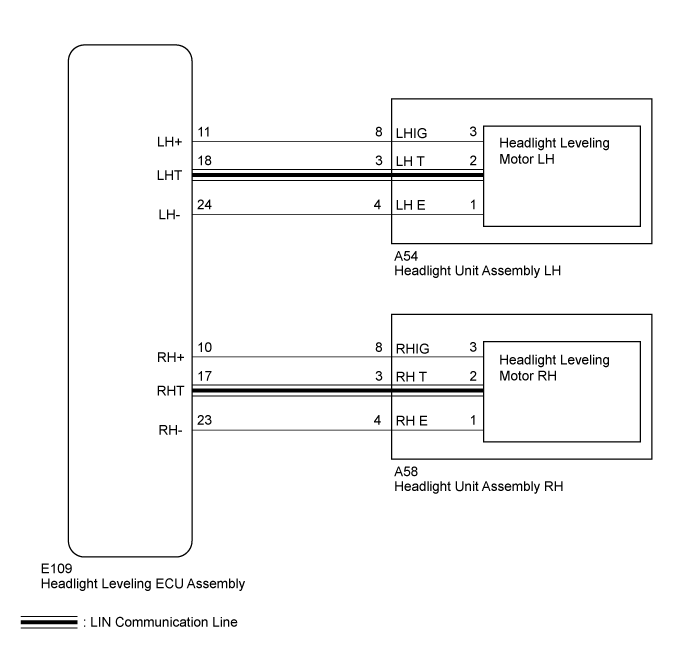

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (HEADLIGHT LEVELING MOTOR)

CHECK HARNESS AND CONNECTOR (HEADLIGHT UNIT ASSEMBLY - HEADLIGHT LEVELING ECU ASSEMBLY)

INSPECT HEADLIGHT UNIT ASSEMBLY

CHECK HEADLIGHT LEVELING MOTOR

LIGHTING SYSTEM - Headlight Beam Level Control Actuator Circuit

DESCRIPTION

The headlight leveling ECU actuates the headlight leveling motors according to the vehicle conditions.

WIRING DIAGRAM

INSPECTION PROCEDURE

- After replacing the headlight leveling ECU, initialization of the ECU is necessary ().

| 1.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (HEADLIGHT LEVELING MOTOR) |

Using the intelligent tester, perform the Active Test ().

HL Auto Leveling| Tester Display | Test Part | Control Range | Diagnostic Note |

| Drive The Leveling Motor UP* | Headlight leveling motor upward operation | ON/OFF | ON: Move up

OFF: Stop |

| Drive The Leveling Motor DOWN* | Headlight leveling motor downward operation | ON/OFF | ON: Move down

OFF: Stop |

*: Perform the Active Test with the engine running and vehicle stopped.

- OK:

- Headlight leveling motors operate normally.

| OK | |

| |

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE ()

|

|

| 2.CHECK HARNESS AND CONNECTOR (HEADLIGHT UNIT ASSEMBLY - HEADLIGHT LEVELING ECU ASSEMBLY) |

Disconnect the E109 headlight leveling ECU connector.

Disconnect the A54*1 or A58*2 headlight leveling motor connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LH| Tester Connection | Condition | Specified Condition |

| E109-11 (LH+) - A54-8 (LHIG) | Always | Below 1 Ω |

| E109-18 (LHT) - A54-3 (LH T) | Always | Below 1 Ω |

| E109-24 (LH-) - A54-4 (LH E) | Always | Below 1 Ω |

| E109-11 (LH+) - Body ground | Always | 10 kΩ or higher |

| E109-18 (LHT) - Body ground | Always | 10 kΩ or higher |

| E109-24 (LH-) - Body ground | Always | 10 kΩ or higher |

for RH| Tester Connection | Condition | Specified Condition |

| E109-10 (RH+) - A58-8 (RHIG) | Always | Below 1 Ω |

| E109-17 (RHT) - A58-3 (RH T) | Always | Below 1 Ω |

| E109-23 (RH-) - A58-4 (RH E) | Always | Below 1 Ω |

| E109-10 (RH+) - Body ground | Always | 10 kΩ or higher |

| E109-17 (RHT) - Body ground | Always | 10 kΩ or higher |

| E109-23 (RH-) - Body ground | Always | 10 kΩ or higher |

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 3.INSPECT HEADLIGHT UNIT ASSEMBLY |

Remove the headlight unit ().

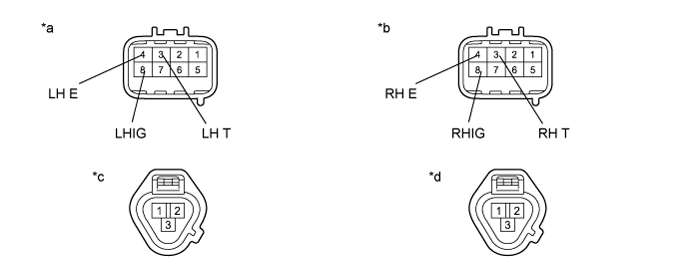

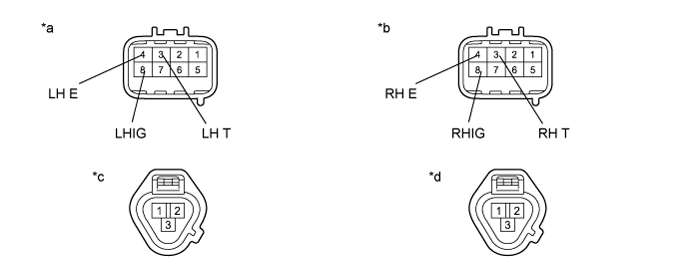

Text in Illustration| *a | Component without harness connected

(Headlight Unit Assembly LH) | *b | Component without harness connected

(Headlight Unit Assembly RH) |

| *c | Front view of wire harness connector

(to Headlight Leveling Motor LH) | *d | Front view of wire harness connector

(to Headlight Leveling Motor RH) |

Disconnect the headlight leveling motor connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

- for LH:

| Tester Connection | Condition | Specified Condition |

| 8 (LHIG) - 3 | Always | Below 1 Ω |

| 3 (LH T) - 2 |

| 4 (LH E) - 1 |

- for RH:

| Tester Connection | Condition | Specified Condition |

| 8 (RHIG) - 3 | Always | Below 1 Ω |

| 3 (RH T) - 2 |

| 4 (RH E) - 1 |

| | REPLACE HEADLIGHT UNIT ASSEMBLY ()

|

|

|

| 4.CHECK HEADLIGHT LEVELING MOTOR |

Temporarily replace the headlight leveling motor with a new or normally functioning one ().

Perform the Active Test of the leveling motors ().

- OK:

- Headlight leveling motors operate normally.

Result| Result | Proceed to |

| OK | A |

| NG (for LHD) | B |

| NG (for RHD) | C |

| | REPLACE HEADLIGHT LEVELING ECU ASSEMBLY ()

|

|

|

| | REPLACE HEADLIGHT LEVELING ECU ASSEMBLY ()

|

|

|

| A | |

| |

| END (HEADLIGHT LEVELING MOTOR WAS DEFECTIVE) |

|