Egr Valve -- Inspection |

| 1. INSPECT ELECTRIC EGR CONTROL VALVE ASSEMBLY |

Inspect the electric EGR control valve.

Text in Illustration *1 Cap - HINT:

- Install a cap to block the other port.

When a vacuum of 27 kPa (200 mmHg, 7.88 in.Hg) is applied to the diaphragm chamber, check that the shaft rises and that air flows out.

While maintaining the above conditions, check that there are no leaks and that the shaft stays in position.

Check that the valve does not have heavy carbon deposits and is not stuck.

If the result is not as specified, replace the electric EGR control valve assembly.

|

Inspect the EGR valve position sensor.

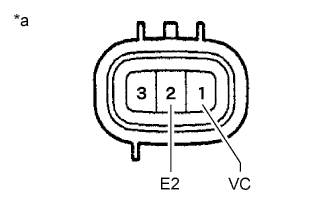

Text in Illustration *a Component without harness connected

(Electric EGR Control Valve)Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition 1 (VC) - 2 (E2) 20°C (68°F) 4.0 to 6.0 kΩ

|

Create a vacuum in the diaphragm chamber.

- HINT:

- Install a cap to block the other port.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition 3 (EGLS) - 2 (E2) 20°C (68°F)

EGR valve is fully opened4.1 kΩ 20°C (68°F)

EGR valve is fully closed0.8 kΩ

Text in Illustration *1 Cap *a Component without harness connected

(Electric EGR Control Valve)- HINT:

- The resistance increases in proportion to the opening amount of the EGR valve.

|