Dtc 22 Engine Coolant Temperature Sensor Circuit Malfunction

DESCRIPTION

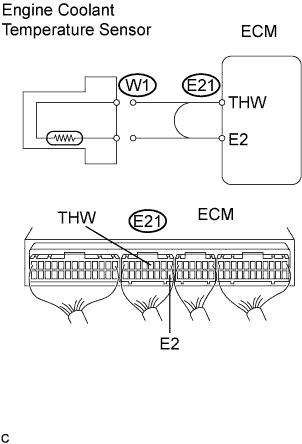

WIRING DIAGRAM

INSPECTION PROCEDURE

When using intelligent tester:

READ VALUE USING INTELLIGENT TESTER (ENGINE COOLANT TEMPERATURE)

READ VALUE USING INTELLIGENT TESTER (CHECK FOR OPEN IN WIRE HARNESS)

READ VALUE USING INTELLIGENT TESTER (CHECK FOR OPEN IN ECM)

READ VALUE USING INTELLIGENT TESTER (CHECK FOR SHORT IN WIRE HARNESS)

READ VALUE USING INTELLIGENT TESTER (CHECK FOR SHORT IN ECM)

When not using intelligent tester:

CHECK ECM (THW VOLTAGE)

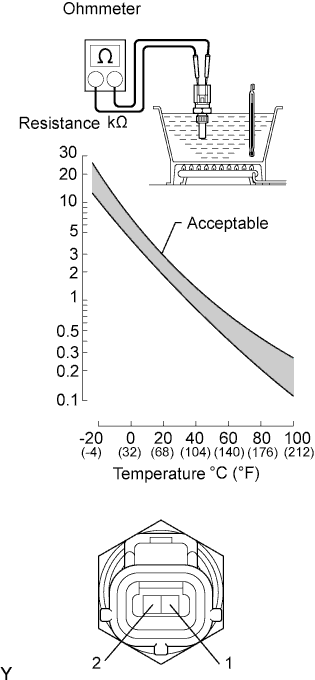

INSPECT ENGINE COOLANT TEMPERATURE SENSOR

CHECK HARNESS AND CONNECTOR (ECM - ENGINE COOLANT TEMPERATURE SENSOR)

DTC 22 Engine Coolant Temperature Sensor Circuit Malfunction |

DESCRIPTION

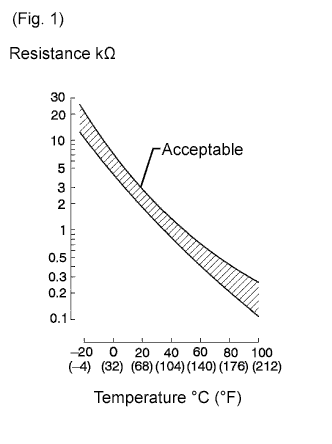

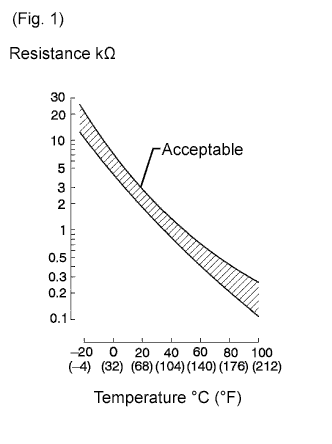

The engine coolant temperature sensor senses the coolant temperature. A thermistor built into the sensor changes the resistance value according to the coolant temperature. The lower the coolant temperature, the greater the thermistor resistance value, and the higher the coolant temperature, the lower the thermistor resistance value (see Fig. 1).The engine coolant temperature sensor is connected to the ECM. The 5 V power source voltage in the ECM is applied to the engine coolant temperature sensor from the terminal THW via resistor R. That is, the resistor R and the engine coolant temperature sensor are connected in series. When the resistance value of the engine coolant temperature sensor changes in accordance with changes in the coolant temperature, the potential at the terminal THW also changes. Based on this signal, the ECM increases the fuel injection volume to improve driveability during cold engine operation.

DTC No.

| DTC Detection Condition

| Trouble Area

|

22

| Open or short in engine coolant temperature sensor circuit for 0.5 sec. or more

| - Open or short in engine coolant temperature sensor circuit

- Engine coolant temperature sensor

- ECM

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- If DTCs that are related to different systems are output simultaneously while terminal E2 is used as a ground terminal, terminal E2 may be open.

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

When using intelligent tester:

| 1.READ VALUE USING INTELLIGENT TESTER (ENGINE COOLANT TEMPERATURE) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

- Result:

Display

| Proceed to

|

-40°C (-40°F)

| A

|

140°C (284°F) or more

| B

|

The same as actual engine coolant temperature

| C

|

- HINT:

- When DTC 22 is present, the type of malfunction can be determined based on the engine coolant temperature (see below).

Temperature Displayed

| Malfunction

|

-40°C (-40°F)

| Open circuit

|

140°C (284°F) or more

| Short circuit

|

| |

|

| | CHECK FOR INTERMITTENT PROBLEMS |

|

|

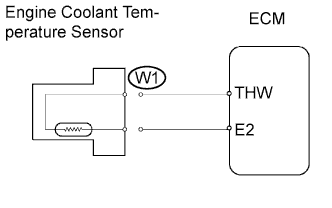

| 2.READ VALUE USING INTELLIGENT TESTER (CHECK FOR OPEN IN WIRE HARNESS) |

Disconnect the W1 engine coolant temperature sensor connector.

Connect terminals 1 and 2 of the engine coolant temperature sensor harness side connector.

Turn the ignition switch ON.

Read the temperature value on the intelligent tester.

- Temperature:

- 140°C (284°F) or more

| | REPLACE ENGINE COOLANT TEMPERATURE SENSOR |

|

|

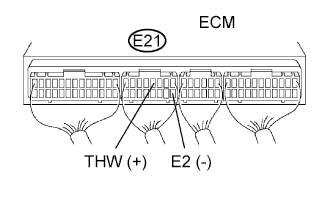

| 3.READ VALUE USING INTELLIGENT TESTER (CHECK FOR OPEN IN ECM) |

Connect between terminals THW and E2 of the ECM connector.

Turn the ignition switch ON.

Read the temperature value on the intelligent tester.

- Temperature:

- 140°C (284°F) or more

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4.READ VALUE USING INTELLIGENT TESTER (CHECK FOR SHORT IN WIRE HARNESS) |

Disconnect the W1 engine coolant temperature sensor connector.

Turn the ignition switch ON.

Read the temperature value on the intelligent tester.

- Temperature:

- -40°C (- 40°F)

| | REPLACE ENGINE COOLANT TEMPERATURE SENSOR |

|

|

| 5.READ VALUE USING INTELLIGENT TESTER (CHECK FOR SHORT IN ECM) |

Disconnect the E21 ECM connector.

Turn the ignition switch ON.

Read the temperature value on the intelligent tester.

- Temperature:

- -40°C (-40°F)

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

When not using intelligent tester:

| 1.CHECK ECM (THW VOLTAGE) |

Turn the ignition switch ON.

Measure the voltage of the ECM connector.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

E21-4 (THW) - E21-9 (E2)

| 20°C (68°F)

| 0.2 to 3.8 V

|

E21-4 (THW) - E21-9 (E2)

| 80°C (176°F)

| 0.1 to 1.5 V

|

| | CHECK FOR INTERMITTENT PROBLEMS |

|

|

| 2.INSPECT ENGINE COOLANT TEMPERATURE SENSOR |

Measure the resistance of the sensor.

- OK:

- The resistance value is within the acceptable range shown in the illustration.

- NOTICE:

- When checking the engine coolant temperature sensor in water, do not allow water to enter the terminals. After checking, wipe the sensor dry.

| | REPLACE ENGINE COOLANT TEMPERATURE SENSOR |

|

|

| 3.CHECK HARNESS AND CONNECTOR (ECM - ENGINE COOLANT TEMPERATURE SENSOR) |

Disconnect the W1 engine coolant temperature sensor connector.

Disconnect the E21 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance :

Tester Connection

| Specified Condition

|

W1-2 - E21-4 (THW)

| Below 1 Ω

|

W1-1 - E21-9 (E2)

| Below 1 Ω

|

E21-4 (THW) - E21-9 (E2)

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|