Overdrive Direct Clutch Inspection

INSPECT OVERDRIVE ONE-WAY CLUTCH

INSPECT OVERDRIVE DIRECT CLUTCH DRUM

INSPECT PISTON STROKE OF OVERDRIVE DIRECT CLUTCH

INSPECT OVERDRIVE DIRECT CLUTCH DISC

INSPECT OVERDRIVE DIRECT CLUTCH RETURN SPRING

INSPECT OVERDRIVE DIRECT CLUTCH PISTON

INSPECT OVERDRIVE PLANETARY GEAR

Overdrive Direct Clutch -- Inspection |

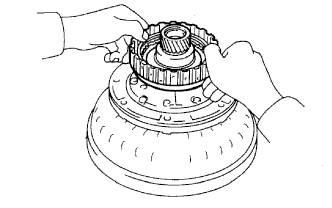

| 1. INSPECT OVERDRIVE ONE-WAY CLUTCH |

Hold the overdrive direct clutch drum, and turn the input shaft.

Check that the input shaft can be turned freely clockwise and locks when turned counterclockwise.

| 2. INSPECT OVERDRIVE DIRECT CLUTCH DRUM |

Using a dial indicator, measure the inside diameter of the clutch drum bushes.

- Maximum inside diameter:

- 27.11 mm (1.0673 in.)

If the inside diameter is more than the maximum, replace the clutch drum.

| 3. INSPECT PISTON STROKE OF OVERDRIVE DIRECT CLUTCH |

Place the oil pump onto the torque converter clutch, and then place the overdrive direct clutch drum assembly onto the oil pump.

Using SST and a dial indicator, measure the overdrive direct clutch piston stroke while applying and releasing compressed air (392 kPa (4.0 kgf/cm2, 57 psi)).

- SST

- 09350-30020(09350-06120)

- Piston stroke:

- 1.85 to 2.15 mm (0.0728 to 0.0846 in.)

If the stroke is not as specified, inspect the discs.

| 4. INSPECT OVERDRIVE DIRECT CLUTCH DISC |

Replace all discs if one of the following problems is present: 1) a disc, plate or flange is worn or burnt, 2) the lining of a disc is peeled off or discolored, or 3) grooves or printed numbers have even a little bit of damage.

- HINT:

- Before assembling new discs, soak them in ATF for at least 15 minutes.

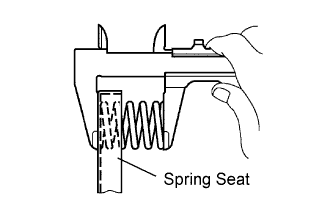

| 5. INSPECT OVERDRIVE DIRECT CLUTCH RETURN SPRING |

Using a vernier caliper, measure the free length of the spring together with the spring seat.

- Standard free length:

- 15.8 mm (0.622 in.)

If the length is not as specified, replace the spring.

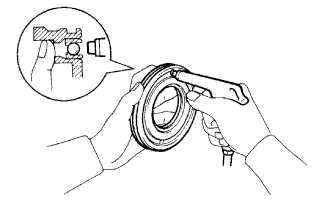

| 6. INSPECT OVERDRIVE DIRECT CLUTCH PISTON |

Check that the check ball is free by shaking the piston.

Check that the valve does not have leaks by applying low-pressure compressed air.

| 7. INSPECT OVERDRIVE PLANETARY GEAR |

Using a dial indicator, measure the inside diameter of the planetary gear bush.

- Maximum inside diameter:

- 11.27 mm (0.4437 in.)

If the inside diameter is more than the maximum, replace the planetary gear.

Using a feeler gauge, measure the planetary pinion gear thrust clearance.

- Standard clearance:

- 0.20 to 0.60 mm (0.00787 to 0.0236 in.)

- Maximum clearance:

- 0.65 mm (0.0256 in.)

If the clearance is more than the maximum, replace the planetary gear.