INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transmission)

INSTALL CHARGE AIR COOLER ASSEMBLY WITH INTAKE AIR CONNECTOR

Oil Pump -- Installation |

- NOTICE:

- When replacing the injectors (including shuffling the injectors between the cylinders), common rail or cylinder head, it is necessary to replace the injection pipes with new ones.

- When replacing the fuel supply pump, common rail, cylinder block, cylinder head, cylinder head gasket or timing gear case, it is necessary to replace the fuel inlet pipe with a new one.

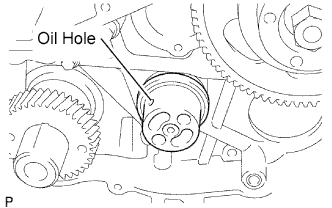

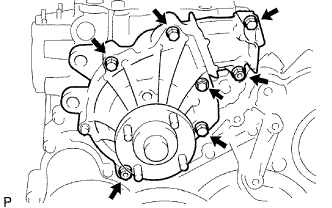

| 1. INSTALL TIMING GEAR CASE ASSEMBLY |

|

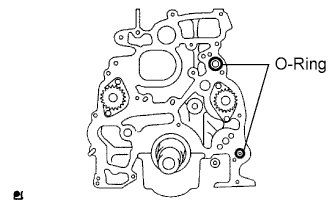

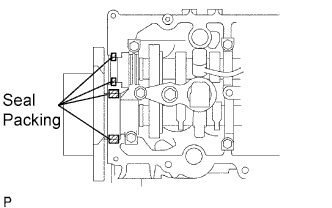

Install 2 new O-rings to the cylinder block.

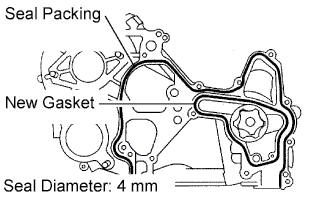

Remove any old seal packing (FIPG) material from the timing gear case and cylinder block.

Set a new oil pump gasket to the timing gear case.

Apply seal packing to the areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 4.0 mm (0.157 in.)

- NOTICE:

- After applying FIPG, install the timing gear case within 3 minutes and tighten the bolts within 15 minutes.

- Do not start the engine for at least 2 hours after the installation.

|

Align the "2" timing marks of the No. 1 balance shaft driven gear and oil pump drive gear, and install the timing gear case to the cylinder block.

|

Tighten the 8 bolts and union bolt.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf} for bolt

- 16 N*m{163 kgf*cm, 12 ft.*lbf} for union bolt

Make sure that the oil pump drive gear rotates smoothly.

- NOTICE:

- If the gear does not rotate smoothly, remove the 8 bolts and union bolt to release the gear. Then install the bolts and gear again.

Install the No. 1 vacuum transmitting pipe with the nut.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 2. INSTALL OIL PAN SUB-ASSEMBLY |

Install a new gasket and the oil strainer with the 2 bolts and nut.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

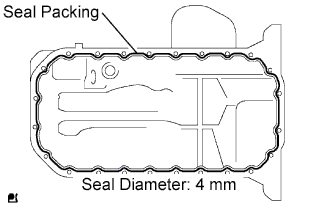

Remove old seal packing (FIPG) from the oil pan and cylinder block.

Apply seal packing to the areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 4.0 mm (0.157 in.)

- NOTICE:

- After applying FIPG, install the oil pan within 3 minutes and tighten the bolts within 15 minutes.

- Do not start the engine for at least 2 hours after the installation.

|

Install the oil pan with the 22 bolts and 2 nuts.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

| 3. INSTALL OIL DIPSTICK GUIDE |

Apply clean engine oil to a new O-ring.

Install the O-ring to the dipstick guide.

Install the dipstick guide with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 4. INSTALL INJECTION GEAR |

|

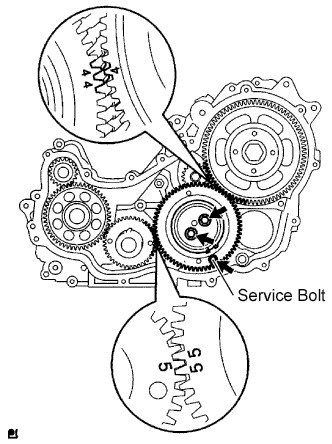

Align the "3" timing marks of the injection gear and No. 2 balance shaft driven gear, and install the injection gear.

- NOTICE:

- Fit the key (protrusion) of the supply pump to the key slot of the injection gear.

Set a new O-ring and then temporarily install the nut. Using your hand, check the thrust clearance of the supply pump drive shaft by driving the injection gear.

- Standard thrust clearance:

- 0.15 to 0.55 mm (0.0059 to 0.0217 in.)

- HINT:

- If the clearance is not within the specified range, remove the injection gear again and reinstall it.

| 5. INSTALL FUEL SUPPLY PUMP ASSEMBLY |

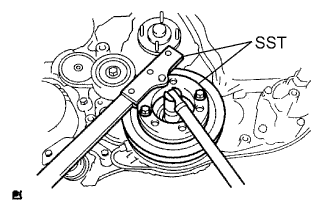

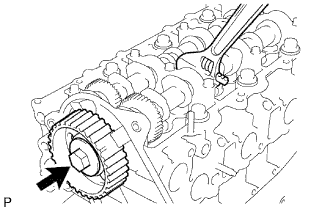

| 6. INSTALL CRANKSHAFT TIMING GEAR |

|

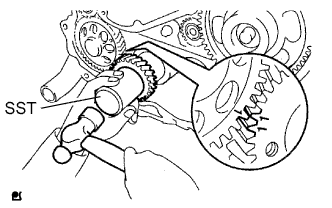

Align the "1" timing marks of the oil pump drive gear and crankshaft timing gear as shown in the illustration. Using SST, install the crankshaft timing gear.

- SST

- 09223-00010

| 7. INSTALL NO. 1 IDLE GEAR |

Install the No. 1 idle gear shaft to the cylinder block.

|

Align the "4" timing marks of the No. 1 idle gear and injection gear, as shown in the illustration.

|

Align the "5" timing marks of the No. 1 idle gear and crankshaft timing gear, and install the No. 1 idle gear, as shown in the illustration.

Install the No. 1 idle gear with the idle gear thrust plate and 2 bolts.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

Remove the service bolt.

Install the No. 1 crankshaft position sensor plate.

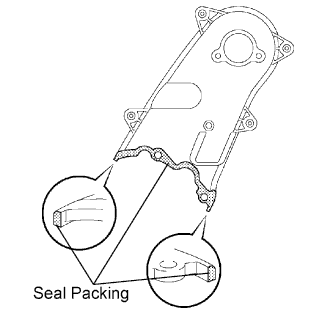

| 8. INSTALL TIMING GEAR COVER |

|

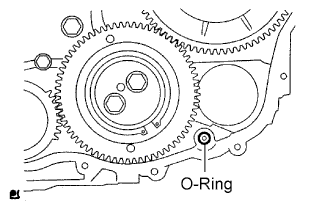

Install a new O-ring to the timing gear case.

Remove any old seal packing (FIPG) material from the timing gear cover.

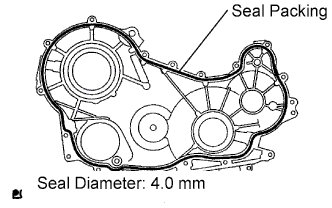

Apply seal packing to the areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 4.0 mm (0.157 in.)

- NOTICE:

- After applying FIPG, install the gear cover within 3 minutes and tighten the bolts and nuts within 15 minutes.

- Do not start the engine for at least 2 hours after the installation.

|

Install the cover with the 14 bolts and 2 nuts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

| 9. INSTALL CRANKSHAFT POSITION SENSOR |

Apply clean engine oil to a new O-ring.

Install the O-ring to the sensor.

Install the sensor with the bolt.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

| 10. INSTALL CAMSHAFT POSITION SENSOR |

Apply clean engine oil to a new O-ring.

Install the O-ring to the sensor.

Install the sensor with the bolt.

- Torque:

- 8.5 N*m{87 kgf*cm, 75 in.*lbf}

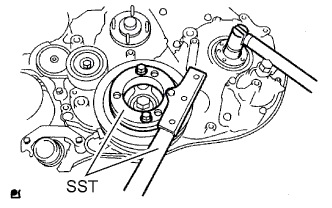

| 11. INSTALL CRANKSHAFT PULLEY |

|

Align the pulley set key with the key groove of the pulley.

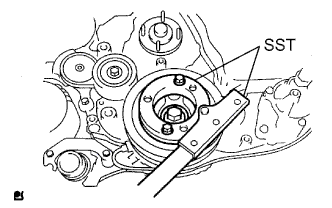

Using SST, install the pulley bolt.

- SST

- 09213-58013

- Torque:

- 365 N*m{3,722 kgf*cm, 270 ft.*lbf}

| 12. INSTALL PUMP DRIVE SHAFT PULLEY |

Install a new O-ring to the supply pump.

Partially install the supply pump with the nut.

Using SST, hold the crankshaft pulley to tighten the nut.

- SST

- 09213-58013

09330-00021

- Torque:

- 64 N*m{653 kgf*cm, 47 ft.*lbf}

|

Install the No. 2 camshaft timing pulley flange and pump drive shaft pulley with the 4 bolts.

- Torque:

- 31 N*m{316 kgf*cm, 23 ft.*lbf}

|

Move the pump drive shaft pulley back and forth to check the thrust clearance of the pump drive shaft.

- Standard thrust clearance:

- 0.15 to 0.55 mm (0.0059 to 0.0217 in.)

- HINT:

- If the clearance is not within the specified range, disassemble and reassemble the supply pump and pump drive shaft pulley. Then repeat the step above.

|

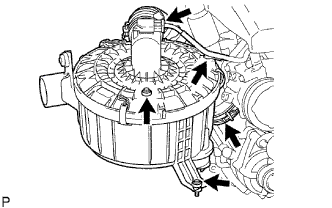

| 13. INSTALL VANE PUMP ASSEMBLY |

Install a new O-ring to the vane pump.

Install the vane pump with the 2 nuts.

- Torque:

- 39 N*m{398 kgf*cm, 29 ft.*lbf}

| 14. INSTALL VACUUM PUMP ASSEMBLY |

Install a new O-ring to the vacuum pump.

Install the vacuum pump with the 2 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 16 ft.*lbf}

| 15. INSTALL WATER PUMP ASSEMBLY |

Install a new gasket and the water pump with the 5 bolts and 2 nuts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

|

| 16. INSTALL NO. 2 TIMING BELT COVER |

|

Apply seal packing (FIPG) to the specified areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- After applying FIPG, install the No. 2 timing belt cover within 3 minutes and tighten its bolts and nut within 15 minutes.

Install the No. 2 timing belt cover with the 4 bolts and nut.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 17. INSTALL NO. 1 TIMING BELT IDLER SUB-ASSEMBLY |

| 18. INSTALL CAMSHAFT TIMING PULLEY |

|

Install the camshaft timing pulley.

Fasten the bolt of the camshaft timing pulley by holding the camshaft with a wrench.

- Torque:

- 98 N*m{1,000 kgf*cm, 72 ft.*lbf}

| 19. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

|

Remove any old seal packing (FIPG) material from the cylinder head.

Apply seal packing to the specific areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surface.

- Install the belt cover within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the seal packing.

Install the gasket and cylinder head cover with the 10 bolts and 2 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

Install 4 new nozzle holder seals.

| 20. INSTALL INJECTION PIPE |

|

- NOTICE:

- When replacing the injector, also replace the injection pipe.

- Keep the joints of the injection pipe clean.

Temporarily install the No. 1, No. 2 and No. 3 injection pipes with the union nuts.

Install the No. 2 and No. 3 injection pipe clamps with the bolt and 2 nuts, as shown in the illustration.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

- HINT:

- If the painted mark on the No. 1 injection pipe has disappeared, use the illustration as a reference to install the clamps.

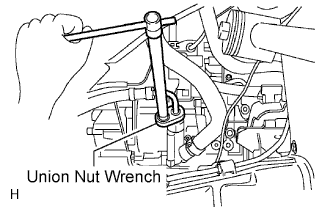

Using union nut wrench, tighten the injection pipe union nuts on the common rail side.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for use with union nut wrench

- 35 N*m{357 kgf*cm, 26 ft.*lbf} for use without union nut wrench

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

|

Using union nut wrench, tighten the injection pipe union nuts on the injector side.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for use with union nut wrench

- 35 N*m{357 kgf*cm, 26 ft.*lbf} for use without union nut wrench

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

Temporarily install the No. 4 injection pipe with the union nuts.

|

Install 2 new injection pipe clamps with the 2 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

- NOTICE:

- Make sure that the inner-rubbers of the injection pipe fit inside the clamps.

- When installing the pipe, check that the inner-rubbers and the clamps are in their proper positions.

Using union nut wrench, tighten the injection pipe union nut on the common rail side.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for use with union nut wrench

- 35 N*m{357 kgf*cm, 26 ft.*lbf} for use without union nut wrench

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

|

Using union nut wrench, tighten the injection pipe union nut on the injector side.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for use with union nut wrench

- 35 N*m{357 kgf*cm, 26 ft.*lbf} for use without union nut wrench

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

| 21. INSTALL FUEL INLET PIPE SUB-ASSEMBLY |

|

Temporarily install the fuel inlet pipe with the union nuts.

- NOTICE:

- If the common rail is replaced, the fuel inlet pipe must be replaced.

- Be careful that dust, dirt or any other foreign matter does not contact the joint area of the fuel inlet pipe.

Using union nut wrench, tighten the inlet pipe union nut on the common rail side.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for use with union nut wrench

- 35 N*m{357 kgf*cm, 26 ft.*lbf} for use without union nut wrench

Using union nut wrench, tighten the inlet pipe union nut on the supply pump side.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for use with union nut wrench

- 35 N*m{357 kgf*cm, 26 ft.*lbf} for use without union nut wrench

Install the oil dipstick guide with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Install the clamp with the bolt.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

|

| 22. INSTALL MANIFOLD STAY |

|

Install the stay with the 2 bolts.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

| 23. INSTALL NO. 1 COMPRESSOR MOUNTING BRACKET |

Install the bracket with the 4 bolts.

- Torque:

- 47 N*m{479 kgf*cm, 35 ft.*lbf}

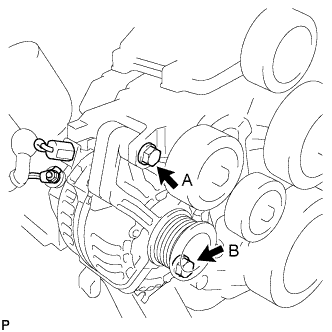

| 24. INSTALL GENERATOR ASSEMBLY |

|

Install the generator with the 2 bolts.

- Torque:

- 62 N*m{630 kgf*cm, 46 ft.*lbf}for bolt A

- 25 N*m{254 kgf*cm, 19 ft.*lbf}for bolt B

Install the generator wire with the nut.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}

Install the terminal cap.

Connect the generator connector.

| 25. INSTALL GENERATOR BRACKET |

| 26. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

|

Install the tensioner with the 4 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- HINT:

- Firmly press and hold the tensioner against the cylinder block to eliminate any gaps in the A areas shown in the illustration. Then uniformly tighten the 4 bolts.

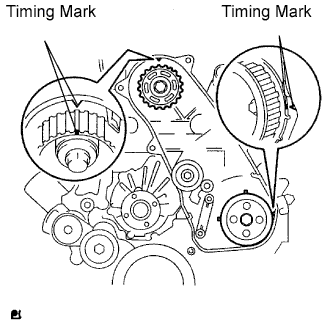

| 27. INSTALL TIMING BELT |

|

Check that the timing marks are aligned as shown in the illustration.

- HINT:

- If reusing the timing belt, align the points marked during removal, and install the belt with the arrow pointing in the direction of engine revolution.

- NOTICE:

- The engine should be cold.

- When turning the crankshaft, the valve heads will hit against the piston's top position. Do not turn it more than necessary.

Using a 10 mm hexagon wrench, install the timing belt idler pulley and new washer with the bolt.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

Check that the idler pulley moves smoothly.

If it does not move smoothly, check the idler sub-assembly and washer.

Install the timing belt to the pump drive shaft pulley, camshaft timing pulley and No. 1 timing belt idler in sequence.

Place the tensioner upright. Then set a press to the top of the tensioner.

- NOTICE:

- Do not scratch or deform the rod end.

- Press in the tensioner rod upward.

- Protect the tip of the push rod with a cloth in order to prevent damage.

|

Using the press, slowly push in the push rod using 981 to 9,807 N (100 to 1,000 kgf, 220 to 2,205 lbf) of force.

- NOTICE:

- Do not impose a load of over 9,807 N (100 to 1,000 kgf, 220 to 2,205 lbf) to the push rod.

Align the holes of the push rod and housing. Then pass a 1.5 mm hexagon wrench through the holes to keep the setting position of the push rod.

Install the timing belt tensioner with the 2 bolts while pushing the idler pulley toward the timing belt.

Tighten the 2 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

- NOTICE:

- Uniformly tighten the 2 bolts and install the tensioner.

Remove the 1.5 mm hexagon wrench from the tensioner.

|

Turn the crankshaft clockwise 720° and check that the timing marks are aligned as shown in the illustration.

|

| 28. INSTALL NO. 1 TIMING BELT TENSIONER ASSEMBLY |

| 29. INSTALL NO. 1 TIMING BELT COVER |

Install the timing belt cover with the 6 bolts.

- Torque:

- 6.0 N*m{61 kgf*cm, 53 in.*lbf}

Install the wire harness clamp.

Install the water hose clamp with the bolt.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

| 30. REMOVE ENGINE FROM ENGINE STAND |

| 31. INSTALL ENGINE ASSEMBLY |

|

Attach the chain block and engine sling device to the engine hangers.

Slowly lower the engine into the engine compartment.

Install the engine mounting bracket with the 4 bolts and 4 nuts.

- Torque:

- 38 N*m{388 kgf*cm, 28 ft.*lbf}

Remove the 2 engine hangers.

| 32. INSTALL REAR END PLATE |

Install the end plate with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 33. INSTALL FLYWHEEL SUB-ASSEMBLY (for Manual Transmission) |

|

Clean the bolt and its hole.

Apply adhesive to 2 or 3 threads of the bolt end.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

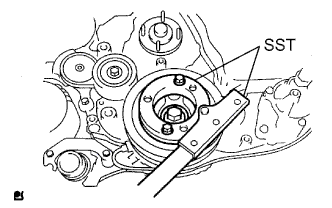

Using SST, hold the crankshaft.

- SST

- 09213-58013

09330-00021

- Torque:

- 365 N*m{3,722 kgf*cm, 270 ft.*lbf}

|

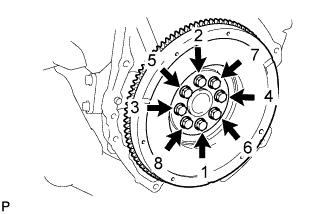

Install the flywheel on the crankshaft.

Uniformly install and tighten the 8 bolts in the sequence shown in the illustration.

- Torque:

- 178 N*m{1,815 kgf*cm, 132 ft.*lbf}

- NOTICE:

- Do not start the engine for at least 1 hour after the installation.

|

| 34. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transmission) |

|

Clean the bolt and its hole.

Apply adhesive to 2 or 3 threads of the bolt end.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Using SST, hold the crankshaft.

- SST

- 09213-58013

09330-00021

- Torque:

- 365 N*m{3722 kgf*cm, 270 in.*lbf}

|

Install the flywheel, drive plate and drive plate spacer on the crankshaft.

Uniformly install and tighten the 8 bolts in the sequence shown in the illustration.

- Torque:

- 178 N*m{1815 kgf*cm, 132 in.*lbf}

- NOTICE:

- Do not start the engine for at least 1 hour after the installation.

|

| 35. INSTALL TRANSMISSION ASSEMBLY |

R151:

Install the transmission (Toyota Fortuner RM0000011B0004X.html).

R151F:

Install the transmission (Toyota Fortuner RM0000011AJ003X.html).

A340E:

Install the transmission (Toyota Fortuner RM0000010NT00IX.html).

| 36. INSTALL FRONT PROPELLER SHAFT ASSEMBLY (for 4WD) |

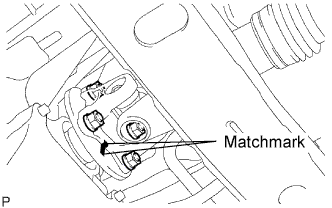

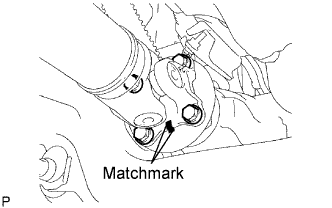

|

Align the matchmarks on the yoke and transfer flange.

Connect the propeller shaft with the 4 washers and 4 nuts.

- Torque:

- 88 N*m{897 kgf*cm, 65 ft.*lbf}

Align the matchmarks on the yoke and differential flange.

|

Install the front propeller shaft with the 4 bolts, 4 washers and 4 nuts.

- Torque:

- 88 N*m{897 kgf*cm, 65 ft.*lbf}

| 37. INSTALL REAR PROPELLER SHAFT ASSEMBLY |

Install the rear propeller shaft (Toyota Fortuner RM000000ZZ1008X.html).

| 38. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

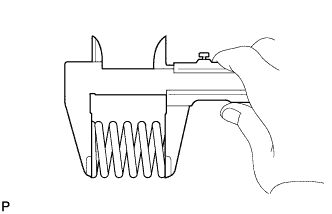

Using a vernier caliper, measure the free length of the compression spring.

- Minimum length:

- 40 mm (1.57 in.)

|

Install the front pipe to the pipe support.

Install a new gasket to the outlet pipe.

- NOTICE:

- Be careful with the installation direction of the gasket.

- Do not reuse the gasket.

- To ensure a proper seal, do not use the front pipe to force the gasket onto the outlet pipe.

- HINT:

- Using a plastic-faced hammer, uniformly strike the gasket so that the gasket and outlet pipe are properly fit.

|

Install the front pipe with the 2 compression springs and 2 bolts. Alternately tighten the bolts in several passes.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

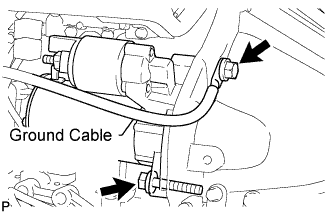

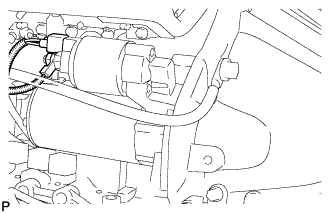

| 39. INSTALL STARTER ASSEMBLY |

Connect the ground cable and install the starter with the 2 bolts.

- HINT:

- Make sure to connect the ground cable with the bolt as shown in the illustration.

- Torque:

- 68 N*m{693 kgf*cm, 50 ft.*lbf}

|

Install the starter wire to terminal 30 with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

|

Connect the starter connector.

| 40. CONNECT COOLER COMPRESSOR ASSEMBLY |

Install the compressor with the 4 bolts.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

| 41. CONNECT HOSES AND CONNECTORS |

|

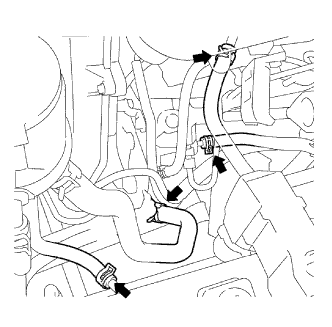

Using a 17 mm union nut wrench, install the pressure feed tube.

- Torque:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

Connect the 2 fuel hoses.

|

Connect the vacuum pump hose.

Connect the oil reservoir to pump hose.

for LHD:

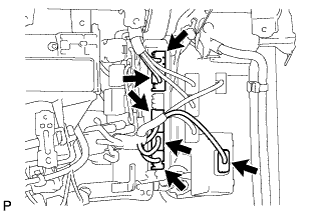

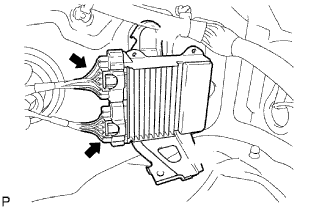

Connect the connectors.Connect the turbo motor driver connector.

Connect the 5 ECM connectors.

for RHD:

Connect the connectors.Connect the turbo motor driver connector.

Connect the 4 ECM connectors.

for LHD:

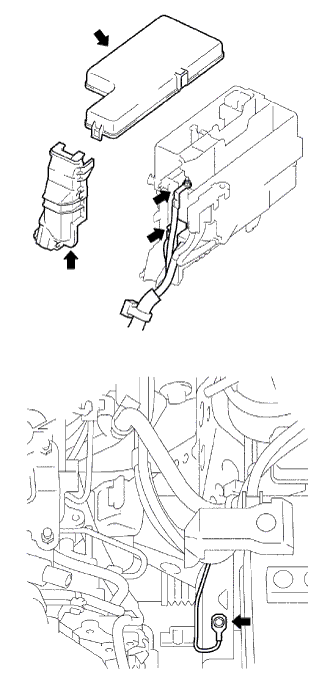

Connect the 2 injector driver connectors.

|

for RHD:

Connect the 2 injector driver connectors.

|

Install the ground cable with the bolt.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

|

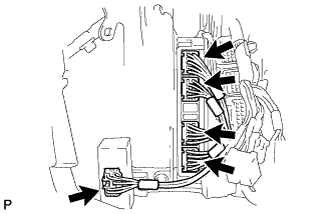

Connect the 2 engine room junction block connectors.

Install the engine room junction block wire with the nut.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Install the engine room relay block cover (side).

Install the engine room relay block cover (upper).

| 42. INSTALL CHARGE AIR COOLER ASSEMBLY WITH INTAKE AIR CONNECTOR |

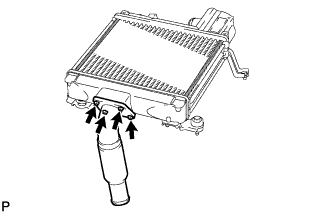

Install a new gasket and the intake air connector with the 4 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

Using a 22 mm deep socket wrench, install a new gasket and the IAT sensor.

- Torque:

- 29.4 N*m{300 kgf*cm, 22 ft.*lbf}

|

Install the CAC with the 4 bolts.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for bolt A

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf} for bolt B

|

Install a new No. 2 air hose and then tighten the 2 hose clamps.

- Torque:

- 6.5 N*m{66 kgf*cm, 58 in.*lbf}

Tighten the 2 hose clamps of the No. 1 air hose.

- Torque:

- 6.5 N*m{66 kgf*cm, 58 in.*lbf}

Connect the diesel turbo IAT sensor connector.

| 43. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY |

|

Install the engine cover with the 3 bolts and 2 nuts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

| 44. INSTALL RADIATOR ASSEMBLY |

Install the radiator (Toyota Fortuner RM00000144D007X.html).

| 45. INSTALL AIR CLEANER ASSEMBLY |

|

Connect the air cleaner hose.

Install the cleaner with the 2 bolts.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

Tighten the hose clamp of the compressor inlet elbow.

Connect the MAF meter connector and install the clamp.

| 46. INSTALL BATTERY TRAY |

| 47. INSTALL BATTERY |

| 48. INSTALL BATTERY BRACKET |

| 49. INSTALL RADIATOR GRILLE |

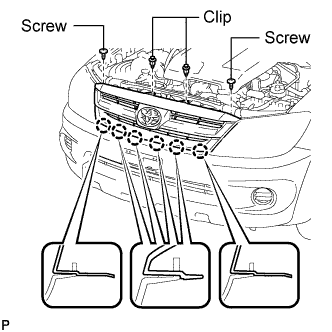

Attach the 6 claws to install the radiator grille.

|

Install the 2 clips and 2 screws.

| 50. INSTALL HOOD SUB-ASSEMBLY |

Install the hood with the 4 bolts.

- Torque:

- 13 N*m{134 kgf*cm, 10 ft.*lbf}

Connect the washer nozzle hose to the washer nozzle.

Adjust the hood (Toyota Fortuner RM00000138K003X.html).

| 51. ADD ENGINE OIL |

Wipe the oil pan and drain plug.

Install a new gasket and the drain plug.

- Torque:

- 34 N*m{347 kgf*cm, 25 ft.*lbf}

Add new oil.

- Standard oil capacity:

Item Specified Condition Drain and refill with oil filter change 6.9 liters (7.3 US qts, 6.1 Imp. qts) Drain and refill without oil filter change 6.6 liters (7.0 US qts, 5.8 Imp. qts) Dry fill 7.4 liters (7.8 US qts, 6.5 Imp. qts)

Install the oil filler cap.

| 52. ADD TRANSMISSION OIL OR TRANSMISSION FLUID |

R151:

Add transmission oil (Toyota Fortuner RM0000011B0004X_01_0013.html).

R151F:

Add transmission oil (Toyota Fortuner RM0000011AJ003X_01_0014.html).

A340E:

Add transmission fluid (Toyota Fortuner RM0000010NT00IX_01_0022.html).

| 53. ADD FUEL |

| 54. TIGHTEN FUEL TANK CAP ASSEMBLY |

| 55. BLEED AIR FROM FUEL SYSTEM |

|

Using the hand pump, bleed air from the fuel system until pumping becomes difficult.

| 56. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 57. CHECK FOR FUEL LEAKS |

- CAUTION:

- During Active Test mode, engine speed becomes high and combustion noise becomes loud, so pay attention.

- During Active Test mode, fuel becomes high-pressured. Be extremely careful not to expose your eyes, hands, or body to escaped fuel.

Check that there are no leaks from any part of the fuel system when the engine is stopped. If there is fuel leakage, repair or replace parts as necessary.

Start the engine and check that there are no leaks from any part of the fuel system. If there is fuel leakage, repair or replace parts as necessary.

Disconnect the return hose from the common rail.

Start the engine and check for fuel leaks from the return pipe.

If there is fuel leakage, replace the common rail.

Connect the intelligent tester to the DLC3.

Start the engine and push the intelligent tester main switch on.

Select the Fuel Leak test from the Active Test mode on the intelligent tester.

If the intelligent tester is not available, fully depress the accelerator pedal quickly. Increase the engine speed to the maximum and maintain that speed for 2 seconds. Repeat this operation several times.

Check that there are no leaks from any part of the fuel system.

- NOTICE:

- A return pipe leakage of less than 10 cc (0.6 cu in.) per minute is acceptable.

Reconnect the return hose to the common rail.

| 58. ADD ENGINE COOLANT |

Tighten the radiator drain cock plug by hand.

Tighten the cylinder block drain cock plug.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

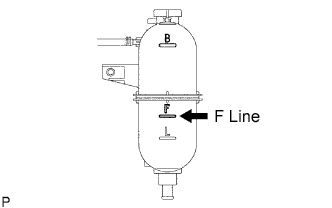

Fill the radiator with TOYOTA Super Long Life Coolant (SLLC) to the reservoir tank's B line.

- Standard Capacity:

Item Specified Condition Manual transmission 9.8 liters (10.4 US qts, 8.6 Imp. qts) Automatic transmission 11.1 liters (11.7 US qts, 9.8 Imp. qts)

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology is a combination of low phosphates and organic acids).

- Please contact your TOYOTA dealer for further details.

- NOTICE:

- Never use water as a substitute for engine coolant.

|

Press the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level drops below the B line, add TOYOTA SLLC to the B line.

Install the radiator reservoir cap.

Using a wrench, install the vent plug.

- Torque:

- 2.0 N*m{20 kgf*cm, 18 in.*lbf}

|

Bleed air from the cooling system.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

Maintain the engine speed at 2,500 to 3,000 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- CAUTION:

- When pressing the radiator hoses:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the radiator fan.

Stop the engine and wait until the coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator reservoir cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

After the coolant cools down, check that the coolant level is at the F line.

If the coolant level is below the F line, add TOYOTA SLLC to the F line.

|

| 59. CHECK FOR ENGINE OIL LEAKS |

| 60. CHECK ENGINE OIL LEVEL |

Warm up the engine, stop the engine and wait for 5 minutes. The oil level should be between the dipstick's low and full level marks.

If the oil level is low, check for leakage and add oil up to the full level mark.- NOTICE:

- Do not add engine oil above the full level mark.

| 61. CHECK FOR ENGINE COOLANT LEAKS |

Check for engine coolant leaks (Toyota Fortuner RM000001443006X.html).

| 62. INSTALL NO. 2 ENGINE UNDER COVER (for 4WD) |

Install the under cover with the 2 bolts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 63. INSTALL NO. 1 ENGINE UNDER COVER (for 4WD) |

Install the under cover with the 4 bolts.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}