Starter -- Inspection |

| 1. INSPECT STARTER ASSEMBLY |

- NOTICE:

- The following tests must be done within 3 to 5 seconds to prevent the coil from burning out.

Perform the pull-in test.

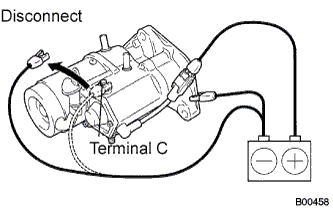

Disconnect the field coil lead wire from terminal C.

Connect the battery to the magnetic switch as shown. Check that the clutch pinion gear moves outward.

|

Perform the hold-in test.

When the battery is connected as above with the clutch pinion gear out, disconnect the negative (-) lead from terminal C. Check that the pinion gear remains out.

|

Inspect the clutch pinion gear return.

Disconnect the negative (-) lead from the starter body. Check that the clutch pinion gear returns inward.

|

Perform the operation test without load.

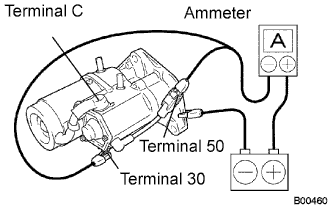

Connect the field coil lead wire to terminal C.

- Torque:

- 5.9 N*m{60 kgf*cm, 52 in.*lbf}

Grip the starter in a vise.

Connect the battery and ammeter to the starter as shown.

Check that the ammeter displays the specified current.

- Specified current:

- 120 A or less at 11.5 V

|

| 2. INSPECT STARTER ARMATURE ASSEMBLY |

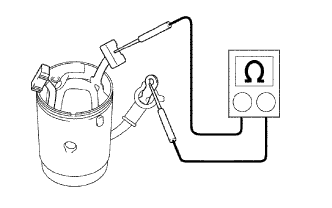

Inspect the commutator for an open circuit.

Measure the resistance between the segments of the commutator.

- Standard resistance:

- Below 1 Ω

- If the result is not as specified, replace the armature assembly.

|

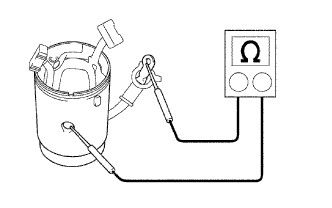

Inspect the commutator for a short circuit.

Using an ohmmeter, check that there is no resistance between the commutator and armature core.

- Standard resistance:

- 10 kΩ or higher

- If the result is not as specified, replace the armature assembly.

|

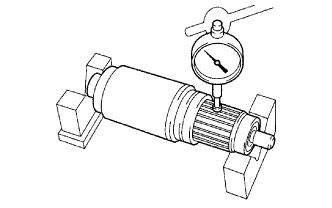

Inspect the commutator circle runout.

Place the armature on the V-blocks.

Using a dial indicator, measure the circle runout.

- Maximum circle runout:

- 0.05 mm (0.0020 in.)

- If the runout is greater than the maximum, correct it with sandpaper (#400) or replace the armature assembly.

|

Using a vernier caliper, measure the commutator diameter.

- Standard diameter:

- 35.0 mm (1.378 in.)

- Minimum diameter:

- 34.0 mm (1.339 in.)

- If the diameter is less than the minimum, replace the armature assembly.

|

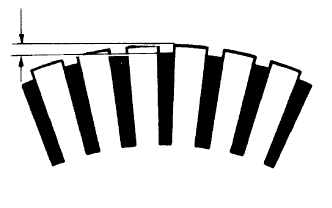

Measure the undercut depth of the commutator.

- Standard depth:

- 0.7 mm (0.028 in.)

- Minimum depth:

- 0.2 mm (0.008 in.)

- If the undercut depth is less than the minimum, correct it with a hacksaw blade.

|

Inspect the bearings.

Check that the bearings rotate smoothly.

If necessary, replace them.

| 3. INSPECT STARTER YOKE ASSEMBLY |

Inspect for an open circuit.

Measure the resistance between the terminal C wire and brushes.

- Standard resistance:

- Below 1 Ω

- If the result is not as specified, replace the starter yoke assembly.

|

Inspect for a short circuit.

Measure the resistance between the terminal C wire and starter yoke body.

- Standard resistance:

- 10 kΩ or higher

Measure the resistance between the brushes and starter yoke body.

- Standard resistance:

- 10 kΩ or higher

- If the result is not as specified, replace the starter yoke assembly.

|

| 4. INSPECT BRUSH |

Using a vernier caliper, measure the brush length.

- Standard brush length:

- 16.5 mm (0.650 in.)

- Minimum brush length:

- 9.0 mm (0.354 in.)

- If the length is less than the minimum, replace the brush holder and starter yoke assembly.

|

| 5. INSPECT STARTER BRUSH HOLDER ASSEMBLY |

Measure the resistance between the positive and negative brush holders.

- Standard resistance:

- 10 kΩ or higher

- If the result is not as specified, replace the brush holder.

|

Using a pull scale, measure the brush spring load.

- Standard spring load:

- 26.5 to 32.3 N (2.7 to 3.3 kgf, 6.0 to 7.3 lbf)

- Minimum spring load:

- 17.6 N (1.8 kgf, 4.0 lbf)

- If the spring load is less than the minimum, replace the brush holder.

|

| 6. INSPECT STARTER CLUTCH SUB-ASSEMBLY |

Check that the starter clutch cannot be rotated counterclockwise, and can be rotated clockwise.

- If the starter clutch is not as specified, replace it.

- If the starter clutch is not as specified, replace it.

|

| 7. INSPECT MAGNET STARTER SWITCH ASSEMBLY |

Inspect the pull-in coil.

Measure the resistance between terminals 50 and C.

- Standard resistance:

- Below 1 Ω

- If the result is not as specified, replace the magnet starter switch assembly.

|

Inspect the hold-in coil.

Measure the resistance between terminal 50 and the switch body.

- Standard resistance:

- Below 2 Ω

- If the result is not as specified, replace the magnet starter switch assembly.

|