Engine Unit -- Disassembly |

- NOTICE:

- When replacing the injectors (including shuffling the injectors between the cylinders), common rail or cylinder head, it is necessary to replace the injection pipes with new ones.

- When replacing the fuel supply pump, common rail, cylinder block, cylinder head, cylinder head gasket or timing gear case, it is necessary to replace the fuel inlet pipe with a new one.

- After removing the injection pipes, clean them with a brush and compressed air.

| 1. REMOVE OIL FILLER CAP SUB-ASSEMBLY |

| 2. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY |

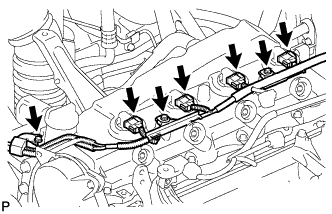

Remove the 3 bolts and disconnect the 4 connectors.

|

Disconnect the ventilation hose.

Using a small screwdriver, remove the nozzle holder seal by prying between the nozzle holder seal and the cutout part of the cylinder head cover.

|

Remove the 10 bolts, 2 nuts, cylinder head cover and cylinder head cover gasket.

|

| 3. REMOVE INJECTOR ASSEMBLY |

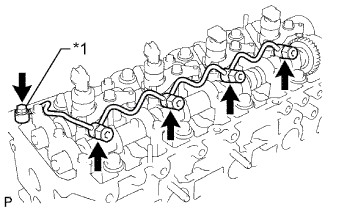

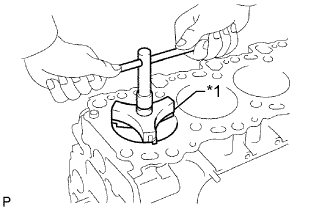

Remove the union bolt, 4 injector hollow screws, 5 gaskets and nozzle leakage pipe.

Text in Illustration *1 Union Bolt - NOTICE:

- When removing the nozzle leakage pipe, place a cushion under the pipe.

- Be careful not to deform or scratch the union seal surface.

- After removing the fuel pipe, put it in a plastic bag to prevent foreign matter from contaminating its injector inlet.

|

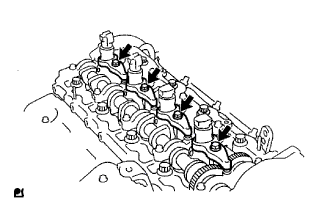

Remove the 4 bolts, 4 washers, 4 No. 1 nozzle holder clamps and 4 injectors.

- HINT:

- Arrange the injectors, No. 1 nozzle holder clamps, washers and bolts in the correct order.

|

Remove the O-ring from each injector.

Remove the 4 injection nozzle seats from the cylinder head.

| 4. REMOVE CAMSHAFT TIMING PULLEY |

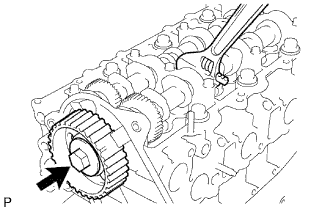

Remove the bolt of the camshaft timing pulley while holding the camshaft with a wrench.

- NOTICE:

- Make sure to remove the bolt of the camshaft timing pulley with the timing belt not installed.

|

Remove the camshaft timing pulley.

| 5. REMOVE NO. 2 TIMING BELT COVER |

Remove the 4 bolts, nut and timing belt cover.

| 6. REMOVE CYLINDER BLOCK INSULATOR |

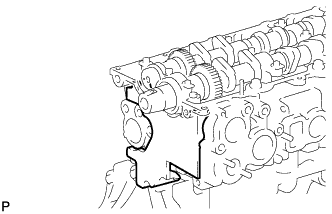

Remove the cylinder block insulator from the cylinder head.

|

| 7. REMOVE CAMSHAFT |

Turn the camshaft with a wrench so that the key groove of the camshaft faces upward.

Text in Illustration *1 Key Groove

|

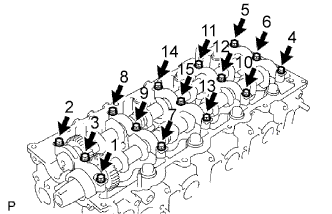

Uniformly loosen the 15 bearing cap bolts in several passes in the sequence shown in the illustration.

|

Remove the 15 bearing cap bolts, 5 bearing caps, oil seal and 2 camshafts.

| 8. REMOVE VALVE LIFTER |

Remove the valve lifters.

- HINT:

- Arrange the valve lifters in the correct order.

| 9. REMOVE CYLINDER HEAD SUB-ASSEMBLY |

|

Uniformly loosen the 18 cylinder head bolts in several passes in the sequence shown in the illustration. Then remove the 18 cylinder head bolts and 18 washers.

- NOTICE:

- Head warpage or cracking could result from removing bolts in the incorrect order.

Lift the cylinder head from the dowels on the cylinder block, and place the cylinder head on wooden blocks on a bench.

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder head and cylinder block.

- HINT:

- If the cylinder head is difficult to lift, use a screwdriver to pry between the cylinder head and block.

| 10. REMOVE CYLINDER HEAD GASKET |

| 11. REMOVE WATER PUMP ASSEMBLY |

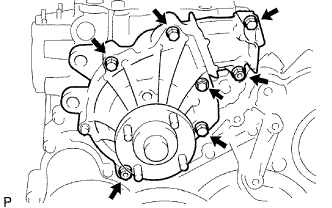

Remove the 5 bolts, 2 nuts, water pump and gasket.

|

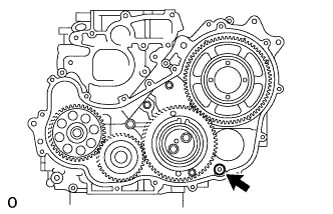

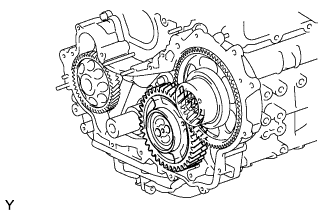

| 12. REMOVE TIMING GEAR COVER |

- NOTICE:

- As the fuel supply pump is not installed, the injection gear is loose inside the timing gear case. Do not allow the injection gear to fall.

- HINT:

- To prevent the injection gear from falling, temporarily install the fuel supply pump.

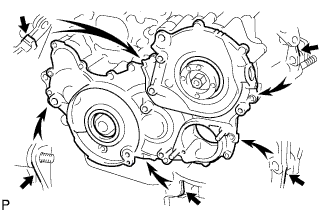

Remove the 14 bolts and 2 nuts.

|

Pry the timing gear cover at the locations shown in the illustration and remove the timing gear cover.

- NOTICE:

- Be careful not to drop the injection gear.

|

Remove the O-ring from the timing gear case.

|

| 13. REMOVE INJECTION GEAR |

Secure the No. 2 idle sub gear to the No. 1 idle gear with a service bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

- NOTICE:

- If the bolt hole of the No. 2 idle sub gear is not aligned with the bolt hole of the No. 1 idle gear, rotate the crankshaft counterclockwise to align the bolt holes. Then install the service bolt.

|

Remove the injection gear.

|

| 14. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE |

Remove the No. 1 crankshaft position sensor plate.

|

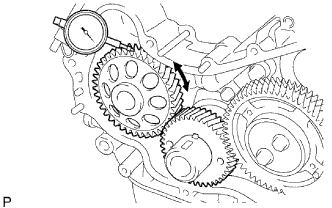

| 15. INSPECT BACKLASH OF CRANKSHAFT TIMING GEAR TO OIL PUMP GEAR |

Using a dial indicator, measure the backlash.

- Standard gear backlash:

- 0.02 to 0.15 mm (0.000787 to 0.00591 in.)

- Maximum gear backlash:

- 0.2 mm (0.00787 in.)

|

| 16. INSPECT BACKLASH OF CRANKSHAFT TIMING GEAR TO NO. 1 IDLE GEAR |

Using a dial indicator, measure the backlash.

- Standard gear backlash:

- 0.02 to 0.15 mm (0.000787 to 0.00591 in.)

- Maximum gear backlash:

- 0.2 mm (0.00787 in.)

|

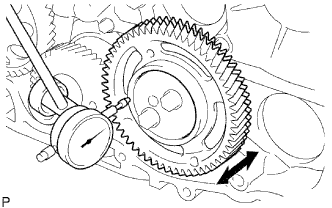

| 17. INSPECT NO. 1 IDLE GEAR THRUST CLEARANCE |

Install the timing gear case, No. 1 idle gear and camshaft timing gear.

Using a dial indicator, measure the thrust clearance.

- Standard thrust clearance:

- 0.06 to 0.11 mm (0.00236 to 0.00433 in.)

- Maximum thrust clearance:

- 0.3 mm (0.0118 in.)

|

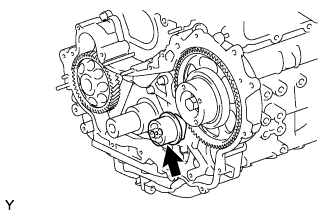

| 18. REMOVE CRANKSHAFT TIMING GEAR |

Using SST, remove the crankshaft timing gear.

- SST

- 09950-50013(09951-05010,09952-05010,09953-05010,09954-05021)

|

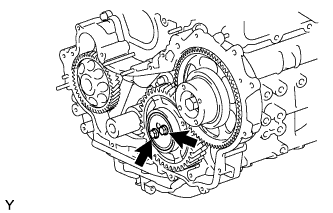

| 19. INSPECT BACKLASH OF INJECTION GEAR TO NO. 1 IDLE GEAR |

Install the fuel supply pump with the 2 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Using SST, install the injection gear with the nut.

- SST

- 09960-10010(09962-01000,09963-01000)

- Torque:

- 64 N*m{650 kgf*cm, 47 ft.*lbf}

|

Using a dial indicator, measure the backlash.

- Standard gear backlash:

- 0.02 to 0.15 mm (0.000787 to 0.00591 in.)

- Maximum gear backlash:

- 0.2 mm (0.00787 in.)

|

Using SST, remove the nut and injection gear.

- SST

- 09960-10010(09962-01000,09963-01000)

|

Remove the 2 nuts and fuel supply pump.

| 20. REMOVE IDLE GEAR THRUST PLATE |

Remove the 2 bolts and idle gear thrust plate.

|

| 21. REMOVE NO. 1 IDLE GEAR |

Remove the No. 1 idle gear together with the No. 2 idle sub gear.

|

| 22. REMOVE NO. 2 IDLE SUB GEAR |

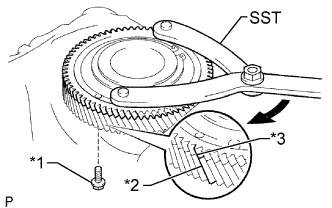

Using SST, turn the No. 2 idle sub gear clockwise and remove the service bolt.

- SST

- 09960-10010(09962-01000,09963-00700)

Text in Illustration *1 Service Bolt *2 No. 1 Idle Gear *3 No. 2 Idle Sub Gear

Turn

|

Using snap ring pliers, remove the snap ring.

|

Remove the wave washer, No. 2 idle sub gear and gear spring.

| 23. REMOVE NO. 1 IDLE GEAR SHAFT |

Remove the No. 1 idle gear shaft.

|

| 24. REMOVE OIL PAN SUB-ASSEMBLY |

Remove the 22 bolts and 2 nuts.

Insert the blade of an oil pan seal cutter between the oil pan and cylinder block, cut through the applied sealer and remove the oil pan.

- NOTICE:

- Do not use the oil pan seal cutter for the area between the oil pan and timing belt case, or for the area between the oil pan and rear oil seal retainer.

- Be careful not to damage the oil pan flange.

|

| 25. REMOVE OIL STRAINER SUB-ASSEMBLY |

Remove the 2 bolts, 2 nuts, oil strainer and gasket.

| 26. REMOVE TIMING GEAR CASE ASSEMBLY |

Remove the bolt and No. 1 vacuum transmitting pipe.

Remove the union bolt and 8 bolts.

|

Pry the timing gear case at the location shown in the illustration and remove the gear case and gasket.

Remove the 2 O-rings.

|

| 27. REMOVE REAR ENGINE OIL SEAL RETAINER |

Remove the 5 bolts.

|

Using a screwdriver, remove the rear engine oil seal retainer by prying between the rear engine oil seal retainer and cylinder block.

| 28. REMOVE FRONT CRANKSHAFT OIL SEAL |

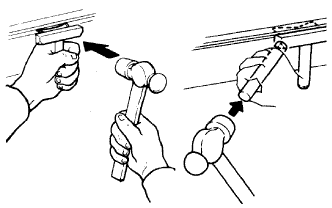

Using a screwdriver and hammer, tap out the oil seal.

|

| 29. REMOVE SUPPLY PUMP OIL SEAL |

Using a screwdriver and hammer, tap out the oil seal.

|

| 30. REMOVE REAR CRANKSHAFT OIL SEAL |

Using a screwdriver and hammer, tap out the oil seal.

|

| 31. REMOVE CYLINDER BLOCK OIL ORIFICE |

| 32. INSPECT CONNECTING ROD THRUST CLEARANCE |

|

Using a dial indicator, measure the thrust clearance while moving the connecting rod back and forth.

- Standard thrust clearance:

- 0.1 to 0.3 mm (0.00394 to 0.0118 in.)

- Maximum thrust clearance:

- 0.4 mm (0.0157 in.)

| 33. INSPECT CONNECTING ROD OIL CLEARANCE |

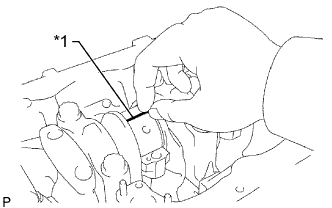

Check the matchmarks on the connecting rod and cap to ensure correct reassembly.

Text in Illustration *1 Matchmark

|

Remove the 2 connecting rod cap bolts.

Using the 2 removed connecting rod bolts, move the connecting rod cap back and forth to remove the connecting rod cap.

|

Remove the lower bearing from the connecting rod cap.

- HINT:

- Keep the lower bearing and connecting rod cap together.

Clean the crank pin and bearings.

Check the crank pin and bearings for pitting and scratches.

If the crank pin or a bearing is damaged, replace the bearings. If necessary, grind or replace the crankshaft.

Lay a strip of Plastigage across the crank pin.

Text in Illustration *1 Plastigage

|

Install the connecting rod cap (See page ).

- NOTICE:

- Do not turn the crankshaft.

Remove the 2 bolts, connecting rod cap and lower bearing.

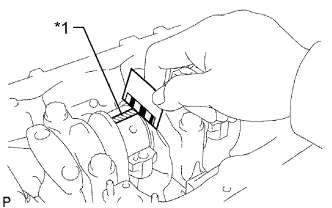

Measure the Plastigage at its widest point.

- Standard Oil Clearance:

Item Specified Condition STD 0.036 to 0.054 mm (0.00142 to 0.00212 in.) U/S 0.25, U/S 0.50 0.037 to 0.077 mm (0.00146 to 0.00303 in.)

- Maximum oil clearance:

- 0.1 mm (0.00394 in.)

If the oil clearance is more than the maximum, replace the bearings. If necessary, grind or replace the crankshaft.Text in Illustration *1 Plastigage - HINT:

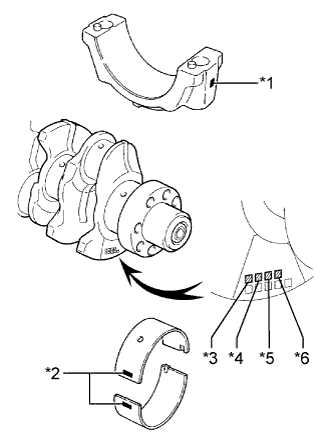

- If using a standard bearing, replace it with one that has the same number. If the number of the bearing cannot be determined, select the correct bearing by adding together the numbers imprinted on the crankshaft and connecting rod cap, and then selecting the bearing with the same number as the total. There are 5 sizes of standard bearings, marked 2, 3, 4, 5 and 6.

Item Number Mark Connecting rod cap 1 2 3 Crankshaft 1 2 3 1 2 3 1 2 3 Bearing to be used 2 3 4 3 4 5 4 5 6 - EXAMPLE:

- Connecting rod cap 3 + Crankshaft 1 =

- Total number 4 (Use bearing 4)

Text in Illustration *1 Mark 1, 2 or 3 *2 Mark 2, 3 or 4 *3 No. 1 *4 No. 2 *5 No. 3 *6 No. 4 - Reference:

- Standard Connecting Rod Big End Inside Diameter:

Item Specified Condition Mark 1 62.014 to 62.020 mm (2.4415 to 2.4417 in.) Mark 2 62.020 to 62.026 mm (2.4417 to 2.4420 in.) Mark 3 62.026 to 62.032 mm (2.4420 to 2.4422 in.)

- Standard Crank Pin Diameter:

Item Specified Condition Mark 1 58.994 to 59.000 mm (2.3226 to 2.3228 in.) Mark 2 58.988 to 58.994 mm (2.3224 to 2.3226 in.) Mark 3 58.982 to 58.988 mm (2.3221 to 2.3224 in.)

- Standard Sized Connecting Rod Bearing Center Wall Thickness:

Item Specified Condition Mark 2 1.486 to 1.489 mm (0.0585 to 0.0586 in.) Mark 3 1.489 to 1.492 mm (0.0586 to 0.0587 in.) Mark 4 1.492 to 1.495 mm (0.0587 to 0.0589 in.) Mark 5 1.495 to 1.498 mm (0.0589 to 0.0590 in.) Mark 6 1.498 to 1.501 mm (0.0590 to 0.0591 in.)

|

Completely remove the Plastigage.

| 34. REMOVE PISTON AND CONNECTING ROD |

Using a ridge reamer, remove all the carbon from the top of the cylinder.

Text in Illustration *1 Ridge Reamer

|

Push the piston, connecting rod assembly and upper bearing through the top of the cylinder block to remove them.

Remove the upper bearing from the connecting rod.

- HINT:

- Keep the bearings, connecting rod and cap together.

- Be sure to organize the removed piston and connecting rod assemblies in such a way that they can be reinstalled exactly as before.

| 35. REMOVE CONNECTING ROD BEARING |

Remove the connecting rod bearings from the connecting rods and connecting rod caps.

- HINT:

- Arrange the removed parts in the correct order.

| 36. REMOVE PISTON RING SET |

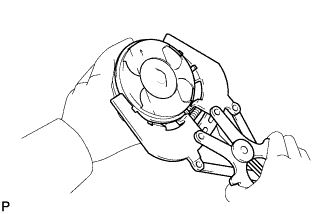

Using a piston ring expander, remove the 2 piston rings.

- HINT:

- Be sure to organize the removed piston rings in such a way that they can be reinstalled exactly as before.

|

Remove the coil and oil ring by hand.

| 37. REMOVE PISTON WITH PIN SUB-ASSEMBLY |

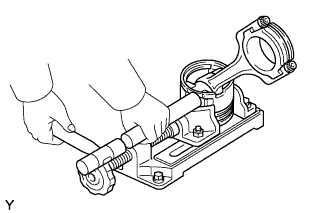

Using a small screwdriver, pry out the 2 snap rings from the piston.

|

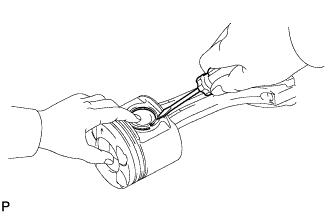

Gradually heat the piston to approximately 80°C (176°F).

Using a plastic-faced hammer and brass bar, lightly tap out the piston pin. Then remove the connecting rod.

- HINT:

- The piston and pin are a matched set.

- Be sure to organize the removed pistons, pins, rings, connecting rods and bearings in such a way that the parts can be reinstalled exactly as before.

|

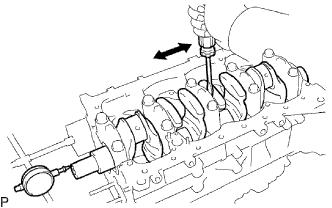

| 38. INSPECT CRANKSHAFT THRUST CLEARANCE |

Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver.

- Standard thrust clearance:

- 0.04 to 0.24 mm (0.00157 to 0.00945 in.)

- Maximum thrust clearance:

- 0.3 mm (0.0118 in.)

- Standard Thrust Washer Thickness:

Item Specified Condition STD 2.430 to 2.480 mm (0.0957 to 0.0976 in.) O/S 0.125 2.555 to 2.605 mm (0.1005 to 0.1025 in.) O/S 0.250 2.680 to 2.730 mm (0.1055 to 0.1074 in.)

|

| 39. INSPECT CRANKSHAFT OIL CLEARANCE |

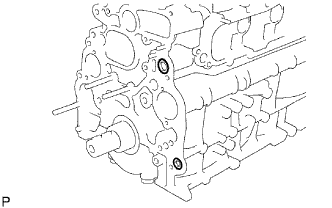

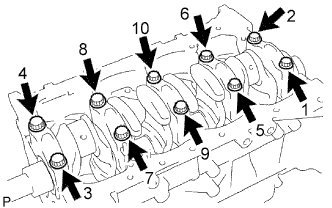

Uniformly loosen and remove the 10 crankshaft bearing cap bolts in several passes in the sequence shown in the illustration.

|

Using the removed crankshaft bearing cap bolts, pry the cap back and forth and remove the crankshaft bearing caps, lower crankshaft bearings and lower thrust washers (No. 5 crankshaft bearing cap only).

- HINT:

- Keep the lower bearing and crankshaft bearing cap together.

- Be sure to organize the bearing caps and lower thrust washers (No. 5 crankshaft bearing only) in such a way that they can be reinstalled exactly as before.

|

Lift out the crankshaft.

Clean each main journal and bearing.

Check each crankshaft journal and bearing for pitting and scratches.

If a journal or one of its bearings is damaged, replace the bearings for that journal. If necessary, grind or replace the crankshaft.

Place the crankshaft on the cylinder block.

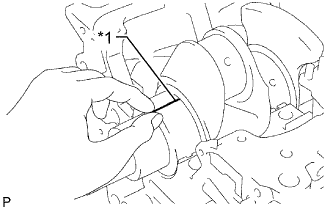

Lay a strip of Plastigage across each journal.

Text in Illustration *1 Plastigage

|

Install the crankshaft bearing caps (See page ).

- NOTICE:

- Do not turn the crankshaft.

Remove the crankshaft bearing caps.

Measure the Plastigage at its widest point.

- Standard Oil Clearance:

Item Specified Condition STD 0.030 to 0.048 mm (0.00118 to 0.00189 in.) U/S 0.25, U/S 0.50 0.037 to 0.077 mm (0.00146 to 0.00303 in.)

- Maximum oil clearance:

- 0.1 mm (0.00394 in.)

If the oil clearance is more than the maximum, replace the bearings. If necessary, grind or replace the crankshaft.Text in Illustration *1 Plastigage - HINT:

- If replacing the cylinder block sub-assembly, the bearing oil clearance will be within the standard range.

- Standard oil clearance:

- 0.030 to 0.048 mm (0.00118 to 0.00189 in.)

- HINT:

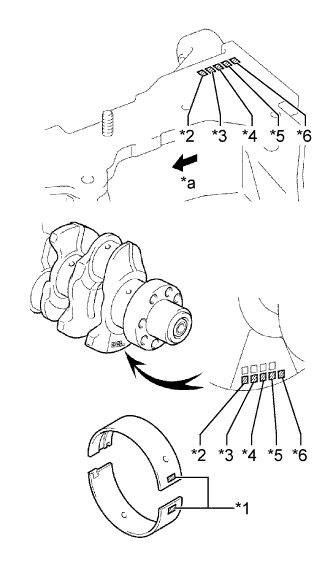

- If using a standard bearing, replace it with one that has the same number. If the number of the bearing cannot be determined, select the correct bearing by adding together the numbers imprinted on the cylinder block and crankshaft, and then selecting the bearing with the same number as the total. There are 5 sizes of standard bearings, marked 2, 3, 4, 5 and 6.

Item Number Mark Cylinder block 1 2 3 Crankshaft 1 2 3 1 2 3 1 2 3 Bearing to be used 2 3 4 3 4 5 4 5 6 - EXAMPLE:

- Cylinder block 2 + crankshaft 1 =

- Total number 3 (Use bearing 3)

Text in Illustration *1 Mark 2, 3, 4, 5 or 6 *2 No. 1 *3 No. 2 *4 No. 3 *5 No. 4 *6 No. 5 *a Front - Reference:

- Standard Cylinder Block Main Journal Bore Diameter:

Item Specified Condition Mark 1 75.000 to 75.006 mm (2.9528 to 2.9530 in.) Mark 2 75.006 to 75.012 mm (2.9530 to 2.9532 in.) Mark 3 75.012 to 75. 018 mm (2.9532 to 2.9535 in.)

- Standard Crankshaft Journal Diameter:

Item Specified Condition Mark 1 69.994 to 70.000 mm (2.7557 to 2.7559 in.) Mark 2 69.988 to 69.994 mm (2.7554 to 2.7557 in.) Mark 3 69.982 to 69.988 mm (2.7552 to 2.7554 in.)

- Standard Sized Main Bearing Center Wall Thickness:

Item Specified Condition Mark 2 2.482 to 2.485 mm (0.0977 to 0.0978 in.) Mark 3 2.485 to 2.488 mm (0.0978 to 0.0980 in.) Mark 4 2.488 to 2.491 mm (0.0980 to 0.0981 in.) Mark 5 2.491 to 2.494 mm (0.0981 to 0.0982 in.) Mark 6 2.494 to 2.497 mm (0.0982 to 0.0983 in.)

|

Completely remove the Plastigage.

| 40. REMOVE CRANKSHAFT |

Lift out the crankshaft.

Remove the upper bearings and upper thrust washers (No. 5 crankshaft bearing only) from the cylinder block.

- HINT:

- Arrange the bearing caps, bearings and thrust washers (No. 5 crankshaft bearing only) in the correct order.

| 41. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY |

Remove the 4 check valves and 4 oil nozzles.

| 42. REMOVE STUD BOLT |

- HINT:

- If a stud bolt is deformed or its threads are damaged, replace it.

Remove the stud bolts.