Oil Pump -- Inspection |

| 1. INSPECT OIL PUMP RELIEF VALVE |

Coat the valve with engine oil and check that it falls smoothly into the valve hole by its own weight.

- If it does not fall smoothly into the valve hole, replace the relief valve. If necessary, replace the timing belt case sub-assembly.

- If it does not fall smoothly into the valve hole, replace the relief valve. If necessary, replace the timing belt case sub-assembly.

|

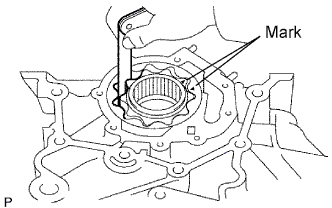

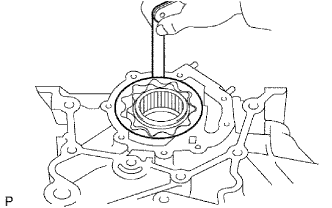

| 2. INSPECT OIL PUMP DRIVE GEAR |

Install the rotors to the timing belt case sub-assembly with the rotors' marks facing outward. Check that the rotors revolve smoothly.

|

Inspect the gear tip clearance.

Using a feeler gauge, measure the clearance between the drive and driven gear tips.

- Standard tip clearance:

- 0.110 to 0.240 mm (0.0043 to 0.0094 in.)

- Maximum tip clearance:

- 0.30 mm (0.0118 in.)

- If the tip clearance is greater than the maximum, replace the gears as a set.

Inspect the gear body clearance.

Using a feeler gauge, measure the clearance between the driven gear and timing belt case.

- Standard body clearance:

- 0.144 to 0.219 mm (0.0057 to 0.0086 in.)

- Maximum body clearance:

- 0.40 mm (0.0157 in.)

- If the body clearance is greater than the maximum, replace the gears as a set. If necessary, replace the timing belt case sub-assembly.

|

Inspect the gear side clearance.

Using a feeler gauge and precision straightedge, measure the clearance between the gears and precision straightedge.

- Standard side clearance:

- 0.035 to 0.085 mm (0.0014 to 0.0033 in.)

- Maximum side clearance:

- 0.15 mm (0.0059 in.)

- If the side clearance is greater than the maximum, replace the gears as a set. If necessary, replace the timing belt case sub-assembly.

|