Direct Clutch -- Inspection |

| 1. INSPECT PACK CLEARANCE OF DIRECT CLUTCH |

|

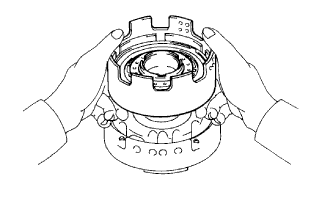

Place the direct clutch assembly onto the O/D support assembly.

Using SST and a dial indicator, measure the direct clutch pack clearance while applying and releasing compressed air (186 to 206 kPa (1.9 to 2.1 kgf/cm2, 27 to 30 psi)).

- SST

- 09350-30020(09350-06120)

- Pack clearance:

- 0.40 to 0.70 mm (0.016 to 0.028 in.)

- HINT:

- If the pack clearance is still not as specified, select another flange.

- There are 8 different flange thicknesses.

Flange thickness: No. Thickness No. Thickness 53 3.3 mm (0.130 in.) 57 3.7 mm (0.146 in.) 54 3.4 mm (0.134 in.) 58 3.8 mm (0.150 in.) 55 3.5 mm (0.138 in.) 60 4.0 mm (0.157 in.) 56 3.6 mm (0.142 in.) 62 4.2 mm (0.165 in.)

|

| 2. INSPECT DIRECT CLUTCH FLANGE |

|

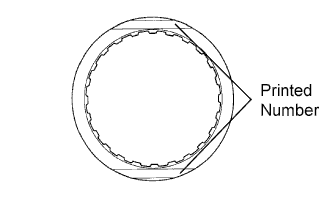

Replace all discs if one of the following problems is present: 1) a disc, plate or flange is worn or burnt, 2) the lining of a disc is peeled off or discolored, or 3) grooves or printed numbers have even a little bit of damage.

- NOTICE:

- Before assembling new discs, soak them in ATF for at least 15 minutes.

| 3. INSPECT DIRECT CLUTCH RETURN SPRING |

|

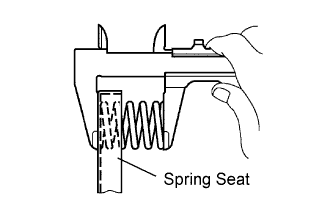

Using a vernier caliper, measure the free length of the spring together with the spring seat.

- Standard free length:

- 21.32 mm (0.839 in.)

| 4. INSPECT DIRECT CLUTCH PISTON |

|

Check that the check ball is free by shaking the piston.

Check that the valve does not have leaks by applying low-pressure compressed air.

| 5. INSPECT DIRECT CLUTCH DRUM |

|

Using a dial indicator, measure the inside diameter of the clutch drum bush.

- Maximum inside diameter:

- 53.97 mm (2.1248 in.)