Clutch Drum And Input Shaft Assembly Reassembly

INSTALL DIRECT CLUTCH PISTON SUB-ASSEMBLY

INSTALL REVERSE CLUTCH PISTON SUB-ASSEMBLY

INSTALL REVERSE CLUTCH RETURN SPRING SUB-ASSEMBLY

INSTALL NO. 3 CLUTCH BALANCER

INSTALL DIRECT CLUTCH DISC

INSPECT PACK CLEARANCE OF DIRECT CLUTCH

INSTALL REVERSE CLUTCH FLANGE

INSTALL REVERSE CLUTCH REACTION SLEEVE

INSPECT PACK CLEARANCE OF REVERSE CLUTCH

REMOVE REVERSE CLUTCH REACTION SLEEVE

INSTALL FORWARD CLUTCH PISTON

INSTALL NO. 1 CLUTCH BALANCER

INSTALL FORWARD MULTIPLE DISC CLUTCH DISC

INSTALL INPUT SHAFT OIL SEAL RING

INSPECT PACK CLEARANCE OF FORWARD CLUTCH

INSTALL INPUT SHAFT ASSEMBLY

INSTALL MULTIPLE DISC CLUTCH HUB

INSTALL FORWARD CLUTCH HUB SUB-ASSEMBLY

INSTALL REAR CLUTCH DISC

INSTALL REVERSE CLUTCH REACTION SLEEVE

INSTALL REVERSE CLUTCH HUB SUB-ASSEMBLY

Clutch Drum And Input Shaft Assembly -- Reassembly |

| 1. INSTALL DIRECT CLUTCH PISTON SUB-ASSEMBLY |

Coat 2 new O-rings with ATF, and install them in the direct clutch piston.

Install the No. 2 clutch balancer and direct clutch return spring to the direct clutch piston.

Coat a new O-ring with ATF, and install it on the clutch drum sub-assembly.

Press the direct clutch piston into the clutch drum with both hands.

- NOTICE:

- Be careful not to damage the O-rings.

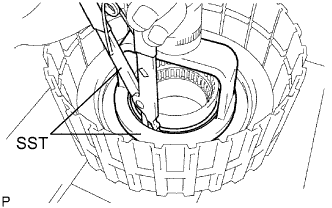

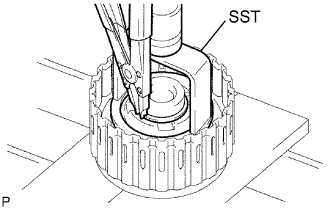

Place SST on the direct clutch piston, and compress the return spring with a press.

- SST

- 09320-89010

09350-30020(09350-07070)

- NOTICE:

- Stop pressing when the spring sheet is lowered to the place 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove to prevent the spring sheet from being deformed.

Install the snap ring with a snap ring expander.

- NOTICE:

- Do not expand the snap ring excessively.

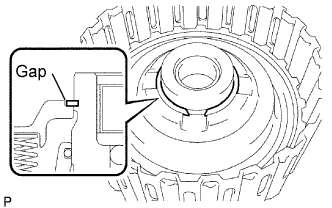

Set the end gap of the snap ring in the piston as shown in the illustration.

- NOTICE:

- Be sure the end gap of the snap ring is not aligned with the spring retainer claw.

| 2. INSTALL REVERSE CLUTCH PISTON SUB-ASSEMBLY |

Coat a new O-ring with ATF, and install it on the clutch drum.

Coat a new O-ring with ATF, and install it on the reverse clutch piston.

Press the clutch drum sub-assembly into the reverse clutch piston with both hands.

- NOTICE:

- Be careful not to damage the O-rings.

| 3. INSTALL REVERSE CLUTCH RETURN SPRING SUB-ASSEMBLY |

Coat a new O-ring with ATF, and install it on the reverse clutch piston.

Install the reverse clutch return spring onto the reverse clutch piston.

| 4. INSTALL NO. 3 CLUTCH BALANCER |

Place SST on the No. 3 clutch balancer, and compress the clutch balancer with a press.

- SST

- 09387-00070

09350-30020(09350-07070)

- NOTICE:

- Stop pressing when the spring sheet is lowered to the place 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove to prevent the spring sheet from being deformed.

Install the snap ring with a snap ring expander.

- NOTICE:

- Do not expand the snap ring excessively.

Set the end gap of the snap ring in the piston as shown in the illustration.

- NOTICE:

- Be sure the end gap of the snap ring is not aligned with the spring retainer claw.

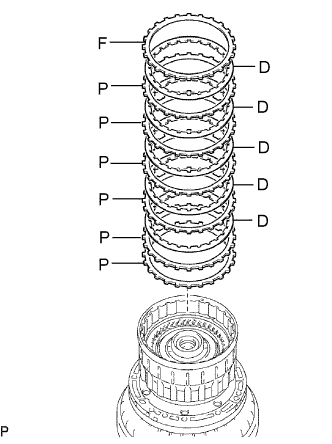

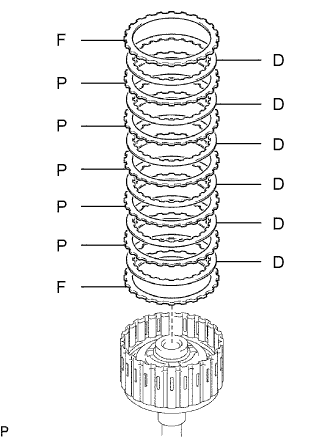

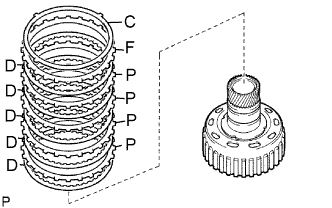

| 5. INSTALL DIRECT CLUTCH DISC |

Install the 6 plates, 5 discs and flange on the clutch drum.

- Install in order:

- P - P - D - P - D - P - D - P - D - P - D - F

- HINT:

- P = Plate

D = Disc

F = Flange

Using a screwdriver, install the 2 hole snap rings on the clutch drum.

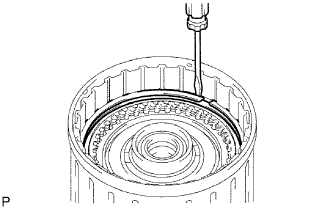

| 6. INSPECT PACK CLEARANCE OF DIRECT CLUTCH |

Using a dial gauge, measure the moving distance (distance A) of the clutch flange at both ends across a diameter while blowing air from the oil hole as shown in the illustration, and calculate the average.

- Standard pack clearance:

- 0.5 to 0.8 mm (0.020 to 0.031 in.)

- NOTICE:

- When measuring the moving distance, install a standard flange (thickness: 3.4 mm (0.031 in.)) to the position of the shaded area in the illustration.

- HINT:

- Flange moving distance A = 0.26 to 1.14 mm (0.010 to 0.045 in.)

- Pack clearance = Flange moving distance A - 0.05 mm (0.002 in.)

If the pack clearance is not within the standard, select and install a clutch flange that makes the pack clearance within the standard.

- Standard flange thickness:

No.

| Thickness

| No.

| Thickness

|

0

| 3.0 mm (0.118 in.)

| 5

| 3.5 mm (0.138 in.)

|

1

| 3.1 mm (0.122 in.)

| 6

| 3.6 mm (0.142 in.)

|

2

| 3.2 mm (0.126 in.)

| 7

| 3.7 mm (0.146 in.)

|

3

| 3.3 mm (0.130 in.)

| 8

| 3.8 mm (0.150 in.)

|

4

| 3.4 mm (0.134 in.)

| -

| -

|

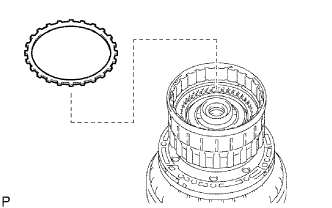

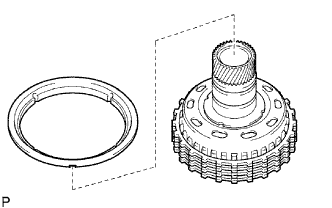

| 7. INSTALL REVERSE CLUTCH FLANGE |

Install the reverse clutch flange to the clutch drum.

| 8. INSTALL REVERSE CLUTCH REACTION SLEEVE |

Install the reverse clutch reaction sleeve, clutch cushion plate, reverse clutch flange, 5 reverse clutch discs, and 4 clutch plates to the reverse clutch hub.

Using a screwdriver, install the hole snap ring.

| 9. INSPECT PACK CLEARANCE OF REVERSE CLUTCH |

Using a dial gauge, measure the reverse clutch piston stroke (distance A) and the moving distance (distance B) of the reverse flange at both ends across a diameter while blowing air (392 kPa, 4 kgf/cm2, 57 psi) from the oil hole as shown in the illustration, and calculate the average.

- Standard pack clearance:

- 0.5 to 0.8 mm (0.020 to 0.031 in.)

- NOTICE:

- When measuring the moving distance, install a standard flange (thickness: 3.3 mm (0.130 in.)) to the position of the shaded area in the illustration.

- HINT:

- Piston stroke A = 1.05 to 2.15 mm (0.041 to 0.085 in.)

- Flange moving distance B = 0.72 to 1.08 mm (0.029 to 0.043 in.)

- Pack clearance = Piston stroke A - Flange moving distance B - 0.06 mm (0.002 in.)

If the pack clearance is not within the standard, select and install a clutch flange that makes the pack clearance within the standard.

- Standard flange thickness:

No.

| Thickness

| No.

| Thickness

|

0

| 2.8 mm (0.110 in.)

| 6

| 3.4 mm (0.134 in.)

|

1

| 2.9 mm (0.114 in.)

| 7

| 3.5 mm (0.138 in.)

|

2

| 3.0 mm (0.118 in.)

| 8

| 3.6 mm (0.142 in.)

|

3

| 3.1 mm (0.122 in.)

| 9

| 3.7 mm (0.146 in.)

|

4

| 3.2 mm (0.126 in.)

| A

| 3.8 mm (0.150 in.)

|

5

| 3.3 mm (0.130 in.)

| -

| -

|

| 10. REMOVE REVERSE CLUTCH REACTION SLEEVE |

Using a screwdriver, remove the snap ring from the clutch drum.

Remove the reverse clutch reaction sleeve, clutch cushion plate, reverse clutch flange, 5 reverse clutch discs, and 4 clutch plates from the reverse clutch hub.

| 11. INSTALL FORWARD CLUTCH PISTON |

Coat 2 new O-rings with ATF, and install them on the No. 1 forward clutch piston.

| 12. INSTALL NO. 1 CLUTCH BALANCER |

Coat a new O-ring with ATF and install it on the clutch balancer.

Install the No. 1 clutch balancer and forward clutch return spring.

- NOTICE:

- Be careful not to damage the O-ring.

Place SST on the No. 1 clutch balancer, and compress the return spring with a press.

- SST

- 09350-30020(09350-07040,09350-07070)

- NOTICE:

- Stop pressing when the spring sheet is lowered to the place 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove to prevent the spring sheet from being deformed.

Install the snap ring with a snap ring expander.

- NOTICE:

- Do not expand the snap ring excessively.

Set the end gap of the snap ring in the piston as shown in the illustration.

- NOTICE:

- Be sure the end gap of the snap ring is not aligned with the spring retainer claw.

| 13. INSTALL FORWARD MULTIPLE DISC CLUTCH DISC |

Install the 2 flanges, 6 discs and 5 plates to the input shaft assembly.

- Install in order:

- F- D - P - D - P - D - P - D - P - D - P - D - F

- HINT:

- F = Flange

- D = Disc

- P = Plate

Using a screwdriver, install the hole snap ring.

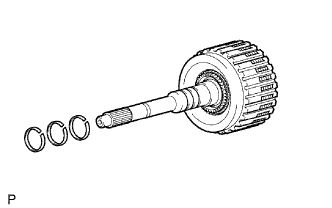

| 14. INSTALL INPUT SHAFT OIL SEAL RING |

Coat the 3 oil seal rings with ATF.

Squeeze the ends of the 3 oil seal rings together, and then install them to the input shaft groove.

- NOTICE:

- Do not over-spread the ring ends.

- HINT:

- After installing the oil seal rings, check that they rotate smoothly.

| 15. INSPECT PACK CLEARANCE OF FORWARD CLUTCH |

Using a dial gauge, measure the moving distance (distance A) of the clutch flange at both ends across a diameter while blowing air from the oil hole as shown in the illustration, and calculate the average.

- Standard pack clearance:

- 0.6 to 0.9 mm (0.024 to 0.354 in.)

- NOTICE:

- When measuring the moving distance, install a standard flange (thickness: 3.4 mm (0.031 in.)) to the position of the shaded area in the illustration.

- HINT:

- Flange moving distance A = 0.26 to 1.36 mm (0.010 to 0.054 in.)

- Pack clearance = Flange moving distance A to 0.01 mm (0.0003 in.)

If the pack clearance is not within the standard, select and install a clutch flange that makes the pack clearance within the standard.

- Standard flange thickness:

No.

| Thickness

| No.

| Thickness

|

0

| 3.0 mm (0.118 in.)

| 6

| 3.6 mm (0.142 in.)

|

1

| 3.1 mm (0.122 in.)

| 7

| 3.7 mm (0.146 in.)

|

2

| 3.2 mm (0.126 in.)

| 8

| 3.8 mm (0.150 in.)

|

3

| 3.3 mm (0.130 in.)

| 9

| 3.9 mm (0.154 in.)

|

4

| 3.4 mm (0.134 in.)

| A

| 4.0 mm (0.158 in.)

|

5

| 3.5 mm (0.138 in.)

| -

| -

|

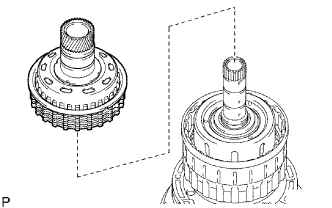

| 16. INSTALL INPUT SHAFT ASSEMBLY |

Install the input shaft to the clutch drum.

Install the thrust needle roller bearing to the clutch drum assembly.

- Standard thrust needle roller bearing diameter:

Item

| Inside

| Outside

|

Thrust needle roller bearing

| 21.3 mm (0.839 in.)

| 41.1 mm (1.618 in.)

|

| 17. INSTALL MULTIPLE DISC CLUTCH HUB |

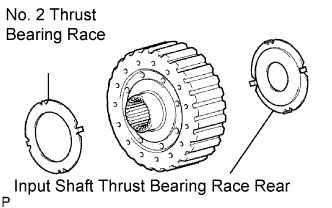

Install the No. 2 thrust bearing race and input shaft thrust bearing race rear to the multiple disc clutch hub.

- Standard bearing and race diameter:

Item

| Inside

| Outside

|

No. 2 thrust bearing race

| 38.4 mm (1.512 in.)

| 63.0 mm (2.480 in.)

|

Input shaft thrust bearing race RR

| 22.6 mm (0.890 in.)

| 60.0 mm (2.362 in.)

|

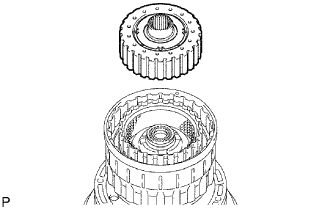

Install the multiple disc clutch hub to the clutch drum.

| 18. INSTALL FORWARD CLUTCH HUB SUB-ASSEMBLY |

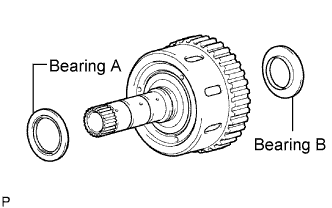

Install the 2 thrust needle roller bearings to the forward clutch hub.

- Bearing and race diameter:

Item

| Inside

| Outside

|

Bearing A

| 42.5 mm (1.673 in.)

| 61.2 mm (2.409 in.)

|

Bearing B

| 33.3 mm (1.311 in.)

| 56.6 mm (2.228 in.)

|

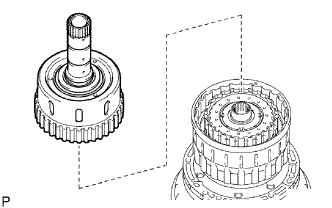

Install the forward clutch hub to the clutch drum.

| 19. INSTALL REAR CLUTCH DISC |

Install the 5 discs, 4 plates, flange and cushion plate to the reverse clutch hub.

- Install in order:

- D - P - D - P - D - P - D - P - D - F

- HINT:

- D = Disc

- P = Plate

F = Flange

C = Cushion plate

| 20. INSTALL REVERSE CLUTCH REACTION SLEEVE |

Install the reverse clutch reaction sleeve to the reverse clutch hub.

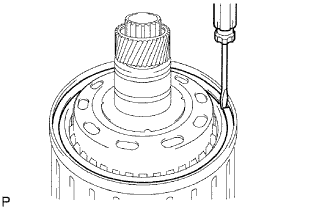

| 21. INSTALL REVERSE CLUTCH HUB SUB-ASSEMBLY |

Install the reverse clutch hub, reverse clutch reaction sleeve, cushion plate, flange, 5 discs, and 4 plates to the clutch drum.

Using a screwdriver, install the snap ring on the clutch drum and input shaft.