Automatic Transmission Assembly Installation

INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY

INSTALL TORQUE CONVERTER CLUTCH ASSEMBLY

INSTALL AUTOMATIC TRANSMISSION ASSEMBLY

INSTALL FLYWHEEL HOUSING SIDE COVER

INSTALL STARTER ASSEMBLY

CONNECT WIRE HARNESS

CONNECT CONNECTOR

INSTALL NO. 1 ENGINE MOUNTING INSULATOR REAR

INSTALL NO. 3 FRAME CROSSMEMBER SUB-ASSEMBLY

INSTALL NO. 1 TRANSMISSION CONTROL CABLE BRACKET

INSTALL TRANSMISSION CONTROL CABLE ASSEMBLY

INSTALL OIL COOLER TUBE

INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH

INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH

INSTALL NO. 2 MANIFOLD STAY

INSTALL MANIFOLD STAY

INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

INSTALL FRONT EXHAUST PIPE ASSEMBLY

CONNECT HEATED OXYGEN SENSOR

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

ADD AUTOMATIC TRANSMISSION FLUID

ADJUST AUTOMATIC TRANSMISSION FLUID

INSPECT SHIFT LEVER POSITION

PERFORM INITIALIZATION

CHECK FOR EXHAUST GAS LEAKS

Automatic Transmission Assembly -- Installation |

| 1. INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY |

Inspect torque converter clutch assembly (Toyota Fortuner RM0000013F201NX.html).

| 2. INSTALL TORQUE CONVERTER CLUTCH ASSEMBLY |

Install the torque converter clutch to the automatic transmission.

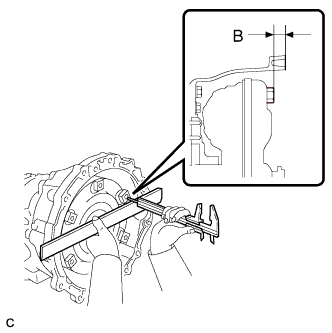

Using a vernier caliper and straightedge, measure dimension A between the contact surfaces of the transmission and engine, and the contact surfaces of the converter and drive plate.

Using a vernier caliper and straightedge, measure dimension B shown in the illustration. Check that B is greater than A.

- Standard:

- B = A + 1.00 mm (0.0394 in.) or more

| 3. INSTALL AUTOMATIC TRANSMISSION ASSEMBLY |

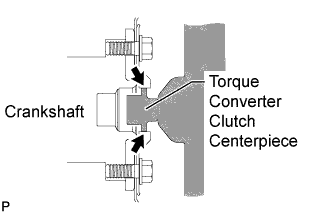

Apply clutch spline grease to the surface of the torque converter centerpiece that contacts the crankshaft.

- Clutch spline grease:

- Toyota Genuine Clutch Spline Grease or equivalent

- Maximum grease amount:

- Approximately 1 g (0.353 oz)

Install the transmission to the engine with the 9 bolts.

- Torque:

- 71 N*m{720 kgf*cm, 53 ft.*lbf}for bolt A

- 37 N*m{380 kgf*cm, 27 ft.*lbf}for bolt B

Hold the crankshaft pulley bolt with a wrench and install the 6 torque converter clutch mounting bolts.

- Torque:

- 48 N*m{489 kgf*cm, 35 ft.*lbf}

- HINT:

- First install the black bolt, and then the other 5 bolts.

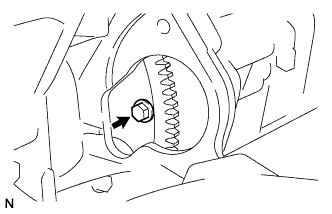

| 4. INSTALL FLYWHEEL HOUSING SIDE COVER |

| 5. INSTALL STARTER ASSEMBLY |

Install starter assembly (Toyota Fortuner RM0000013XI00DX.html).

Connect the connectors.

Connect the park/neutral position switch connector.

Connect the transmission wire connector.

Connect the 3 speed sensor connectors.

| 8. INSTALL NO. 1 ENGINE MOUNTING INSULATOR REAR |

Install the engine mounting insulator to the transmission with the 4 bolts.

- Torque:

- 47 N*m{479 kgf*cm, 35 ft.*lbf}

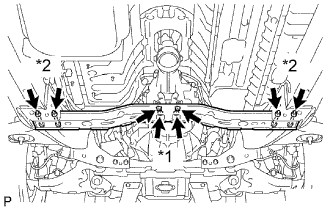

| 9. INSTALL NO. 3 FRAME CROSSMEMBER SUB-ASSEMBLY |

*1: Install the 4 set bolts of the engine mounting insulator.

- Torque:

- 27 N*m{275 kgf*cm, 20 ft.*lbf}

*2: Install the frame crossmember with the 4 bolts and 4 nuts.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

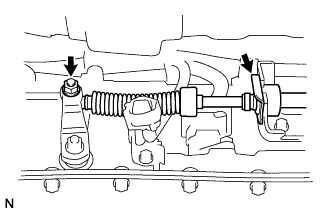

| 10. INSTALL NO. 1 TRANSMISSION CONTROL CABLE BRACKET |

Install the control cable bracket with the 2 bolts.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

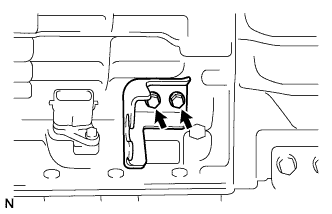

| 11. INSTALL TRANSMISSION CONTROL CABLE ASSEMBLY |

Connect the control cable with the clip.

Connect the control cable with the nut.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

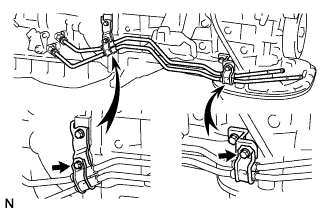

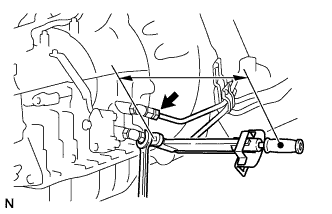

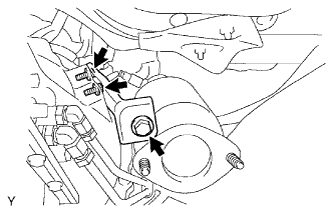

| 12. INSTALL OIL COOLER TUBE |

Loosely install the tip of the oil cooler tube inlet to the automatic transmission by hand.

Loosely install the tip of the oil cooler tube outlet to the automatic transmission by hand.

Install the 2 clamps with the 2 bolts.

- Torque:

- 5.0 N*m{50 kgf*cm, 43 in.*lbf}

Using a union nut wrench, tighten the oil cooler inlet and outlet tubes.

- Torque:

- 34 N*m{346 kgf*cm, 25 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (Toyota Fortuner RM000000UYX010X.html).

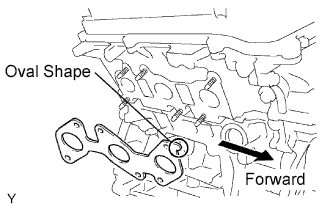

| 13. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH |

Set a new gasket to the RH cylinder head with the oval shape facing forward.

- NOTICE:

- Be careful of the installation direction.

Install the exhaust manifold with the 6 nuts. Uniformly tighten the nuts in several passes.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Connect the A/F sensor connector.

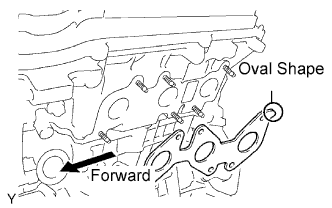

| 14. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH |

Set a new gasket to the LH cylinder head with the oval shape facing backward.

- NOTICE:

- Be careful of the installation direction.

Install the exhaust manifold with the 6 nuts. Uniformly tighten the nuts in several passes.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Connect the A/F sensor connector.

| 15. INSTALL NO. 2 MANIFOLD STAY |

Install the manifold stay with the 3 bolts.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

| 16. INSTALL MANIFOLD STAY |

Install the manifold stay with the 3 bolts.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

| 17. INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY |

Install the propeller shaft with center bearing assembly (Toyota Fortuner RM000000ZZ1008X.html).

| 18. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Install the exhaust pipe (Toyota Fortuner RM000001216003X.html).

| 19. CONNECT HEATED OXYGEN SENSOR |

| 20. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- Certain systems need to be initialized after disconnecting and reconnecting the cable from the negative (-) battery terminal.

| 21. ADD AUTOMATIC TRANSMISSION FLUID |

Add automatic transmission fluid (Toyota Fortuner RM0000013BU03NX.html).

| 22. ADJUST AUTOMATIC TRANSMISSION FLUID |

Adjust the automatic transmission fluid (Toyota Fortuner RM0000013BU03NX.html).

| 23. INSPECT SHIFT LEVER POSITION |

When moving the shift lever from P to R with the ignition switch ON and the brake pedal depressed, make sure that the shift lever moves smoothly and correctly into position.

Start the engine and make sure that the vehicle moves forward after moving the shift lever from N to D, and moves rearward after shifting to the R.

If the results are not as specified, inspect the park/neutral position switch and check the shift lever.

| 24. PERFORM INITIALIZATION |

- HINT:

- Refer to "INTRODUCTION REPAIR INSTRUCTION-INITIALIZATION" and perform initialization.

| 25. CHECK FOR EXHAUST GAS LEAKS |