Automatic Transmission Unit Reassembly

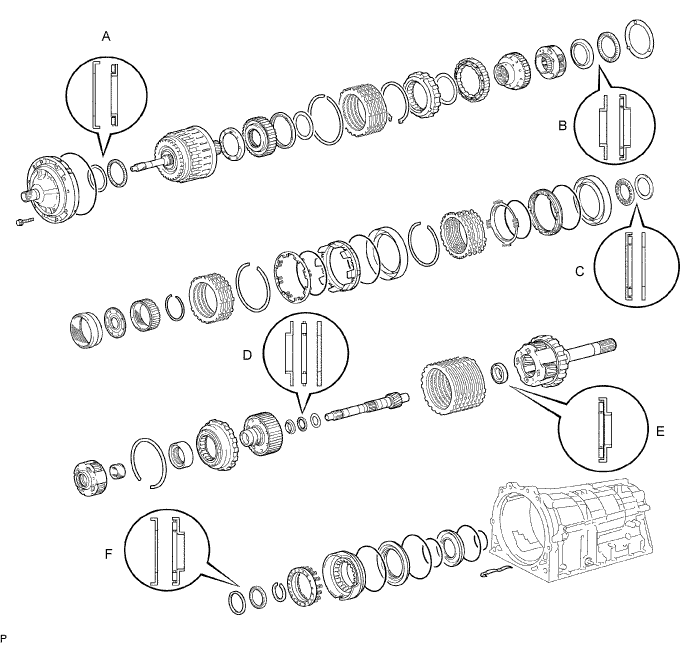

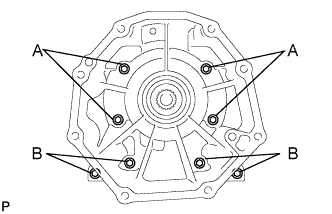

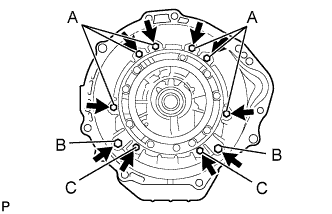

BEARING POSITION

INSTALL NO. 4 BRAKE PISTON

INSTALL BRAKE REACTION SLEEVE

INSTALL 1ST AND REVERSE BRAKE PISTON

INSTALL 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY

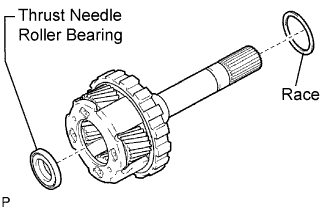

INSTALL REAR PLANETARY GEAR ASSEMBLY

INSPECT PACK CLEARANCE OF 1ST AND REVERSE BRAKE

INSTALL NO. 4 BRAKE DISC

INSTALL BRAKE PLATE STOPPER SPRING

INSTALL REAR PLANETARY RING GEAR FLANGE SUB-ASSEMBLY

INSTALL NO. 3 1-WAY CLUTCH ASSEMBLY

INSTALL INTERMEDIATE SHAFT

INSTALL CENTER PLANETARY GEAR ASSEMBLY

INSTALL NO. 2 BRAKE PISTON

INSTALL NO. 2 BRAKE DISC

INSTALL NO. 1 BRAKE PISTON

INSTALL BRAKE PISTON RETURN SPRING SUB-ASSEMBLY

INSTALL BRAKE PISTON RETURN SPRING SNAP RING

INSTALL NO. 1 BRAKE DISC

INSTALL CENTER PLANETARY RING GEAR

INSTALL FRONT PLANETARY RING GEAR

INSTALL FRONT PLANETARY GEAR ASSEMBLY

INSPECT NO. 1 PISTON STROKE OF BRAKE PISTON

INSTALL 2ND BRAKE PISTON

INSTALL 2ND BRAKE CYLINDER

INSTALL 1-WAY CLUTCH ASSEMBLY

INSTALL 2ND BRAKE PISTON HOLE SNAP RING

INSTALL NO. 3 BRAKE DISC

INSTALL NO. 3 BRAKE SNAP RING

INSTALL NO. 2 1-WAY CLUTCH ASSEMBLY

INSTALL CLUTCH DRUM AND INPUT SHAFT ASSEMBLY

INSTALL OIL PUMP ASSEMBLY

INSTALL MANUAL VALVE LEVER SHAFT OIL SEAL

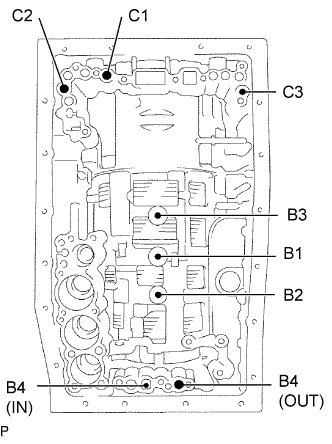

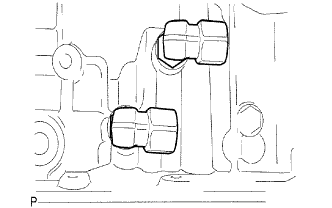

INSPECT INDIVIDUAL PISTON OPERATION INSPECTION

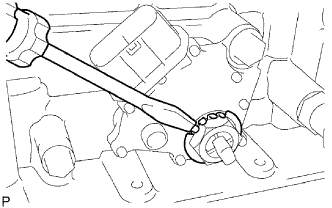

INSTALL MANUAL VALVE LEVER SUB-ASSEMBLY

INSTALL PARKING LOCK PAWL SHAFT

CONNECT PARKING LOCK ROD SUB-ASSEMBLY

INSTALL PARKING LOCK PAWL BRACKET

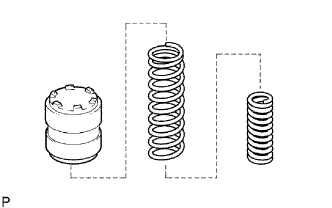

INSTALL C-1 ACCUMULATOR VALVE

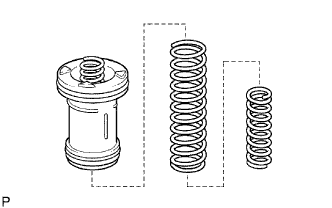

INSTALL C-3 ACCUMULATOR PISTON

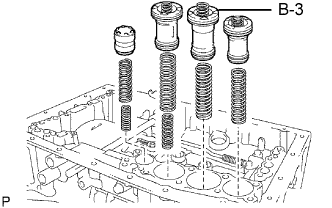

INSTALL B-3 ACCUMULATOR PISTON

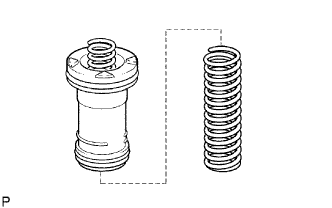

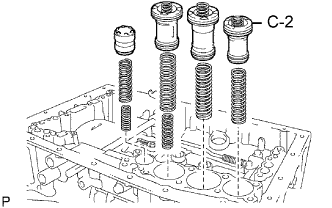

INSTALL C-2 ACCUMULATOR PISTON

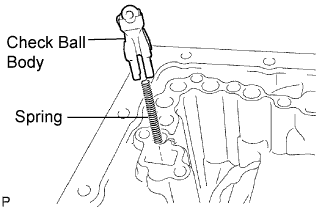

INSTALL CHECK BALL BODY

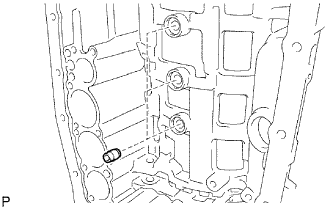

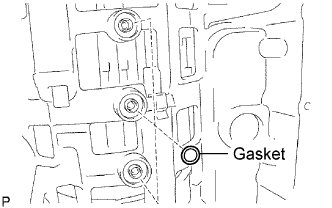

INSTALL BRAKE DRUM GASKET

INSTALL TRANSAXLE CASE GASKET

INSTALL TRANSMISSION VALVE BODY ASSEMBLY

INSTALL TRANSMISSION WIRE

INSTALL VALVE BODY OIL STRAINER ASSEMBLY

INSTALL TRANSMISSION OIL CLEANER MAGNET

INSTALL AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY

INSTALL TRANSMISSION CASE ADAPTER OIL SEAL

INSTALL TRANSMISSION CASE ADAPTER SUB-ASSEMBLY

INSTALL AUTOMATIC TRANSMISSION HOUSING

INSTALL AUTOMATIC TRANSAXLE BREATHER TUBE

INSTALL TRANSMISSION REVOLUTION SENSOR (NT) AND (SP2)

INSTALL OIL COOLER TUBE UNION

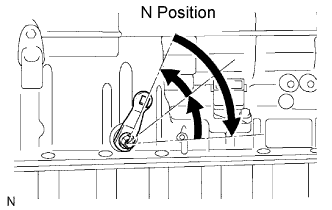

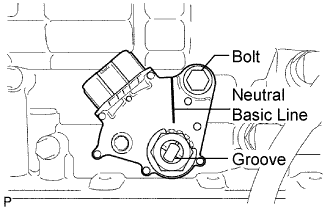

INSTALL PARK/NEUTRAL POSITION SWITCH ASSEMBLY

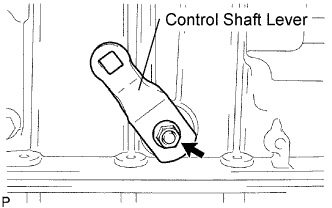

INSTALL TRANSMISSION CONTROL SHAFT LEVER LH

Automatic Transmission Unit -- Reassembly |

- Bearing diameter:

Mark

| Front Race Diameter Inside / Outside

| Thrust Bearing Diameter Inside / Outside

| Rear Race Diameter Inside / Outside

|

A

| 73.6 mm (2.898 in.) / 102.0 mm (4.016 in.)

| 71.9 mm (2.831 in.) / 85.6 mm (3.370 in.)

| -

|

B

| 38.0 mm (1.496 in.) / 57.0 mm (2.244 in.)

| 43.4 mm (1.709 in.) / 58.3 mm (2.295 in.)

| -

|

C

| -

| 55.7 mm (2.193 in.) / 76.4 mm (3.008 in.)

| 53.7 mm (2.114 in.) / 74.0 mm (2.913 in.)

|

D

| 33.4 mm (1.315 in.) / 49.0 mm (1.929 in.)

| 32.1 mm (1.264 in.) / 49.35 mm (1.943 in.)

| 32.1 mm (1.2649 in.) / 49.0 mm (1.929 in.)

|

E

| -

| 21.5 mm(0.847 in.) / 40.8 mm (1.606 in.)

| -

|

F

| 48.5 mm (1.909 in.) / 62.7 mm (2.469 in.)

| 45.9 mm (1.807 in.) / 64.0 mm (2.520 in.)

| -

|

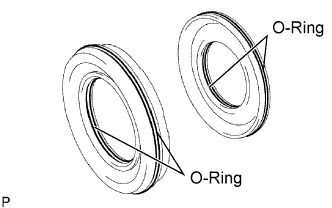

| 2. INSTALL NO. 4 BRAKE PISTON |

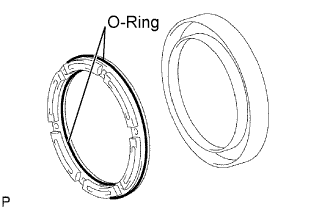

Coat 2 new O-rings with ATF, and install them to the brake reaction sleeve.

Coat 2 new O-rings with ATF, and install them to the No. 4 brake piston.

Install the No. 4 brake piston to the reaction sleeve.

| 3. INSTALL BRAKE REACTION SLEEVE |

Install the brake reaction sleeve and the No. 4 brake piston to the transmission case.

- NOTICE:

- Be careful not to damage the O-rings.

- Make sure the No. 4 brake piston is underneath the brake reaction sleeve.

| 4. INSTALL 1ST AND REVERSE BRAKE PISTON |

Coat a new O-ring with ATF.

Install the O-ring on the 1st and reverse brake piston.

With the spring seat of the piston facing upwards (the front side), place the piston in the transmission case.

- NOTICE:

- Be careful not to damage the O-ring.

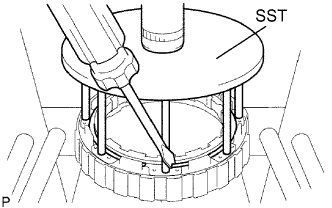

| 5. INSTALL 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY |

Place the 1st and reverse brake return spring onto the No. 4 brake piston.

Place SST on the spring retainer, and compress the return spring.

- SST

- 09350-30020(09350-07050)

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07070)

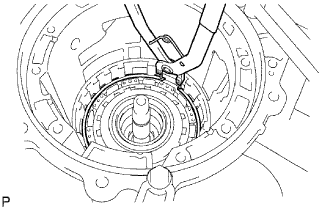

| 6. INSTALL REAR PLANETARY GEAR ASSEMBLY |

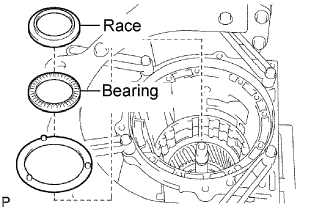

Install the thrust needle roller bearing.

- Standard thrust needle roller bearing diameter:

Item

| Inside

| Outside

|

Thrust needle roller bearing

| 45.9 mm (1.807 in.)

| 64.0 mm (2.520 in.)

|

Install the thrust needle roller bearing.

Coat the No. 9 thrust bearing race with petroleum jelly, and install it onto the rear planetary ring gear.

- Standard bearing and race diameter:

Item

| Inside

| Outside

|

Bearing

| 21.5 mm (0.847 in.)

| 40.8 mm (1.606 in.)

|

Race

| 48.5 mm (1.909 in.)

| 62.7 mm (2.469 in.)

|

Install the rear planetary gear assembly.

| 7. INSPECT PACK CLEARANCE OF 1ST AND REVERSE BRAKE |

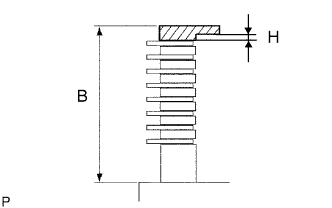

Make sure the 1st and reverse brake pistons move smoothly when applying compressed air into and releasing compressed air from the transmission case.

Using a vernier caliper, measure the level difference (length A) between the upper surface of the 1st and reverse brake piston and the hitting surface of the No. 4 brake flange at both ends across a diameter, and calculate the average.

- NOTICE:

- The 1st and reverse brake piston must be installed tightly to the end face of the transmission case.

- HINT:

- Length A = 36.35 to 37.09 mm (1.431 to 1.460 in.)

Using a vernier caliper, measure the thickness (length B) of the 2 brake flanges, 7 No. 4 brake plates and 8 No. 4 brake discs at both ends across a diameter, and calculate the average.

- HINT:

- Pack clearance = Length A - Length B - 0.25 mm to 1.8 mm (0.010 to 0.071 in.)

- Length B = 36.04 to 37.14 mm (1.419 to 1.462 in.)

- Pack clearance:

- 0.8 to 1.1 mm (0.031 to 0.043 in.)

If the pack clearance is not within the standard, select and install a brake flange that makes the pack clearance within the standard.

- H thickness:

No.

| Thickness

| No.

| Thickness

|

0

| 0 mm (0 in.)

| 8

| 0.8 mm (0.032 in.)

|

2

| 0.2 mm(0.008 in.)

| 10

| 1.0 mm (0.039 in.)

|

4

| 0.4 mm (0.016 in.)

| 12

| 1.2 mm (0.047 in.)

|

6

| 0.6 mm (0.024 in.)

| 14

| 1.4 mm (0.055 in.)

|

| 8. INSTALL NO. 4 BRAKE DISC |

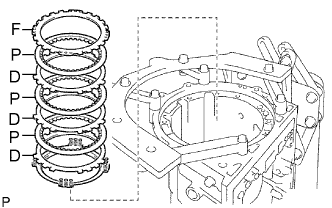

Install the 2 flanges, 8 discs and 7 plates.

- Install in order:

- F - D - P - D - P - D- P - D -P - D - P - D - P - D - P - D - F

- HINT:

- F = Flange

- D = Disc

- P = Plate

| 9. INSTALL BRAKE PLATE STOPPER SPRING |

Install the brake stopper spring.

| 10. INSTALL REAR PLANETARY RING GEAR FLANGE SUB-ASSEMBLY |

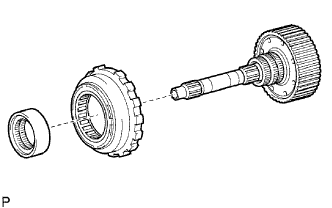

Install the No. 8 thrust bearing race, thrust needle roller bearing, No. 7 thrust bearing race and planetary ring gear flange to the intermediate shaft.

- Standard bearing and race diameter:

Item

| Inside

| Outside

|

No. 7 thrust bearing race

| 33.4 mm (1.315 in.)

| 49.0 mm (1.929 in.)

|

Thrust needle roller bearing

| 32.1 mm (1.264 in.)

| 49.35 mm (1.943 in.)

|

No. 8 thrust bearing race

| 32.1 mm (1.264 in.)

| 49.0 mm (1.929 in.)

|

| 11. INSTALL NO. 3 1-WAY CLUTCH ASSEMBLY |

Install the No. 3 1-way clutch assembly and the 1-way clutch inner race to the intermediate shaft.

| 12. INSTALL INTERMEDIATE SHAFT |

Install the intermediate shaft with the No. 3 1-way clutch assembly to the case.

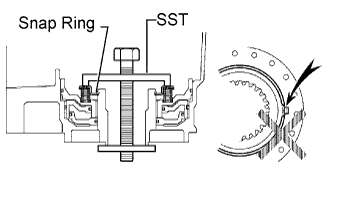

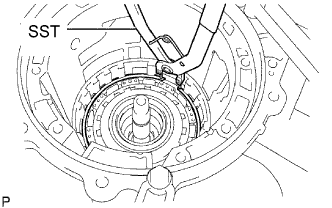

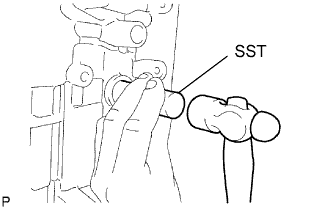

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07050,09350-07060)

| 13. INSTALL CENTER PLANETARY GEAR ASSEMBLY |

Install the center planetary gear assembly and planetary sun gear to the case.

Coat the thrust bearing race with petroleum jelly, and install it onto the center planetary gear.

- Standard race diameter:

Item

| Inside

| Outside

|

Race

| 53.7 mm (2.114 in.)

| 74.0 mm (2.913 in.)

|

| 14. INSTALL NO. 2 BRAKE PISTON |

Coat 2 new O-rings with ATF, and install them to the No. 2 brake piston.

Be careful not to damage the O-rings. Press the No. 2 brake piston into the No. 2 brake cylinder with both hands.

Install the No. 2 brake piston to the case.

| 15. INSTALL NO. 2 BRAKE DISC |

Install the brake piston return spring, 3 discs, 3 plates and flange.

- Install in order:

- D - P - D - P - D - P - F

- HINT:

- D = Disc

- P = Plate

F = Flange

Using SST and press, install the No. 2 brake spring snap ring.

- SST

- 09351-40010

| 16. INSTALL NO. 1 BRAKE PISTON |

Coat 2 new O-rings with ATF, and install them on the No. 1 brake piston.

Be careful not to damage the O-rings. Press the No. 1 brake piston into the No. 1 brake cylinder with both hands.

| 17. INSTALL BRAKE PISTON RETURN SPRING SUB-ASSEMBLY |

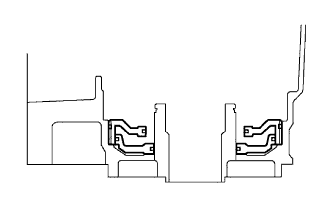

Install the brake piston return spring and No. 1 brake piston with No. 1 brake cylinder on the transmission case.

| 18. INSTALL BRAKE PISTON RETURN SPRING SNAP RING |

Using SST and a press, install the brake piston return spring snap ring.

- SST

- 09351-40010

| 19. INSTALL NO. 1 BRAKE DISC |

Install the 3 plates, 3 discs and flange.

- Install in order:

- P - D - P - D - P - D - F

- HINT:

- P = Plate

D = Disc

F = Flange

| 20. INSTALL CENTER PLANETARY RING GEAR |

Install the center planetary ring gear and front planetary ring gear flange on the front planetary ring gear.

Using a screwdriver, install the snap ring.

| 21. INSTALL FRONT PLANETARY RING GEAR |

Install the front planetary ring gear and thrust needle roller bearing on the case.

- Standard thrust needle roller bearing diameter:

Item

| Inside

| Outside

|

Thrust needle roller bearing

| 55.7 mm (2.193 in.)

| 76.4 mm (3.008 in.)

|

| 22. INSTALL FRONT PLANETARY GEAR ASSEMBLY |

Install the thrust needle roller bearing and thrust washer.

Coat the thrust race with petroleum jelly, and install it onto the front planetary ring gear.

- Standard thrust needle roller bearing and race diameter:

Item

| Inside

| Outside

|

Thrust needle roller bearing

| 43.4 mm (1.709 in.)

| 58.3 mm (2.295 in.)

|

Race

| 38.0 mm (1.496 in.)

| 57.0 mm (2.244 in.)

|

Install the front planetary gear and 1-way clutch inner race to the case.

| 23. INSPECT NO. 1 PISTON STROKE OF BRAKE PISTON |

Make sure the No. 1 brake piston moves smoothly when applying compressed air into and releasing compressed air from the transmission case.

Using a feeler gauge, measure the B3 brake pack clearance between the snap ring and flange.

- Standard piston stroke:

- 0.42 to 0.72 mm (0.017 to 0.028 in.)

If the piston stroke is not within the specification, parts may have been assembled incorrectly.

Perform the reassembly.

If the piston stroke is still not within the specification, select another flange.

- HINT:

- There are 4 different thicknesses for the flange.

- Standard flange thickness:

No.

| Thickness

| No.

| Thickness

|

0

| 2.0 mm (0.079 in.)

| 2

| 2.4 mm (0.094 in.)

|

1

| 2.2 mm (0.087 in.)

| 3

| 2.6 mm (0.102 in.)

|

| 24. INSTALL 2ND BRAKE PISTON |

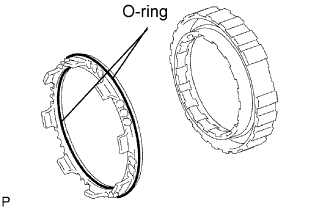

Coat 2 new O-rings with ATF, and install them to the 2nd brake piston.

Be careful not to damage the O-rings. Press the 2nd brake cylinder into the 2nd brake piston with both hands.

Using SST and press, install the snap ring.

- SST

- 09351-40010

- NOTICE:

- Be sure the end gap of the snap ring is not aligned with the spring retainer claw.

| 25. INSTALL 2ND BRAKE CYLINDER |

Install the 2nd brake cylinder to the case.

| 26. INSTALL 1-WAY CLUTCH ASSEMBLY |

Install the 1-way clutch and thrust washer to the case.

| 27. INSTALL 2ND BRAKE PISTON HOLE SNAP RING |

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07060)

| 28. INSTALL NO. 3 BRAKE DISC |

Install the cushion plate, 4 plates, 4 discs and flange on the case.

- Install in order:

- C - P - D - P - D - P - D - P - D - F

- HINT:

- C = Cushion

- P = Plate

D = Disc

F = Flange

| 29. INSTALL NO. 3 BRAKE SNAP RING |

Using a screwdriver, install the snap ring.

| 30. INSTALL NO. 2 1-WAY CLUTCH ASSEMBLY |

Coat the race with petroleum jelly and install it onto the No. 2 clutch drum thrust washer.

Install the No. 2 1-way clutch and washer.

| 31. INSTALL CLUTCH DRUM AND INPUT SHAFT ASSEMBLY |

Install the thrust needle roller bearing.

Coat the race with petroleum jelly and install it onto the clutch drum and input shaft.

- Standard thrust needle roller bearing and diameter:

Item

| Inside

| Outside

|

Thrust needle roller bearing

| 71.9 mm (2.831 in.)

| 85.6 mm (3.370 in.)

|

Race

| 73.6 mm (2.898 in.)

| 102.0 mm (4.016 in.)

|

Install the clutch drum and input shaft drum assembly onto the transmission case.

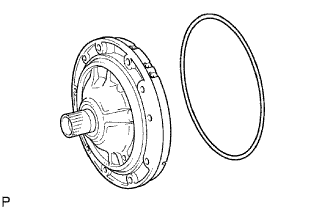

| 32. INSTALL OIL PUMP ASSEMBLY |

Install the No. 1 thrust bearing race to the front oil pump.

- Standard No. 1 thrust bearing race diameter:

Item

| Inside

| Outside

|

Race

| 74.2 mm (2.921 in.)

| 87.74 mm (3.454 in.)

|

Coat a new O-ring with ATF, and install it around the oil pump.

Place the oil pump through the input shaft, and align the bolt holes of the oil pump with the transmission case.

Hold the input shaft, and lightly press the oil pump body to slide the O-rings into the overdrive direct clutch drum.

- NOTICE:

- Do not push on the oil pump strongly, as the O-ring will stick to the direct clutch drum.

Install the 10 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 33. INSTALL MANUAL VALVE LEVER SHAFT OIL SEAL |

Using SST, taps in 2 new oil seals.

- SST

- 09350-30020(09350-07110)

Coat the lip of the oil seals with MP grease.

| 34. INSPECT INDIVIDUAL PISTON OPERATION INSPECTION |

Check the operating sound while applying compressed air into the oil holes indicated in the illustration.

- HINT:

- When inspecting the O/D direct clutch, check with the C3 accumulator piston holes indicated in the illustration.

- If there is no sound, disassemble and check the installation condition of the parts.

- (1) No. 2 clutch (C2)

- (2) No. 3 clutch (C3)

- (3) No. 1 clutch (C1)

- (4) No. 3 brake (B1)

- (5) No. 1 brake (B1)

- (6) No. 2 brake (B2)

- (7) No. 4 brake (B4)

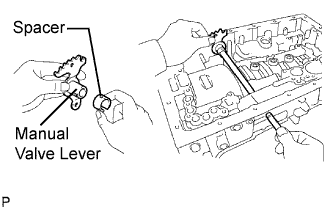

| 35. INSTALL MANUAL VALVE LEVER SUB-ASSEMBLY |

Install a new spacer to the manual valve lever.

Install the manual valve lever shaft to the transmission case through the manual valve lever.

Using a hammer, tap in a new spring pin.

Align the manual valve lever indentation with the spacer hole, and stake them together with a punch and hammer.

Make sure the shaft rotates smoothly.

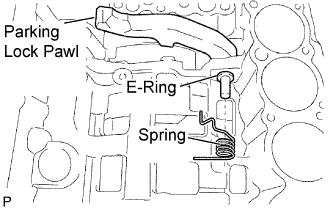

| 36. INSTALL PARKING LOCK PAWL SHAFT |

Install the E-ring to the shaft.

Install the parking lock pawl, shaft and spring.

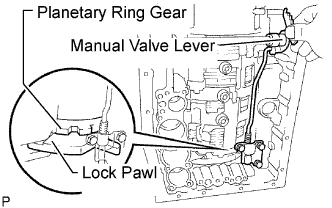

| 37. CONNECT PARKING LOCK ROD SUB-ASSEMBLY |

Connect the parking lock rod to the manual valve lever.

| 38. INSTALL PARKING LOCK PAWL BRACKET |

Place the parking lock pawl bracket onto the transmission case and torque the 3 bolts.

- Torque:

- 7.4 N*m{75 kgf*cm, 65 in.*lbf}

Shift the manual valve lever to the P position, and confirm that the planetary ring gear is correctly locked up by the lock pawl.

| 39. INSTALL C-1 ACCUMULATOR VALVE |

Coat a new O-ring with ATF, and install it to the piston.

Install the springs and accumulator valve to the hole.

- Standard accumulator spring:

Spring

| Free length

Outer diameter

| Color

|

C-1 Inner

| 30.40 mm (1.197 in.)

11.40 mm (0.449 in.)

| Pink

|

C-1 Outer

| 48.76 mm (1.920 in.)

16.60 mm (0.654 in.)

| Light green

|

| 40. INSTALL C-3 ACCUMULATOR PISTON |

Coat 2 new O-rings with ATF, and install them to the piston.

Install the springs and accumulator piston to the hole.

- Standard accumulator spring:

Spring

| Free length

Outer diameter

| Color

|

C-3 Inner

| 44.0 mm (1.732 in.)

14.0 mm (0.551 in.)

| Yellow

|

C-3 Outer

| 73.35 mm (2.888 in.)

19.90 mm (0.784 in.)

| Red

|

| 41. INSTALL B-3 ACCUMULATOR PISTON |

Coat 2 new O-rings with ATF, and install them to the piston.

Install the spring and accumulator piston to the hole.

- Standard accumulator spring:

Spring

| Free length

Outer diameter

| Color

|

B-3

| 70.5 mm (2.776 in.)

19.7 mm (0.776 in.)

| Purple

|

| 42. INSTALL C-2 ACCUMULATOR PISTON |

Coat 2 new O-rings with ATF, and install them to the piston.

Install the spring and accumulator piston to the hole.

- Standard accumulator spring:

Spring

| Free length

Outer diameter

| Color

|

C-2

| 62.0 mm (2.441 in.)

15.9 mm (03626 in.)

| White

|

| 43. INSTALL CHECK BALL BODY |

Install the check ball body and spring.

| 44. INSTALL BRAKE DRUM GASKET |

Install the 3 brake drum gaskets.

| 45. INSTALL TRANSAXLE CASE GASKET |

Install the 3 transaxle case gaskets.

| 46. INSTALL TRANSMISSION VALVE BODY ASSEMBLY |

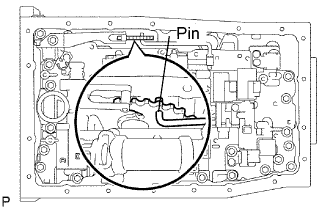

Align the groove of the manual valve with the pin of the lever.

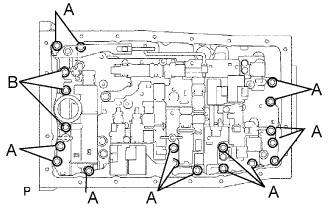

Install the 19 bolts.

- Torque:

- 11 N*m{110 kgf*cm, 8 ft.*lbf}

- HINT:

- Each bolt length is indicated below.

- Bolt length:

- 25 mm (0.98 in.) for bolt A

- 36 mm (1.42 in.) for bolt B

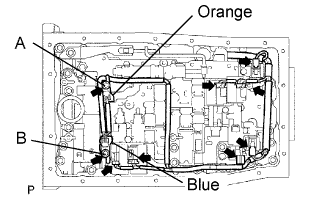

| 47. INSTALL TRANSMISSION WIRE |

Install a new O-ring to the transmission wire.

Install the transmission wire harness.

Install the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Connect the solenoid connector.

Connect the 7 solenoid connectors.

Install the ATF temperature sensor.

Install the clamp and the 2 bolts.

- Torque:

- 10 N*m{100 kgf*cm, 7 ft.*lbf} for bolt A

- 11 N*m{112 kgf*cm, 8 ft.*lbf} for bolt B

- HINT:

- Each bolt length is indicated below.

- Bolt length:

- 12 mm (0.47 in.) for bolt A

- 36 mm (1.42 in.) for bolt B

| 48. INSTALL VALVE BODY OIL STRAINER ASSEMBLY |

Coat a new O-ring with ATF, and install it to the valve body oil strainer.

Install the oil strainer with the 4 bolts.

- Torque:

- 10 N*m{100 kgf*cm, 7 ft.*lbf}

| 49. INSTALL TRANSMISSION OIL CLEANER MAGNET |

Install the 4 transmission oil cleaner magnets.

| 50. INSTALL AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY |

Install a new gasket on the oil pan.

Install and torque the 20 bolts.

- Torque:

- 4.4 N*m{45 kgf*cm, 39 in.*lbf}

Install the drain plug.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

| 51. INSTALL TRANSMISSION CASE ADAPTER OIL SEAL |

Using SST and a hammer, tap in a new oil seal.

- SST

- 09226-10010

| 52. INSTALL TRANSMISSION CASE ADAPTER SUB-ASSEMBLY |

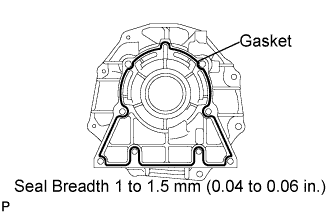

Apply seal packing or equivalent to the 8 bolts.

- Seal packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

Install the transmission case adapter with the 8 bolts.

- Torque:

- 34 N*m{345 kgf*cm, 25 ft.*lbf}

- HINT:

- Each bolt length is indicated below.

- Bolt length:

- 50 mm (1.969 in.) for bolt A

- 40 mm (1.575 in.) for bolt B

| 53. INSTALL AUTOMATIC TRANSMISSION HOUSING |

Clean the threads of the bolts and case with white gasoline.

Install the transmission housing with the 10 bolts.

- Torque:

- 34 N*m{345 kgf*cm, 25 ft.*lbf} for bolt A (14 mm head)

- 57 N*m{581 kgf*cm, 42 ft.*lbf} for bolt B (17 mm head)

- 34 N*m{345 kgf*cm, 25 ft.*lbf} for bolt C (14 mm head)

| 54. INSTALL AUTOMATIC TRANSAXLE BREATHER TUBE |

Install a new O-ring to the breather tube.

Install the breather tube with the 3 bolts.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 55. INSTALL TRANSMISSION REVOLUTION SENSOR (NT) AND (SP2) |

Coat 2 new O-rings with AFT, and install it to the sensors.

Install the 2 sensors.

Install the 2 bolts.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 56. INSTALL OIL COOLER TUBE UNION |

Coat a new O-ring with ATF, and install it to the oil cooler tube union.

Install the 2 oil cooler tube unions.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 57. INSTALL PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Install the park/neutral position switch onto the manual valve lever shaft, and temporarily install the adjusting bolt.

Install a new lock washer. Install and torque the nut.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

Push the control shaft rearward as much as possible.

Return the control shaft lever 2 notches to the N position.

Align the neutral basic line with the switch groove as shown in the illustration, and tighten the adjusting bolt.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Using a screwdriver, bend the tabs of the lock washer.

- HINT:

- Bend at least 2 of the lock washer tabs.

| 58. INSTALL TRANSMISSION CONTROL SHAFT LEVER LH |

Install the control shaft lever LH with the washer and nut.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}