Automatic Transmission Unit Reassembly

BEARING POSITION

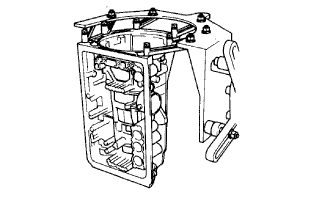

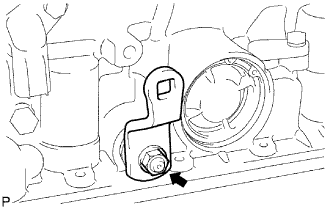

FIX TRANSMISSION CASE

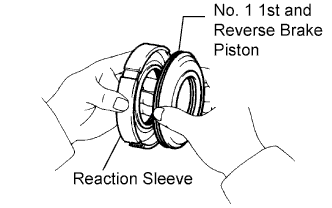

INSTALL NO. 1 1ST AND REVERSE BRAKE PISTON

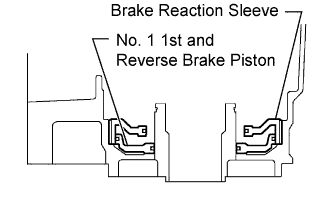

INSTALL BRAKE REACTION SLEEVE

INSTALL NO. 2 1ST AND REVERSE BRAKE PISTON

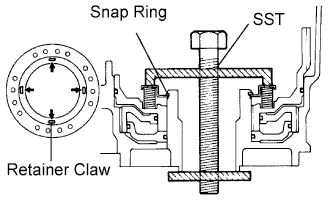

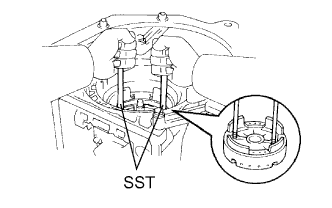

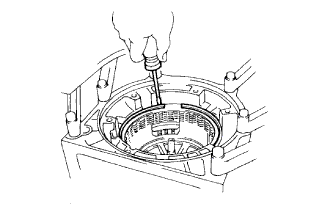

INSTALL 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY

INSPECT PISTON STROKE OF 1ST AND REVERSE BRAKE

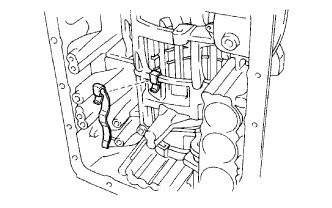

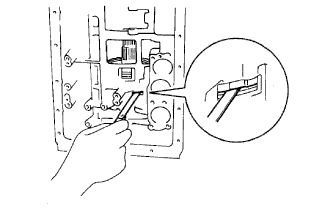

INSTALL LEAF SPRING

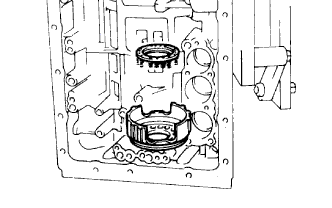

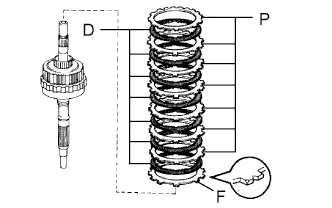

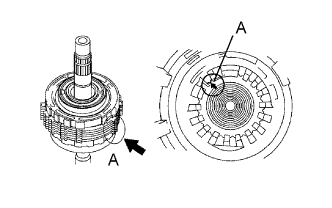

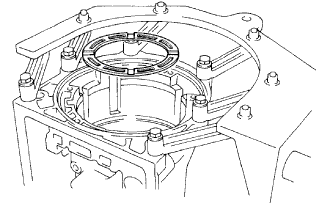

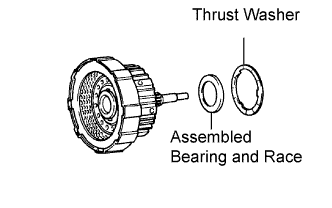

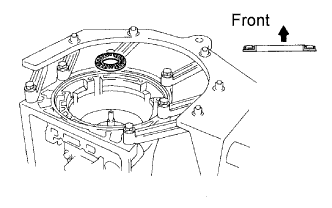

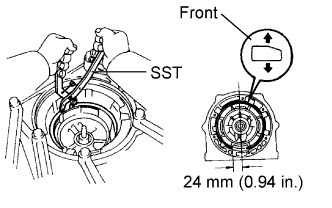

INSTALL REAR PLANETARY GEAR ASSEMBLY

INSPECT PACK CLEARANCE OF 1ST AND REVERSE BRAKE

INSTALL 2ND BRAKE PISTON SLEEVE

INSTALL BRAKE DRUM GASKET

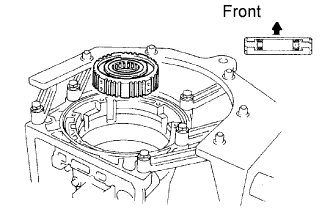

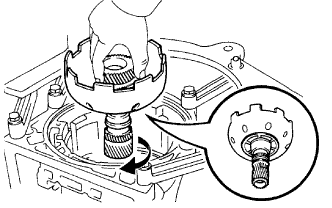

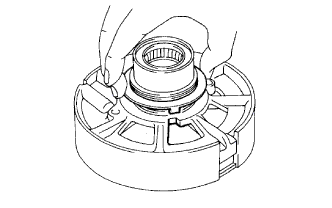

INSTALL NO. 1 ONE-WAY CLUTCH

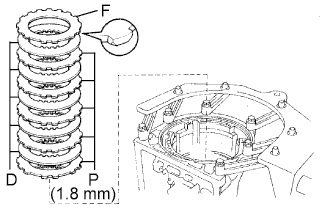

INSTALL 1ST AND REVERSE BRAKE CLUTCH DISC

INSPECT PACK CLEARANCE OF 2ND BRAKE

INSTALL PLANETARY SUN GEAR ASSEMBLY AND ONE-WAY CLUTCH ASSEMBLY

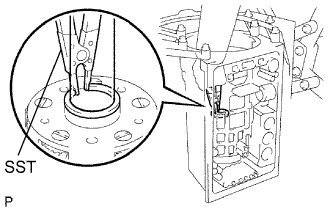

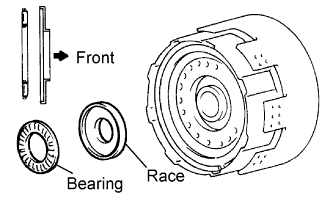

INSTALL FRONT PLANETARY GEAR

INSTALL 2ND COAST BRAKE BAND

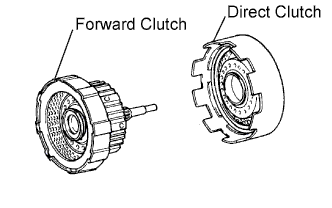

INSTALL DIRECT CLUTCH ASSEMBLY

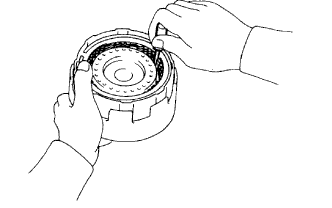

INSTALL FRONT PLANETARY RING GEAR

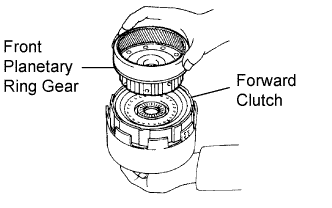

INSTALL FORWARD CLUTCH ASSEMBLY

INSTALL 2ND COAST BRAKE PISTON ASSEMBLY

INSPECT PISTON STROKE OF 2ND COAST BRAKE

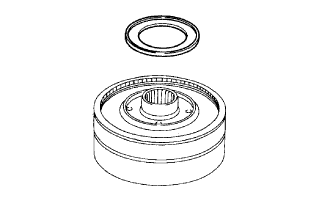

INSTALL OVERDRIVE BRAKE ASSEMBLY

INSPECT OUTPUT SHAFT

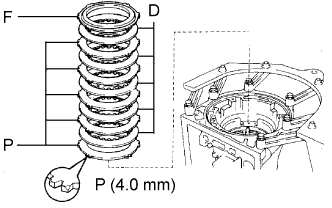

INSTALL OVERDRIVE BRAKE CLUTCH DISC

INSPECT OVERDRIVE BRAKE PISTON

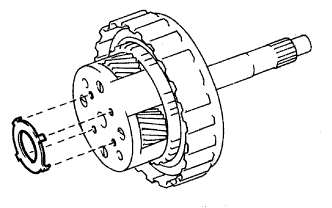

INSTALL OVERDRIVE PLANETARY RING GEAR

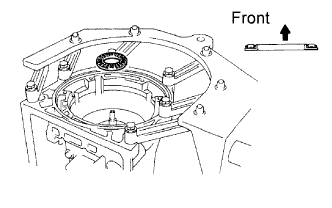

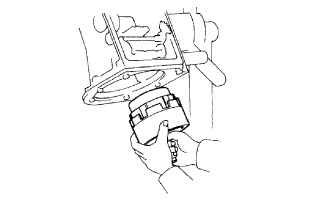

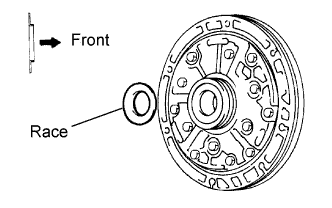

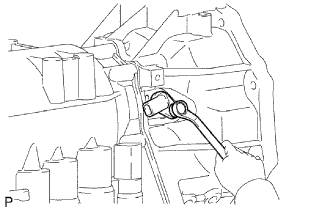

INSTALL OIL PUMP ASSEMBLY

INSPECT INPUT SHAFT SUB-ASSEMBLY

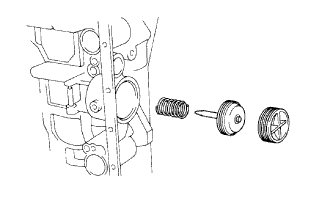

INSTALL TRANSMISSION CASE PLUG

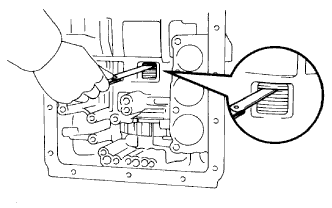

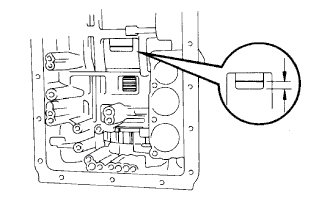

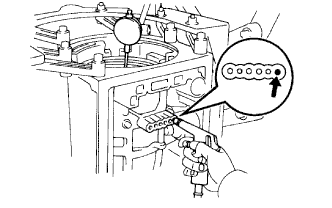

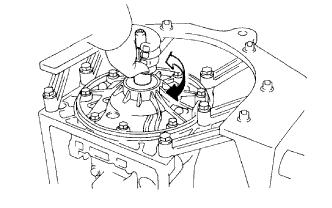

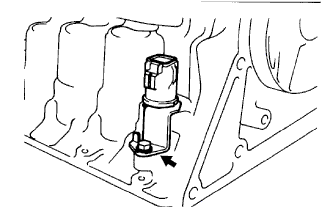

INSPECT INDIVIDUAL PISTON OPERATION

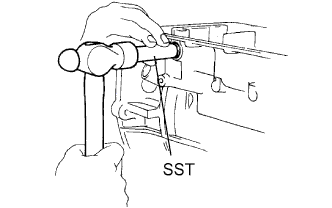

INSTALL MANUAL VALVE LEVER SHAFT OIL SEAL

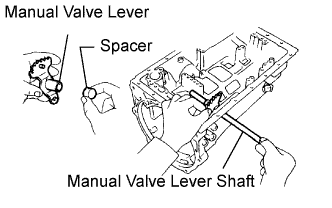

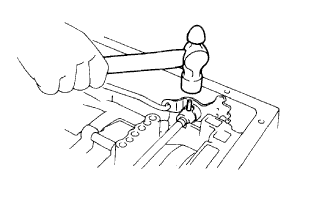

INSTALL MANUAL VALVE LEVER SHAFT

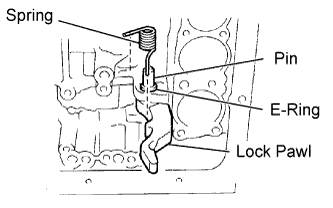

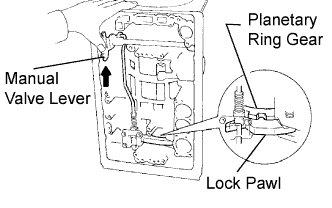

INSTALL PARKING LOCK PAWL SHAFT

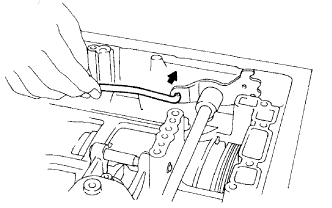

INSTALL PARKING LOCK ROD

INSTALL PARKING LOCK PAWL BRACKET

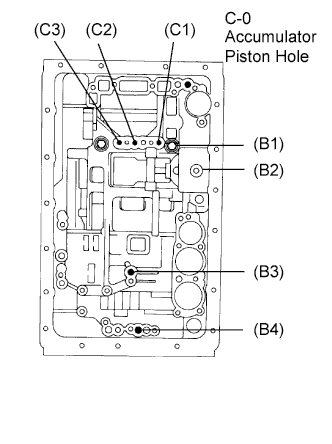

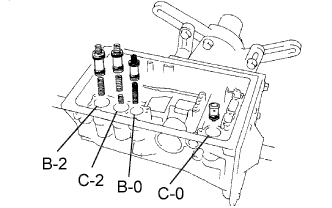

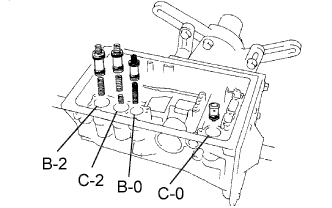

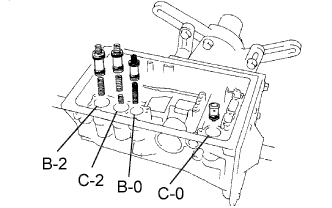

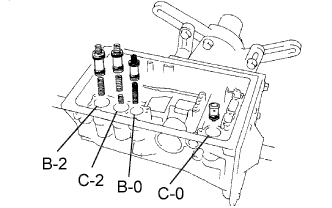

INSTALL C-0 ACCUMULATOR PISTON

INSTALL B-0 ACCUMULATOR PISTON

INSTALL C-2 ACCUMULATOR PISTON

INSTALL B-2 ACCUMULATOR PISTON

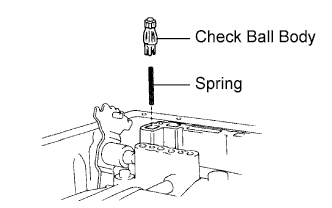

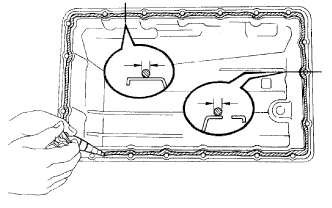

INSTALL CHECK BALL BODY

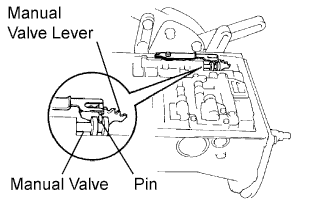

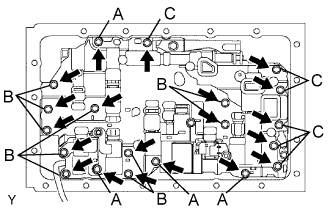

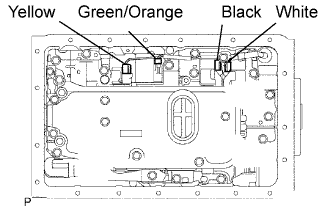

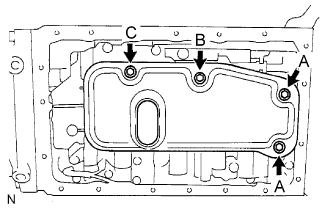

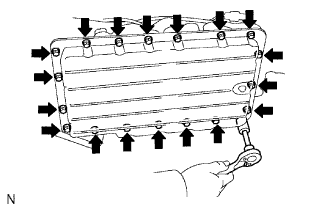

INSTALL TRANSMISSION VALVE BODY ASSEMBLY

INSTALL TRANSMISSION WIRE

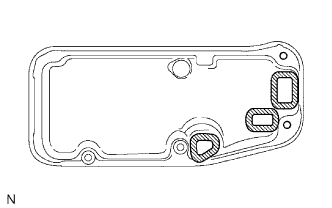

INSTALL VALVE BODY OIL STRAINER ASSEMBLY

INSTALL OIL CLEANER MAGNET

INSTALL AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY

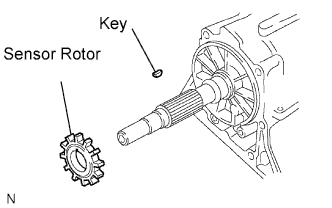

INSTALL SENSOR ROTOR

INSTALL TRANSFER CASE ADAPTER REAR OIL SEAL

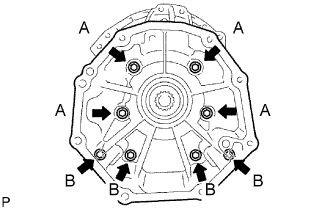

INSTALL REAR TRANSFER ADAPTER

INSTALL AUTOMATIC TRANSMISSION HOUSING

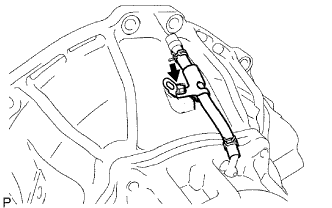

INSTALL SPEED SENSOR (SP2)

INSTALL SPEED SENSOR (NCO)

INSTALL OIL COOLER TUBE UNION

INSTALL AUTOMATIC TRANSMISSION FLUID TEMPERATURE SENSOR

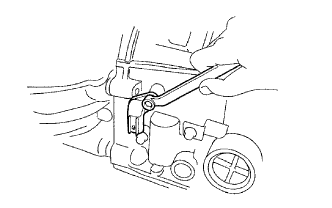

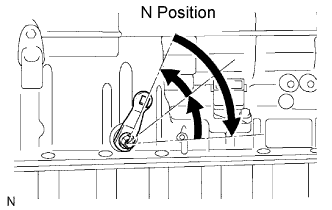

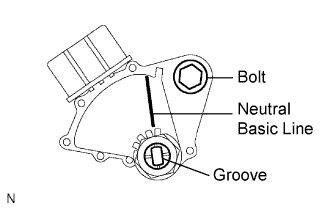

INSTALL PARK/NEUTRAL POSITION SWITCH ASSEMBLY

INSTALL TRANSMISSION CONTROL SHAFT LEVER LH

INSTALL BREATHER HOSE

INSTALL DRAIN PLUG

Automatic Transmission Unit -- Reassembly |

- Bearing diameter:

Mark

| Front Race Diameter

Inside / Outside

| Thrust Bearing Diameter

Inside / Outside

| Rear Race Diameter

Inside / Outside

|

A

| 28.45 mm (1.120 in.) / 47.3 mm (1.862 in.)

| 29.2 mm (1.15 in.) / 50.2 mm (1.976 in.)

| -

|

B

| 28.6 mm (1.126 in.) / 46.4 mm (1.827 in.)

| 28.9 mm (1.138 in.) / 50.2 mm (1.976 in.)

| -

|

C

| 33.0 mm (1.299 in.) /50.4 mm (1.984 in.)

| 31.4 mm (1.236 in.) / 49.4 mm (1.945 in.)

| -

|

D

| 37.2 mm (1.465 in.) / 58.8 mm (2.315 in.)

| 33.8 mm (1.331 in.) / 50.0 mm (1.969 in.)

| -

|

E

| 36.8 mm (1.449 in.) / 50.9 mm (2.004 in.)

| 33.7 mm (1.327 in.) / 47.6 mm (1.874 in.)

| -

|

F

| 26.0 mm (1.024 in.) / 48.9 mm (1.925 in.)

| 26.0 mm (1.024 in.) / 42.8 mm (1.685 in.)

| 26.8 mm (1.055 in.) / 53.67 mm (2.113 in.)

|

G

| -

| 49.9 mm (.1.965 in.) /64.4 mm (2.535 in.)

| 53.4 mm (2.102 in.) / 63.6 mm (2.504 in.)

|

H

| 33.7 mm (1.327 in.) / 47.6 mm (1.874 in.)

| 35.5 mm (1.398 in.) / 47.7 mm (1.878 in.)

| -

|

I

| 28.5 mm (1.122 in.) / 44.2 mm (1.740 in.)

| 27.7 mm (1.091 in.) / 44.2 mm (1.740 in.)

| -

|

J

| -

| 39.38 mm (1.550 in.) / 58.1 mm (2.287 in.)

| -

|

Install the transmission case in the overhaul attachment.

| 3. INSTALL NO. 1 1ST AND REVERSE BRAKE PISTON |

Coat 2 new O-rings with ATF.

Install the 2 O-rings on the No. 1 brake piston.

Install the No. 1 brake piston to the reaction sleeve.

| 4. INSTALL BRAKE REACTION SLEEVE |

Coat a new O-ring with ATF, and install it to the reaction sleeve.

With the No. 1 brake piston underneath (the rear side), install the brake reaction sleeve and No. 1 brake piston to the transmission case.

- NOTICE:

- Be careful not to damage the O-rings.

| 5. INSTALL NO. 2 1ST AND REVERSE BRAKE PISTON |

Coat a new O-ring with ATF.

Install the O-ring on brake piston.

With the spring seat of the piston facing upward (the front side), place the piston in the transmission case.

- NOTICE:

- Be careful not to damage the O-ring.

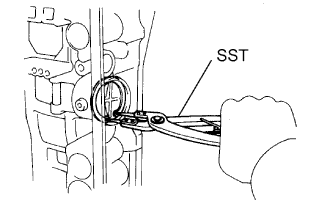

| 6. INSTALL 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY |

Place the No. 2 brake return spring onto the brake piston.

Place SST on the brake return spring, and compress the brae return spring.

- SST

- 09350-30020(09350-07050)

Using SST, install the snap ring. Make sure the end gap of the snap ring is not aligned with the spring retainer claw.

- SST

- 09350-30020(09350-07070)

| 7. INSPECT PISTON STROKE OF 1ST AND REVERSE BRAKE |

Make sure the 1st and reverse brake pistons move smoothly when compressed air is applied into the transmission case.

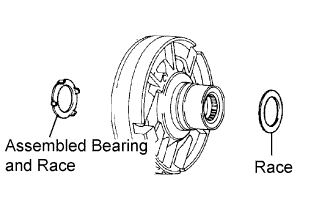

| 9. INSTALL REAR PLANETARY GEAR ASSEMBLY |

Install the flange with the rounded edge facing upward.

Install the 7 discs and 7 plates.

- Install in order:

- F - D - P - D - P - D - P - D - P - D - P - D - P - D - P

- HINT:

- F = Flange

- P = Plate

- D = Disc

Coat the assembled bearing and race with petroleum jelly, and install it onto the case.

- Assembled bearing and race diameter:

Item

| Inside

| Outside

|

Assembled bearing and race

| 39.38 mm (1.550 in.)

| 58.1 mm (2.287 in.)

|

- NOTICE:

- Be careful of the installation direction of the assembled bearing and race.

Align the teeth on the flange, discs and plates.

Face the snap ring upward (front side), and install the 2nd brake drum to the planetary gear.

- NOTICE:

- Face the oil hole in the drum towards the lower side of the transmission case (the side where the valve body is installed).

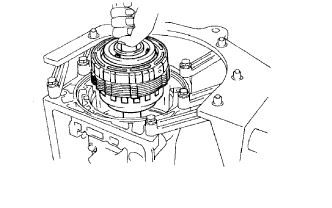

Align the splines of the transmission case with the assembled rear planetary gear and 1st and reverse brake with the output shaft, indicated by A.

Install the assembled output shaft.

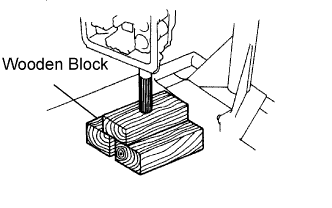

Reset the output shaft on wooden blocks.

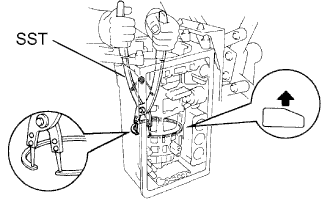

Using SST, Install the snap ring.

- SST

- 09350-30020(09350-07060)

| 10. INSPECT PACK CLEARANCE OF 1ST AND REVERSE BRAKE |

Using a feeler gauge, measure the clearance between the plate and 2nd brake drum.

- Clearance:

- 0.70 to 1.22 mm (0.0276 to 0.048 in.)

- HINT:

- If the clearance is not as specified, select another flange.

- There are 8 different thicknesses for the flange.

Flange thickness:No.

| Thickness

| No.

| Thickness

|

67

| 5.4mm (0.213 in.)

| 52

| 4.6 mm (0.181 in.)

|

66

| 5.2 mm (0.205 in.)

| 53

| 4.4 mm (0.173 in.)

|

50

| 5.0 mm (0.197 in.)

| 54

| 4.2 mm (0.165 in.)

|

51

| 4.8 mm (0.189 in.)

| 55

| 4.0 mm (0.157 in.)

|

| 11. INSTALL 2ND BRAKE PISTON SLEEVE |

| 12. INSTALL BRAKE DRUM GASKET |

Coat a new gasket with ATF, and install the brake drum gasket.

| 13. INSTALL NO. 1 ONE-WAY CLUTCH |

Install the thrust washer onto the 2nd brake piston sleeve.

Install the No. 1 one-way clutch as shown in the illustration.

| 14. INSTALL 1ST AND REVERSE BRAKE CLUTCH DISC |

Install the 1.8 mm (0.071 in.) thick plate with the rounded edge side of the plate facing the disc.

Install the flange, 5 plates and 5 discs.

- Install in order:

- P - D - P - D - P - D - P - D - P - D - F

- HINT:

- F = Flange

- P = Plate

- D = Disc

Using a screwdriver, install the snap ring.

| 15. INSPECT PACK CLEARANCE OF 2ND BRAKE |

Using a feeler gauge, measure the clearance between the snap ring and flange.

- Clearance:

- 0.62 to 1.98 mm (0.0244 to 0.0780 in.)

If the clearance is not as specified, inspect the discs.

| 16. INSTALL PLANETARY SUN GEAR ASSEMBLY AND ONE-WAY CLUTCH ASSEMBLY |

While turning the sun gear clockwise, install it into the one-way clutch.

- HINT:

- Confirm that the thrust washer is installed correctly.

| 17. INSTALL FRONT PLANETARY GEAR |

Coat the bearing and race with petroleum jelly, and install them onto the planetary gear.

- Bearing and race diameter:

Item

| Inside

| Outside

|

Bearing

| 35.5 mm (1.398 in.)

| 47.7 mm (1.878 in.)

|

Race

| 33.7 mm (1.327 in.)

| 47.6 mm (1.874 in.)

|

- NOTICE:

- Be careful of the installation direction of the bearing and race.

Install the planetary gear to the sun gear input drum.

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07070)

Remove the wooden blocks under the output shaft.

Coat the race with petroleum jelly, and install it onto the planetary gear.

- Race diameter:

Item

| Inside

| Outside

|

Race

| 53.4 mm (2.102 in.)

| 63.6 mm (2.504 in.)

|

- NOTICE:

- Be careful to the installation direction of the race.

| 18. INSTALL 2ND COAST BRAKE BAND |

Install the brake band to the case.

Install the E-ring to the pin.

Install the pin through the brake band.

| 19. INSTALL DIRECT CLUTCH ASSEMBLY |

Install the assembled bearing and race and thrust washer to the forward clutch.

Install the direct clutch to the forward clutch.

| 20. INSTALL FRONT PLANETARY RING GEAR |

Coat the race with petroleum jelly, and install them onto the forward clutch.

- Bearing and race diameter:

Item

| Inside

| Outside

|

Bearing

| 26.0 mm (1.024 in.)

| 42.8 mm (1.685 in.)

|

Race

| 26.0 mm (1.024 in.)

| 48.9 mm (1.925 in.)

|

- NOTICE:

- Be careful of the installation direction of the bearing and race.

Coat the race with petroleum jelly, and install it onto the front planetary ring gear.

- Race diameter:

Item

| Inside

| Outside

|

Race

| 26.8 mm (1.055 in.)

| 53.67 mm (2.113 in.)

|

- NOTICE:

- Be careful of the installation direction of the race.

Align the flukes of the discs in the forward clutch.

Align the splines of the planetary ring gear with the flukes of the discs and install the planetary ring gear to the forward clutch.

| 21. INSTALL FORWARD CLUTCH ASSEMBLY |

Coat the bearing and race with petroleum jelly, and install them onto the ring gear.

- Bearing and race diameter:

Item

| Inside

| Outside

|

Bearing

| 49.9 mm (1.965 in.)

| 64.4 mm (2.535 in.)

|

Race

| 53.4 mm (2.102 in.)

| 63.6 mm (2.504 in.)

|

- NOTICE:

- Be careful of the installation direction of the bearing and race.

Install the assembled direct clutch, forward clutch and front planetary ring gear into the transmission case.

Using a vernier caliper, measure the distance between the sun gear input drum and direct clutch drum as shown in the illustration.

- Distance:

- 5.3 to 7.3 mm (0.209 to 0.287 in.)

If the distance is not as specified, check for an improper installation.

Coat the assembled bearing and race with petroleum jelly and install it onto the forward clutch.

- Assembled bearing and race diameter:

Item

| Inside

| Outside

|

Assembled bearing and race

| 33.7 mm (1.327 in.)

| 47.6 mm (1.874 in.)

|

- NOTICE:

- Be careful of the installation direction of the assembled bearing and race.

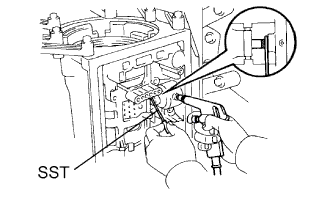

| 22. INSTALL 2ND COAST BRAKE PISTON ASSEMBLY |

Coat 2 new O-rings with ATF, and install them to the cover.

Install the spring, the piston assembly and cover to the case.

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07060)

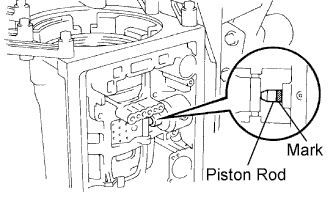

| 23. INSPECT PISTON STROKE OF 2ND COAST BRAKE |

Place a mark on the 2nd coast brake piston rod.

Using SST, measure the stroke while applying and releasing compressed air (392 kPa (4.0 kgf/cm2, 57 psi)).

- SST

- 09240-00020

If the stroke is not as specified, replace the brake band with a new one.

| 24. INSTALL OVERDRIVE BRAKE ASSEMBLY |

Coat the assembled bearing and race and race with petroleum jelly, and install it onto the overdrive brake assembly.

- Assembled bearing and race and race diameter:

Item

| Inside

| Outside

|

Race

| 36.8 mm (1.449 in.)

| 50.9 mm (2.004 in.)

|

Assembled bearing and race

| 33.8 mm (1.331 in.)

| 50.0 mm (1.969 in.)

|

- NOTICE:

- Be careful of the installation direction of the assembled bearing and race and race.

Confirm that the thrust washer is installed correctly.

- HINT:

- Make sure that the tab of the washer fits into the hole on the overdrive brake assembly.

Using 2 bolts of SST, aim the bolt and oil holes of the overdrive rake assembly toward the valve body side, and align them with the bolt holes of the transmission case. Insert the overdrive brake assembly.

- SST

- 09350-30020(09350-07020)

Temporarily tighten the 2 bolts.

Using SST, install the snap ring.

- SST

- 09350-30020(09350-07060)

- HINT:

- Install the snap ring open end toward the valve body.

Tighten the 2 bolts.

- Torque:

- 25 N*m{260 kgf*cm, 19 ft.*lbf}

Using a dial indicator, measure the end play of the output shaft with hand.

- End play:

- 0.30 to 1.04 mm (0.0118 to 0.0409 in.)

If the end play is not as specified, check for an improper installation.

Check that the output shaft rotates smoothly.

| 26. INSTALL OVERDRIVE BRAKE CLUTCH DISC |

Install the 4.0 mm (0.157 in.) thick flange (flat ring) with the rounded edge side of the flange facing the discs.

Install the 5 plates, 5 discs and flange.

- Install in order:

- P - D - P - D - P - D - P - D - P - D - F

- HINT:

- F = Flange

- P = Plate

- D = Disc

Using a screwdriver, install the snap ring.

| 27. INSPECT OVERDRIVE BRAKE PISTON |

Place SST and a dial indicator onto the overdrive brake piston.

- SST

- 09350-30020(09350-06120)

Measure the stroke while applying and releasing compressed air (392 kPa (4.0 kgf/cm2, 57 psi)).

- Piston stroke:

- 1.75 to 2.05 mm (0.0689 to 0.0807 in.)

If the piston stroke is not as specified, parts may have been assembled incorrectly. Check and reassemble again.

- HINT:

- If the piston stroke is still outside the standard, select another flange.

- There are 7 different thicknesses for the flange.

Flange thickness:No.

| Thickness

| No.

| Thickness

|

77

| 3.3 mm (0.130 in.)

| 81

| 3.8 mm (0.150 in.)

|

78

| 3.5 mm (0.138 in.)

| 82

| 3.9 mm (0.154 in.)

|

79

| 3.6 mm (0.142 in.)

| 83

| 4.0 mm (0.157 in.)

|

80

| 3.7 mm (0.146 in.)

| -

| -

|

| 28. INSTALL OVERDRIVE PLANETARY RING GEAR |

Coat the race with petroleum jelly, and install it onto the overdrive brake assembly.

- Race diameter:

Item

| Inside

| Outside

|

Race

| 37.2 mm (1.465 in.)

| 58.8 mm (2.315 in.)

|

- NOTICE:

- Be careful of the installation direction of the race.

Install the ring gear.

Coat the assembled bearing and race with petroleum jelly, and install them onto the ring gear.

- Assembled bearing and race diameter:

Item

| Inside

| Outside

|

Assembled bearing and race

| 31.4 mm (1.236 in.)

| 49.4 mm (1.945 in.)

|

- NOTICE:

- Be careful of the installation direction of the assembled bearing and race.

Coat the race with petroleum jelly, and install it onto the planetary gear.

- Race diameter:

Item

| Inside

| Outside

|

Race

| 24.7 mm (0.972 in.)

| 41.8 mm (1.646 in.)

|

- NOTICE:

- Be careful of the installation direction of the race.

Install the overdrive planetary gear, overdrive direct clutch and one-way clutch.

Place SST on the transmission case.

- SST

- 09350-36010(09350-06090)

Using a vernier caliper, measure the distance between the top of SST and clutch drum.

- Standard distance:

- 15.5 to 16.5 mm (0.610 to 0.650 in.)

If the distance is not as specified, check for an improper installation.

Coat the assembled bearing and race with petroleum jelly, and install it onto the overdrive direct clutch.

- Assembled bearing and race diameter:

Item

| Inside

| Outside

|

Assembled bearing and race

| 29.2 mm (1.150 in.)

| 50.2 mm (1.976 in.)

|

- NOTICE:

- Be careful of the installation direction of the assembled bearing and race.

| 29. INSTALL OIL PUMP ASSEMBLY |

Coat the race with petroleum jelly, and install it onto the oil pump.

- Race diameter:

Item

| Inside

| Outside

|

Race

| 28.45 mm (1.120 in.)

| 47.3 mm (1.862 in.)

|

- NOTICE:

- Be careful of the installation direction of the race.

Coat a new O-ring with ATF, and install it around the pump body.

Place the oil pump through the input shaft, and align the bolt holes of the pump body with the transmission case.

Hold the input shaft, and lightly press the oil pump body to slide the oil seal rings into the overdrive direct clutch drum.

- NOTICE:

- Do not forcefully push on the oil pump as the oil seal ring will stick to the direct clutch drum.

Install the 7 bolts.

- Torque:

- 22 N*m{220 kgf*cm, 16 ft.*lbf}

| 30. INSPECT INPUT SHAFT SUB-ASSEMBLY |

Make sure the input shaft rotates smoothly.

| 31. INSTALL TRANSMISSION CASE PLUG |

Coat a new O-ring with ATF, and install it to the plug.

Install the plug to the case with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 32. INSPECT INDIVIDUAL PISTON OPERATION |

Check the operating sound while applying compressed air into the oil hole indicated in the illustration.

- HINT:

- When inspecting the overdrive direct clutch, check with the C-0 accumulator piston hole closed.

- If there is no sound, disassemble and check the parts installation condition.

Overdrive direct clutch (C1)

Direct clutch (C2)

Forward clutch (C3)

Overdrive brake (B1)

2nd coast brake (B2)

2nd brake (B3)

1st and reverse brake (B4)

| 33. INSTALL MANUAL VALVE LEVER SHAFT OIL SEAL |

Using SST and a hammer, tap in 2 new oil seals.

- SST

- 09350-30020(09350-07110)

| 34. INSTALL MANUAL VALVE LEVER SHAFT |

Install a new spacer to the manual valve lever.

Install the manual valve lever shaft to the transmission case through the manual valve lever.

Using a hammer, tap in a new spring pin.

Align the manual valve lever indentation with the spacer hole, and stake them with the punch.

Make sure that the shaft rotates smoothly.

| 35. INSTALL PARKING LOCK PAWL SHAFT |

Install the E-ring to the shaft.

Install the parking lock pawl, shaft and spring.

| 36. INSTALL PARKING LOCK ROD |

Connect the parking lock rod to the manual valve lever.

| 37. INSTALL PARKING LOCK PAWL BRACKET |

Place the parking lock pawl bracket onto the transmission case and install the 3 bolts.

- Torque:

- 7.4 N*m{75 kgf*cm, 65 in.*lbf}

Shift the manual valve lever to the P position, and confirm that the planetary ring gear is correctly locked up by the lock pawl.

| 38. INSTALL C-0 ACCUMULATOR PISTON |

Coat a new O-ring with ATF, and install it to the piston.

Install the 2 springs and accumulator piston to the hole.

- C-0 accumulator spring:

- Inner spring:

Free Length

| Outer Diameter

| Color

|

51.5 mm (2.028 in.)

| 14.02 mm (0.552 in.)

| Red

|

- Outer spring:

Free Length

| Outer Diameter

| Color

|

79.9 mm (3.146 in.)

| 20.9 mm (0.823 in.)

| Light Blue

|

| 39. INSTALL B-0 ACCUMULATOR PISTON |

Coat 2 new O-rings with ATF, and install them to the piston.

Install the spring and accumulator piston to the hole.

- B-0 accumulator spring:

Free Length

| Outer Diameter

| Color

|

62.0 mm (2.441 in.)

| 16.0 mm (0.630 in.)

| Green

|

| 40. INSTALL C-2 ACCUMULATOR PISTON |

Coat 2 new O-rings with ATF, and install them to the piston.

Install the 2 springs and accumulator piston to the hole.

- C-2 accumulator spring:

- Inner spring:

Free Length

| Outer Diameter

| Color

|

42.1 mm (1.657 in.)

| 14.7 mm (0.579 in.)

| Pink

|

- Outer spring:

Free Length

| Outer Diameter

| Color

|

68.53 mm (2.698 in.)

| 20.2 mm (0.795 in.)

| Blue

|

| 41. INSTALL B-2 ACCUMULATOR PISTON |

Coat 2 new O-rings with ATF, and install them to the piston.

Install the spring and accumulator piston to the hole.

- B-2 accumulator spring:

Free Length

| Outer Diameter

| Color

|

70.5 mm (2.776 in.)

| 19.9 mm (0.784 in.)

| Light Grey

|

| 42. INSTALL CHECK BALL BODY |

Install the spring and check ball body.

| 43. INSTALL TRANSMISSION VALVE BODY ASSEMBLY |

Align the groove of the manual with the pin of the lever.

Install the 20 bolts.

- Torque:

- 11 N*m{110 kgf*cm, 8 ft.*lbf}

- HINT:

- Each bolt length is indicated below.

- Bolt length:

- 23 mm (0.91 in.) for A

- 28 mm (1.10 in.) for B

- 36 mm (1.42 in.) for C

| 44. INSTALL TRANSMISSION WIRE |

Coat a new O-ring with ATF, and install it to the transmission wire.

Install the transmission wire to the case, and install the stopper plate with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Connect the connectors to the shift solenoid valves.

| 45. INSTALL VALVE BODY OIL STRAINER ASSEMBLY |

Install 3 new gaskets on the oil strainer.

Install the oil strainer with the 4 bolts.

- Torque:

- 11 N*m{110 kgf*cm, 8 ft.*lbf}

- HINT:

- Each bolt length is indicated below.

- Bolt length:

- 14 mm (0.55 in.) for A

- 20 mm (0.79 in.) for B

- 23 mm (0.91 in.) for C

| 46. INSTALL OIL CLEANER MAGNET |

Install the 3 magnets.

| 47. INSTALL AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY |

Remove any seal packing material.

- NOTICE:

- Be careful not to drop oil on the contacting surfaces of the transmission case and oil pan.

Apply seal packing to the oil pan.

- Seal packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- Seal diameter:

- 2 to 3 mm (0.0787 to 0.118 in.)

Install the oil pan with the 19 bolts.

- Torque:

- 7.4 N*m{75 kgf*cm, 65 in.*lbf}

Install the key on the output shaft.

Align the groove of the sensor rotor with the key, and install the sensor rotor.

Using snap ring pliers, install the snap ring.

| 49. INSTALL TRANSFER CASE ADAPTER REAR OIL SEAL |

Using SST and a hammer, install a new oil seal.

- SST

- 09950-60010(09951-00560)

09950-70010(09951-07150)

| 50. INSTALL REAR TRANSFER ADAPTER |

Install the rear transfer adaptor and gasket.

Install the 8 bolts.

- Torque:

- 34 N*m{344 kgf*cm, 25 ft.*lbf}

- HINT:

- Each bolt length is indicated below.

- Bolt length:

- 50 mm (1.969 in.) for A

- 40 mm (1.575 in.) for B

| 51. INSTALL AUTOMATIC TRANSMISSION HOUSING |

Clean the threads of the bolts and case with white gasoline.

Apply adhesive or equivalent to the 6 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the transmission housing with the 6 bolts.

- Torque:

- 34 N*m{345 kgf*cm, 25 ft.*lbf}for 14 mm bolt

- 57 N*m{580 kgf*cm, 42 ft.*lbf}for 17 mm bolt

| 52. INSTALL SPEED SENSOR (SP2) |

Coat a new O-ring with ATF.

Install a new O-ring to the sensor.

Install the sensor with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 53. INSTALL SPEED SENSOR (NCO) |

Coat a new O-ring with ATF.

Install a new O-ring to the sensor.

Install the speed sensor with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 54. INSTALL OIL COOLER TUBE UNION |

Coat 2 new O-rings with ATF, and install them to each tube union.

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

| 55. INSTALL AUTOMATIC TRANSMISSION FLUID TEMPERATURE SENSOR |

Coat the O-ring with ATF.

Install the temperature sensor.

- Torque:

- 15 N*m{150 kgf*cm, 11 ft.*lbf}

| 56. INSTALL PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Install the park/neutral position switch onto the manual valve lever shaft, and temporarily install the adjusting bolt.

Install a new lock washer. Install and tighten the nut.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

Push the control shaft rearward as much as possible.

Return the control shaft lever 2 notches to the N position.

Align the neutral basic line with the switch groove, as shown in the illustration, and tighten the adjusting bolt.

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

- HINT:

- Bend at least 2 of the lock washer tabs.

| 57. INSTALL TRANSMISSION CONTROL SHAFT LEVER LH |

Install the control shaft lever with the washer and nut.

- Torque:

- 16 N*m{160 kgf*cm, 12 ft.*lbf}

| 58. INSTALL BREATHER HOSE |

Install the breather hose with the bolt.

- Torque:

- 7.4 N*m{75 kgf*cm, 65 in.*lbf}

- Torque:

- 20 N*m{205 kgf*cm, 15 ft.*lbf}