Ecd System -- Data List / Active Test |

| READ DATA LIST |

- HINT:

- Using the intelligent tester's Data List allows switch, sensor, actuator, and other item values to be read without removing any parts. Reading the Data List early in troubleshooting is one way to save time.

- NOTICE:

- In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

Warm up the engine.

Turn the ignition switch OFF.

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON.

Turn the intelligent tester ON.

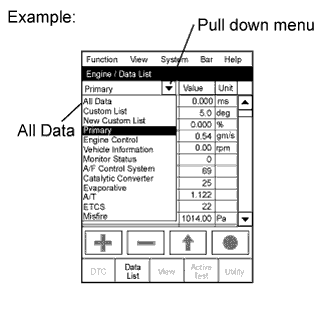

Enter the following menus: Powertrain / Engine and ECT / Data List.

- HINT:

- To display the entire Data List, press the pull down menu button next to Primary. Then select All Data.

Read the Data List.

Tester Display Measurement Item/Range Normal Condition Diagnostic Note Vehicle Speed Vehicle speed:

Min.: 0 km/h, Max.: 255 km/hActual vehicle speed Speed indicated on speedometer Engine Speed Engine speed:

Min.: 0 rpm, Max.: 16,383 rpm700 to 800 rpm: Idling - Calculate Load Calculated load by ECM:

Min.: 0%, Max.: 100%- 11.4 to 16.4%: Idling

- 13.1 to 18.9%: Running without load (2,500 rpm)

- MAF Air flow rate from MAF meter status:

Min.: 0 gm/s

Max.: 655.35 gm/s- 5 to 12 gm/s: Idling

- 23 to 31 gm/s: Running without load (2,000 rpm)

If value approximately 0 gm/s: - Mass air flow meter power source circuit open

- VG circuit open or shorted

- EVG circuit open

Atmosphere Pressure Atmospheric pressure value:

Min.: 0 kPa

Max.: 255 kPaActual atmospheric pressure - MAP Absolute pressure inside intake manifold:

Min.: 0 kPa, Max.: 255 kPa- 90 to 105 kPa: Idling

- 100 to 125 kPa:

Engine running at 3000 rpm

- Coolant Temp Engine coolant temperature:

Min.: -40°C, Max.: 140°C80 to 90°C (176 to 194°F):

After warming up engineIf value is -40°C (-40°F) or 140°C (284°F), sensor circuit open or shorted Intake Air Intake air temperature:

Min.: -40°C, Max.: 140°CEquivalent to temperature at location of mass air flow meter If value is -40°C (-40°F) or 140°C (284°F), sensor circuit open or shorted Intake Air Temp (Turbo) Intake air temperature after intercooler:

Min.: -40°C, Max.: 190°CChanges depending on operating conditions - Engine Run Time Engine run time:

Min.: 0 s,

Max.: 255 sTime after engine started Service data Initial Engine Coolant Temp Initial engine coolant temperature:

Min.: -40°C, Max.: 120°CECT when engine starts - Initial Intake Air Temp Initial intake air temperature:

Min.: -40°C, Max.: 120°CIntake air temperature when engine starts - Battery Voltage Battery voltage:

Min.: 0 V,

Max.: 65.535 V9 to 14 V: Idling - Alternate Duty Ratio Alternate duty ratio:

Min.: 0%, Max.: 100%- No electrical load:

20 to 60%

- High electrical load:

100%

- Pre Glow Pre-glow operation:

ON or OFF- This is the ECM command. After Glow After-glow operation:

ON or OFF- This is the ECM command. Accel Position Accelerator position status:

Min.: 0%, Max.: 99.6%- Accelerator pedal released:

0% - Accelerator pedal depressed:

100%

Read value with ignition switch ON (do not start engine) Accel Sens. No.1 Volt % Accelerator position No. 1:

Min.: 0%, Max.: 100%- Accelerator pedal released:

8 to 28% - Accelerator pedal depressed:

51 to 86%

Read value with ignition switch ON (do not start engine) Accel Sens. No.2 Volt % Accelerator position No. 2:

Min.: 0%, Max.: 100%- Accelerator pedal released:

30 to 55% - Accelerator pedal depressed:

73 to 98%

Read value with ignition switch ON (do not start engine) Target Throttle Position Target throttle position

Min.: -128%, Max.: 127%- Throttle valve fully opened:

0% - Throttle valve fully closed:

100%

If there is a malfunction of the throttle actuator, compare the target and actual throttle position values for troubleshooting. Actual Throttle Position Actual diesel throttle position:

Min.: -128%, Max.: 127%- - Throttle Close Learning Val. Throttle fully closed position learned value:

Min.: 0 deg, Max.: 84 deg- - Diesel Throttle Learn Status Diesel throttle learn status:

OK or NGOK - Injection Volume Injection volume:

Min.: 0 mm3/st, Max.: 1,279.98 mm3/st3 to 10 mm3/st: Idling - Inj. FB Vol. for Idle Idle stability status integral control volume:

Min.: -80 mm3/st, Max.: 79.9975 mm3/st-10 to 10 mm3/st - Inj Vol Feedback Learning Injection volume compensation learned value:

Min.: -10 mm3/st, Max.: 9.92 mm3/st-4.0 to 4.0 mm3/st: Idling - Injection Feedback Val #1 Injection volume correction for cylinder 1:

Min.: -10 mm3/st, Max.: 10 mm3/st-3.0 to 3.0 mm3/st: Idling - "Injection Feedback Val" more than 3.0 mm3/st: Injector breakdown is causing injection volume deviation, or insufficient compression is causing poor combustion.

- Even if "Injection Feedback Val" for a cylinder is less than -3.0 mm3/st, the cylinder with this value does not necessarily have a problem.

- HINT:

- The ECM adjusts each cylinder so that the average "Injection Feedback Val" of the 4 cylinders is approximately 0 mm3/st.

- If more than one cylinder has a positive correction value, a normal cylinder may have a value less than -3.0 mm3/st.

Injection Feedback Val #2 Injection volume correction for cylinder 2:

Min.: -10 mm3/st, Max.: 10 mm3/st-3.0 to 3.0 mm3/st: Idling Injection Feedback Val #3 Injection volume correction for cylinder 3:

Min.: -10 mm3/st, Max.: 10 mm3/st-3.0 to 3.0 mm3/st: Idling Injection Feedback Val #4 Injection volume correction for cylinder 4:

Min.: -10 mm3/st, Max.: 10 mm3/st-3.0 to 3.0 mm3/st: Idling Pilot 1 Injection Period Pilot 1 injection period:

Min.: 0 μs, Max.: 65,535 μs370 to 470 μs: Idling - Pilot 2 Injection Period Pilot 2 injection period:

Min.: 0 μs, Max.: 65,535 μs400 to 500 μs: Idling - Main Injection Period Main injection period:

Min.: 0 μs, Max.: 65,535 μs450 to 650 μs: Idling - After Injection Period After injection period:

Min.: 0 μs, Max.: 65,535 μs- - Pilot 1 Injection Timing Pilot 1 injection timing:

Min.: -70°CA, Max.: 20°CA-16 to -12°CA: idle after engine warmed up and vehicle is under normal atmospheric pressure - Pilot 2 Injection Timing Pilot 2 injection timing:

Min.: -50°CA, Max.: 20°CA-12 to -6°CA: idle after engine warmed up and vehicle is under normal atmospheric pressure - Main Injection Timing Main injection timing:

Min.: -90°CA, Max.: 90°CA3 to 7°CA: idle after engine warmed up and vehicle is under normal atmospheric pressure - After Injection Timing After injection timing:

Min.: -10°CA, Max.: 50°CA- - Injector Memory Error Injector Memory Error:

No Error or ErrorNo Error If the fuel injector compensation codes are not input into the new ECM, or if a fuel injector compensation code of a different injector model or a compensation code representing a value which exceeds the compensation setting range is input into the new ECM, DTC P1601 is stored and "Injector Memory Error" displays "Error". Reju Pilot Quantity Learning Pilot quantity learning prohibition state:

READY or NG- - Pilot Quantity Learning State of "Pilot Quantity Learning":

Standby / Wait / Learn / Stop / Comple- If "Pilot Quantity Learning" is incomplete, the MIL illuminates and DTC P1601 is stored. Injection Pressure Correction Injection pressure correction:

Min.: -500 mm3/st,

Max.: 779.9 mm3/st-400 to 400 mm3/st - Target Common Rail Pressure Target common rail pressure:

Min.: 0 kPa, Max.: 655350 kPa30000 to 160000 kPa - Fuel Press Fuel pressure:

Min.: 0 kPa, Max.: 655350 kPa28000 to 40000 kPa: Idling - Common Rail Pres Sens 2 Common rail pressure sensor (Sub)

Min.: 0 kPa, Max.: 655350 kPa28000 to 40000 kPa: Idling - Fuel Temperature Fuel temperature:

Min.: -40°C, Max.: 215°CActual fuel temperature ECD freeze frame data Fuel Return Temp Fuel return temperature:

Min.: -40°C, Max.: 215°CIdling after engine warmed-up: 35 to 85°C If the "Fuel Return Temp" value is not between 35°C (95°F) and 110°C (230°F), "Pilot Quantity Learning" is prohibited. Target Pump SCV Current Pump current target final value:

Min.: 0 mA, Max.: 4000 mA- - Pressure Discharge Valve Pressure discharge valve operation:

ON or OFFON: Pressure discharge valve open This is the ECM command. Target EGR Position EGR valve target opening angle:

Min.: 0%, Max.: 100%Level surface, engine warmed up and engine idling:

50 to 100%- EGR Close Learn Val. EGR valve lift volume learning value/

Min.: 0 V, Max.: 5 V- - Actual EGR Valve Pos. EGR valve position:

Min.: 0%, Max.: 100%Idling after engine warmed up:

40 to 60%- EGR Close Lrn. Status EGR valve fully closed position learning status:

OK or NGOK - EGR Operation Prohibit EGR operation prohibit:

OK or NGOK: Active Test item "Control the EGR Step Position" can be performed - OK: "EGR Valve Control Active Test Possible" Condition.

- NG: "Not Possible" Condition.

EGR Cut VSV EGR Cut VSV:

ON or OFF- - Target Booster Pressure Target booster pressure:

Min.: 0 kPa, Max.: 320 kPaIdling and vehicle under normal atmospheric pressure:

pressure: 90 to 105 kPa- VN Turbo Command VN turbo command:

Min.: 0%, Max.: 100%0 to 100% "VN Turbo Command" is a command value. VN Turbo Type VN turbo type:

Not Aul or Commo or VacuumCommo - VN Turbo Max Angle VN turbo max angle:

Min.: 0%, Max.: 99.6%90%: Idling - VN Turbo Min Angle VN turbo min angle:

Min.: 0%, Max.: 99.6%15 to 25%: Full throttle - Starter Signal Starter signal:

ON or OFFON: Cranking - Neutral Position SW Signal Neutral position switch status:

ON or OFFON: Shift lever in neutral - Clutch Switch Clutch switch:

ON or OFFON: Clutch pedal depressed - Stop Light Switch Stop light switch:

ON or OFF- ON: Brake pedal depressed

- OFF: Brake pedal released

- A/C Signal A/C signal:

ON or OFFON: A/C ON - Immobiliser Communication Immobiliser communication:

ON or OFF- ON: Normal

- OFF: Engine cannot be started due to immobiliser communication malfunction

- Check Mode Check mode:

ON or OFFON: Check mode ON - # Codes (Include History) Number of codes:

Min.: 0, Max.: 255- Number of detected DTCs MIL MIL status:

ON or OFFON: MIL ON - Time After DTC Cleared Time after DTC cleared:

Min.: 0 minutes,

Max.: 65,535 minutesEquivalent to time after DTCs were erased - Distance from DTC Cleared Distance after DTC cleared:

Min.: 0 km,

Max.: 65,535 kmEquivalent to drive distance after DTCs were erased - Warmup Cycle Cleared DTC Warmup cycle after DTC cleared:

Min.: 0,

Max.: 255- Number of warmup cycles after DTC cleared OBD Requirements Identifying OBD requirement - - Number of Emission DTC Number of emission DTCs - - TC and TE1 TC and TE1 terminal of DLC3:

ON or OFF- Active Test support data Engine Start Time Engine start time:

Min.: 0 ms,

Max.: 267000 ms- Time necessary for the engine to start. Engine Speed (Starter Off) Engine speed when starter off:

Min.: 0 rpm,

Max.: 1593 rpm- Engine speed immediately after starting the engine. Starter Count Starter on count:

Min.: 0,

Max.: 255- Number of times the starter turned on from the time the ignition switch was turned to ON. Run Dist of Previous Trip Distance driven during previous trip:

Min.: 0 km,

Max.: 326 km- Used to confirm the driving conditions of the previous trip (before the malfunction occurred). Electric Duty Feedback Value Electric load feedback value:

Min.: 0 mm3/st,

Max.: 39.8 mm3/st0 to 10 mm3/st Expected injection volume increase after the electrical load turns from off to on. A/C Duty Feedback Value A/C load feedback value:

Min.: 0 mm3/st,

Max.: 39.8 mm3/st0 to 10 mm3/st Expected injection volume increase after the A/C turns from off to on. PS Duty Feedback Value Power steering load feedback value:

Min.: 0 mm3/st,

Max.: 39.8 mm3/st0 to 10 mm3/st Expected injection volume increase after the power steering turns from off to on. Idle Injection Volume (Min) Injection volume feedback learned value:

Min.: 0 mm3/st,

Max.: 39.8 mm3/st0 to 5 mm3/st - When the engine is warmed up and in a stable idling condition, this learning will be performed.

- Only when the ignition switch is turned off is the learned value updated gradually.

Swirl Control Valve VSV VSV for Swirl control valve status:

ON or OFFON: Idling - ACT VSV A/C cut status for Active Test:

ON or OFF- Active Test support data Model Code Model code - Identifying model code: Engine Type Engine type - Identifying engine type:

1KDFTVCylinder Number Cylinder number:

Min.: 0, Max.: 255- Identifying cylinder number:

4Transmission Type Transmission type - Identifying transmission type:

MT / ECT 4thDestination Destination - Identifying destination:

VModel Year Model year:

Min.: 1900, Max.: 2155- Identifying mode year:

20##System Identification System Identification - - Engine Speed of Cyl #1 Engine speed for No. 1 cylinder:

Min.: 0 rpm, Max.: 51199 rpm"Engine speed" of all cylinders almost same - Output only when the Active Test "Check the Cylinder Compression" is performed.

- Indicates the speed of each cylinder when cranking.

Engine Speed of Cyl #2 Engine speed for No. 2 cylinder:

Min.: 0 rpm, Max.: 51199 rpm"Engine speed" of all cylinders almost same As above Engine Speed of Cyl #3 Engine speed for No. 3 cylinder:

Min.: 0 rpm, Max.: 51199 rpm"Engine speed" of all cylinders almost same As above Engine Speed of Cyl #4 Engine speed for No. 4 cylinder:

Min.: 0 rpm, Max.: 51199 rpm"Engine speed" of all cylinders almost same As above Av Engine Speed of All Cyl Engine speed for all cylinders:

Min.: 0 rpm, Max.: 51199 rpm- As above - HINT:

- Normal Condition: If no idling conditions are specified, the shift lever is in the neutral position, and the A/C switch and all accessory switches are OFF.

- 11.4 to 16.4%: Idling

|

| PERFORM ACTIVE TEST |

- HINT:

- Performing the intelligent tester's Active Test allows relay, VSV, actuator and other items to be operated without removing any parts. Performing the Active Test early in troubleshooting is one way to save time.

- The Data List can be displayed during the Active Test.

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON.

Turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Active Test.

Perform the Active Test.

Tester Display Test Part Control Range Diagnostic Note Activate the VSV for Swirl Control Valve Activate VSV for No. 1 Swirl Control Valve ON/OFF - Control the A/C cut Signal Control the A/C signal ON/OFF - Connect the TC and TE1 Turn on TC and TE1 connection ON/OFF - Activate the VSV for EGR Cut Activate VSV (for EGR Cut) ON/OFF - Control the EGR Step Position Control the EGR valve position 0 to 110 Step - Test the Turbo Charger Step Motor Activate DC motor for turbocharger 40 to 100% Active test available only while engine idling or not running (ignition switch ON) Test the Fuel Leak Pressurizes common rail internal fuel pressure, and checks for fuel leaks Stop/Start - Fuel pressure inside common rail pressurized to specified value and engine speed increased to 2,000 rpm when ON is selected

- Above conditions preserved while test is ON

Activate the VN Turbo Open Activate the turbocharger Open/OFF Confirm that the engine is running. Activate the EGR Valve Close Activate electric vacuum regulating valve assembly Close/OFF - Control the Cylinder#1 Fuel Cut Cut off fuel injection from No. 1 injector ON/OFF Fuel injection stopped while test is ON Control the Cylinder#2 Fuel Cut Cut off fuel injection from No. 2 injector ON/OFF As above Control the Cylinder#3 Fuel Cut Cut off fuel injection from No. 3 injector ON/OFF As above Control the Cylinder#4 Fuel Cut Cut off fuel injection from No. 4 injector ON/OFF As above Control the ALL Cylinders Fuel Cut Injector fuel cut for all cylinders ON/OFF Fuel injection stops in all cylinders. Check the Cylinder Compression* Check the cylinder compression pressure ON/OFF Fuel injection stops in all cylinders. - Fuel pressure inside common rail pressurized to specified value and engine speed increased to 2,000 rpm when ON is selected

- HINT:

- *: When cranking the engine, the Active Test measures the speed of each cylinder. In this Active Test, the fuel of all cylinders is cut when the engine is cranked for approximately 10 seconds.

- Warm up the engine.

- Turn the ignition switch off.

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to ON and turn the tester on.

- Enter the following menus: Powertrain / Engine and ECT / Active Test / Check the Cylinder Compression.

- HINT:

- If the results are not displayed normally, select the display items from the Data List before performing the Active Test. Enter the following menus: Powertrain / Engine and ECT / Data List / Compression / Engine Speed of Cyl #1, Engine Speed of Cyl #2, Engine Speed of Cyl #3, Engine Speed of Cyl #4 and Av Engine Speed of All Cyl.

- While the engine is not running, press the RIGHT or LEFT button to change Check the Cylinder Compression to ON.

- HINT:

- After performing the above procedure, the Active Test Check the Cylinder Compression will start. Fuel injection for all cylinders is prohibited, and the engine speed measurement of each cylinder will enter standby mode.

- Crank the engine for about 10 seconds.

- Monitor the engine speed (Engine Speed of Cyl #1 to #4, Av Engine Speed of All Cyl) displayed on the tester.

- HINT:

- At first, the tester display will show the engine speed measurement of each cylinder to be extremely high. After approximately 10 seconds of engine cranking, the engine speed measurement of each cylinder will change to the actual engine speed.

- NOTICE:

- After the Active Test Check the Cylinder Compression is turned on, it will automatically turn off after 255 seconds.

- When the Check the Cylinder Compression test is off and the engine is cranked, the engine will start.

- If the Check the Cylinder Compression test needs to be performed after it is turned on and performed once, press EXIT to return to the Active Test menu screen. Then perform the Check the Cylinder Compression test again.

- Use a fully-charged battery.

| SYSTEM CHECK |

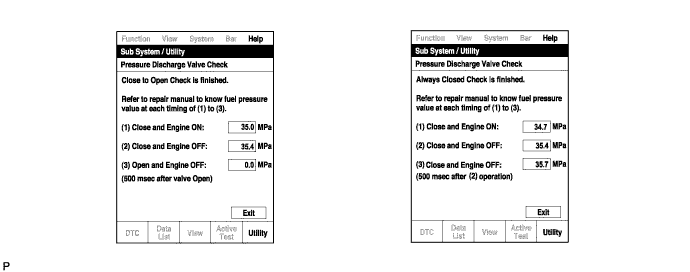

Activate the Pressure Discharge Valve Check

- HINT:

- This is the procedure for troubleshooting fuel pressure control malfunctions and combustion problems.

- Malfunctions can be determined by checking the fuel pressure when performing a fuel cut and operating the pressure discharge valve with the intelligent tester.

- During "Pressure Discharge Valve Check", the intelligent tester measures the fuel pressure while the engine is running, after the engine is stopped, and after the pressure discharge valve operates.

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the tester on.

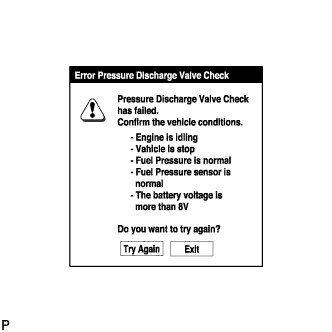

- NOTICE:

- Confirm the following conditions:

- Engine is idling.

- Vehicle is stopped.

- Fuel pressure is not extremely high (less than 100000 kPa).

- Fuel pressure is not extremely low (higher than 26000 kPa).

- Fuel pressure sensor is normal.

- Battery voltage is more than 8 V.

- HINT:

- When the common rail pressure is unstable, the fuel pressure may decrease to a level where the test cannot be performed. In this situation, wait until the common rail pressure meets the test condition, and then perform the test.

Enter the following menus: Powertrain / Engine and ECT / Utility / Pressure Discharge Valve Check.

Press "Next".

Press "Next" again to proceed.

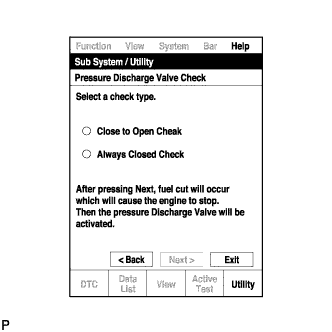

Select the "Pressure Discharge Valve Check" type.

- HINT:

- "Close to Open Check" opens the pressure discharge valve after the engine stops.

- "Always Closed Check" holds the pressure discharge valve closed during the check.

Press "Next".

Perform troubleshooting based on the measurement results.

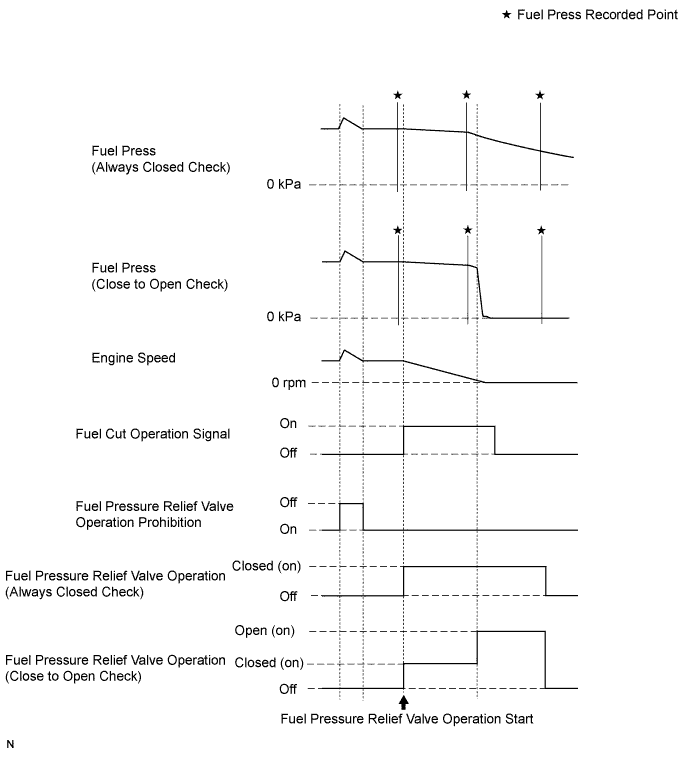

- HINT:

- During "Close to Open Check", if there is no large change in fuel pressure when the pressure discharge valve is closed while the engine is running and after the engine is stopped, and if the value is 0 kPa when the pressure discharge valve is open, the system is normal.

- Perform "Always Closed Check" if the value is not 0 kPa when the pressure discharge valve is open during "Close to Open Check". If the results are the same as during "Close to Open Check", there is a pressure discharge valve operation malfunction.

- If the fuel temperature is high, perform "Pressure Discharge Valve Check" after the fuel has cooled to the outside air temperature.

- If a large amount of fuel is leaking, the fuel pressure decreases when the engine is stopped. However, the condition of the pressure discharge valve can still be determined by comparing the measurement results of "Close to Open Check" and "Always Closed Check".