Output Shaft Installation

INSTALL NO. 2 TRANSMISSION HUB SLEEVE

INSTALL 3RD GEAR NEEDLE ROLLER BEARING

INSTALL 3RD GEAR

INSTALL NO. 2 SYNCHRONIZER RING (for 3rd Gear)

INSTALL NO. 2 TRANSMISSION CLUTCH HUB

INSTALL 2ND GEAR NEEDLE ROLLER BEARING

INSTALL 2ND GEAR

INSTALL NO. 1 SYNCHRONIZER RING SET (for 2nd Gear)

INSTALL REVERSE GEAR

INSTALL NO. 1 TRANSMISSION CLUTCH HUB

INSTALL 1ST GEAR BEARING SPACER

INSTALL 1ST GEAR NEEDLE ROLLER BEARING

INSTALL 1ST GEAR THRUST WASHER PIN

INSTALL NO. 1 SYNCHRONIZER RING SET (for 1st Gear)

INSTALL 1ST GEAR

INSTALL 1ST GEAR THRUST WASHER

INSTALL OUTPUT SHAFT CENTER BEARING

INSTALL 5TH GEAR

INSPECT 1ST GEAR THRUST CLEARANCE

INSPECT 2ND GEAR THRUST CLEARANCE

INSPECT 3RD GEAR THRUST CLEARANCE

INSPECT 1ST GEAR RADIAL CLEARANCE

INSPECT 2ND GEAR RADIAL CLEARANCE

INSPECT 3RD GEAR RADIAL CLEARANCE

Output Shaft -- Installation |

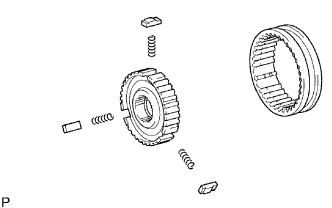

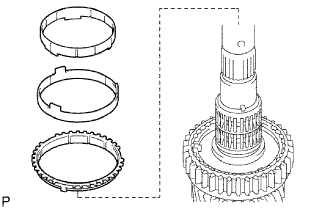

| 1. INSTALL NO. 2 TRANSMISSION HUB SLEEVE |

Install the 3 No. 2 synchromesh shifting key springs and 3 synchromesh shifting keys to the No. 2 clutch hub.

- NOTICE:

- Be careful of the directions of the No. 2 hub sleeve and No. 2 clutch hub.

Apply gear oil to the sliding part of the No. 2 hub sleeve, and install it to the No. 2 clutch hub.

| 2. INSTALL 3RD GEAR NEEDLE ROLLER BEARING |

Apply gear oil to the needle roller bearing, and install it to the output shaft.

Apply gear oil to the 3rd gear, and install it to the output shaft.

| 4. INSTALL NO. 2 SYNCHRONIZER RING (for 3rd Gear) |

Apply gear oil to the No. 2 synchronizer ring, and install it to the 3rd gear.

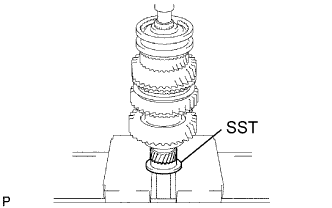

| 5. INSTALL NO. 2 TRANSMISSION CLUTCH HUB |

Using SST and a press, press in the No. 2 clutch hub to the output shaft.

- SST

- 09608-06041

- NOTICE:

- Install the hub while aligning the key groove of the hub and the shifting key position.

- The 3rd gear should be able to rotate smoothly.

Select a snap ring so that the clearance between the No. 2 clutch hub and snap ring is within the specification.

- Standard clearance:

- 0.10 mm (0.0039 in.) or less

- NOTICE:

- Do not damage the sliding surface of the bearing.

- Standard snap ring thickness:

Mark

| Thickness

|

A

| 1.80 to 1.85 mm (0.0709 to 0.0728 in.)

|

B

| 1.85 to 1.90 mm (0.0728 to 0.0748 in.)

|

C

| 1.90 to 1.95 mm (0.0748 to 0.0768 in.)

|

D

| 1.95 to 2.00 mm (0.0768 to 0.0787 in.)

|

E

| 2.00 to 2.05 mm (0.0787 to 0.0807 in.)

|

F

| 2.05 to 2.10 mm (0.0807 to 0.0827 in.)

|

G

| 2.10 to 2.15 mm (0.0827 to 0.0846 in.)

|

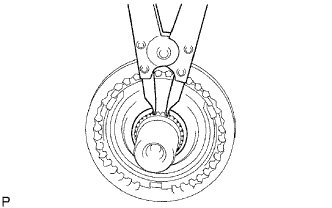

Using a snap ring expander, install the snap ring.

| 6. INSTALL 2ND GEAR NEEDLE ROLLER BEARING |

Apply gear oil to the needle roller bearing, and install it to the output shaft.

Apply gear oil to the 2nd gear, and install it to the output shaft.

| 8. INSTALL NO. 1 SYNCHRONIZER RING SET (for 2nd Gear) |

Apply gear oil to the No. 1 synchronizer ring set, and install it to the 2nd gear.

Using a screwdriver, install the 3 synchromesh shifting key springs and 3 No. 1 synchromesh shifting keys to the No. 1 clutch hub.

Apply gear oil to the reverse gear, and install it to the No. 1 clutch hub.

| 10. INSTALL NO. 1 TRANSMISSION CLUTCH HUB |

Using SST and a press, press in the No. 1 clutch hub to the output shaft.

- SST

- 09316-60011(09316-00041)

- NOTICE:

- While performing the step above, make sure that the No. 1 synchronizer ring key groove and No. 1 synchromesh shifting key position are aligned.

- The 1st gear should rotate freely.

Select a snap ring so that the thrust clearance between the No. 1 clutch hub and snap ring is within the specification.

- Standard clearance:

- 0.10 mm (0.039 in.) or less

- NOTICE:

- Do not damage the sliding surface of the bearing.

- Standard snap ring thickness:

Mark

| Thickness

|

A

| 2.30 to 2.35 mm (0.0906 to 0.0925 in.)

|

B

| 2.35 to 2.40 mm (0.0925 to 0.0945 in.)

|

C

| 2.40 to 2.45 mm (0.0945 to 0.0965 in.)

|

D

| 2.45 to 2.50 mm (0.0965 to 0.0984 in.)

|

E

| 2.50 to 2.55 mm (0.0984 to 0.1004 in.)

|

F

| 2.55 to 2.60 mm (0.1004 to 0.1024 in.)

|

G

| 2.60 to 2.65 mm (0.1024 to 0.1043 in.)

|

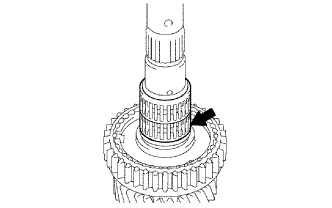

Using a brass bar and hammer, tap in the snap ring.

| 11. INSTALL 1ST GEAR BEARING SPACER |

Apply gear oil to the bearing spacer, and install it to the output shaft.

| 12. INSTALL 1ST GEAR NEEDLE ROLLER BEARING |

Apply gear oil to the needle roller bearing, and install it to the output shaft.

| 13. INSTALL 1ST GEAR THRUST WASHER PIN |

Install the thrust washer pin to the output shaft.

| 14. INSTALL NO. 1 SYNCHRONIZER RING SET (for 1st Gear) |

Apply gear oil to the No. 1 synchronizer ring set, and install them to the output shaft.

Apply gear oil to the 1st gear, and install it to the output shaft.

| 16. INSTALL 1ST GEAR THRUST WASHER |

Apply gear oil to the thrust washer, and install it to the output shaft.

| 17. INSTALL OUTPUT SHAFT CENTER BEARING |

Using SST and a press, press in a new center bearing to the output shaft.

- SST

- 09316-60011(09316-00031)

- NOTICE:

- Install the center bearing so that the snap ring groove of the bearing faces to the rear side.

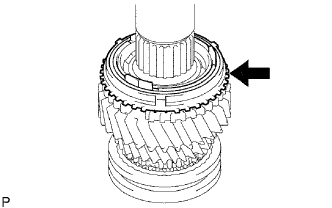

Using SST and a press, press in the 5th gear to the output shaft.

- SST

- 09316-60011(09316-00031)

- NOTICE:

- Check that the 5th gear and the spline of the output shaft fit before installing it.

- Face the convex part of the gear to the front side.

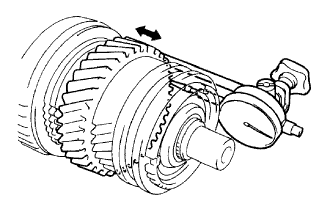

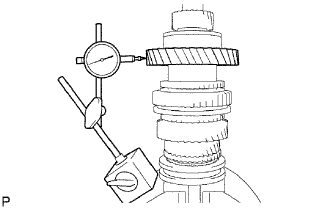

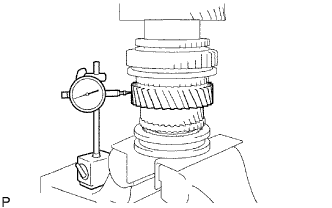

| 19. INSPECT 1ST GEAR THRUST CLEARANCE |

Using a dial indicator, measure the thrust clearance.

- Standard clearance:

- 0.20 to 0.45 mm (0.0079 to 0.0177 in.)

If the clearance is not as specified, replace the No. 1 synchronizer ring.

| 20. INSPECT 2ND GEAR THRUST CLEARANCE |

Using a dial indicator, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.25 mm (0.0039 to 0.0098 in.)

If the clearance is not as specified, replace the No. 1 synchronizer ring set.

| 21. INSPECT 3RD GEAR THRUST CLEARANCE |

Using a feeler gauge, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.25 mm (0.0039 to 0.0098 in.)

If the clearance is not as specified, replace the No. 2 synchronizer ring.

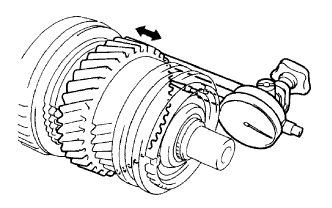

| 22. INSPECT 1ST GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.020 to 0.073 mm (0.0008 to 0.00029 in.)

If the clearance is not as specified, replace the 1st gear needle roller bearing with a new one.

| 23. INSPECT 2ND GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.015 to 0.068 mm (0.0006 to 0.0027 in.)

If the clearance is not as specified, replace the 2nd gear needle roller bearing with a new one.

| 24. INSPECT 3RD GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.015 to 0.068 mm (0.0006 to 0.0027 in.)

If the clearance is not as specified, replace the 3rd gear needle roller bearing with a new one.