Output Shaft -- Removal |

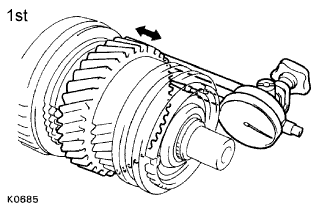

| 1. INSPECT 1ST GEAR THRUST CLEARANCE |

|

Using a dial indicator, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.25 mm (0.0039 to 0.0098 in.)

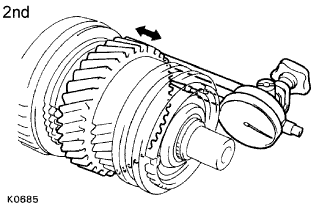

| 2. INSPECT 2ND GEAR THRUST CLEARANCE |

|

Using a dial indicator, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.25 mm (0.0039 to 0.0098 in.)

| 3. INSPECT 3RD GEAR THRUST CLEARANCE |

|

Using a feeler gauge, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.25 mm (0.0039 to 0.0098 in.)

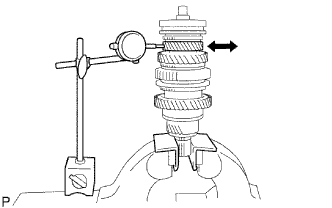

| 4. INSPECT 1ST GEAR RADIAL CLEARANCE |

|

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.009 to 0.056 mm (0.0004 to 0.0022 in.)

| 5. INSPECT 2ND GEAR RADIAL CLEARANCE |

|

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.008 to 0.034 mm (0.0003 to 0.0013 in.)

- If the clearance is not as specified, replace the 2nd gear needle roller bearing.

| 6. INSPECT 3RD GEAR RADIAL CLEARANCE |

|

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.008 to 0.034 mm (0.0003 to 0.0013 in.)

- If the clearance is not as specified, replace the 3rd gear needle roller bearing.

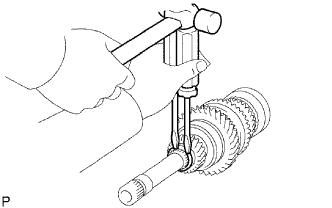

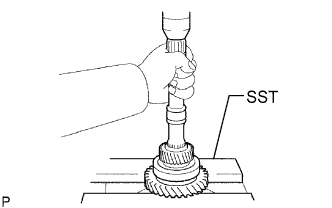

| 7. REMOVE 1ST GEAR |

|

Using 2 screwdrivers and a hammer, tap out the snap ring from the output shaft.

Using SST and a press, press out the 5th gear, center bearing, 1st gear, 1st gear needle roller bearing and 1st gear bearing inner race from the output shaft.

- SST

- 09527-10011

|

| 8. REMOVE NO. 1 SYNCHRONIZER RING (for 1st Gear) |

|

Remove the No. 1 synchronizer ring (for the 1st gear) from the No. 1 clutch hub.

| 9. REMOVE 1ST GEAR BEARING INNER RACE LOCK BALL |

|

Using a magnetic finger, remove the lock ball.

| 10. REMOVE 2ND GEAR |

|

Using SST and a press, press out the No. 1 transmission clutch hub, reverse gear, No. 1 synchronizer ring and 2nd gear.

- SST

- 09950-00020

| 11. REMOVE NO. 1 SYNCHRONIZER RING (for 2nd Gear) |

|

Remove the No. 1 synchronizer ring from the 2nd gear.

| 12. REMOVE 2ND GEAR NEEDLE ROLLER BEARING |

|

Remove the needle roller bearing from the output shaft.

| 13. DISASSEMBLE NO. 1 TRANSMISSION CLUTCH HUB |

|

Remove the 2 synchromesh shifting key springs.

Remove the reverse gear and 3 synchromesh shifting keys from the transmission clutch hub.

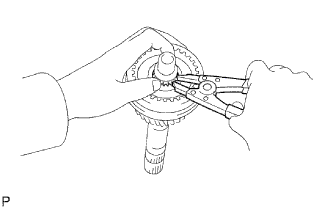

| 14. REMOVE 3RD GEAR |

|

Using a snap ring expander, remove the snap ring from the output shaft.

Using a press, press out the No. 2 transmission clutch hub and 3rd gear.

|

| 15. REMOVE NO. 2 SYNCHRONIZER RING |

|

Remove the synchronizer ring from the 3rd gear.

| 16. REMOVE 3RD GEAR NEEDLE ROLLER BEARING |

|

Remove the needle roller bearing from the output shaft.

| 17. DISASSEMBLE NO. 2 TRANSMISSION CLUTCH HUB |

|

Remove the 2 synchromesh shifting key springs.

Remove the transmission hub sleeve and 3 synchromesh shifting keys from the transmission clutch hub.

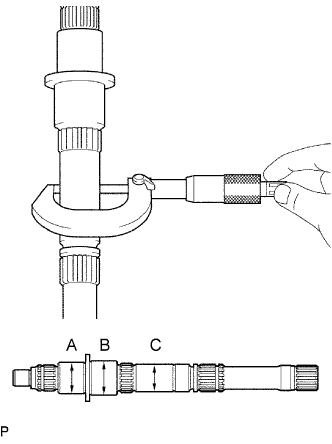

| 18. INSPECT OUTPUT SHAFT |

|

Using a micrometer, measure the outside diameter of the output shaft journal surface.

- Standard outside diameter:

Position Specified Condition Part A 34.984 to 35.000 mm (1.3773 to 1.3780 in.) Part B 37.984 to 38.000 mm (1.4945 to 1.4960 in.) Part C 30.384 to 30.400 mm (1.1962 to 1.1968 in.)

- If the outside diameter is not as specified, replace the output shaft.

Using a micrometer, measure the flange thickness.

- Standard thickness:

- 4.80 to 5.20 mm (0.1890 to 0.2047 in.)

- Minimum thickness:

- 4.80 mm (0.1890 in.)

- If the thickness is less than the minimum, replace the output shaft.

|

| 19. INSPECT 1ST GEAR BEARING INNER RACE |

|

Using a micrometer, measure the inner race thickness.

- Standard thickness:

- 4.00 to 4.20 mm (0.1575 to 0.1654 in.)

- Minimum thickness:

- 4.00 mm (0.1575 in.)

- If the thickness is less than the minimum, replace the 1st gear bearing inner race.

Using a micrometer, measure the outside diameter of the inner race.

- Standard outside diameter:

- 38.985 to 39.000 mm (1.5348 to 1.5354 in.)

- Minimum outside diameter:

- 38.985 mm (1.5348 in.)

- If the outside diameter is less than the minimum, replace the 1st gear bearing inner race.

|

| 20. INSPECT NO. 1 SYNCHRONIZER RING (for 1st Gear) |

|

Coat the 1st gear cone with gear oil. Check the braking effect of the No. 1 synchronizer ring. Fit the ring to the shaft cone. Apply pressure to the ring and attempt to turn it in both directions. Check that the ring locks.

- If the braking effect is insufficient, apply a small amount of fine lapping compound between the No. 1 synchronizer ring and the 1st gear cone. Lightly rub the No. 1 synchronizer ring and the 1st gear cone together.

- NOTICE:

- Ensure the fine lapping compound is completely washed off after rubbing.

- If the braking effect is insufficient, apply a small amount of fine lapping compound between the No. 1 synchronizer ring and the 1st gear cone. Lightly rub the No. 1 synchronizer ring and the 1st gear cone together.

Check the braking effect of the No. 1 synchronizer ring again.

Using a feeler gauge, measure the clearance between the No. 1 synchronizer ring back and 1st gear spline end.

- Standard clearance:

- 1.00 to 2.00 mm (0.0394 to 0.0787 in.)

- If the clearance is not as specified, replace the No. 1 synchronizer ring and apply a small amount of fine lapping compound on the 1st gear cone.

- NOTICE:

- Ensure the fine lapping compound is completely washed off after rubbing.

|

| 21. INSPECT NO. 1 SYNCHRONIZER RING (for 2nd Gear) |

|

Coat the 2nd gear cone with gear oil. Check the braking effect of the No. 1 synchronizer ring. Fit the ring to the shaft cone. Apply pressure to the ring and attempt to turn it in both directions. Check that the ring locks.

- If the braking effect is insufficient, apply a small amount of fine lapping compound between the No. 1 synchronizer ring and the 2nd gear cone. Lightly rub the No. 1 synchronizer ring and the 2nd gear cone together.

- NOTICE:

- Ensure the fine lapping compound is completely washed off after rubbing.

- If the braking effect is insufficient, apply a small amount of fine lapping compound between the No. 1 synchronizer ring and the 2nd gear cone. Lightly rub the No. 1 synchronizer ring and the 2nd gear cone together.

Check the braking effect of the No. 1 synchronizer ring again.

Using a feeler gauge, measure the clearance between the No. 1 synchronizer ring back and 2nd gear spline end.

- Standard clearance:

- 1.00 to 2.00 mm (0.0394 to 0.0787 in.)

- If the clearance is not as specified, replace the No. 1 synchronizer ring, and apply a small amount of fine lapping compound on the 2nd gear cone.

- NOTICE:

- Ensure the fine lapping compound is completely washed off after rubbing.

|

| 22. INSPECT NO. 2 SYNCHRONIZER RING |

|

Coat the 3rd gear cone with gear oil. Check the braking effect of the No. 2 synchronizer ring. Fit the ring to the shaft cone. Apply pressure to the ring and attempt to turn it in both directions. Check that the ring locks.

- If the braking effect is insufficient, apply a small amount of fine lapping compound between the No. 2 synchronizer ring and the 3rd gear cone. Lightly rub the No. 2 synchronizer ring and the 3rd gear cone together.

- NOTICE:

- Ensure the fine lapping compound is completely washed off after rubbing.

- If the braking effect is insufficient, apply a small amount of fine lapping compound between the No. 2 synchronizer ring and the 3rd gear cone. Lightly rub the No. 2 synchronizer ring and the 3rd gear cone together.

Check the braking effect of the No. 2 synchronizer ring again.

Using a feeler gauge, measure the clearance between the No. 2 synchronizer ring back and 3rd gear spline end.

- Standard clearance:

- 1.0 to 2.0 mm (0.0394 to 0.0787 in.)

- If the clearance is not as specified, replace the No. 2 synchronizer ring and apply a small amount of fine lapping compound on the 3rd gear cone.

- NOTICE:

- Ensure the fine lapping compound is completely washed off after rubbing.

|

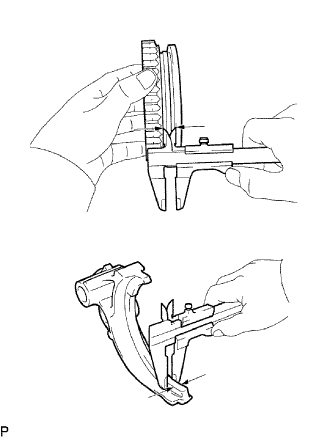

| 23. INSPECT REVERSE GEAR |

|

Using a vernier caliper, measure the clearance between the reverse gear and No. 1 gear shift fork.

- Standard clearance:

- 0.15 to 0.35 mm (0.0059 to 0.0138 in.)

- Minimum clearance:

- 0.35 mm (0.0138 in.)

- If the clearance is less than the minimum, replace the No. 1 gear shift fork and reverse gear.

Check that the No. 1 transmission clutch hub and reverse gear slide smoothly.

|

Check that the spline gear's edges of the reverse gear are not worn down.

| 24. INSPECT NO. 2 TRANSMISSION HUB SLEEVE |

|

Using a vernier caliper, measure the No. 2 hub sleeve and No. 2 gear shift fork as shown in the illustration.

- Standard clearance:

- 0.15 to 0.35 mm (0.0059 to 0.0138 in.)

- If the clearance is not as specified, replace the transmission hub sleeve and the No. 2 gear shift fork.

Check the sliding condition between the No. 2 hub sleeve and No. 2 clutch hub.

|

Check that the spline gear's edges of the No. 2 transmission hub sleeve are not worn down.

| 25. INSPECT 1ST GEAR |

|

Using a cylinder gauge, measure the inside diameter of the 1st gear.

- Standard inside diameter:

- 44.015 to 44.040 mm (1.7329 to 1.7339 in.)

- Maximum inside diameter:

- 44.040 mm (1.7339 in.)

- If the inside diameter is greater than the maximum, replace the 1st gear.

| 26. INSPECT 2ND GEAR |

|

Using a cylinder gauge, measure the inside diameter of the 2nd gear.

- Standard inside diameter:

- 44.015 to 44.040 mm (1.7329 to 1.7339 in.)

- Maximum inside diameter:

- 44.040 mm (1.7339 in.)

- If the inside diameter is greater than the maximum, replace the 2nd gear.

| 27. INSPECT 3RD GEAR |

|

Using a cylinder gauge, measure the inside diameter of the 3rd gear.

- Standard inside diameter:

- 44.015 to 44.040 mm (1.7329 to 1.7339 in.)

- Maximum inside diameter:

- 44.040 mm (1.7339 in.)

- If the inside diameter is greater than the maximum, replace the 3rd gear.