Output Shaft Installation

ASSEMBLE NO. 2 TRANSMISSION CLUTCH HUB

INSTALL 3RD GEAR NEEDLE ROLLER BEARING

INSTALL 3RD GEAR

INSTALL NO. 2 SYNCHRONIZER RING

INSTALL NO. 2 TRANSMISSION CLUTCH HUB

INSPECT 3RD GEAR THRUST CLEARANCE

ASSEMBLE NO. 1 TRANSMISSION CLUTCH HUB

INSTALL 2ND GEAR NEEDLE ROLLER BEARING

INSTALL 2ND GEAR

INSTALL NO. 1 SYNCHRONIZER RING (for 2nd Gear)

INSTALL NO. 1 TRANSMISSION CLUTCH HUB

INSPECT 2ND GEAR THRUST CLEARANCE

INSTALL NO. 1 SYNCHRONIZER RING (for 1st Gear)

INSTALL 1ST GEAR BEARING INNER RACE LOCK BALL

INSTALL 1ST GEAR BEARING INNER RACE

INSTALL 1ST GEAR

INSTALL OUTPUT SHAFT CENTER BEARING

INSPECT 1ST GEAR THRUST CLEARANCE

INSTALL 5TH GEAR

INSPECT 3RD GEAR RADIAL CLEARANCE

INSPECT 2ND GEAR RADIAL CLEARANCE

INSPECT 1ST GEAR RADIAL CLEARANCE

Output Shaft -- Installation |

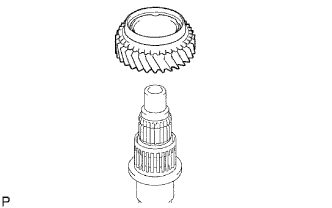

| 1. ASSEMBLE NO. 2 TRANSMISSION CLUTCH HUB |

Coat the hub sleeve with gear oil, and install it to the clutch hub.

- NOTICE:

- Be sure to set the hub sleeve to the clutch hub in the correct direction.

Install the 3 synchromesh shifting keys to the clutch hub with the 2 synchromesh shifting key springs.

- HINT:

- Do not set both openings of the shifting key springs in the same position.

| 2. INSTALL 3RD GEAR NEEDLE ROLLER BEARING |

Coat the needle roller bearing with gear oil, and install it to the output shaft.

Coat the 3rd gear with gear oil, and install it to the output shaft.

| 4. INSTALL NO. 2 SYNCHRONIZER RING |

Coat the synchronizer ring with gear oil, and install it to the 3rd gear.

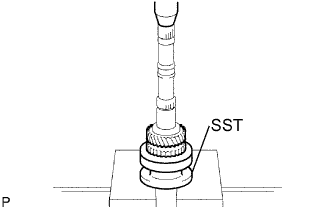

| 5. INSTALL NO. 2 TRANSMISSION CLUTCH HUB |

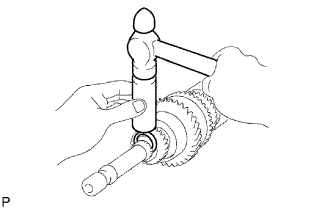

Using SST and a press, press in the No. 2 clutch hub to the output shaft.

- SST

- 09316-60011(09316-00021)

Select a clutch hub shaft snap ring that will allow minimal axial play.

- Standard clearance:

- 0.10 mm (0.039 in.) or less

- Standard clutch hub shaft snap ring thickness:

Mark

| Thickness

|

C-1

| 1.75 to 1.80 mm (0.0689 to 0.0709 in.)

|

D

| 1.80 to 1.85 mm (0.0709 to 0.0728 in.)

|

D-1

| 1.85 to 1.90 mm (0.0728 to 0.0748 in.)

|

E

| 1.90 to 1.95 mm (0.0748 to 0.0768 in.)

|

E-1

| 1.95 to 2.00 mm (0.0768 to 0.0787 in.)

|

F

| 2.00 to 2.05 mm (0.0787 to 0.0807 in.)

|

F-1

| 2.05 to 2.10 mm (0.0807 to 0.0827 in.)

|

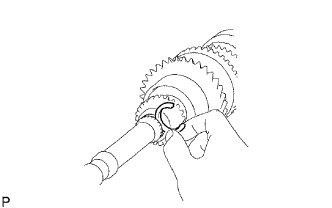

Using a snap ring expander, install the snap ring.

| 6. INSPECT 3RD GEAR THRUST CLEARANCE |

Using a feeler gauge, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.25 mm (0.0039 to 0.0098in.)

| 7. ASSEMBLE NO. 1 TRANSMISSION CLUTCH HUB |

Coat the reverse gear with gear oil, and install it to the clutch hub.

- NOTICE:

- Be sure to set the reverse gear to the clutch hub in the correct direction.

Install 3 synchromesh shifting keys to the clutch hub with the 2 synchromesh shifting key springs.

- HINT:

- Do not set both openings of the shifting key springs in the same position.

| 8. INSTALL 2ND GEAR NEEDLE ROLLER BEARING |

Coat the needle roller bearing with gear oil, and install it to the output shaft.

Coat the 2nd gear with gear oil, and install it to the output shaft.

| 10. INSTALL NO. 1 SYNCHRONIZER RING (for 2nd Gear) |

Coat the No. 1 synchronizer ring with gear oil, and install it to the 2nd gear.

| 11. INSTALL NO. 1 TRANSMISSION CLUTCH HUB |

Using SST and a press, press in the clutch hub to the output shaft.

- SST

- 09316-60011

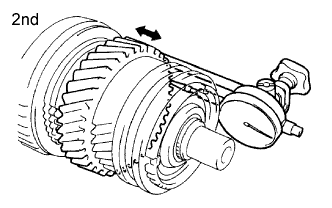

| 12. INSPECT 2ND GEAR THRUST CLEARANCE |

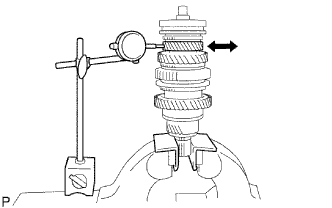

Using a dial indicator, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.250 mm (0.0039 to 0.0098 in.)

| 13. INSTALL NO. 1 SYNCHRONIZER RING (for 1st Gear) |

Coat the synchronizer ring with gear oil, and install it to the No. 1 clutch hub.

| 14. INSTALL 1ST GEAR BEARING INNER RACE LOCK BALL |

Coat the lock ball with gear oil, and install it to the output shaft.

| 15. INSTALL 1ST GEAR BEARING INNER RACE |

Coat the needle roller bearing with gear oil.

Install the inner race and needle roller bearing to the 1st gear.

Coat the 1st gear with gear oil, and install it to the output shaft.

| 17. INSTALL OUTPUT SHAFT CENTER BEARING |

Using SST and a press, press in the center bearing to the output shaft.

- SST

- 09316-60011(09316-00021)

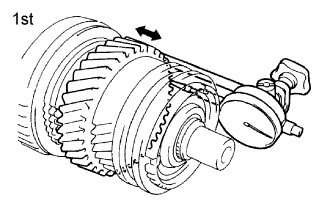

| 18. INSPECT 1ST GEAR THRUST CLEARANCE |

Using a dial indicator, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.25 mm (0.0039 to 0.0078 in.)

Using SST and a press, press in the 5th gear to the output shaft.

- SST

- 09316-60011(09316-00021)

Select a snap ring that will allow minimal axial play.

- Standard clearance:

- 0.10 mm (0.039 in.) or less

- Standard output shaft bearing shaft snap ring:

Mark

| Thickness

|

A

| 2.67 to 2.72 mm (0.1051 to 0.1071 in.)

|

B

| 2.73 to 2.78 mm (0.1075 to 0.1094 in.)

|

C

| 2.79 to 2.84 mm (0.1098 to 0.1118 in.)

|

D

| 2.85 to 2.90 mm (0.1122 to 0.1141 in.)

|

E

| 2.91 to 2.96 mm (0.1146 to 0.1165 in.)

|

F

| 2.97 to 3.02 mm (0.1169 to 0.1189 in.)

|

G

| 3.03 to 3.08 mm (0.1193 to 0.1213 in.)

|

H

| 3.09 to 3.14 mm (0.1217 to 0.1236 in.)

|

J

| 3.15 to 3.20 mm (0.1240 to 0.1260 in.)

|

K

| 3.21 to 3.26 mm (0.1264 to 0.1283 in.)

|

L

| 3.27 to 3.32 mm (0.1287 to 0.1307 in.)

|

Using a brass bar and hammer, tap in the snap ring.

| 20. INSPECT 3RD GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.008 to 0.034 mm (0.0003 to 0.0013 in.)

- If the clearance is not as specified, replace the needle roller bearing.

| 21. INSPECT 2ND GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.008 to 0.034 mm (0.0003 to 0.0013 in.)

- If the clearance is not as specified, replace the needle roller bearing.

| 22. INSPECT 1ST GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.009 to 0.056 mm (0.0004 to 0.0022 in.)

- If the clearance is not as specified, replace the needle roller bearing.