Counter Gear And Reverse Idler Gear Removal

INSPECT COUNTER SHAFT 5TH GEAR RADIAL CLEARANCE

REMOVE COUNTER 5TH GEAR BEARING

REMOVE NO. 3 TRANSMISSION HUB SLEEVE

INSPECT NO. 3 SYNCHRONIZER RING

INSPECT NO. 3 TRANSMISSION HUB SLEEVE

INSPECT COUNTER SHAFT 5TH GEAR

INSPECT COUNTER GEAR

INSPECT COUNTER GEAR FRONT BEARING

REPLACE COUNTER GEAR FRONT BEARING

Counter Gear And Reverse Idler Gear -- Removal |

| 1. INSPECT COUNTER SHAFT 5TH GEAR RADIAL CLEARANCE |

Install the 5th gear thrust washer lock ball, 5th gear thrust washer and 5th gear to the counter gear.

Using a dial indicator, measure the 5th gear radial clearance.

- Standard clearance:

- 0.008 to 0.034 mm (0.0003 to 0.0013 in.)

- If the clearance is not as specified, replace the 5th gear bearing.

| 2. REMOVE COUNTER 5TH GEAR BEARING |

Remove the 5th gear bearing from the 5th gear.

| 3. REMOVE NO. 3 TRANSMISSION HUB SLEEVE |

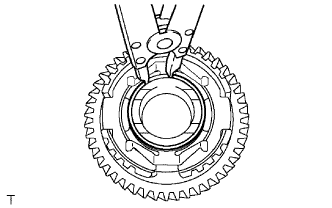

Using a snap ring expander, remove the snap ring from the 5th gear.

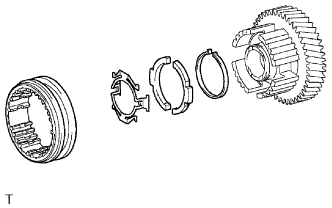

Remove the No. 3 hub sleeve, 2 No. 3 synchromesh shifting keys, key spring (return spring) and key spring (C spring) from the 5th gear.

| 4. INSPECT NO. 3 SYNCHRONIZER RING |

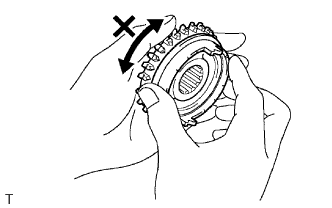

Coat the No. 5 gear spline piece cone with gear oil. Check the braking effect of the No. 3 synchronizer ring. Fit the ring to the shaft cone. Apply pressure to the ring and attempt to turn it in both directions. Check that the ring locks.

- If the braking effect is insufficient, apply a small amount of fine lapping compound between the No. 3 synchronizer ring and the No. 5 gear spline piece cone. Lightly rub the No. 3 synchronizer ring and No. 5 gear spline piece cone.

- NOTICE:

- Ensure the fine lapping compound is completely washed off after rubbing.

Check the braking effect of the No. 3 synchronizer ring again.

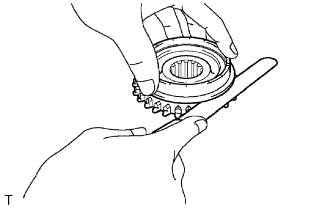

Using a feeler gauge, measure the clearance between the No. 3 synchronizer ring back and the No. 5 gear spline piece cone.

- Standard clearance:

- 0.65 to 1.35 mm (0.0256 to 0.0531 in.)

- If the clearance is not as specified, replace the No. 3 synchronizer ring, and apply a small amount of fine lapping compound on the No. 5 gear spline piece cone.

- NOTICE:

- Ensure the fine lapping compound is completely washed off after rubbing.

| 5. INSPECT NO. 3 TRANSMISSION HUB SLEEVE |

Check the sliding condition between the No. 3 hub sleeve and center shaft 5th gear.

Check that the spline gear's edges of the No. 3 hub sleeve are not worn down.

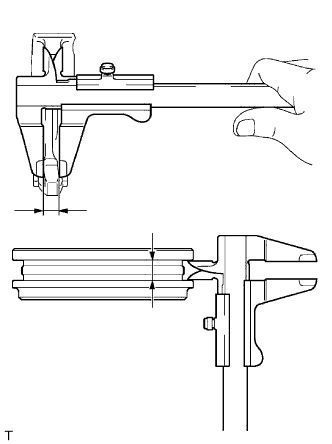

Using a vernier caliper, measure the No. 3 hub sleeve and No. 3 gear shift fork as shown in the illustration.

- Standard clearance:

- 0.25 to 0.45 mm (0.0098 to 0.0177 in.)

- If the clearance is not as specified, replace the No. 3 hub sleeve and No. 3 gear shift fork.

| 6. INSPECT COUNTER SHAFT 5TH GEAR |

Using a cylinder gauge, measure the inside diameter of the 5th gear.

- Standard inside diameter:

- 33.015 to 33.040 mm (1.2998 to 1.3008 in.)

- Maximum inside diameter:

- 33.040 mm (1.3008 in.)

- If the inside diameter is greater than the maximum, replace the 5th gear.

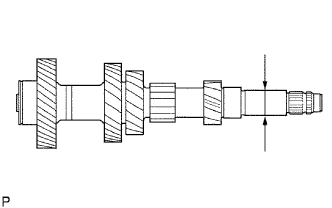

Using a micrometer, measure the outside diameter of the journal surface.

- Standard outside diameter:

- 25.984 to 26.000 mm (1.0230 to 1.0236 in.)

- Minimum outside diameter:

- 25.984 mm (1.0230 in.)

- If the outside diameter is less than the minimum, replace the counter gear.

| 8. INSPECT COUNTER GEAR FRONT BEARING |

Make sure the front bearing rotates smoothly.

- If the bearing does not rotate smoothly, replace the bearing.

| 9. REPLACE COUNTER GEAR FRONT BEARING |

Using a snap ring expander, remove the No. 2 counter gear front bearing snap ring from the counter gear.

Using SST, a press and 14 mm socket wrench, remove the counter gear front bearing from the counter gear.

- SST

- 09515-10010