Lighting System - Headlight Leveling Ecu Power Source Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK VEHICLE TYPE

READ VALUE USING INTELLIGENT TESTER (IGNITION POWER SUPPLY)

CHECK HARNESS AND CONNECTOR (HEADLIGHT LEVELING ECU ASSEMBLY - BATTERY AND BODY GROUND)

READ VALUE USING INTELLIGENT TESTER (IGNITION POWER SUPPLY)

CHECK HARNESS AND CONNECTOR (HEADLIGHT SWIVEL ECU ASSEMBLY - BATTERY AND BODY GROUND)

LIGHTING SYSTEM - Headlight Leveling ECU Power Source Circuit

DESCRIPTION

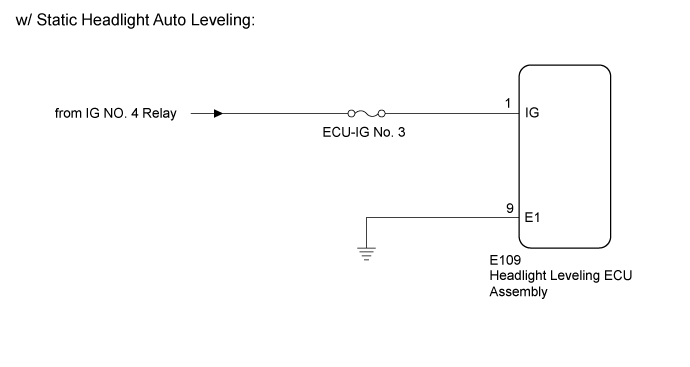

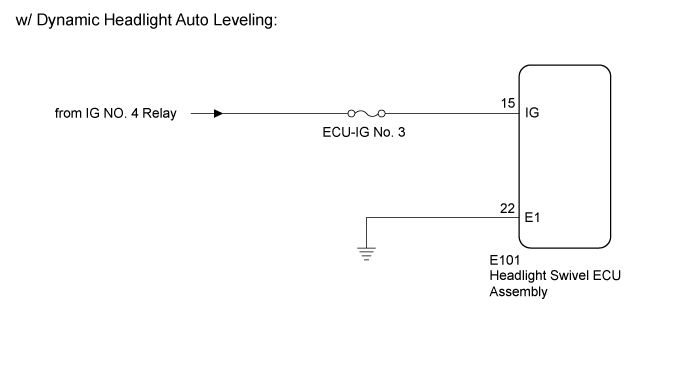

This circuit detects the state of the ignition switch, and sends it to the headlight leveling ECU*1 or headlight swivel ECU*2.

*1: w/ Static Headlight Auto Leveling

*2: w/ Dynamic Headlight Auto Leveling

WIRING DIAGRAM

INSPECTION PROCEDURE

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

After replacing the headlight leveling ECU*1 or headlight swivel ECU*2, initialization of the ECU is necessary (except w/ Dynamic Headlight Auto Leveling) ().

*1: w/ Static Headlight Auto Leveling

*2: w/ Dynamic Headlight Auto Leveling

Check the vehicle type.

Result| Result | Proceed to |

| w/ Static Headlight Auto Leveling | A |

| w/ Dynamic Headlight Auto Leveling | B |

| 2.READ VALUE USING INTELLIGENT TESTER (IGNITION POWER SUPPLY) |

Using the intelligent tester, read the Data List ().

HL Auto Leveling| Tester Display | Measurement Item/Range | Normal Condition | Diagnostic Note |

| +B | Ignition power supply voltage value / 0 to 19.75 V | 11 to 14 V | - |

- OK:

- The display is as specified in the normal condition column.

| OK | |

| |

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE ()

|

|

| 3.CHECK HARNESS AND CONNECTOR (HEADLIGHT LEVELING ECU ASSEMBLY - BATTERY AND BODY GROUND) |

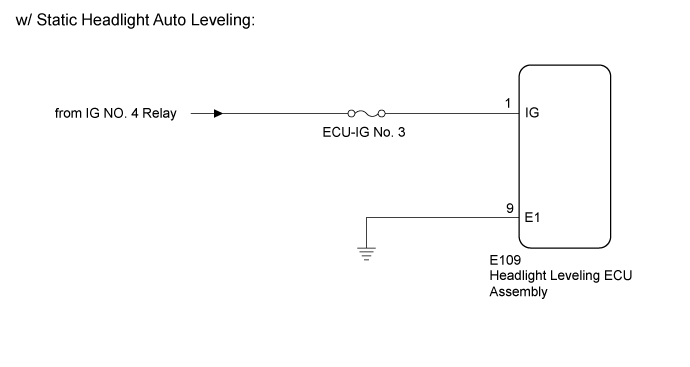

Disconnect the headlight leveling ECU connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

| Tester Connection | Switch Condition | Specified Condition |

| E109-1 (IG) - Body ground | Ignition switch ON | 11 to 14 V |

| Ignition switch off | Below 1 V |

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| E109-9 (E1) - Body ground | Always | Below 1 Ω |

Text in Illustration| *a | Front view of wire harness connector

(to Headlight Leveling ECU Assembly) |

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| OK | |

| |

| REPLACE HEADLIGHT LEVELING ECU ASSEMBLY ()

|

|

| 4.READ VALUE USING INTELLIGENT TESTER (IGNITION POWER SUPPLY) |

Using the intelligent tester, read the Data List ().

AFS| Tester Display | Measurement Item/Range | Normal Condition | Diagnostic Note |

| +B | Ignition power supply voltage value / 0 to 19.75 V | 11 to 14 V | - |

- OK:

- The display is as specified in the normal condition column.

| OK | |

| |

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE ()

|

|

| 5.CHECK HARNESS AND CONNECTOR (HEADLIGHT SWIVEL ECU ASSEMBLY - BATTERY AND BODY GROUND) |

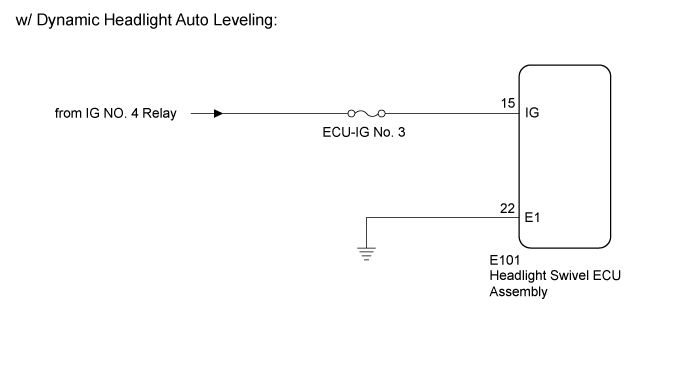

Disconnect the headlight leveling ECU connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

| Tester Connection | Switch Condition | Specified Condition |

| E101-15 (IG) - Body ground | Ignition switch ON | 11 to 14 V |

| Ignition switch off | Below 1 V |

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| E101-22 (E1) - Body ground | Always | Below 1 Ω |

Text in Illustration| *a | Front view of wire harness connector

(to Headlight Swivel ECU Assembly) |

Result| Result | Proceed to |

| OK (for LHD) | A |

| OK (for RHD) | B |

| NG | C |

| | REPLACE HEADLIGHT SWIVEL ECU ASSEMBLY ()

|

|

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| A | |

| |

| REPLACE HEADLIGHT SWIVEL ECU ASSEMBLY ()

|

|